CV Operator Petrochemical 17 Years

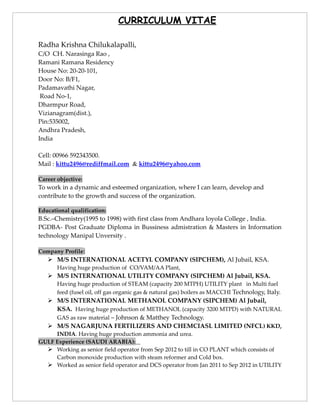

- 1. CURRICULUM VITAE Radha Krishna Chilukalapalli, C/O CH. Narasinga Rao , Ramani Ramana Residency House No: 20-20-101, Door No: B/F1, Padamavathi Nagar, Road No-1, Dharmpur Road, Vizianagram(dist.), Pin:535002, Andhra Pradesh, India Cell: 00966 592343500. Mail : kittu2496@rediffmail.com & kittu2496@yahoo.com Career objective: To work in a dynamic and esteemed organization, where I can learn, develop and contribute to the growth and success of the organization. Educational qualification: B.Sc.–Chemistry(1995 to 1998) with first class from Andhara loyola College , India. PGDBA- Post Graduate Diploma in Bussiness admistration & Masters in Information technology Manipal Unversity . Company Profile: M/S INTERNATIONAL ACETYL COMPANY (SIPCHEM), Al Jubail, KSA. Having huge production of CO/VAM/AA Plant, M/S INTERNATIONAL UTILITY COMPANY (SIPCHEM) Al Jubail, KSA. Having huge production of STEAM (capacity 200 MTPH) UTILITY plant in Multi fuel feed (fusel oil, off gas organic gas & natural gas) boilers as MACCHI Technology, Italy. M/S INTERNATIONAL METHANOL COMPANY (SIPCHEM) Al Jubail, KSA. Having huge production of METHANOL (capacity 3200 MTPD) with NATURAL GAS as raw material – Johnson & Matthey Technology. M/S NAGARJUNA FERTILIZERS AND CHEMCIASL LIMITED (NFCL) KKD, INDIA. Having huge production ammonia and urea. GULF Experience (SAUDI ARABIA): Working as senior field operator from Sep 2012 to till in CO PLANT which consists of Carbon monoxide production with steam reformer and Cold box. Worked as senior field operator and DCS operator from Jan 2011 to Sep 2012 in UTILITY

- 2. PLANT, which consists of DM unit, Air Compressors, Incinerator, Waste Water System, condensate system, Cooling Towers, PHE, CLCW system and Steam boilers. Worked as field and DCS operator from Jun 2007 to Dec 2010 in METHNANOL PLANT (H2 + CO) which consists of Sulphur Removal Unit, Furnace - Steam Reformer, Feed gas and Syn. gas Centrifugal compressor, ARC convertor, waste heat boiler, saturator, De-saturator, vent scrubber, and Distillation Column (CDU & MDU), Centrifugal and Reciprocating Pumps, Heat Exchangers etc. Experience in INDIA: Worked as senior supervisor and having commissioning and working experience in field and DCS from Jan 1999 to Jun 2007 in NFCL (M/S Nagarjuna Fertilizers and chemicals limited in Cold Startups, Planned Shutdowns and Emergency Shutdowns of Ammonia plant. Achievements: Erection and commissioning experience in Carbon Mono-oxide plant in SIPCHEM, KSA. Question Mark preparation in CITRIX software for operator Assessments. Appreciated Certificate for trouble shooting in IMC PLANT in SIPCHEM, KSA. Experience Highlights: Total Experience in petro chemical and Gas Plant from 1997 - 17.0 yrs. Gulf Experience (Saudi Arabia) from Jan- 2009 - 8.5 yrs. H2S removal. Steam Reformer and Amine treatment. Steam Reformer & Cold Box. Booster and hyper compressor up to 3000 bar Naphtha Tanks handling. Ammonia Liquefaction and PGRU Furnaces & Fire heaters (Natural & Balanced Drafts). Centrifugal & Reciprocating Compressors and Pumps for turbine and motor drive. Steam Turbine (Condensing Type). DM unit - 248M3 /Hr. for two Train systems. IA and PA unit – 4000 M3 /Hrs. CLCW system - 18000 M3 /Hrs. All type of Heat Exchanger (shell and tube, fin fan, PHE and cooling towers. High Pressure Waste Heat Recovery Boiler and steam boiler. Synthesis (H2 + CO) Gas Production. Erection & Commissioning Experience: Air blowing in process lines. Steam blowing of HP & LP Steam lines. Flushing & degreasing of lines. Mechanical completion checking of various lines with isometric views. Hot lube oil circulations.

- 3. Chemical cleaning. Catalyst Loading in Reformer, Hydro-generator, Desulphurisers, etc. Dry out & Boil out of FURNACE & STEAM DRUM. Distillation column trays fixing and leak testing. Punch list preparing and updating. Unsafe and near miss area identifying and eliminating for safe work place. DCS System Handled: Emerson Delta V Yokogawa Centum CS 3000 Catalysts handled: Experienced in loading, unloading & stabilization of various catalysts as Ni Catalyst (Alumina based Alkali activated Nickel Catalyst). CoMoX (Cobalt Molybdenum Oxide), Zno (Zinc Oxide) &Vanadium pent oxide (V2O5). Job Responsibilities: Shift relieving and follow up of activities, continuous monitoring all running equipment’s parameters and controlling of process parameters & equipment's condition. Abnormalities identification and reporting start & shut down of plant followed by standard operating procedure and emergency activities. Shift log reporting and follow up maintenance activities for isolation and normalizing to process then Maintaining safety and housekeeping in work area. Preparing and updating the unit operating manuals Studying of P&IDs and Writing of SOPs for safe start-up of equipment’s or plant. Troubleshoots problems or abnormal occurrences and optimizing operation to ensure minimum disruption to production. Giving training to junior operators. Special Training & safety courses attended: Basic training on usage of personal safety devices Mock drill on emergency attendance Human Relations & Psychology Team building. SAFETY: I have thorough knowledge and practice on the application of the following systems. Work permit system : Cold work Permit, Hot work Permit and Vehicle Entry Permit Confined Space Entry Permit Process Safety Management System JOSE (Job On Site Evaluation) / Risk Assessment Immediate Danger to Life & Health (IDLH) Work system Fire Extinguishers and Personal Protective Equipment (PPE) Material Safety Data Sheet (MSDS) Deluge system and Fire Hydrant System

- 4. Personal Information: Name : Radha Krishna Father’s Name : Narasinga Rao Date of Birth : 10-08-1978 Marital Status : Married Languages Known : English & Telugu Passport No. : Z1978679 (Valid up to 06-11-2023) Given an opportunity to work in your esteemed organization, I can prove the skills required for the above position and can assure you of my best services. Thanking you in anticipation. Yours faithfully, (Radha Krishna)