production technology notes

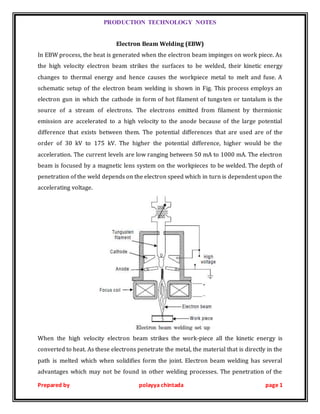

- 1. PRODUCTION TECHNOLOGY NOTES Prepared by polayya chintada page 1 Electron Beam Welding (EBW) In EBW process, the heat is generated when the electron beam impinges on work piece. As the high velocity electron beam strikes the surfaces to be welded, their kinetic energy changes to thermal energy and hence causes the workpiece metal to melt and fuse. A schematic setup of the electron beam welding is shown in Fig. This process employs an electron gun in which the cathode in form of hot filament of tungsten or tantalum is the source of a stream of electrons. The electrons emitted from filament by thermionic emission are accelerated to a high velocity to the anode because of the large potential difference that exists between them. The potential differences that are used are of the order of 30 kV to 175 kV. The higher the potential difference, higher would be the acceleration. The current levels are low ranging between 50 mA to 1000 mA. The electron beam is focused by a magnetic lens system on the workpieces to be welded. The depth of penetration of the weld depends on the electron speed which in turn is dependent upon the accelerating voltage. When the high velocity electron beam strikes the work-piece all the kinetic energy is converted to heat. As these electrons penetrate the metal, the material that is directly in the path is melted which when solidifies form the joint. Electron beam welding has several advantages which may not be found in other welding processes. The penetration of the

- 2. PRODUCTION TECHNOLOGY NOTES Prepared by polayya chintada page 2 beam is high. The depth to width ratios lies between 10:1 to 30:1 can be easily realized with electron beam welding. It is also possible to closely control this penetration by controlling the accelerating voltage, beam current, and beam focus. The process can be used at higher welding speeds typically between 125 and 200 mm/sec. No filler metal or flux needs to be used in this process. The heat liberated is low and also is in a narrow zone, thus the heat affected zone is minimal as well as weld distortions are virtually eliminated. It is possible to carry out the electron beam welding in open atmosphere. For welding in vacuum, the work-piece is enclosed in a box in which the vacuum is created. When electron beam moves in the normal atmosphere, the electrons would be impinging with the gas molecules in the atmosphere and would thus be scattered. This scattering increases the spot size of the electron beam and consequently there is lower penetration. As the vacuum increases, the scattering effect of the electron beam decreases and hence, penetration increases. The other advantage of using vacuum is that the weld metal is not contaminated. The EBW process is mainly used for welding of reactive metals (nuclear reactor components), titanium, zirconium, stainless steel, etc. for aero-space and automotive industries. SOLID STATE WELDING PROCESSES In these processes, the base materials to be joined are heated to a temperature below or just upto the solidus temperature and then continuous pressure is applied to form the welded joint. No filler metal is used in solid-state welding processes. The various solid- state welding processes are- (1) Forge Welding (2) Cold Pressure Welding (3) Friction Welding (4) Explosive Welding (5) Diffusion Welding (6) Thermo-compression Welding Some of the above important welding processes are discussed as under, Forge Welding

- 3. PRODUCTION TECHNOLOGY NOTES Prepared by polayya chintada page 3 In this welding process, the work-pieces to be welded are heated to the plastic condition (above 1000°C), and then placed together and forged while hot by applying force. Force may be applied by hammering, rolling, drawing or squeezing to achieve the forging action. Forge welding was originally the first process of welding. In this process the two metal pieces to be joined are heated in a forge or furnace to a plait condition and then they are united by pressure. The ends to be joined are heated in a furnace to plastic condition and formed to the required shape by upsetting. Then they are brought together and hammered, so as to get the finished joint similarly, a butt joint can be prepared by forge welding as shown in Fig. Before joining the two pieces, their ends are formed to the required shape according to the type of joint. The forge welding is a manual process and is limited to light work because all forming and welding are done with a hand sledge. It is a slow process and there is considerable danger of an oxide scale forming on tile surfaces. The tendency to oxidize can be counteracted somewhat by using a thick fuel bed and by covering the surfaces with a fluxing material, which dissolves the oxides. Borax in combination with salt ammoniac is commonly used as flux. The forge welding is recommended to such metals, which have a large welding temperature range like low carbon steel and wrought iron. By the increase of carbon content, this range decreases rapidly. High carbon steels alloy steels require considerably more care in controlling temperature and producing the welds. Large work may be welded in hammer forges driven by steam. Welded steel pipe is made mechanically by running the preheated strips through rolls, which form the pipe to size and apply the necessary pressure for the weld. Friction Welding In this process, the heat for welding is obtained from mechanically induced sliding motion between rubbing surfaces of work-pieces as shown in Fig. In friction welding, one part is firmly held while the other (usually cylindrical) is rotated under simultaneous application of axial pressure. As these parts are brought to rub against each other under pressure, they get heated due to friction. When the desired forging temperature is attained, the rotation is stopped and the axial pressure is increased to obtain forging action and hence welded joint.

- 4. PRODUCTION TECHNOLOGY NOTES Prepared by polayya chintada page 4 Most of the metals and their dissimilar combinations such as aluminium and titanium, copper and steel, aluminium and steel etc. can be welded using friction welding. Explosive Welding In explosive welding, strong metallurgical bonds can be produced between metal combinations which cannot be welded by other methods or processes. For example, tantalum can be explosively welded to steel although the welding point of tantalum is higher than the vaporization temperature of steel. Explosive welding process is shown in Fig. It is carried out by bringing together properly paired metal surfaces with high relative velocity at a high pressure and a proper orientation to each other so that a large amount of plastic interaction occurs between the surfaces. The work piece, held fixed is called the target plate and the other called flyer plate. While a variety of procedures have been successfully employed, the main techniques of explosive welding can be divided into contact techniques and impact techniques. In critical space and nuclear application, explosive welding permits fabrication of structures that cannot be made by any other means and, in some commercial applications, explosive joining is the least costly method. The main advantage of explosive welding includes the simplicity of the process, and the extremely large surface that can be welded. Incompatible materials can also be bonded, and thin foils can be bonded to heavier plates.

- 5. PRODUCTION TECHNOLOGY NOTES Prepared by polayya chintada page 5 RESISTANCE WELDING- TYPES In resistance welding the metal parts to be joined are heated by their resistance to the flow of an electrical current. Usually this is the only source of heat, but a few of the welding operations combine resistance heating with arc heating, and possibly with combustion of metal in the arc. The process applies to practically all metals and most combinations of pure metals and those alloys, which have only a limited plastic range, are welded by heating the parts to fusion (melting). Some alloys, however, may welded without fusion; instead, the parts are heated to a plastic state at which the applied pressure causes their crystalline structures to grow together. The welding of dissimilar metals may be accomplished by melting both metals frequently only the metal with the lower melting point is melted, and an alloy bond is formed at the surface of the unmelted metal. In resistance welding processes no fluxes are employed, the filler metal is rarely used and the joints are usually of the lap type. The amount of heat generated in the workpiece depend on the following factors: (1) Magnitude of the current, (2) Resistance of the current conducting path, and Mathematically, H = IVt = I(IR)t = I2Rt Where H = heat generated in joules I = current in Amp.

- 6. PRODUCTION TECHNOLOGY NOTES Prepared by polayya chintada page 6 R = resistance in ohms t = time of current flow in seconds. Types of Resistance welding The major types of resistance welding are given as under: (1) Spot Welding (2) Seam Welding (3) Projection Welding (4) Resistance Butt Welding (5) Flash Butt Welding (6) Percussion Welding (7) High Frequency Resistance Welding (8) High Frequency Induction Welding Some of the above important welding processes are discussed as under, Spot Welding In this process overlapping sheets are joined by local fusion at one or more spots, by the concentration of current flowing between two electrodes. This is the most widely used resistance welding process. A typical resistance spot welding machine is shown in Fig. It essentially consists of two electrodes, out of which one is fixed. The other electrode is fixed to a rocker arm (to provide mechanical advantage) for transmitting the mechanical force from a pneumatic cylinder. This is the simplest type of arrangement. The other possibility is that of a pneumatic or hydraulic cylinder being directly connected to the electrode without any rocker arm. For welding large assemblies such as car bodies, portable spot welding machines are used. Here the electrode holders and the pneumatic pressurizing system are present in the form of a portable assembly which is taken to the place, where the spot is to be made. The electric current, compressed air and the cooling water needed for the electrodes is supplied through cables and hoses from the main welding machine to the portable unit. In spot welding, a satisfactory weld is obtained when a proper current density is maintained. The current density depends on the contact area between the electrode and the work-piece. With the continuous use, if the tip becomes upset and- the contact area increases, the current density will be lowered and consequently the weld is

- 7. PRODUCTION TECHNOLOGY NOTES Prepared by polayya chintada page 7 obtained over a large area. This would not be able to melt the metal and hence there would be no proper fusion. A resistance welding schedule is the sequence of events that normally take place in each of the welds. The events are: 1. The squeeze time is the time required for the electrodes to align and clamp the two work-pieces together under them and provide the necessary electrical contact. 2. The weld time is the time of the current flow through the work-pieces till they are heated to the melting temperature. 3. The hold time is the time when the pressure is to be maintained on the molten metal without the electric current. During this time, the pieces are expected to be forged welded. 4. The off time is time during which, the pressure on the electrode is taken off so that the plates can be positioned for the next spot. Before spot welding one must make sure that (i) The job is clean, i.e., free from grease, dirt, paint, scale, oxide etc. (ii) Electrode tip surface is clean, since it has to conduct the current into the work with as little loss as possible. Very fine emery cloth may be used for routine cleaning. (iii) Water is running through the electrodes in order to (a) Avoid them from getting overheated and thus damaged, (b) Cool the weld. (iv) Proper welding current has been set on the current selector switch. (v) Proper time has been set on the weld-timer. Spot welding electrodes Spot welding electrodes are made of materials which have (1) Higher electrical and thermal resistivities, and

- 8. PRODUCTION TECHNOLOGY NOTES Prepared by polayya chintada page 8 (2) Sufficient strength to withstand high pressure at elevated temperatures. Copper base alloys such as copper beryllium and copper tungsten are commonly used materials for spot welding electrodes. For achieving the desired current density, It is important to have proper electrode shape for which three main types of spot welding electrodes are used which are pointed, domed and flat electrodes. Applications of Spot Welding (i) It has applications in automobile and aircraft industries (ii) The attachment of braces, brackets, pads or clips to formed sheet-metal parts such as cases, covers or trays is another application of spot welding. (iii) Spot welding of two 12.5 mm thick steel plates has been done satisfactorily as a replacement for riveting. (iv) Many assemblies of two or more sheet metal stampings that do not require gas tight or liquid tight joints can be more economically joined by spot welding than by mechanical methods. (v) Containers and boxes frequently are spot welded. Resistance Seam Welding It is a continuous type of spot welding wherein spot welds overlap each other to the desired extent. In this process coalescence at the faying surfaces is produced by the heat obtained from the resistance to electric current (flow) through the work pieces held together under pressure by circular electrodes. The resulting weld is a series of overlapping resistance-spots welds made progressively along a joint by rotating the circular electrodes. The principle of seam welding is shown in Fig. (a) and resistance seam welding process set up is shown in Fig. (b). The seam welding is similar to spot welding, except that circular rolling electrodes are used to produce a continuous air-tight seam of overlapping welds. Overlapping continuous spot welds seams are produced by the rotating electrodes and a regularly interrupted current.

- 9. PRODUCTION TECHNOLOGY NOTES Prepared by polayya chintada page 9 Applications 1. It is used for making leak proof joints in fuel tanks of automobiles. 2. Except for copper and high copper alloys, most other metals can be seam welded. 3. It is also used for making flange welds for use in watertight tanks. Resistance Projection Welding Fig. shows the projection welding. This process is a resistance welding process in which two or more than two spot welds are made simultaneously by making raised portions or projections on predetermined locations on one of the workpiece. These projections act to localize the heat of the welding circuit. The pieces to be welded are held in position under pressure being maintained by electrodes. The projected contact spot for welding should be approximately equal to the weld metal thickness. The welding of a nut on the automotive chasis is an example of projection welding. Resistance Upset Butt and Flash Butt Welding

- 10. PRODUCTION TECHNOLOGY NOTES Prepared by polayya chintada page 10 This welding is also used for joining metal pieces end to end but it has largely replaced the butt-welding method for weld articles small cross-sections. It can be used for thick sections also. Initially the current is switched on and then one end the moveable part to be welded is brought gently closer to the fixed end of the other part to localize heat at the ends and thus raises the temperature of the ends quickly to the welding heat. On acquiring contact of fixed end and moveable end with each other, the moveable end is then pressed against one another by applying mechanical pressure. Thus the molten metal and slag to be squeezed out in the form of sparks enabling the pure metal to form the joint and disallowing the heat to spread back. The principle of upset butt welding and flash butt welding are depicted in Fig. (a, b). In this resistance welding single phase A.C. machines are commonly employed. The merits and demerit of flash welding over simple butt-welding are follows: Merits 1. It is comparatively much faster than butt welding. 2. This method utilizes less current in comparison to butt welding as the small portion of the metal is only being heated for getting a good weld 3. Created joint by this welding is much stronger than the butt welding joint. Also the strength of the weld produced is high even more than that of the base metal. The end of the metal pieces to be welded in this welding need not be squared as it is the basic requirement in butt-welding. 4. A high degree of accuracy can be easily achieved in terms of length alignment of weld. Demerits

- 11. PRODUCTION TECHNOLOGY NOTES Prepared by polayya chintada page 11 1. The periodic maintenance of machine and replacement of insulation is needed as flashing particles of molten metal are thrown out during welding which may enter into the slide ways and insulation of the set up. 2. Welder has to take enough care against possible fire hazard due to flashing during welding. 3. Additional stock has to be provided for compensating loss of metal during f1ashing and upsetting. This increases to the cost of weld. 4. Cost of removal of flash weld metal by trimming, chipping, grinding, etc. will increase to the welded product. 5. Surface of the jobs where they come in contact with the gripping surfaces should be clean otherwise they will restrict the flow of electric current. 6. The available power, opening between the jaws of the gripping clamps and upsetting pressure of the welding set limit the size and cross sectional area of the jobs to be welded. Applications All conducting forged metals can be easily be flash welded. A number of dissimilar metals can also be welded by controlling the welding conditions carefully. Metals generally welded metal by the process involves lead, tin, antimony, zinc, bismuth and their alloys, low carbon steels, stainless steel, alloy steels, tool steels, copper alloys, aluminium alloys, magnesium alloys nickel alloys, molybdenum alloys, and titanium alloys. This process is used in automobile industry, welding of solid and tubular structural assemblies, etc. in air-craft industry, welding of band saw blades, welding of tool steel drills, reamers and taps etc. to mild steel or alloy steel shanks, welding of pipes and tubes. Common Advantages of Resistance Welding Some common advantages of resistance welding include: (a) It is well suited for mass production. (b) It is economical in operation, since nothing is consumed except electrical power. (c) Skilled welders are not required. (d) Welds are quickly made. (e) It is possible to weld dissimilar metals.

- 12. PRODUCTION TECHNOLOGY NOTES Prepared by polayya chintada page 12 Some disadvantages of resistance welding include: (a) High initial cost of the resistance welding equipment (b) Certain resistance welding processes are limited to lap joints. (c) A lap joint has an inherent service between the two metal pieces, which causes stress concentrations in applications where fatigue is present. This service may also cause trouble when corrosion is present. RESISTANCE WELDING- TYPES In resistance welding the metal parts to be joined are heated by their resistance to the flow of an electrical current. Usually this is the only source of heat, but a few of the welding operations combine resistance heating with arc heating, and possibly with combustion of metal in the arc. The process applies to practically all metals and most combinations of pure metals and those alloys, which have only a limited plastic range, are welded by heating the parts to fusion (melting). Some alloys, however, may welded without fusion; instead, the parts are heated to a plastic state at which the applied pressure causes their crystalline structures to grow together. The welding of dissimilar metals may be accomplished by melting both metals frequently only the metal with the lower melting point is melted, and an alloy bond is formed at the surface of the unmelted metal. In resistance welding processes no fluxes are employed, the filler metal is rarely used and the joints are usually of the lap type. The amount of heat generated in the workpiece depend on the following factors: (1) Magnitude of the current, (2) Resistance of the current conducting path, and Mathematically, H = IVt = I(IR)t = I2Rt Where H = heat generated in joules I = current in Amp. R = resistance in ohms t = time of current flow in seconds. Types of Resistance welding

- 13. PRODUCTION TECHNOLOGY NOTES Prepared by polayya chintada page 13 The major types of resistance welding are given as under: (1) Spot Welding (2) Seam Welding (3) Projection Welding (4) Resistance Butt Welding (5) Flash Butt Welding (6) Percussion Welding (7) High Frequency Resistance Welding (8) High Frequency Induction Welding Some of the above important welding processes are discussed as under, Spot Welding In this process overlapping sheets are joined by local fusion at one or more spots, by the concentration of current flowing between two electrodes. This is the most widely used resistance welding process. A typical resistance spot welding machine is shown in Fig. It essentially consists of two electrodes, out of which one is fixed. The other electrode is fixed to a rocker arm (to provide mechanical advantage) for transmitting the mechanical force from a pneumatic cylinder. This is the simplest type of arrangement. The other possibility is that of a pneumatic or hydraulic cylinder being directly connected to the electrode without any rocker arm. For welding large assemblies such as car bodies, portable spot welding machines are used. Here the electrode holders and the pneumatic pressurizing system are present in the form of a portable assembly which is taken to the place, where the spot is to be made. The electric current, compressed air and the cooling water needed for the electrodes is supplied through cables and hoses from the main welding machine to the portable unit. In spot welding, a satisfactory weld is obtained when a proper current density is maintained. The current density depends on the contact area between the electrode and the work-piece. With the continuous use, if the tip becomes upset and- the contact area increases, the current density will be lowered and consequently the weld is obtained over a large area. This would not be able to melt the metal and hence there would be no proper fusion. A resistance welding schedule is the sequence of events that normally take place in each of the welds. The events are:

- 14. PRODUCTION TECHNOLOGY NOTES Prepared by polayya chintada page 14 1. The squeeze time is the time required for the electrodes to align and clamp the two work-pieces together under them and provide the necessary electrical contact. 2. The weld time is the time of the current flow through the work-pieces till they are heated to the melting temperature. 3. The hold time is the time when the pressure is to be maintained on the molten metal without the electric current. During this time, the pieces are expected to be forged welded. 4. The off time is time during which, the pressure on the electrode is taken off so that the plates can be positioned for the next spot. Before spot welding one must make sure that (i) The job is clean, i.e., free from grease, dirt, paint, scale, oxide etc. (ii) Electrode tip surface is clean, since it has to conduct the current into the work with as little loss as possible. Very fine emery cloth may be used for routine cleaning. (iii) Water is running through the electrodes in order to (a) Avoid them from getting overheated and thus damaged, (b) Cool the weld. (iv) Proper welding current has been set on the current selector switch. (v) Proper time has been set on the weld-timer. Spot welding electrodes Spot welding electrodes are made of materials which have (1) Higher electrical and thermal resistivities, and (2) Sufficient strength to withstand high pressure at elevated temperatures. Copper base alloys such as copper beryllium and copper tungsten are commonly used materials for spot welding electrodes. For achieving the desired current density, It is important to have

- 15. PRODUCTION TECHNOLOGY NOTES Prepared by polayya chintada page 15 proper electrode shape for which three main types of spot welding electrodes are used which are pointed, domed and flat electrodes. Applications of Spot Welding (i) It has applications in automobile and aircraft industries (ii) The attachment of braces, brackets, pads or clips to formed sheet-metal parts such as cases, covers or trays is another application of spot welding. (iii) Spot welding of two 12.5 mm thick steel plates has been done satisfactorily as a replacement for riveting. (iv) Many assemblies of two or more sheet metal stampings that do not require gas tight or liquid tight joints can be more economically joined by spot welding than by mechanical methods. (v) Containers and boxes frequently are spot welded. Resistance Seam Welding It is a continuous type of spot welding wherein spot welds overlap each other to the desired extent. In this process coalescence at the faying surfaces is produced by the heat obtained from the resistance to electric current (flow) through the work pieces held together under pressure by circular electrodes. The resulting weld is a series of overlapping resistance-spots welds made progressively along a joint by rotating the circular electrodes. The principle of seam welding is shown in Fig. (a) and resistance seam welding process set up is shown in Fig. (b). The seam welding is similar to spot welding, except that circular rolling electrodes are used to produce a continuous air-tight seam of overlapping welds. Overlapping continuous spot welds seams are produced by the rotating electrodes and a regularly interrupted current.

- 16. PRODUCTION TECHNOLOGY NOTES Prepared by polayya chintada page 16 Applications 1. It is used for making leak proof joints in fuel tanks of automobiles. 2. Except for copper and high copper alloys, most other metals can be seam welded. 3. It is also used for making flange welds for use in watertight tanks. Resistance Projection Welding Fig. shows the projection welding. This process is a resistance welding process in which two or more than two spot welds are made simultaneously by making raised portions or projections on predetermined locations on one of the workpiece. These projections act to localize the heat of the welding circuit. The pieces to be welded are held in position under pressure being maintained by electrodes. The projected contact spot for welding should be approximately equal to the weld metal thickness. The welding of a nut on the automotive chasis is an example of projection welding. Resistance Upset Butt and Flash Butt Welding

- 17. PRODUCTION TECHNOLOGY NOTES Prepared by polayya chintada page 17 This welding is also used for joining metal pieces end to end but it has largely replaced the butt-welding method for weld articles small cross-sections. It can be used for thick sections also. Initially the current is switched on and then one end the moveable part to be welded is brought gently closer to the fixed end of the other part to localize heat at the ends and thus raises the temperature of the ends quickly to the welding heat. On acquiring contact of fixed end and moveable end with each other, the moveable end is then pressed against one another by applying mechanical pressure. Thus the molten metal and slag to be squeezed out in the form of sparks enabling the pure metal to form the joint and disallowing the heat to spread back. The principle of upset butt welding and flash butt welding are depicted in Fig. (a, b). In this resistance welding single phase A.C. machines are commonly employed. The merits and demerit of flash welding over simple butt-welding are follows: Merits 1. It is comparatively much faster than butt welding. 2. This method utilizes less current in comparison to butt welding as the small portion of the metal is only being heated for getting a good weld 3. Created joint by this welding is much stronger than the butt welding joint. Also the strength of the weld produced is high even more than that of the base metal. The end of the metal pieces to be welded in this welding need not be squared as it is the basic requirement in butt-welding. 4. A high degree of accuracy can be easily achieved in terms of length alignment of weld. Demerits

- 18. PRODUCTION TECHNOLOGY NOTES Prepared by polayya chintada page 18 1. The periodic maintenance of machine and replacement of insulation is needed as flashing particles of molten metal are thrown out during welding which may enter into the slide ways and insulation of the set up. 2. Welder has to take enough care against possible fire hazard due to flashing during welding. 3. Additional stock has to be provided for compensating loss of metal during f1ashing and upsetting. This increases to the cost of weld. 4. Cost of removal of flash weld metal by trimming, chipping, grinding, etc. will increase to the welded product. 5. Surface of the jobs where they come in contact with the gripping surfaces should be clean otherwise they will restrict the flow of electric current. 6. The available power, opening between the jaws of the gripping clamps and upsetting pressure of the welding set limit the size and cross sectional area of the jobs to be welded. Applications All conducting forged metals can be easily be flash welded. A number of dissimilar metals can also be welded by controlling the welding conditions carefully. Metals generally welded metal by the process involves lead, tin, antimony, zinc, bismuth and their alloys, low carbon steels, stainless steel, alloy steels, tool steels, copper alloys, aluminium alloys, magnesium alloys nickel alloys, molybdenum alloys, and titanium alloys. This process is used in automobile industry, welding of solid and tubular structural assemblies, etc. in air-craft industry, welding of band saw blades, welding of tool steel drills, reamers and taps etc. to mild steel or alloy steel shanks, welding of pipes and tubes. Common Advantages of Resistance Welding Some common advantages of resistance welding include: (a) It is well suited for mass production. (b) It is economical in operation, since nothing is consumed except electrical power. (c) Skilled welders are not required. (d) Welds are quickly made. (e) It is possible to weld dissimilar metals.

- 19. PRODUCTION TECHNOLOGY NOTES Prepared by polayya chintada page 19 Some disadvantages of resistance welding include: (a) High initial cost of the resistance welding equipment (b) Certain resistance welding processes are limited to lap joints. (c) A lap joint has an inherent service between the two metal pieces, which causes stress concentrations in applications where fatigue is present. This service may also cause trouble when corrosion is present. Plasma-arc welding (PAW) Plasma-arc Welding. In plasma-arc welding (PAW), developed in the 1960s, a concentrated plasma arc is produced and directed towards the weld area. The arc is stable and reaches temperatures as high as 33,000°C. A plasma is an ionized hot gas composed of nearly equal numbers of electrons and ions. The plasma is initiated between the tungsten electrode and the orifice by a low-current pilot arc. What makes plasma-arc welding unlike other processes is that the plasma arc is concentrated because it is forced through a relatively small orifice. Operating currents usually are below 100 A, but they can be higher for special applications. When a filler metal is used, it is fed into the arc, as is done in GTAW. Arc and weld-zone shielding is supplied by means of an outer-shielding ring and the use of gases such as argon, helium, or mixtures. There are two methods of plasma-arc welding: In the transferred-arc method (Fig.a), the workpiece being welded is part of the electrical circuit. The arc transfers from the electrode to the workpiece hence the term transferred. In the nontransferred method (Fig.b), the arc occurs between the electrode and the nozzle, and the heat is carried to the workpiece by the plasma gas. This thermal- transfer mechanism is similar to that for an oxyfuel flame.

- 20. PRODUCTION TECHNOLOGY NOTES Prepared by polayya chintada page 20 Compared with other arc-welding processes, plasma-arc welding has better arc stability, less thermal distortion, and higher energy concentration, thus permitting deeper and narrower welds. In addition, higher welding speeds, from 120 to 1000 mm/min, can be achieved. A variety of metals can be welded with part thicknesses generally less than 6 mm. The high heat concentration can penetrate completely through the joint (known as the keyhole technique), with thicknesses as much as 20 mm for some titanium and aluminum alloys. In the keyhole technique, the force of the plasma arc displaces the molten metal and produces a hole at the leading edge of the weld pool. Plasma-arc welding (rather than the GTAW process) often is used for butt and lap joints because of its higher energy concentration, better arc stability, and higher welding speeds. Proper training and skill are essential for operators who use this equipment. Safety considerations include protection against glare, spatter, and noise from the plasma arc. Gas Cutting

- 21. PRODUCTION TECHNOLOGY NOTES Prepared by polayya chintada page 21 In addition to being cut by mechanical means, material can be cut into various contours with the use of a heat source that melts and removes a narrow zone in the workpiece. The sources of heat can be torches, electric arcs, or lasers. Oxyfuel-gas Cutting. Ox;/fuel-gas cutting (OFC) is similar to oxyfuel welding, but the heat source is now used to remove a narrow zone from a metal plate or sheet (Fig.a). This process is suitable particularly for steels. The basic reactions with steel are Fe + O ----> FeO + Heat, 3Fe +2O2 -> Fe3O4 + Heat, and 4Fe + 3O2 -> 2 Fe2O3 + Heat. The greatest heat is generated by the second reaction, and it can produce a temperature rise to about 870°C. However, this temperature is not sufficiently high to cut steels; therefore, the workpiece is preheated with fuel gas, and oxygen is introduced later (see the nozzle cross section in Fig.a). The higher the carbon content of the steel, the higher is the preheating temperature required. Cutting takes place mainly by the oxidation (burning) of the steel; some melting also takes place. Cast irons and steel castings also can be cut by this method. The process generates a kerf similar to that produced by sawing with a saw blade or by wire electrical discharge machining. The maximum thickness that can be cut by OFC depends mainly on the gases used. With oxyacetylene gas, the maximum thickness is about 300 mm; with oxyhydrogen, it is about

- 22. PRODUCTION TECHNOLOGY NOTES Prepared by polayya chintada page 22 600 mm. Kerf widths range from about 1.5 to 10 mm, with reasonably good control of tolerances. The flame leaves drag lines on the cut surface (Fig.b), resulting in a rougher surface than that produced by processes such as sawing, blanking, or other operations that use mechanical cutting tools. Distortion caused by uneven temperature distribution can be a problem in OFC. Although long used for salvage and repair work, OFC can be used in manufacturing as well. Torches may be guided along specified paths either manually, mechanically, or automatically by machines using programmable controllers and robots. Underwater cutting is done with specially designed torches that produce a blanket of compressed air between the flame and the surrounding water. Arc Cutting. Arc-cutting processes are based on the same principles as arc-welding processes. A variety of materials can be cut at high speeds by arc cutting. As in welding, these processes also leave a heat-affected zone that needs to be taken into account, particularly in critical applications. In air carbon-arc cutting (CAC-A), a carbon electrode is used and the molten metal is blown away by a high-velocity air jet; thus, the metal being cut doesn’t have to oxidize. This process is used especially for gouging and scarfing (removal of metal from a surface). However, the process is noisy, and the molten metal can be blown substantial distances and cause safety hazards. Plasma-arc cutting (PAC) produces the highest temperatures. It is used for the rapid cutting of nonferrous and stainless-steel plates. The cutting productivity of this process is higher than that of oxyfuel-gas methods. PAC produces a good surface finish and narrow kerfs, and is the most popular cutting process utilizing programmable controllers employed in manufacturing today. Electron beams and lasers also are used for very accurately cutting a wide variety of metals. The surface finish is better than that of other thermal cutting processes, and the kerf is narrower. Gas Tungusten Arc Welding (GTAW) or Tungusten Inert Gas Welding (TIG) In this process a non-consumable tungsten electrode is used with an envelope of inert shielding gas around it. The shielding gas protects the tungsten electrode and the molten metal weld pool from the atmospheric contamination. The shielding gases generally used

- 23. PRODUCTION TECHNOLOGY NOTES Prepared by polayya chintada page 23 are argon, helium or their mixtures. Typical tungsten inert gas welding setup is shown in Fig. Electrode materials The electrode material may be tungsten, or tungsten alloy (thoriated tungsten or zirconiated tungsten). Alloy-tungsten electrodes possess higher current carrying capacity; produce a steadier arc as compared to pure tungsten electrodes and high resistance to contamination. Electric power source Both AC and DC power source can be used for TIG welding. DC is preferred for welding of copper, copper alloys, nickel and stainless steel whereas DC reverse polarity (DCRP) or AC is used for welding aluminium, magnesium or their alloys. DCRP removes oxide film on magnesium and aluminium. Inert gases The following inert gases are generally used in TIG welding: 1. Argon 2. Helium 3. Argon-helium mixtures 4. Argon-hydrogen mixtures

- 24. PRODUCTION TECHNOLOGY NOTES Prepared by polayya chintada page 24 Tig Nozzle The nozzle or shield size (the diameter of the opening of the shroud around the electrode) to be chosen depends on the shape of the groove to be welded as well as the required gas flow rate. The gas flow rate depends on the position of the weld as well as its size. Too high a gas consumption would give rise to turbulence of the weld metal pool and consequently porous welds. Because of the use of shielding gases, no fluxes are required to be used in inert gas shielded arc welding. However for thicker sections, it may be desirable to protect the root side of the joint by providing a flux. The process is generally used for welding aluminium, magnesium and stainless steel. Gas Metal ARC Welding (GMAW) or Metal Inert Gas Welding (MIG) Metal inert gas arc welding (MIG) or more appropriately called as gas metal arc welding (GMAW) utilizes a consumable electrode and hence, the term metal appears in the title. There are other gas shielded arc welding processes utilizing the consumable electrodes, such as flux cored arc welding (FCAW) all of which can be termed under MIG. Though gas tungsten arc welding (GTAW) can be used to weld all types of metals, it is more suitable for thin sheets. When thicker sheets are to be welded, the filler metal requirement makes GTAW difficult to use. In this situation, the GMAW comes handy. The typical setup for GMAW or MIG welding process is shown in Fig.

- 25. PRODUCTION TECHNOLOGY NOTES Prepared by polayya chintada page 25 The consumable electrode is in the form of a wire reel which is fed at a constant rate, through the feed rollers. The welding torch is connected to the gas supply cylinder which provides the necessary inert gas. The electrode and the work-piece are connected to the welding power supply. The power supplies are always of the constant voltage type only. The current from the welding machine is changed by the rate of feeding of the electrode wire. Normally DC arc welding machines are used for GMAW with electrode positive (DCRP). The DCRP increases the metal deposition rate and also provides for a stable arc and smooth electrode metal transfer. With DCSP, the arc becomes highly unstable and also results in a large spatter. But special electrodes having calcium and titanium oxide mixtures as coatings are found to be good for welding steel with DCSP. In the GMAW process, the filler metal is transferred from the electrode to the joint. Depending on the current and voltage used for a given electrode, the metal transfer is done in different ways.