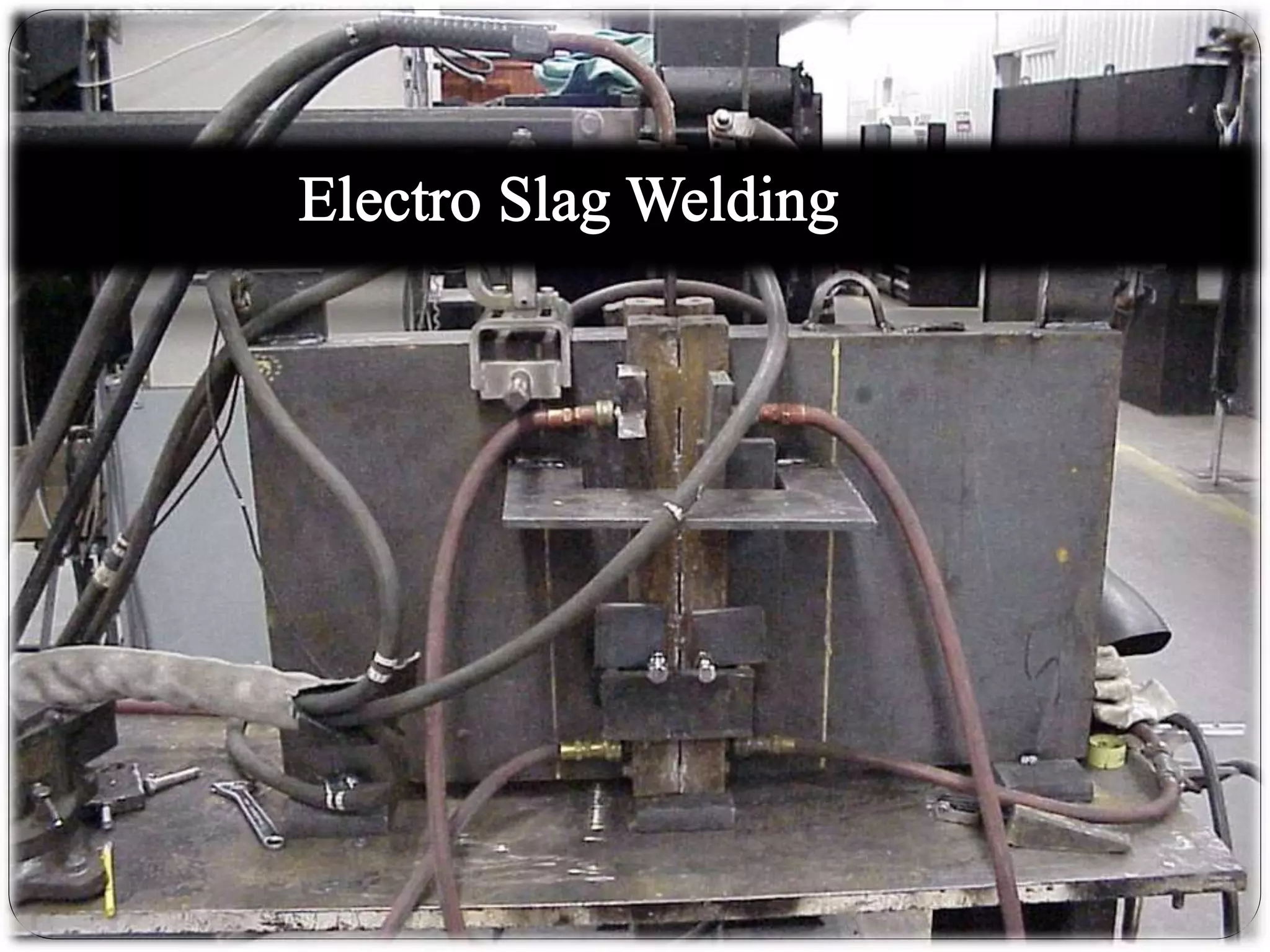

This document provides information about electro-slag welding (ESW) and electro-gas welding (EGW). ESW uses resistance heating of a molten slag to generate heat and fuse metals, while EGW uses an arc to melt an electrode in an inert gas environment. Both processes can weld very thick steel plates (up to 460mm for ESW and 100mm for EGW) in a single pass. Key advantages are high deposition rates and reduced residual stresses compared to other welding methods. ESW and EGW require specialized equipment and are limited to vertical welds.