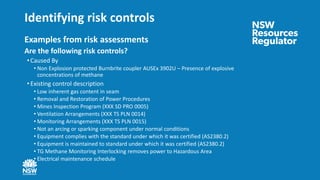

This document summarizes electrical incident data from various mining industries between 2018-2019. It reports on:

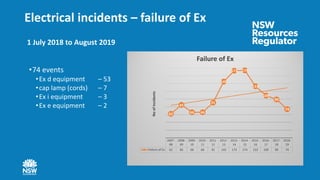

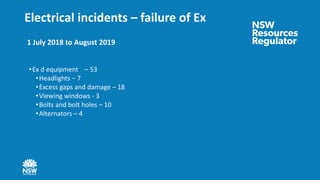

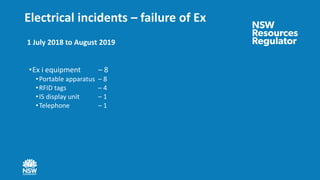

- 74 failures of explosion-protected equipment, primarily related to Ex d and cap lamp equipment.

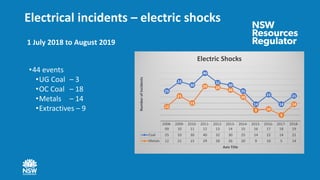

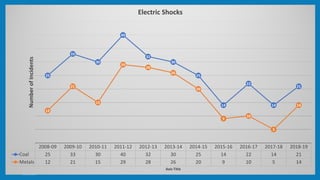

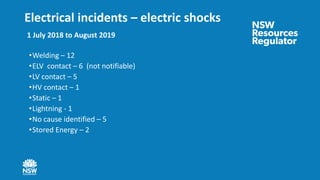

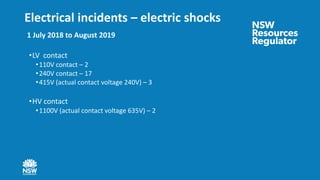

- 44 electric shock events, most occurring in coal and metals mining. Common causes included welding, low voltage contact and lightning.

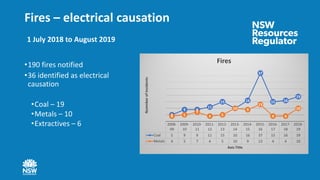

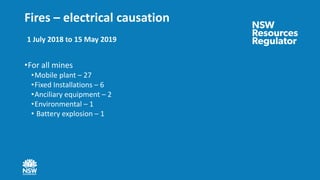

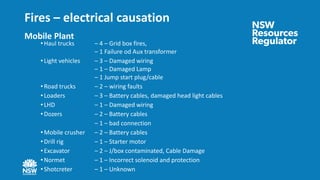

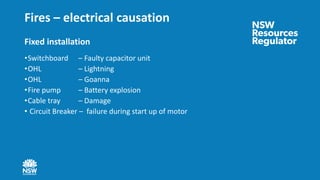

- 36 electrical fires identified across coal, metals and extractive mining industries. The majority involved mobile plant such as haul trucks and loaders.