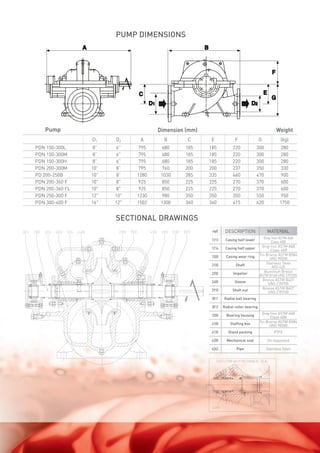

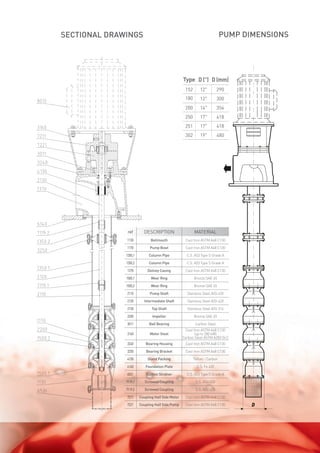

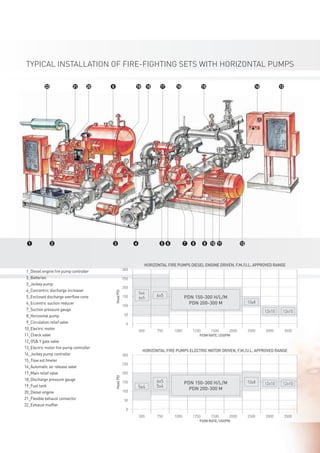

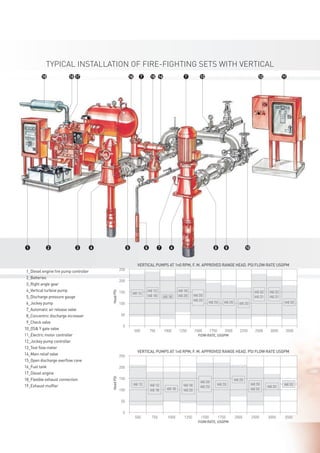

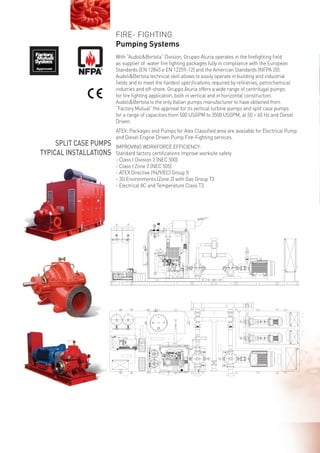

This document provides specifications for horizontal and vertical fire-fighting pumps and packages that meet UNI EN 12845 and UNI EN 12259-12 standards. It includes performance ranges, dimensions, materials, and test procedures for horizontal split-case centrifugal pumps and vertical shaft turbine pumps. Installation diagrams and specifications are also provided for electric motor and diesel engine driven fire pump sets with controllers.