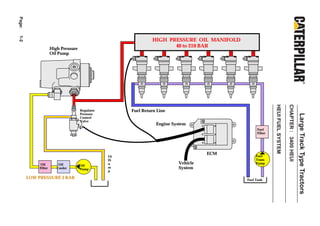

The document provides information about service training for the 3400 HEUI engine used in large track type tractors. It includes diagrams and descriptions of the key components and operation of the HEUI fuel system, including the hydraulic supply pump group, injectors, fuel injection cycle, pressure control, start-up process, and destroke process. The document is intended to train service technicians on testing and adjusting the 3400 HEUI engine.