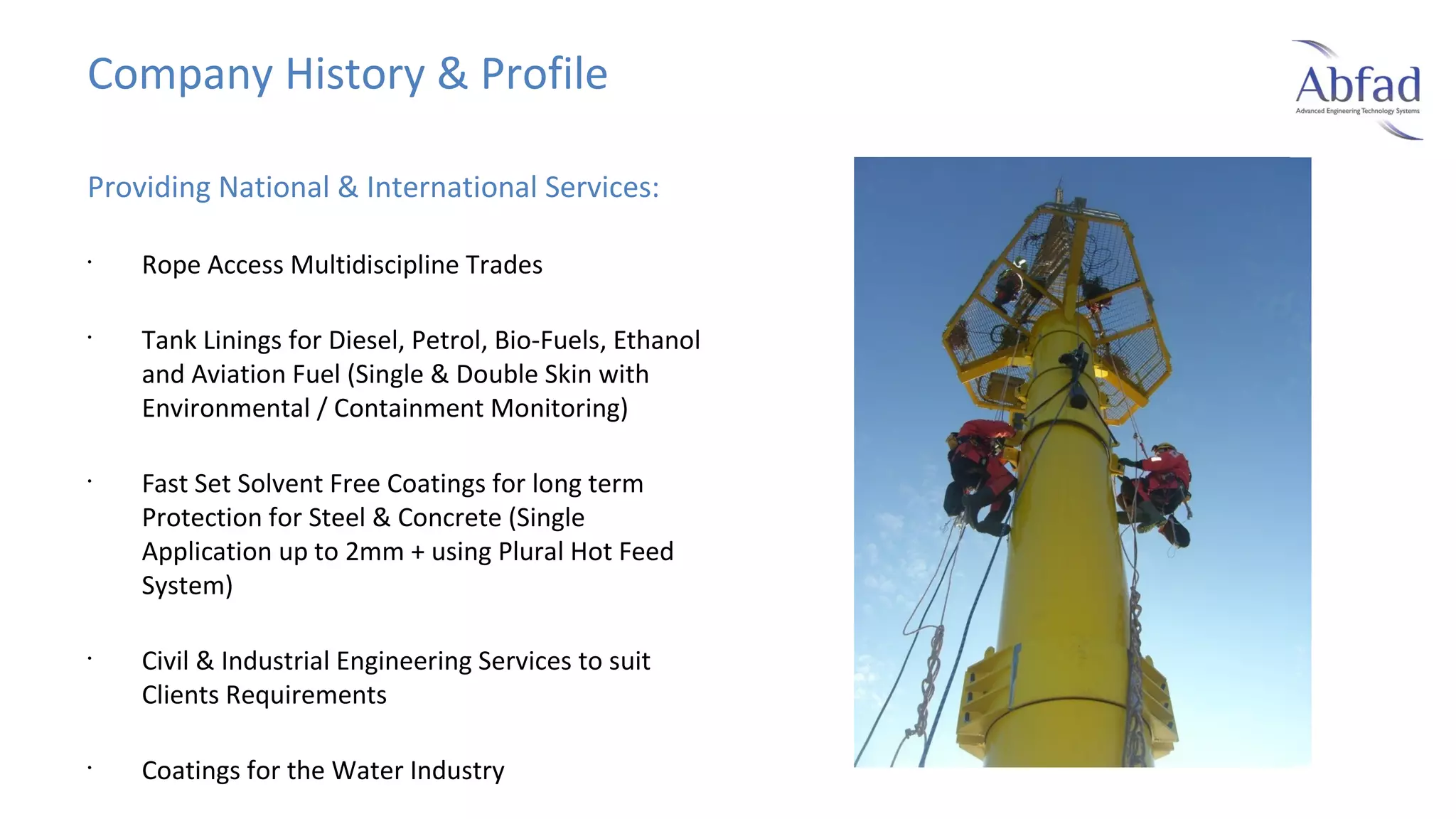

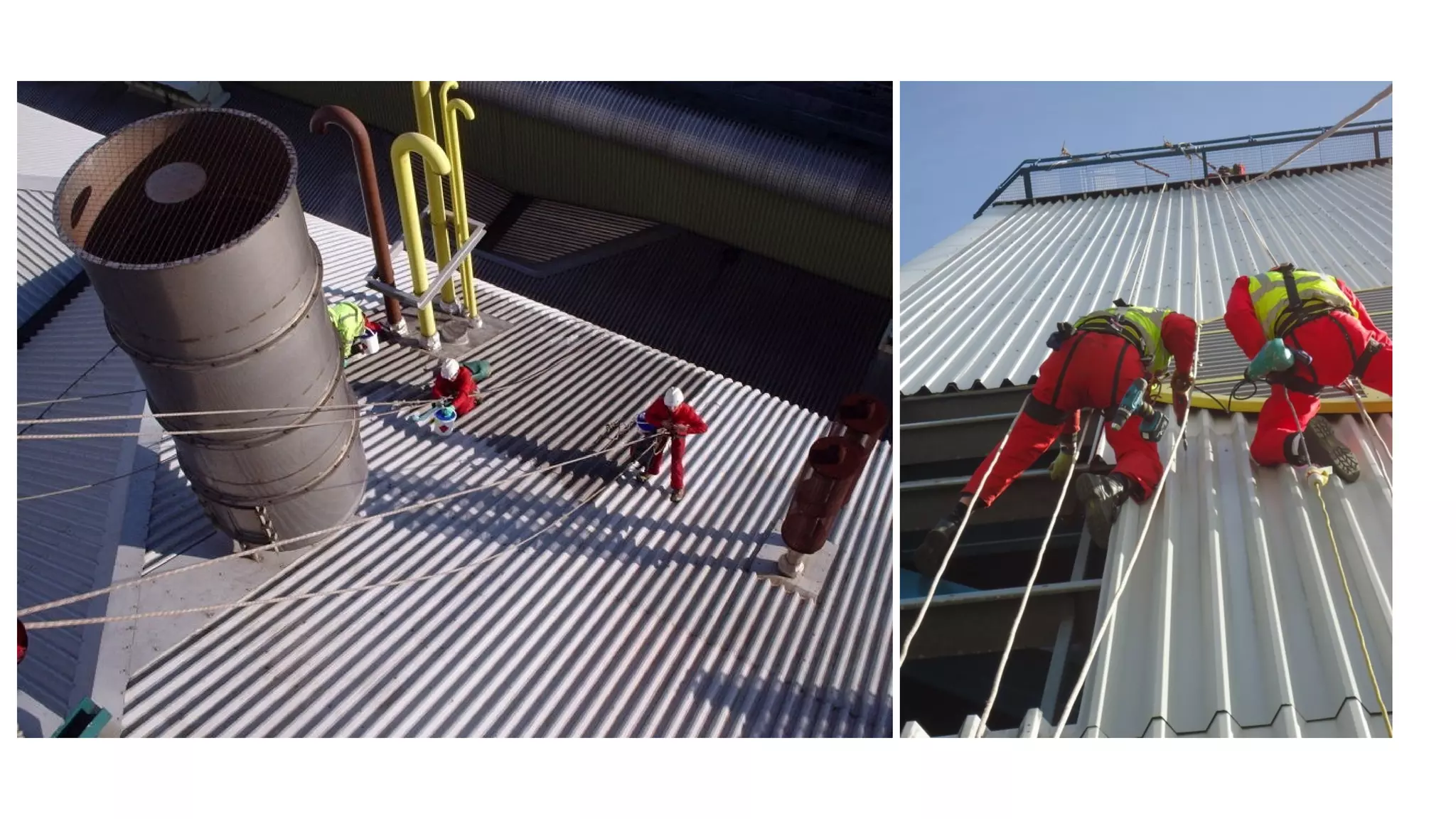

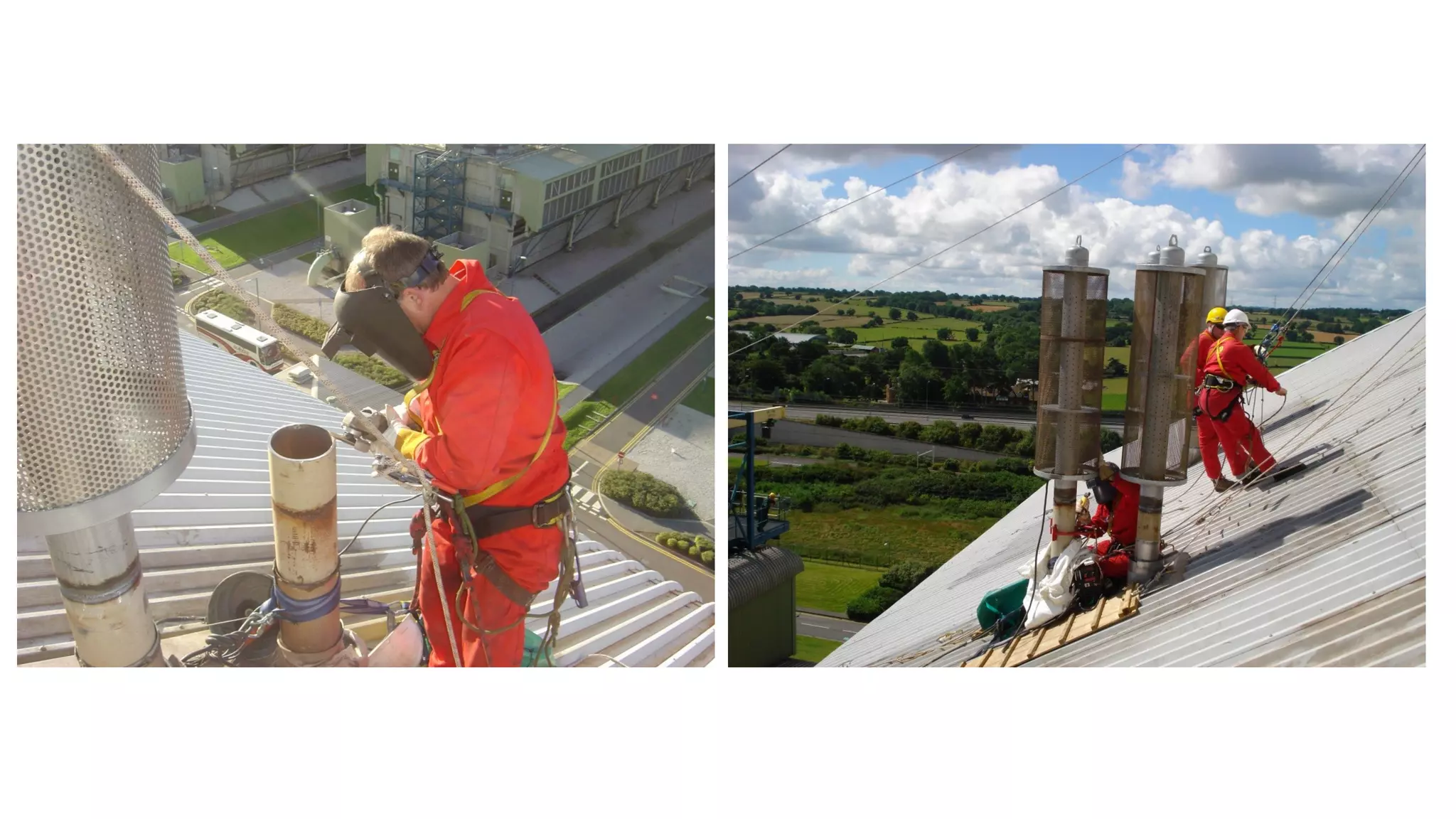

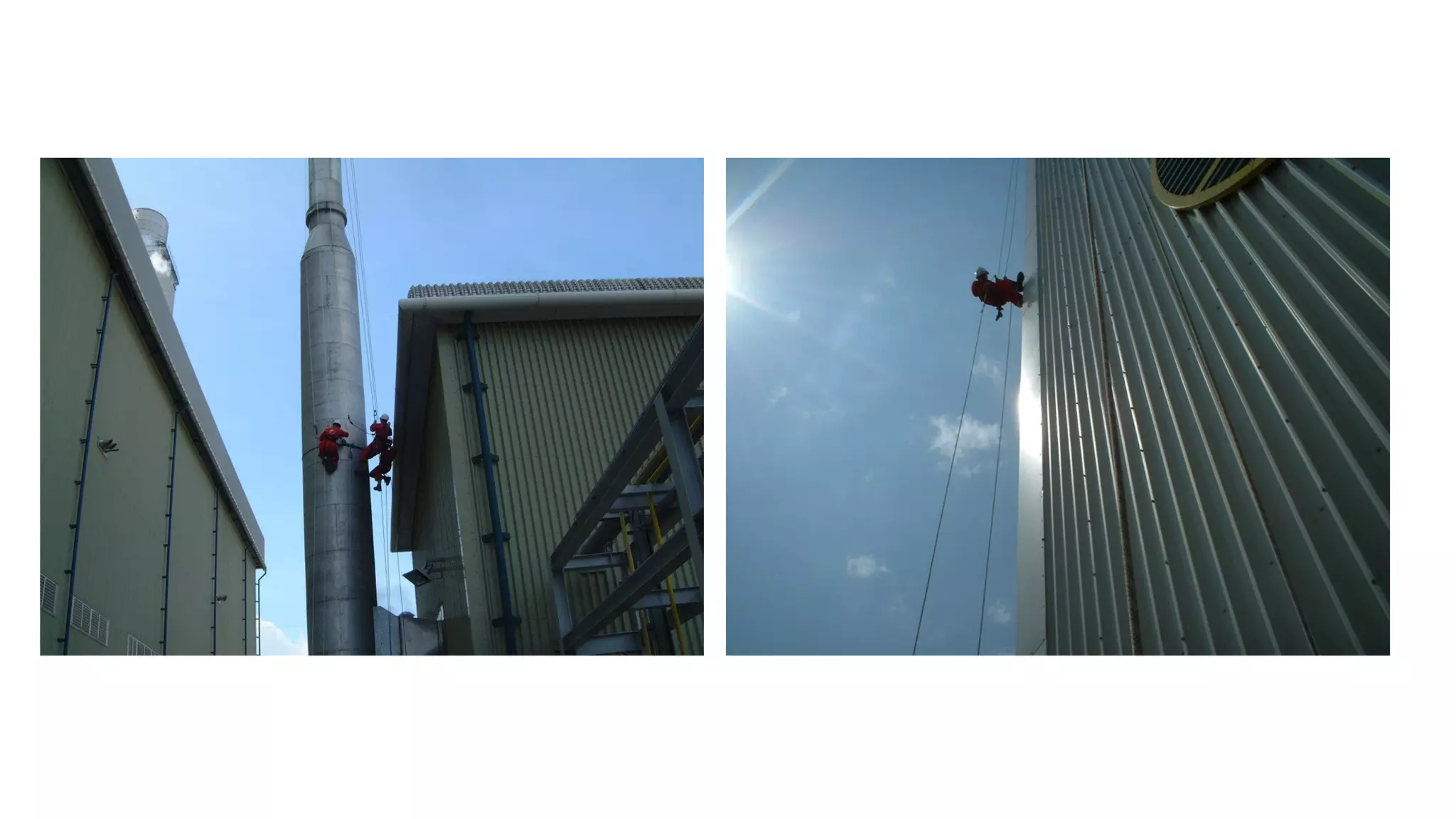

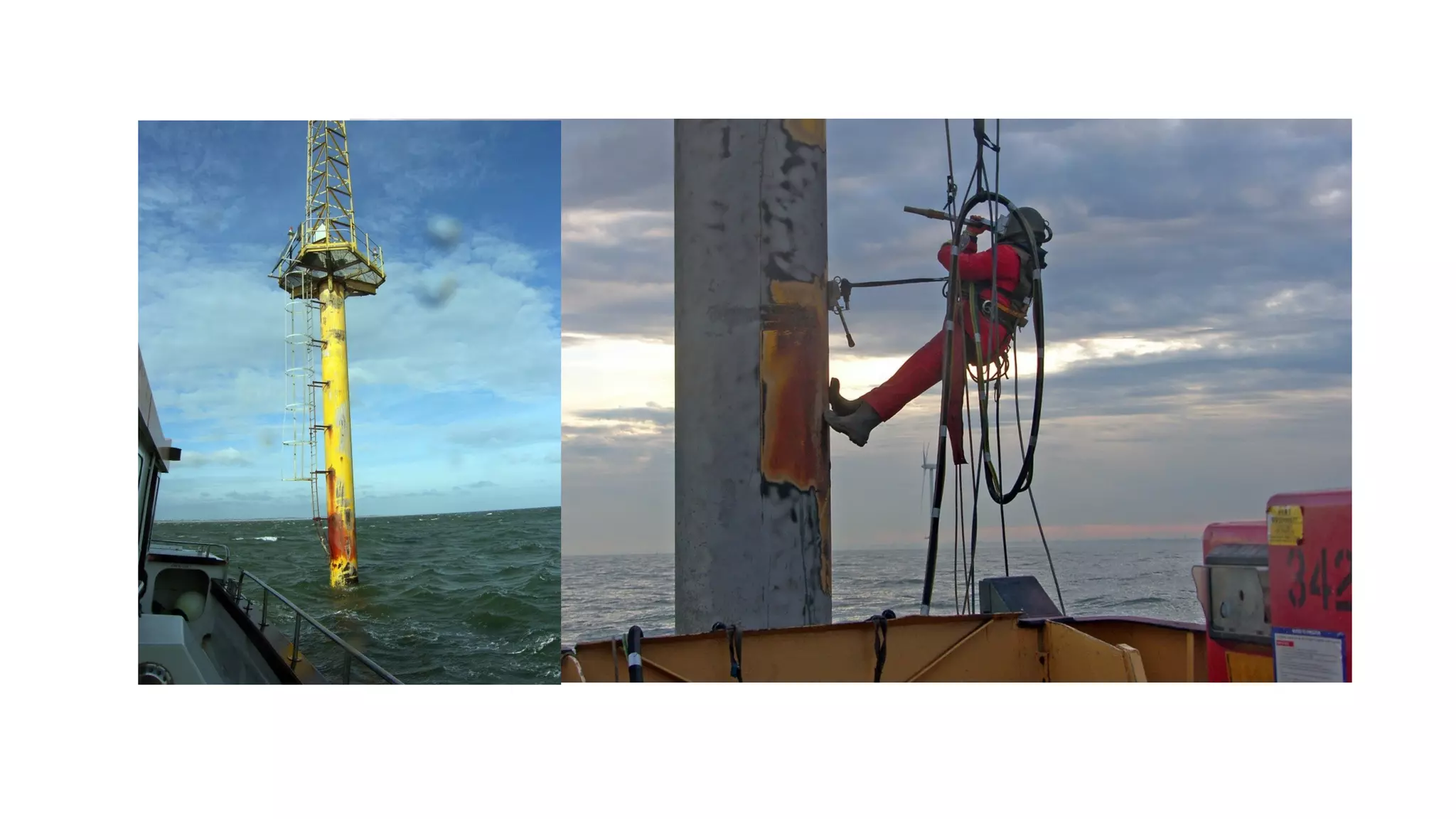

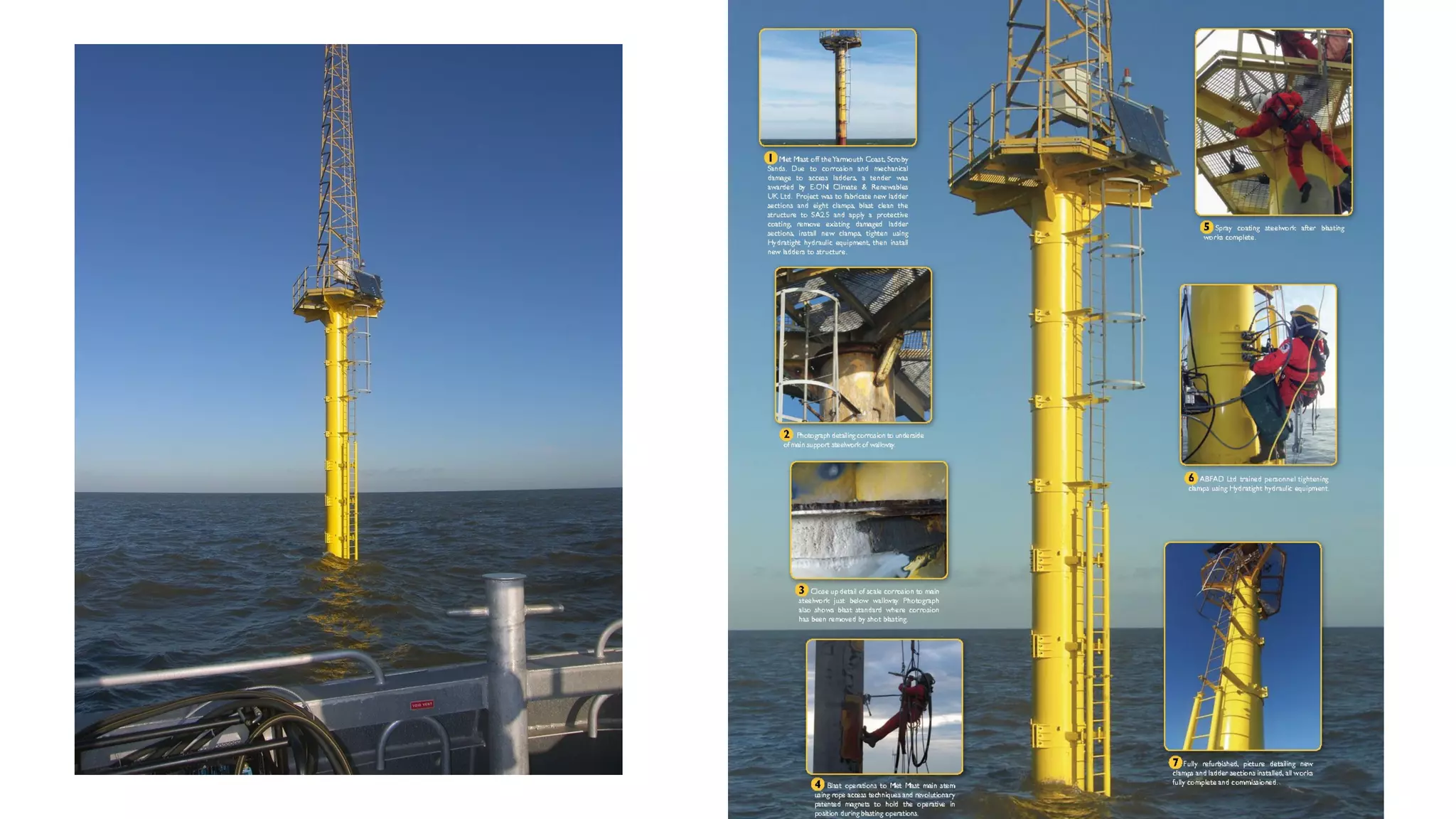

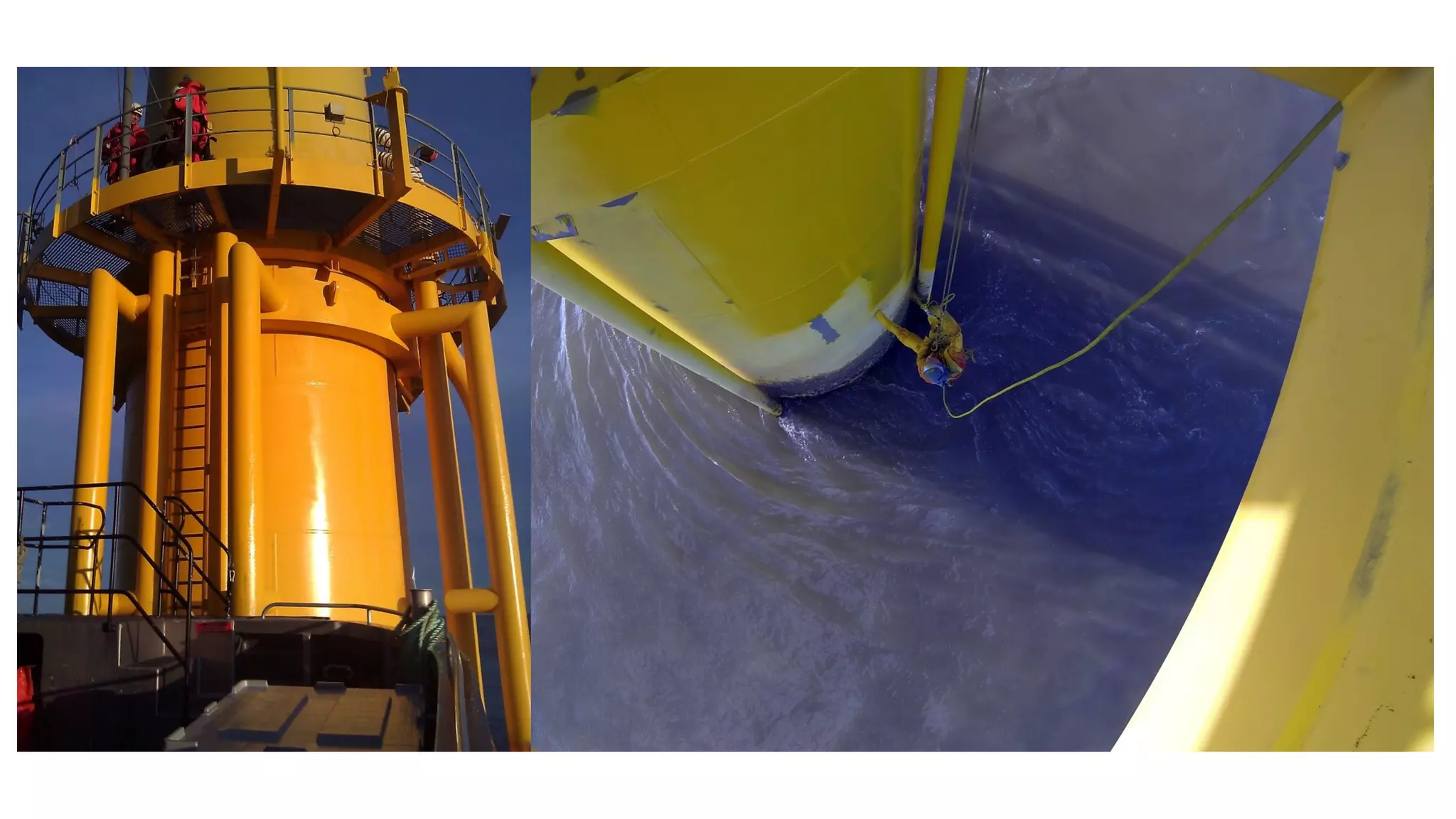

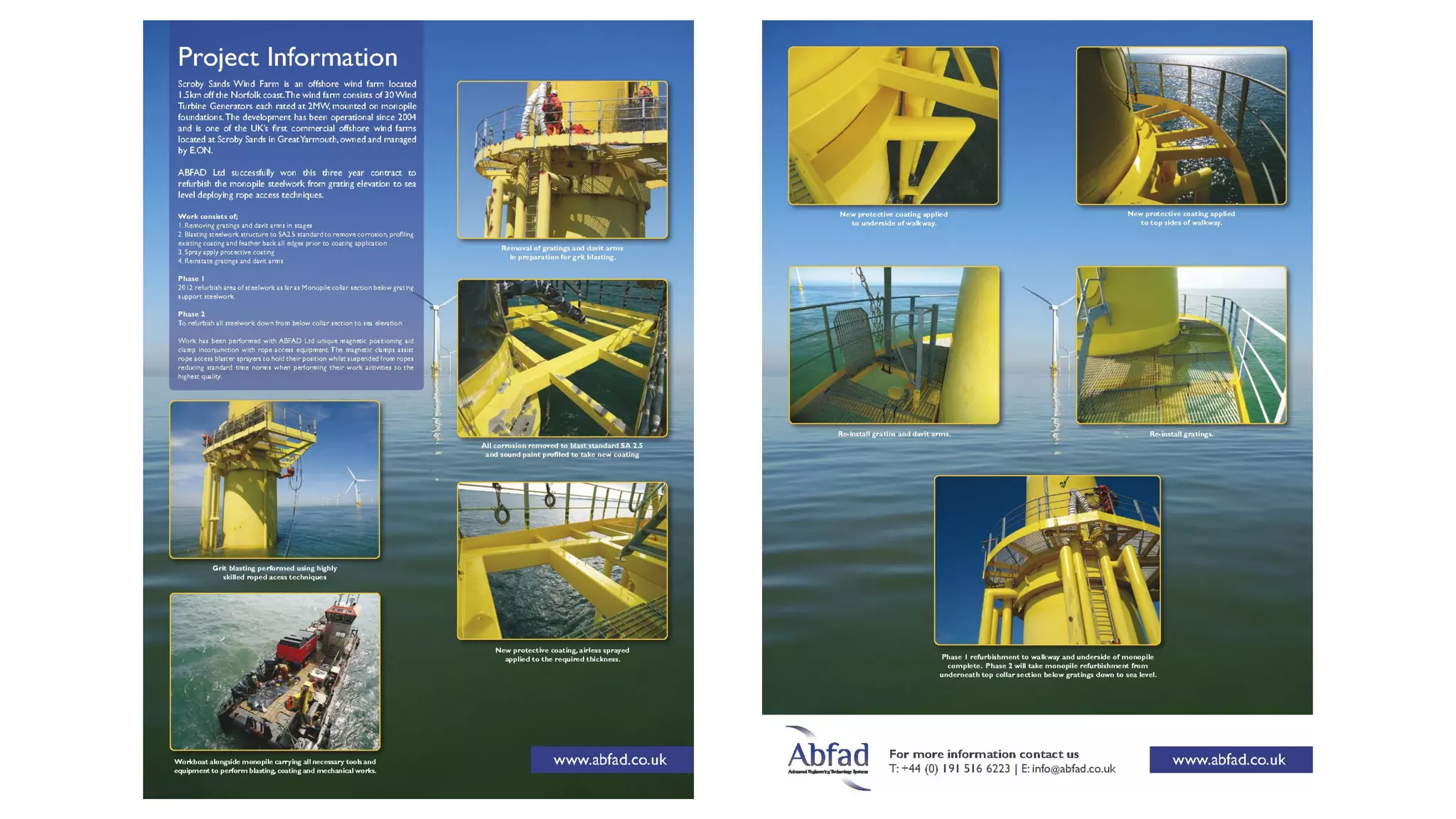

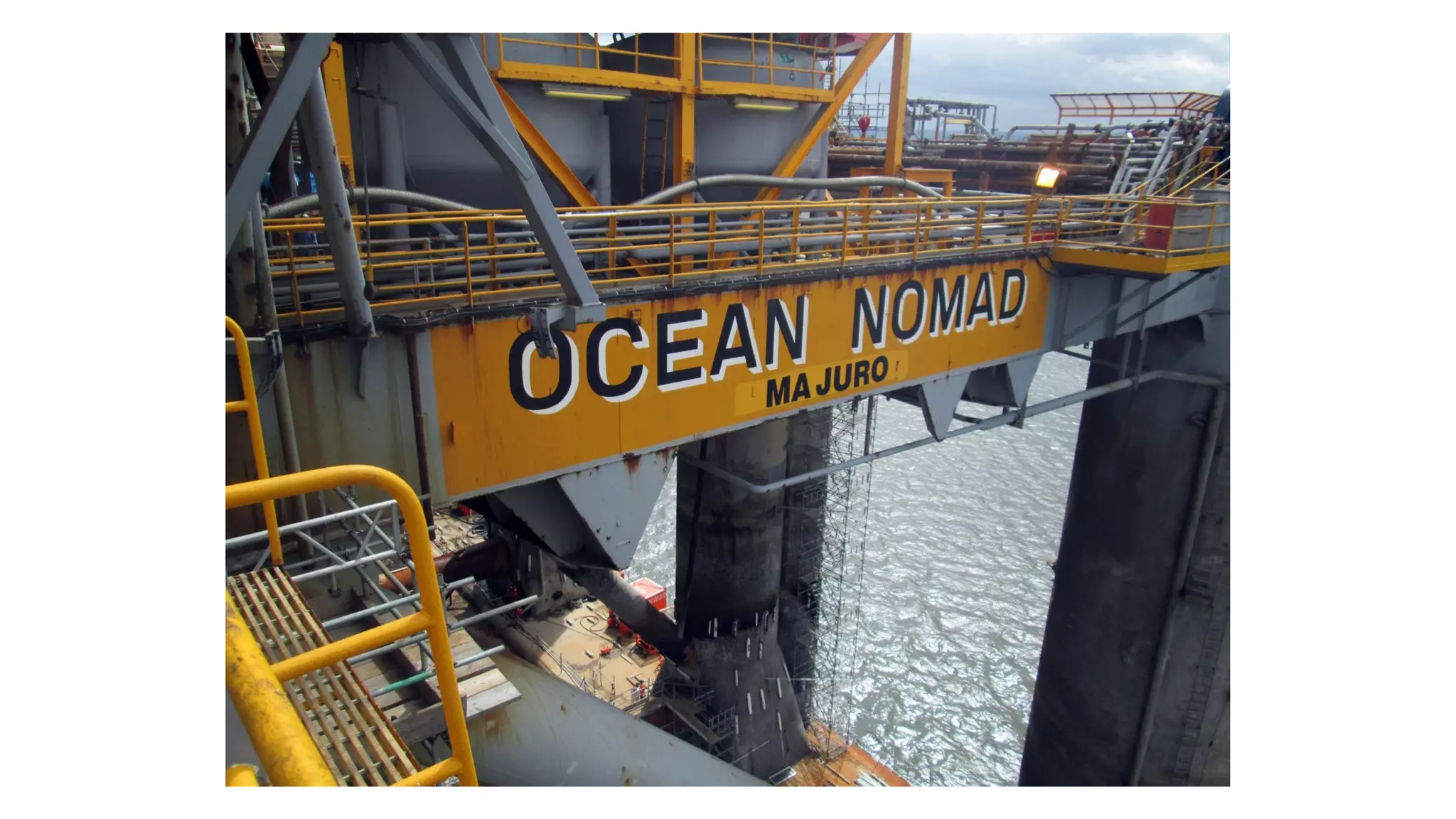

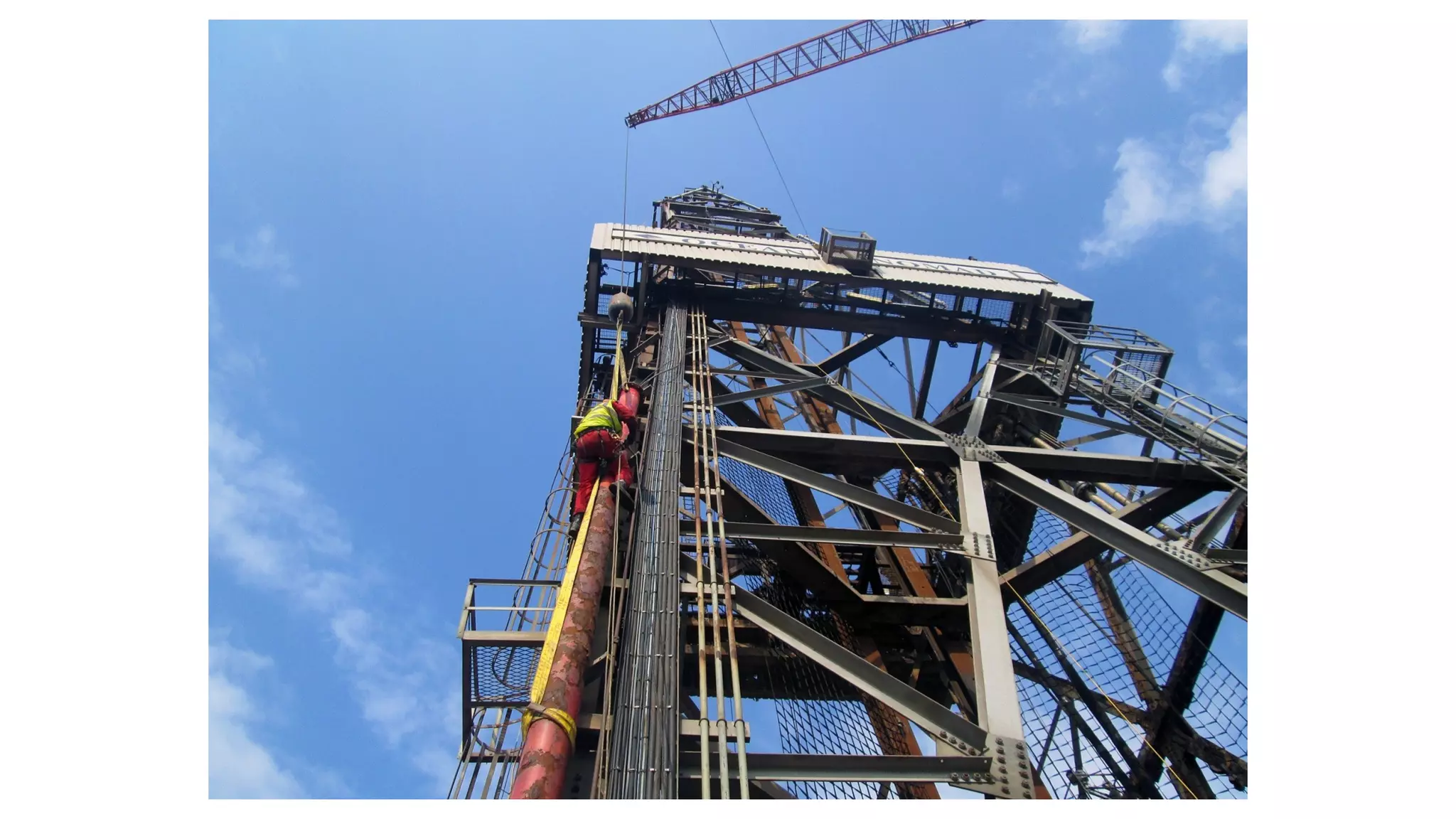

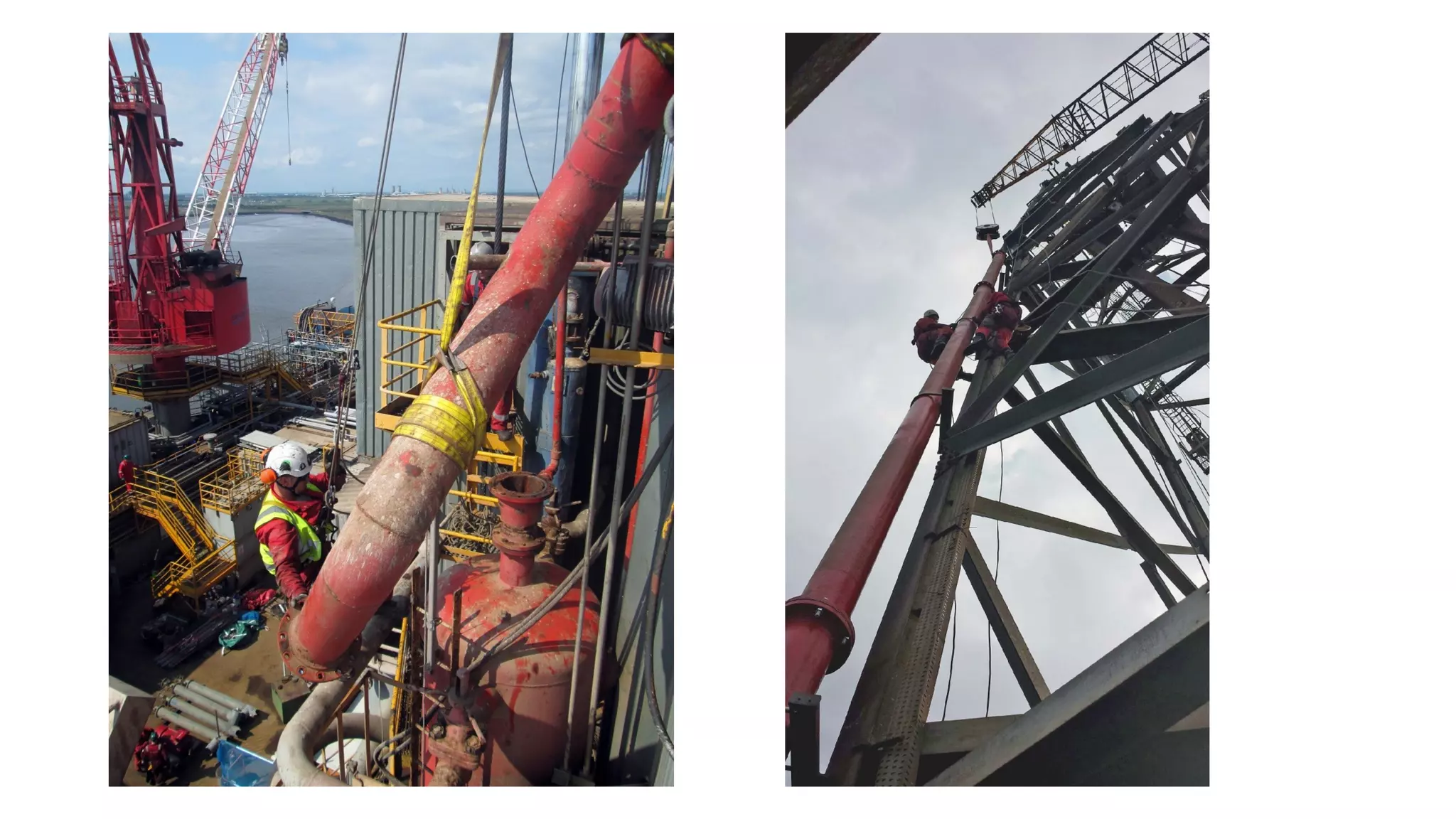

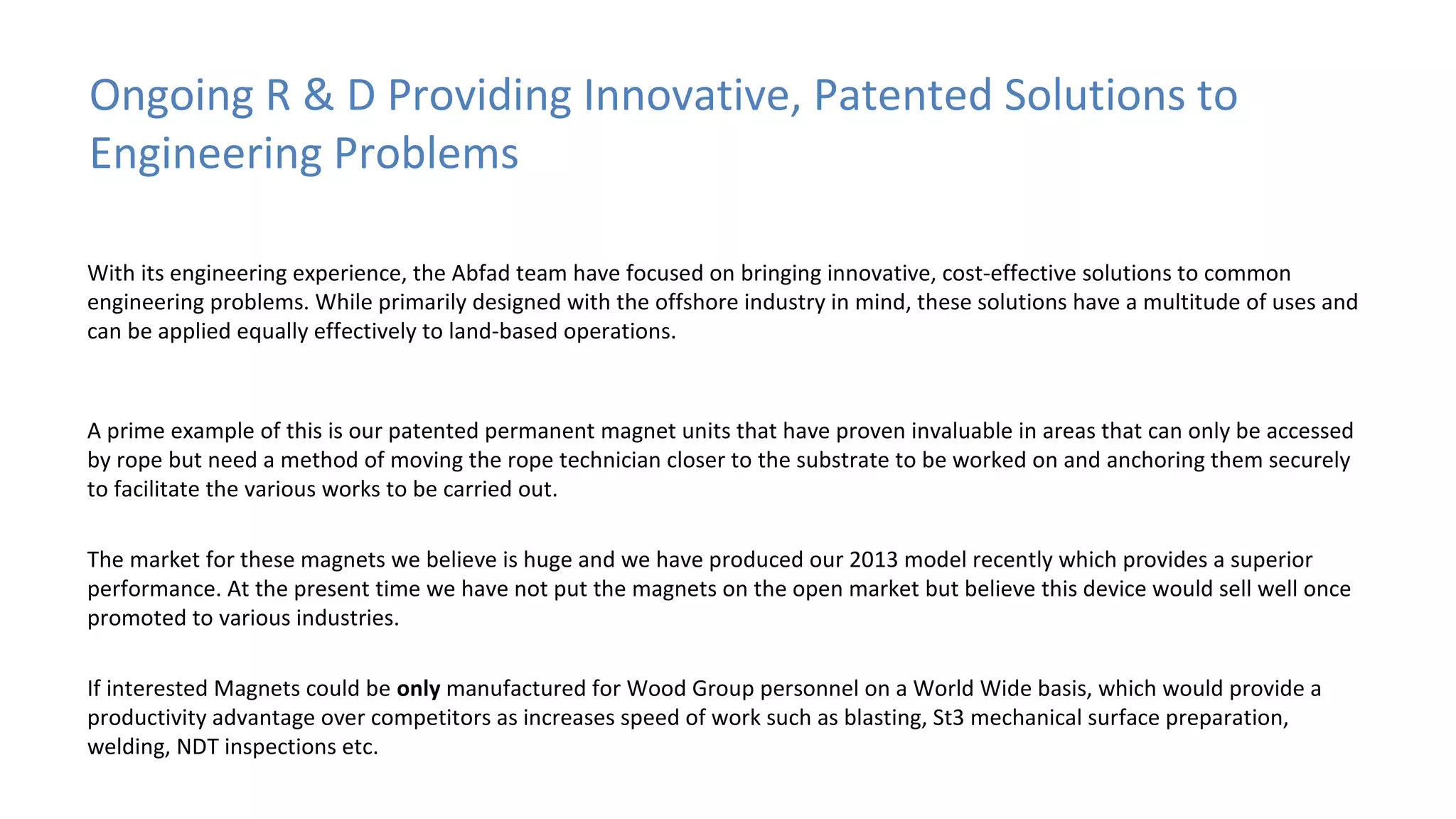

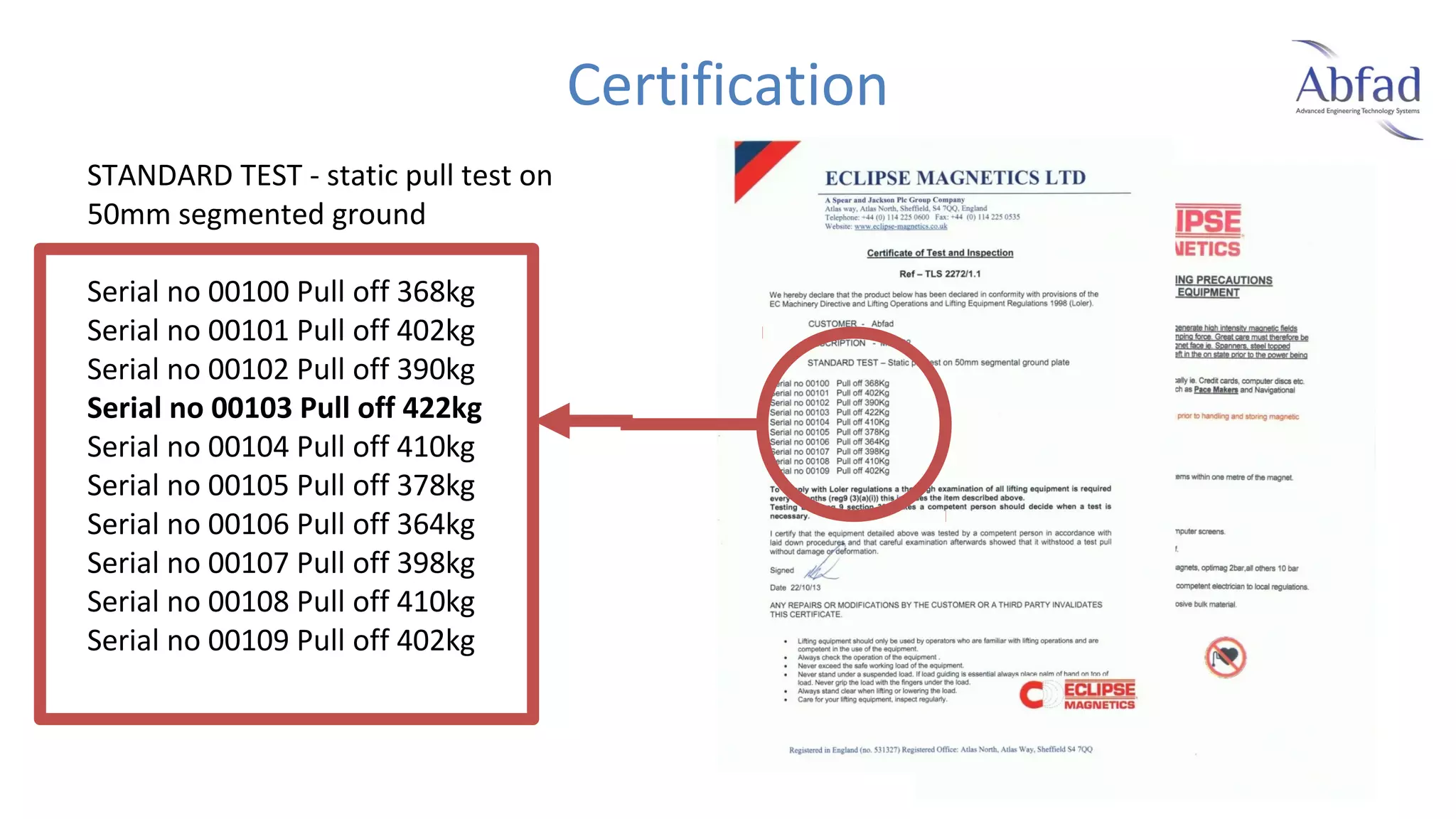

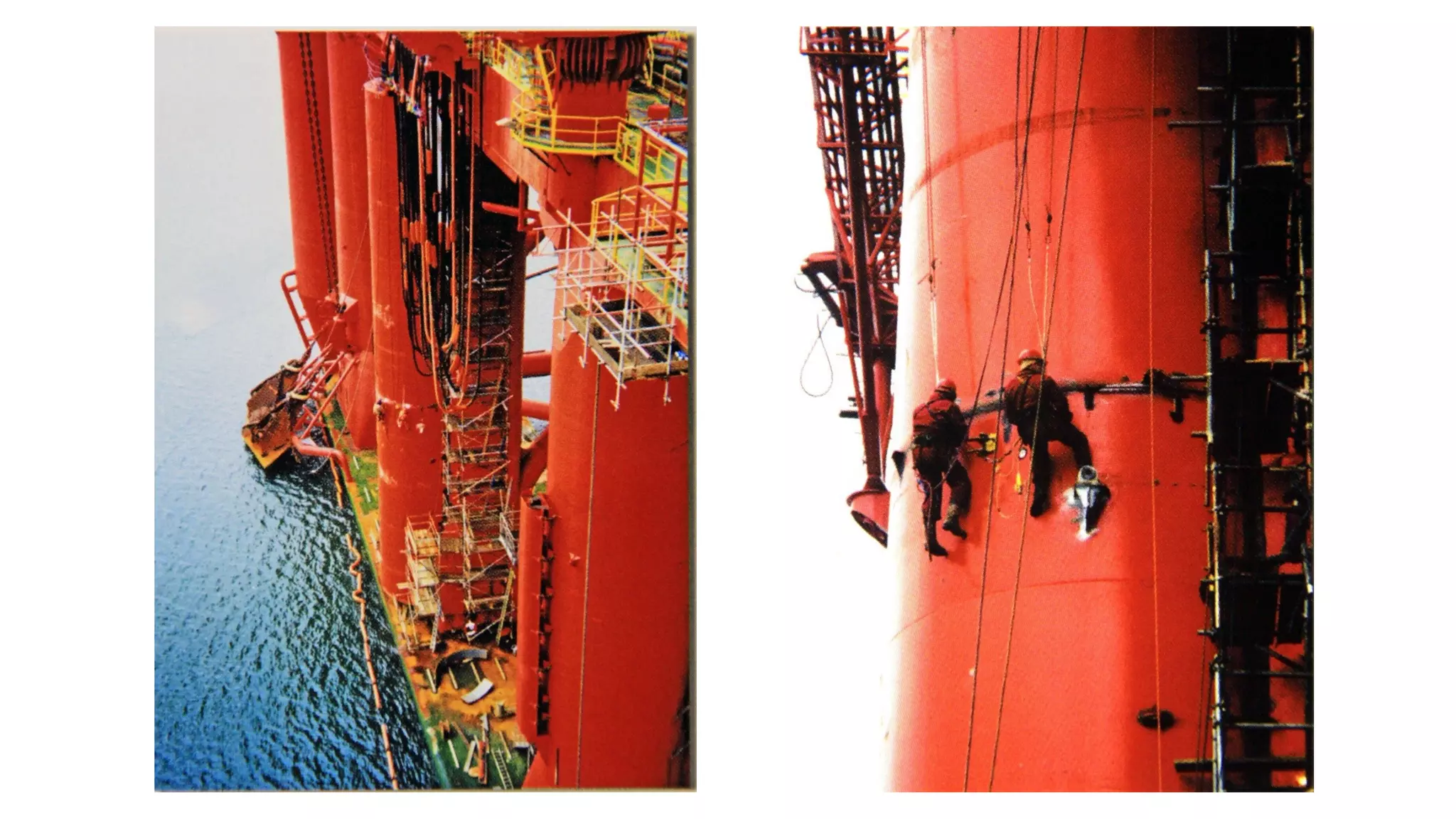

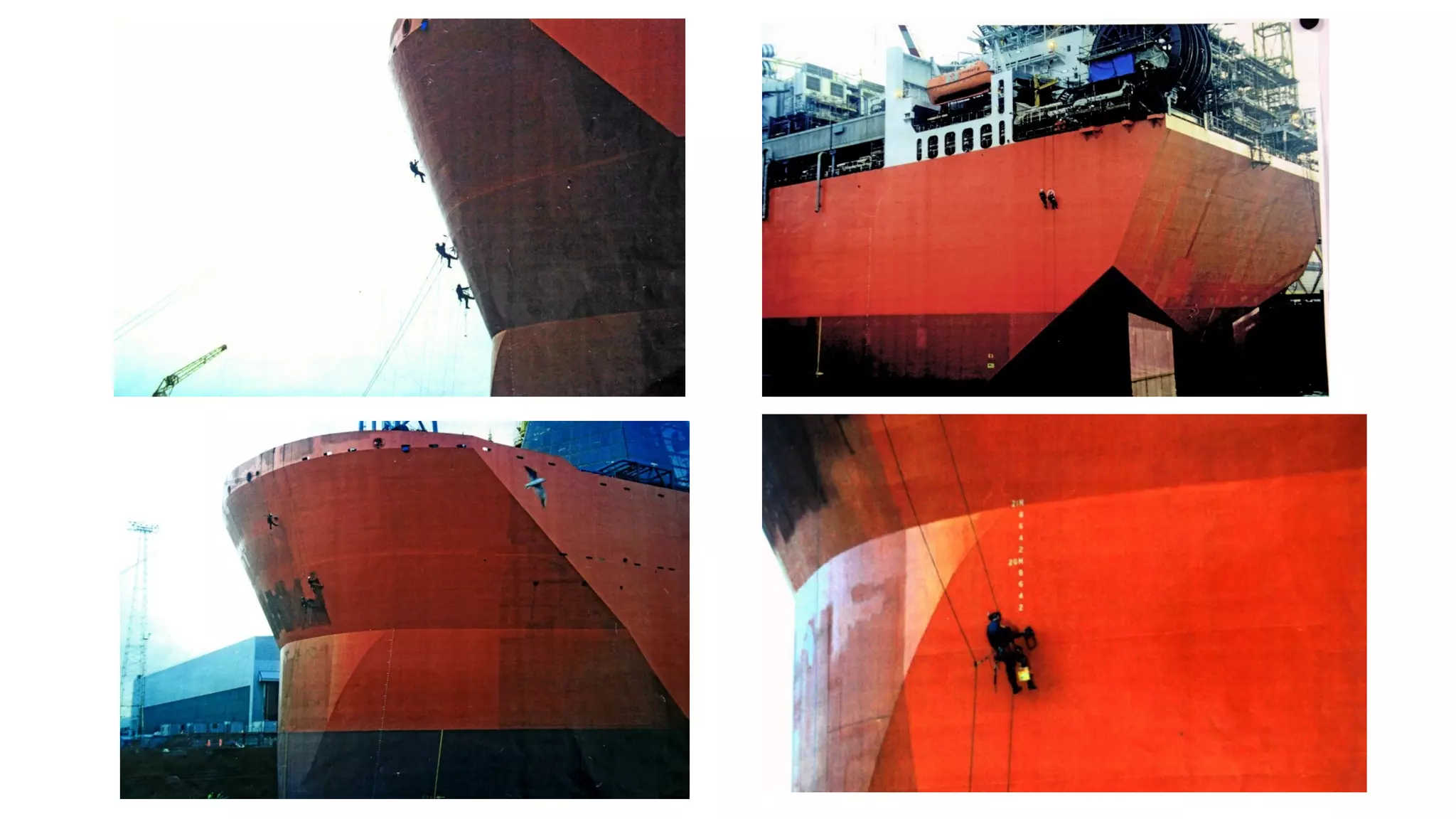

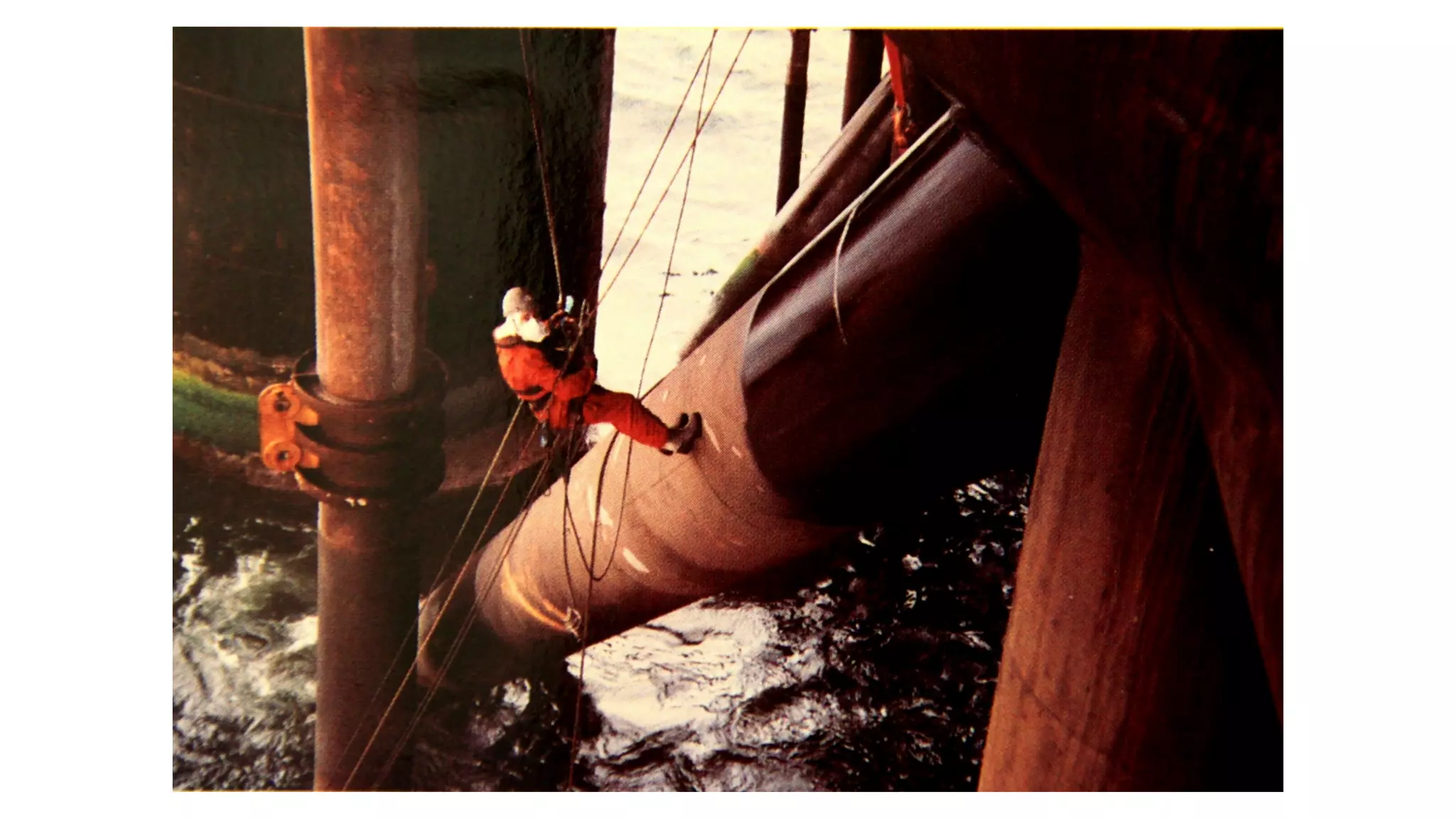

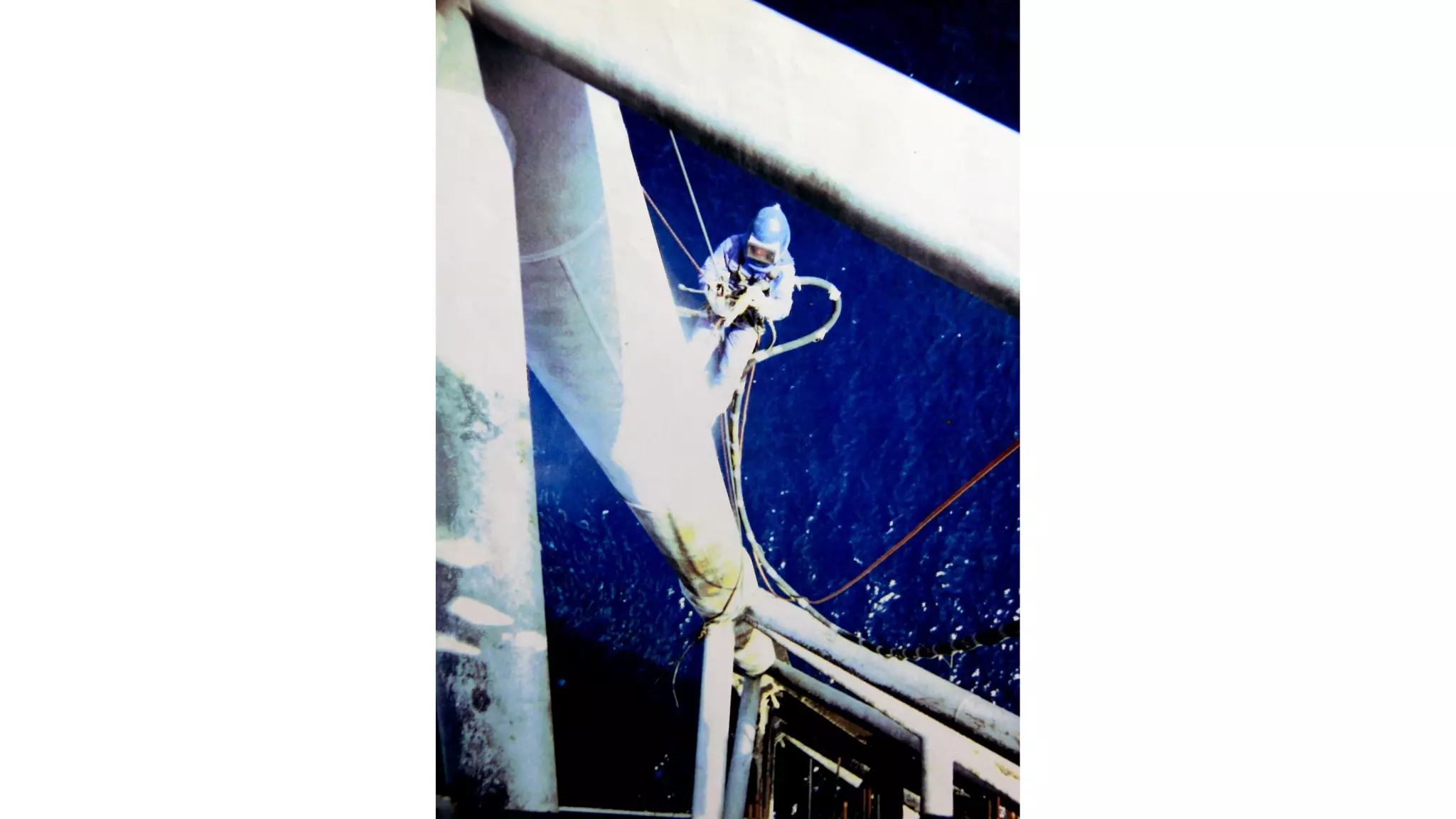

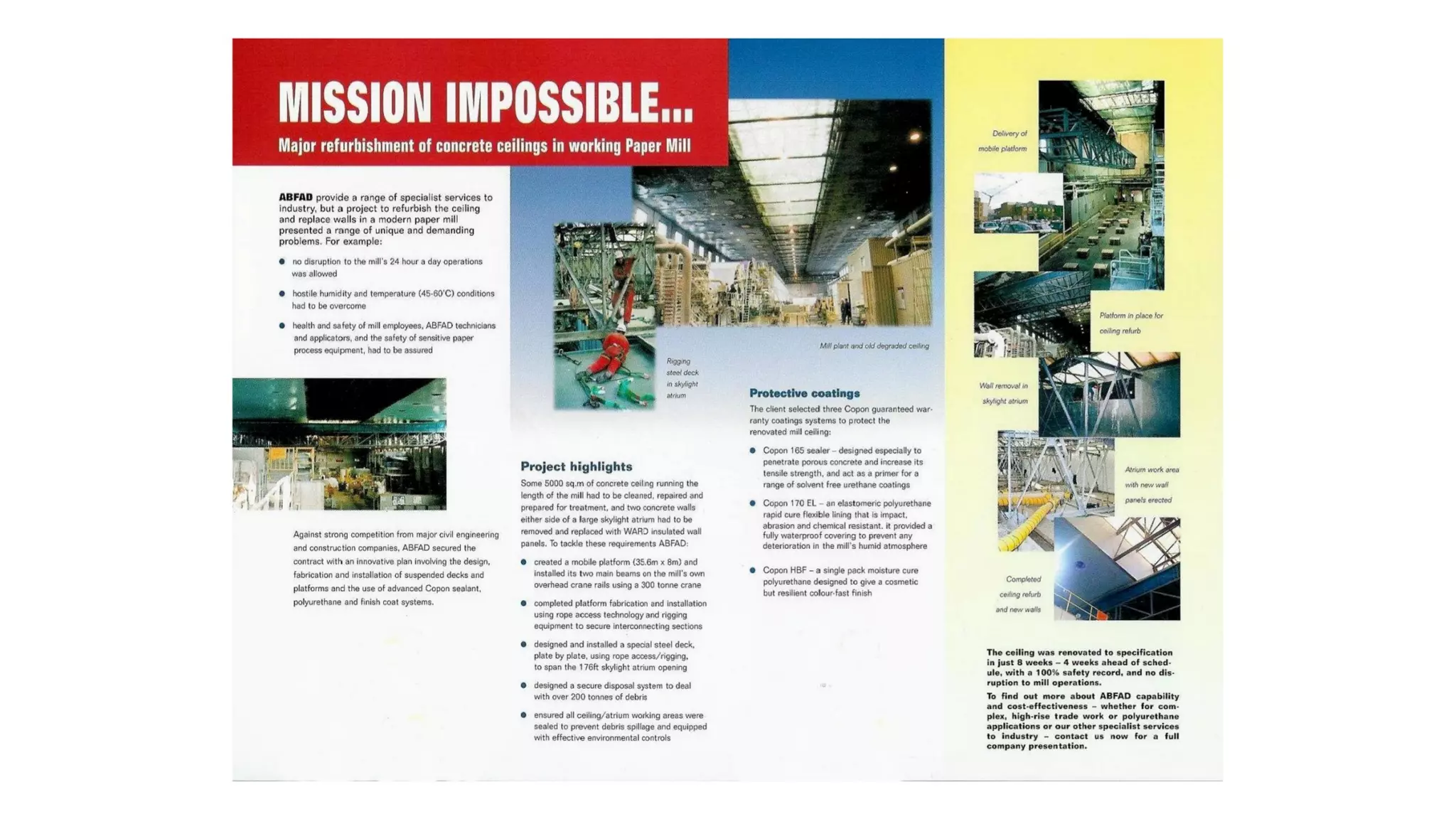

Abfad Ltd specializes in rope access services and multidisciplinary trades, offering solutions for various industries including oil and gas, and water. The company emphasizes safety and skill development, training personnel extensively to perform tasks safely at height, and is involved in innovative projects like the patented Fuelvac® double skin lining system for tanks. With a strong history of successful projects and safety accreditation, Abfad aims to enhance operational quality and security for clients in offshore and onshore sectors.