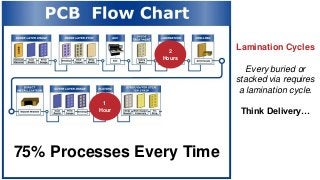

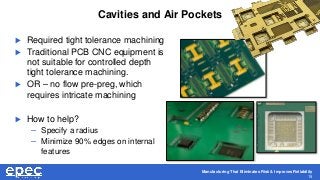

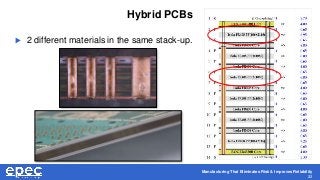

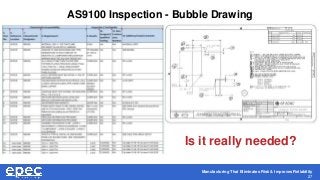

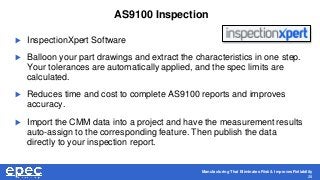

When manufacturing higher technology circuit boards, there are many variables that could increase the costs of your parts or increase the lead time. The goal of this webinar is to demonstrate how design choices add cost and time to the manufacturing process of printed circuit boards.

While we all understand that hi-speed/high technology PCBs need to have these complex features in order to deliver their intended result,in many cases these features can be left out during the development and prototype stages in order to help the designer prove out ideas quicker.

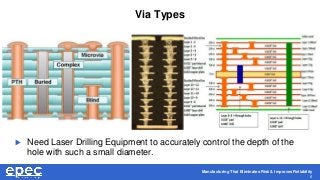

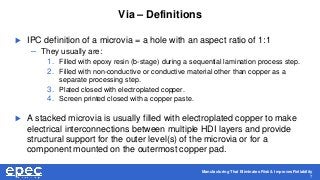

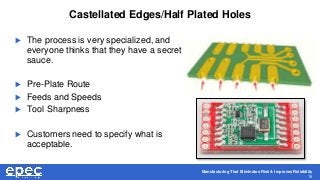

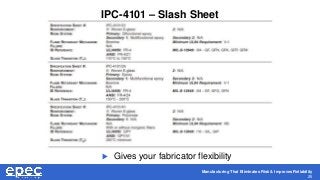

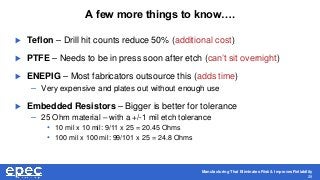

In this webinar, our goal is to help everyone understand what to expect in terms of delivery time for features,such as the material selection, vias, castellated edges, and embedded resistors that they incorporate into their circuit boards.

For more information on our printed circuit board solutions,visit http://www.epectec.com/pcb/.