Process capability

An introduction to SigmaXL's Process Capability tools. Established in 1998, SigmaXL Inc. is a leading provider of user friendly Excel Add-ins for Lean Six Sigma graphical and statistical tools and Monte Carlo simulation. SigmaXL® customers include market leaders like Agilent, Diebold, FedEx, Microsoft, Motorola and Shell. SigmaXL® software is also used by numerous colleges, universities and government agencies. Our flagship product, SigmaXL®, was designed from the ground up to be a cost-effective, powerful, but easy to use tool that enables users to measure, analyze, improve and control their service, transactional, and manufacturing processes. As an add-in to the already familiar Microsoft Excel, SigmaXL® is ideal for Lean Six Sigma training and application, or use in a college statistics course. DiscoverSim™ enables you to quantify your risk through Monte Carlo simulation and minimize your risk with global optimization. Business decisions are often based on assumptions with a single point value estimate or an average, resulting in unexpected outcomes. DiscoverSim™ allows you to model the uncertainty in your inputs so that you know what to expect in your outputs.

Recommended

Recommended

More Related Content

Viewers also liked

Viewers also liked (16)

Recently uploaded

Recently uploaded (20)

Process capability

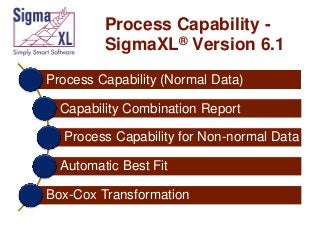

- 1. Process Capability SigmaXL® Version 6.1 Process Capability (Normal Data) Capability Combination Report Process Capability for Non-normal Data Automatic Best Fit Box-Cox Transformation

- 2. Process Capability (Normal Data) Process Capability/Sigma Level Templates Multiple Histograms and Process Capability Capability Combination Report for Individuals/Subgroups: Histogram Capability Report (Cp, Cpk, Pp, Ppk, Cpm, ppm, %) Normal Probability Plot Anderson-Darling Normality Test Control Charts Back to Index

- 3. -12.66 28.28 3.28 81 10 1 12 1 14 1 16 1 18 1 20 1 22 1 24 1 26 1 28 1 30 1 32 1 34 1 36 1 38 1 40 1 42 1 44 1 46 1 48 1 50 1 52 1 54 1 56 1 58 1 60 1 62 1 64 1 66 1 68 1 70 1 72 1 7.34 81 10 1 12 1 14 1 16 1 18 1 20 1 22 1 24 1 26 1 28 1 30 1 32 1 34 1 36 1 38 1 40 1 42 1 44 1 46 1 48 1 50 1 52 1 54 1 56 1 58 1 60 1 62 1 64 1 66 1 68 1 70 1 72 1 61 41 21 1 Delivery Time Deviation 10 0 -1.72 0.00 27 40 17 60 7 3 70 -3 80 -13 50 NSCORE 90 -23 25.5 23.9 22.2 20.6 19.0 17.4 15.7 14.1 12.5 10.9 9.2 7.6 6.0 4.4 2.7 1.1 -0.5 Target = 0 61 41 21 1 Individuals - Delivery Time Deviation LSL = -10 MR - Delivery Time Deviation -2.1 -3.8 -5.4 -7.0 -8.6 -10.3 -11.9 Process Capability: Capability Combination Report USL = 10 4 2 1 0 30 -1 20 -2 -3 -4 Delivery Time Deviation 27.34 27.61 22.34 17.34 12.34 2.34 Mean CL: 6.00 -2.66 -7.66 -17.66 -15.60 33.28 23.28 26.54 18.28 13.28 8.28 8.12 Back to Index

- 4. Process Capability for Nonnormal Data Box-Cox Transformation (includes an automatic threshold option so that data with negative values can be transformed) Johnson Transformation Distributions supported: Half-Normal Lognormal (2 & 3 parameter) Exponential (1 & 2 parameter) Weibull (2 & 3 parameter) Beta (2 & 4 parameter) Gamma (2 & 3 parameter) Logistic Loglogistic (2 & 3 parameter) Largest Extreme Value Smallest Extreme Value Back to Index

- 5. Process Capability for Nonnormal Data Automatic Best Fit based on AD p-value Nonnormal Process Capability Indices: Z-Score (Cp, Cpk, Pp, Ppk) Percentile (ISO) Method (Pp, Ppk) Distribution Fitting Report All valid distributions and transformations reported with histograms, curve fit and probability plots Sorted by AD p-value Back to Index

- 6. Process Capability for Nonnormal Data Distribution options displayed visually Back to Index

- 7. 97 99 93 95 89 91 85 87 81 83 77 79 73 75 69 71 65 67 61 63 57 59 53 55 49 51 45 47 41 43 37 39 33 35 29 31 25 27 21 23 17 19 13 15 9 11 7 5 3 1 Individuals: Overall Satisfaction (Percentile Control Limits) 5.26 4.98 4.71 4.44 4.17 3.90 3.62 3.35 3.08 2.81 2.54 2.26 1.99 1.72 1.45 Nonnormal Process Capability: Automatic Best Fit LSL = 3.5 16 14 12 10 8 6 4 2 0 Overall Satisfaction 5.500 5.000 5.136 4.500 4.000 3.500 3.885 3.000 2.500 2.000 1.500 1.548 Back to Index

- 8. Process Capability: Box-Cox Power Transformation Normality Test is automatically applied to transformed data! Back to Index