Dover ALS Safety Moment of the Week 15-Aug-2016

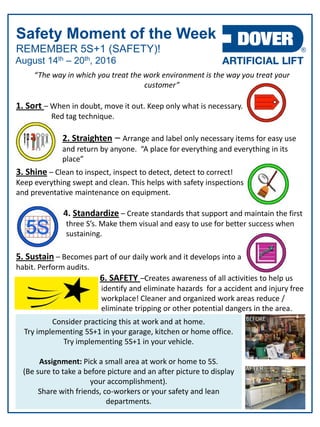

- 1. REMEMBER 5S+1 (SAFETY)! Safety Moment of the Week August 14th – 20th, 2016 “The way in which you treat the work environment is the way you treat your customer” 1. Sort – When in doubt, move it out. Keep only what is necessary. Red tag technique. 2. Straighten – Arrange and label only necessary items for easy use and return by anyone. “A place for everything and everything in its place” 3. Shine – Clean to inspect, inspect to detect, detect to correct! Keep everything swept and clean. This helps with safety inspections and preventative maintenance on equipment. 4. Standardize – Create standards that support and maintain the first three S’s. Make them visual and easy to use for better success when sustaining. 5. Sustain – Becomes part of our daily work and it develops into a habit. Perform audits. 6. SAFETY –Creates awareness of all activities to help us identify and eliminate hazards for a accident and injury free workplace! Cleaner and organized work areas reduce / eliminate tripping or other potential dangers in the area. Consider practicing this at work and at home. Try implementing 5S+1 in your garage, kitchen or home office. Try implementing 5S+1 in your vehicle. Assignment: Pick a small area at work or home to 5S. (Be sure to take a before picture and an after picture to display your accomplishment). Share with friends, co-workers or your safety and lean departments.

- 2. Safety Moment of the Week August 14th – 20th , 2016 REMEMBER 5s+1 (SAFETY)! 5S Workplaces: When Safety and Lean Meet The five in a 5S workplace organizational and housekeeping methodology refers to five steps – sort, straighten, shine, standardize and sustain. Safety is the honorary sixth “S.” The 5S methodology is a simple workplace organizational tool that creates a high performance worksite. It’s a universal approach that works in different business models, all over the world. Key components of the 5S philosophy are safety and good housekeeping practices. Safety is an integral part of the sort, straighten and shine segment of any 5S project. Standardize and sustain refers to methods used to ensure that safety and good housekeeping is maintained. Check sheets can be used to build good habits in these areas and to ensure good housekeeping is maintained in all areas. 5S is a system to reduce waste and increase productivity through maintaining an orderly workplace and using visual cues to achieve more consistent operational results. “A place for everything, and everything in its place” Implementing the 5S method means cleaning up and organizing the workplace in its existing configuration. It typically is the first lean method that organizations implement. This lean method encourages workers to improve their working conditions (including safety and ergonomics) and helps them to learn to reduce waste, eliminate unplanned downtime and conduct in-process inventory. Storage solutions play an important part in implementing waste elimination, one of the key pillars of 5S. Safety and good housekeeping principles particularly are important when it comes to storage. An effective storage solution gives the ability to store many items close to the operation, and a visual labeling system makes it easy, quick and safe to store, find and retrieve items. The ability to pull a drawer or shelf all the way out to retrieve items keeps employees from placing themselves in an unsafe position and environment, while storage solutions free up floor space, eliminating tripping hazards and clutter and improve visual management. Systems should be set up so everything has a place and readily is available when needed. Everything should be labeled and identified. Local storage minimizes travel time, and adjustable storage and workbenches make it easier to adapt to the differing needs of individual employees. A clean, well-organized and safe work environment is, of course, an efficient and productive work environment. A less obvious, but still important, aspect of lean is that it gets the employees involved throughout the process, engaging and challenging best practices, encouraging the employees to have a real sense of involvement and to work hard to maintain all the effort the team has invested.