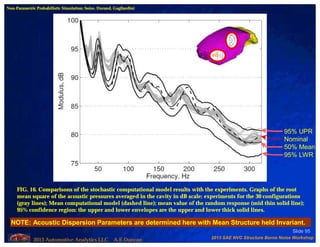

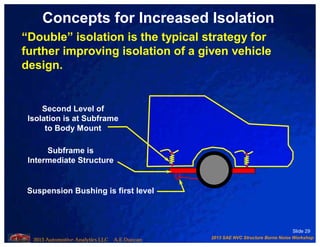

This document summarizes a 2013 workshop on structure-borne noise presented by Alan Duncan of Automotive Analytics LLC. The workshop objectives were to review concepts of structure-borne automotive noise, propose generic noise targets, and present a new technology example. The workshop included introductions, discussions of low and mid-frequency noise basics, a live noise attenuation demo, a discussion of new technologies, and closing remarks. Various noise reduction strategies were discussed, including improved isolation, mode management, nodal point mounting, and dynamic absorbers.

![2013 SAE NVC Structure Borne Noise Workshop

2013 Automotive Analytics LLC A.E.Duncan

Slide 48

Powertrain Example of Dynamic Absorber

Anti-Node Identified

at end of Powerplant

k c

Absorber attached at anti-node acting in

the Vertical and Lateral plane.

Tuning Frequency = √√√√ k/m

m

[Figure Courtesy of DaimlerChrysler Corporation]](https://image.slidesharecdn.com/2013nvhstrborneworkshopweb-130610224838-phpapp01/85/2013-nvh-str_borne_workshop_web-48-320.jpg)

![2013 SAE NVC Structure Borne Noise Workshop

2013 Automotive Analytics LLC A.E.Duncan

Slide 49

Baseline Sound Level

63 Hz Dynamic Absorber

63 + 110 Hz Absorbers

Baseline Sound Level

63 Hz Dynamic Absorber

63 + 110 Hz Absorbers

[Figure Courtesy of DaimlerChrysler Corporation]

10

dB](https://image.slidesharecdn.com/2013nvhstrborneworkshopweb-130610224838-phpapp01/85/2013-nvh-str_borne_workshop_web-49-320.jpg)

![2013 SAE NVC Structure Borne Noise Workshop

2013 Automotive Analytics LLC A.E.Duncan

Slide 64

Identifying Key NVH Paths

Key NVH paths are identified by Transfer Path Analysis (TPA)

Fi

Tactile

Transfer

Tactile

Transfer

Acoustic

Transfer

Acoustic

Transfer

Operating loads Operating loads

Break the system at the

points where the forces

enter the body (Receiver)

Total Acoustic Response is summation of partial responses

over all noise paths

Pt = ΣΣΣΣ paths [Pi ] = ΣΣΣΣ paths [ (P/F) i * Fi ]](https://image.slidesharecdn.com/2013nvhstrborneworkshopweb-130610224838-phpapp01/85/2013-nvh-str_borne_workshop_web-64-320.jpg)

![2013 SAE NVC Structure Borne Noise Workshop

2013 Automotive Analytics LLC A.E.Duncan

Slide 66

Identifying Key NVH Paths

TPA Example: Sum of Key Transfer Paths at One Peak

P/T Load

Crank torque

P/T Load

Crank torque

Total Response: Pt = ΣΣΣΣ paths [Pi ] = ΣΣΣΣ paths [ (P/F) i * Fi ]](https://image.slidesharecdn.com/2013nvhstrborneworkshopweb-130610224838-phpapp01/85/2013-nvh-str_borne_workshop_web-66-320.jpg)

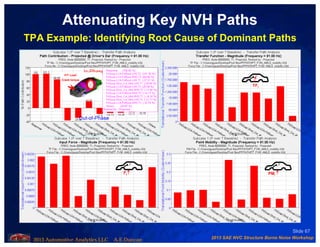

![2013 SAE NVC Structure Borne Noise Workshop

2013 Automotive Analytics LLC A.E.Duncan

Slide 70

Designing Noise Paths

Fi

Acoustic Transfer (P/F)i

Acoustic Transfer (P/F)i

Operating loads create

Forces (Fi) into body at

All noise paths

F F

F F

F

F F

Pt = ΣΣΣΣ paths [Pi ] = ΣΣΣΣ paths [ Fi * (P/F) i ]

= ΣΣΣΣ paths [ Fi * (P/V) i * (V/F)i]

P/V

P/F

(Kbody)

V/F

Measurement Parameters Generic Targets

P/F Acoustic Sensitivity 50 - 60 dBL/N

V/F Structural Point Mobility

(Receiver Side)

0.2 to 0.3

mm/sec/N](https://image.slidesharecdn.com/2013nvhstrborneworkshopweb-130610224838-phpapp01/85/2013-nvh-str_borne_workshop_web-70-320.jpg)

![2013 SAE NVC Structure Borne Noise Workshop

2013 Automotive Analytics LLC A.E.Duncan

Slide 71

Recall for Acoustic Response Pt

Pt = ΣΣΣΣ paths [Pi ] = ΣΣΣΣ paths [ Fi * (P/V) i * (V/F)i]

“Downstream” Effects: Body Panels

(P/V)i !!!! “Downstream” (Body Panel) System Dynamics: Three Main Effects:

Increased Damping

Increased Stiffness

1. Panel Damping

2. Panel Stiffness

3. Panel Acoustic Contribution](https://image.slidesharecdn.com/2013nvhstrborneworkshopweb-130610224838-phpapp01/85/2013-nvh-str_borne_workshop_web-71-320.jpg)

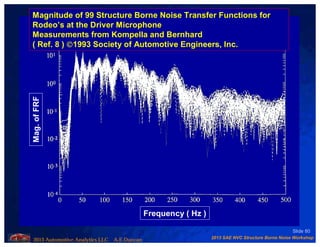

![2013 SAE NVC Structure Borne Noise Workshop

2013 Automotive Analytics LLC A.E.Duncan

Slide 81

SoundPressure[dB(lin)]

Frequency ( Hz )

Acoustic Scatter from Simulation of the

vibroacoustic behavior of a vehicle due

to possible tolerances in the component

area and in the production process.

© 2000 Society of Automotive Engineers, Inc.

Reproduced with permission from paper

by Freymann, et. Al. (Ref. 9)

12 dB Variation

Experimentally detected Scatter in low

frequency vibroacoustic behavior of

production vehicles.

Freymann, BMW NVH Scatter Results](https://image.slidesharecdn.com/2013nvhstrborneworkshopweb-130610224838-phpapp01/85/2013-nvh-str_borne_workshop_web-81-320.jpg)