2011 SAE Structure Borne NVH Workshop Web

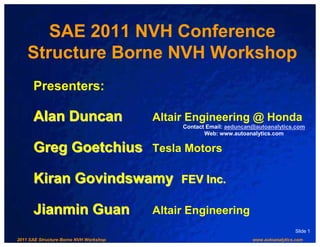

- 1. SAE 2011 NVH Conference Structure Borne NVH Workshop Presenters: Alan Duncan Altair Engineering @ Honda Contact Email: aeduncan@autoanalytics.com Web: www.autoanalytics.com Greg Goetchius Tesla Motors Kiran Govindswamy FEV Inc. Jianmin Guan Altair Engineering Slide 1 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 2. Structure Borne NVH Workshop Workshop Objectives - 1. Review Basic Concepts of Automotive Structure Borne Noise. 2. Propose Generic Targets. 3. Present Real World Application Example. Intended Audience – • New NVH Engineers. • “Acoustics” Engineers seeking new perspective. • “Seasoned Veterans” seeking to brush up skills. Slide 2 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 3. Structure Borne NVH Workshop • Introduction • Low Frequency Basics • Mid Frequency Basics • Live Noise Attenuation Demo • Case Studies • Interior Noise Diagnosis using VINS • NVH Principles: Applications • Closing Remarks Slide 3 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 4. Structure Borne NVH Workshop • Introduction Greg Goetchius • Low Frequency Basics • Mid Frequency Basics • Live Noise Attenuation Demo • Case Studies • Interior Noise Diagnosis using VINS • NVH Principles: Applications • Closing Remarks Slide 4 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 5. Structure Borne NVH Workshop • Introduction • Low Frequency Basics • Mid Frequency Basics • Live Noise Attenuation Demo • Case Studies • Interior Noise Diagnosis using VINS • NVH Principles: Applications • Closing Remarks Slide 5 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 6. Competing Vehicle Design Disciplines Ride Impact and CrashWorthiness Handling NVH Durability Slide 6 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 7. Structure Borne Noise and Vibration Vibrating Source Frequency Range: up to 1000 Hz System Characterization • Source of Excitation • Transmission through Structural Paths • “Felt” as Vibration • “Heard” as Noise Slide 7 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 8. Automotive NVH Frequency Range Structure Borne Noise Airborne Noise Response Absorption + Mass + Local Stiffness Sealing + + Global Stiffness Damping Damping “Low” “Mid” “High” ~ 150 Hz ~ 1000 Hz ~ 10,000 Hz Log Frequency Slide 8 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 9. Structure Borne NVH Workshop • Introduction • Low Frequency Basics • Mid Frequency Basics • Live Noise Attenuation Demo • Case Studies • Vehicle Interior Noise Simulation • NVH Principles: Applications • Closing Remarks Slide 9 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 10. Low Frequency Basics • Source-Path-Receiver Concept • Single DOF System Vibration • NVH Source Considerations • Receiver Considerations • Vibration Attenuation Strategies Provide Improved Isolation Mode Management Nodal Point Mounting Dynamic Absorbers Slide 10 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 11. Low Frequency Basics • Source-Path-Receiver Concept • Single DOF System Vibration • NVH Source Considerations • Receiver Considerations • Vibration Attenuation Strategies Provide Improved Isolation Mode Management Nodal Point Mounting Dynamic Absorbers Slide 11 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 12. Structure Borne NVH Basics RECEIVER PATH SOURCE Slide 12 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 13. Low Frequency Basics • Source-Path-Receiver Concept • Single DOF System Vibration • NVH Source Considerations • Receiver Considerations • Vibration Attenuation Strategies Provide Improved Isolation Mode Management Nodal Point Mounting Dynamic Absorbers Slide 13 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 14. Single Degree of Freedom Vibration APPLIED FORCE F = FO sin 2 π f t 1 + (2ζ f fn ) 2 TR = FT / F = (1 − f fn ) + (2ζ f fn ) 2 2 2 2 m Transmitted Force k c FT ζ = fraction of critical damping fn = natural frequency k m f = operating frequency Slide 14 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 15. Vibration Isolation Principle 4 0.1 APPLIED FORCE Transmissibility Ratio 0.15 F = FO sin 2 π f t 3 m TR = FT / F 0.25 2 k c FT Transmitted 0.375 Force 0.5 1.0 1 Isolation Region Isolation Region 0 0 1 1.414 2 3 4 5 Frequency Ratio (f / fn) Slide 15 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 16. Low Frequency Basics • Source-Path-Receiver Concept • Single DOF System Vibration • NVH Source Considerations • Receiver Considerations • Vibration Attenuation Strategies Provide Improved Isolation Mode Management Nodal Point Mounting Dynamic Absorbers Slide 16 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 17. NVH Source Considerations Suspension Powertrain Two Main Sources Slide 17 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 18. Typical NVH Pathways to the Passenger PATHS FOR STRUCTURE BORNE NVH Slide 18 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 19. Structure Borne NVH Sources Slide 19 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 20. Structure Borne NVH Sources Primary Consideration: Reduce the Source first as much as possible because whatever enters the structure is transmitted through multiple paths to the receiver. Transmission through multiple paths is more subject to variability. Slide 20 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 21. Low Frequency Basics • Source-Path-Receiver Concept • Single DOF System Vibration • NVH Source Considerations • Receiver Considerations • Vibration Attenuation Strategies Provide Improved Isolation Mode Management Nodal Point Mounting Dynamic Absorbers Slide 21 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 22. Receiver Considerations Subjective to Objective Conversions Subjective NVH Ratings are typically based on a 10 Point Scale resulting from Ride Testing Receiver Sensitivity is a Key Consideration A 2 ≈ 1/2 A 1 Represents 1.0 Rating Change TACTILE: 50% reduction in motion SOUND : 6.dB reduction in sound pressure level ( long standing rule of thumb ) Slide 22 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 23. Low Frequency Basics • Source-Path-Receiver Concept • Single DOF System Vibration • NVH Source Considerations • Receiver Considerations • Vibration Attenuation Strategies Provide Improved Isolation Mode Management Nodal Point Mounting Dynamic Absorbers Slide 23 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 24. Symbolic Model of Unibody Passenger Car 8 Degrees of Freedom 2 4 8 1 3 5 6 7 Total 2178.2 Kg (4800LBS) Tires 350.3 N/mm Mass Sprung 1996.7 Kg KF 43.8 N/mm Unsprung 181.5 Kg (8.33% of Total) KR 63.1 N /mm Powertrain 181.5 Kg Beam mass lumped on grids like a beam M2,3,4 =2 * M1,5 Slide 24 From Reference 6 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 25. 8 Degree of Freedom Vehicle NVH Model Engine Mass 8 Engine Flexible Beam for Body Isolator 1 2 3 4 5 Suspension Springs 6 7 Wheels Tires Slide 25 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 26. 8 Degree of Freedom Vehicle NVH Model Force Applied to Powertrain Assembly Feng 8 1 2 3 4 5 6 7 Forces at Powertrain could represent a First Order Rotating Imbalance Slide 26 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 27. Engine Isolation Example Response at M id Car 1.0000 Constant Force Load; F~A 15.9 Hz 8.5 Hz Velocity (mm/sec) 0.1000 7.0 Hz 0.0100 0.0010 2 4 8 1 3 5 6 7 700 Min. RPM First Order Unbalance 0.0001 Operation Range of Interest 5.0 10.0 15.0 20.0 Frequency Hz Slide 27 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 28. Concepts for Increased Isolation “Double” isolation is the typical strategy for further improving isolation of a given vehicle design. Second Level of Isolation is at Subframe to Body Mount Subframe is Intermediate Structure Suspension Bushing is first level Slide 28 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 29. 8 Degree of Freedom Vehicle NVH Model Removed Double Isolation Effect 8 1 2 3 4 5 Wheel 6 Mass 7 Removed Slide 29 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 30. Double Isolation Example Vertical Response at DOF3 6.0E+00 Base Model 5.0E+00 (mm/sec) Without Double_ISO 4.0E+00 2 4 8 1 3 5 6 7 3.0E+00 Velocity 1.414*fn 2.0E+00 1.0E+00 0.0E+00 5.0 10.0 15.0 20.0 Frequency Hz Slide 30 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 31. Low Frequency Basics • Source-Path-Receiver Concept • Single DOF System Vibration • NVH Source Considerations • Receiver Considerations • Vibration Attenuation Strategies Provide Improved Isolation Mode Management Nodal Point Mounting Dynamic Absorbers Slide 31 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 32. Mode Management Chart EXCITATION SOURCES Inherent Excitations (General Road Spectrum, Reciprocating Unbalance, Gas Torque, etc.) Process Variation Excitations (Engine, Driveline, Accessory, Wheel/Tire Unbalances) 0 5 10 15 20 25 30 35 40 45 50 First Order Wheel/Tire Unbalance Hz V8 Idle Hot - Cold CHASSIS/POWERTRAIN MODES Suspension Hop and Tramp Modes Ride Modes Suspension Longitudinal Modes Powertrain Modes Exhaust Modes 0 5 10 15 20 25 30 35 40 45 50 Hz BODY/ACOUSTIC MODES Body First Torsion Steering Column First Vertical Bending Body First Bending First Acoustic Mode 0 5 10 15 20 25 30 35 40 45 50 Hz (See Ref. 1) Slide 32 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 33. 8 Degree of Freedom Vehicle NVH Model Bending Mode Frequency Separation 8 1 2 3 4 5 Beam Stiffness was adjusted to align Bending Frequency with Suspension 6 7 Modes and then progressively separated back to Baseline. Slide 33 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 34. 8 DOF Mode Separation Example Response at Mid Car 18.2 Hz Bending 13.Hz Bending 100.00 10.6 Bending 2 4 8 1 3 5 Velocity (mm/sec) 6 7 10.6 Hz 10.00 13.0 Hz 18.2 Hz 1.00 0.10 5 10 15 20 Frequency Hz Slide 34 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 35. Low Frequency Basics • Source-Path-Receiver Concept • Single DOF System Vibration • NVH Source Considerations • Receiver Considerations • Vibration Attenuation Strategies Provide Improved Isolation Mode Management Nodal Point Mounting Dynamic Absorbers Slide 35 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 36. Mount at Nodal Point First Bending: Nodal Point Mounting Example Front input forces Rear input forces Locate wheel centers at node points of the first bending modeshape to prevent excitation coming from suspension input motion. Slide 36 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 37. Mount at Nodal Point First Torsion: Nodal Point Mounting Examples Side View Rear View Passenger sits at Engine node point for First Torsion. Transmission Mount of a 3 Mount N-S P/T is near the Torsion Node. Slide 37 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 38. Powertrain Bending Mode Nodal Mounting 1 2 3 4 5 6 7 Mount system is placed to support Powertrain at the Nodal Locations of the First order Bending Mode. Best compromise with Plan View nodes should also be considered. Slide 38 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 39. 8 Degree of Freedom Vehicle NVH Model Bending Node Alignment with Wheel Centers Redistribute Beam Masses 8 to move Node Points to Align with points 2 and 4 1 2 3 4 5 6 7 Slide 39 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 40. First Bending Nodal Point Alignment Response at Mid-Car 4.0E+00 Node Shifted 4 Base Model 8 2 (m m /sec) 1 3 5 6 7 3.0E+00 2.0E+00 Velocity 1.0E+00 0.0E+00 5.0 10.0 15.0 20.0 Frequency Hz Slide 40 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 41. Low Frequency Basics • Source-Path-Receiver Concept • Single DOF System Vibration • NVH Source Considerations • Receiver Considerations • Vibration Attenuation Strategies Provide Improved Isolation Mode Management Nodal Point Mounting Dynamic Absorbers Slide 41 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 42. Dynamic Absorber Concept Auxiliary Spring-Mass-Damper m = M / 10 x x SDOF 2DOF M M YO YO Slide 42 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 43. Powertrain Example of Dynamic Absorber Anti-Node Identified at end of Powerplant k c m Absorber attached at anti-node acting in the Vertical and Lateral plane. Tuning Frequency = √ k/m Slide 43 [Figure Courtesy of DaimlerChrysler Corporation] 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 44. Baseline Sound Level Baseline Sound Level 63 Hz Dynamic Absorber 63 Hz Dynamic Absorber 63 + 110 Hz Absorbers 63 + 110 Hz Absorbers 10 dB Slide 44 [Figure Courtesy of DaimlerChrysler Corporation] 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 45. Low Frequency Basics - Review • Source-Path-Receiver Concept • Single DOF System Vibration • NVH Source Considerations • Receiver Considerations • Vibration Attenuation Strategies Provide Improved Isolation Mode Management Nodal Point Mounting Dynamic Absorbers Slide 45 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 46. Structure Borne NVH Workshop • Introduction • Low Frequency Basics • Mid Frequency Basics Alan Duncan • Live Noise Attenuation Demo • Case Studies • Interior Noise Diagnosis using VINS • NVH Principles: Applications • Closing Remarks Slide 46 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 47. Mid Frequency NVH Fundamentals This looks familiar! Frequency Range of Interest has changed to 150 Hz to 1000 Hz Slide 47 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 48. Typical NVH Pathways to the Passenger PATHS FOR STRUCTURE Noise Paths are the BORNE Noise Paths are the same as Low same as Low NVH Frequency Region Frequency Region Slide 48 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 49. Mid-Frequency Analysis Character Structure Borne Noise Airborne Noise • Mode separation is less practical in • Mode separation is less practical in High modal density mid-frequency mid-frequency and coupling in source, path and • New Strategy is Effective Isolation: • New Strategy is Effective Isolation: receiver Achieved by reducing energy transfer Achieved by reducing energy transfer locally between source and receiver at locally between source and receiver at key paths. key paths. Response Absorption + Local Stiffness Mass + + Global Stiffness Damping Sealing “Low” “Mid” “High” ~ 150 Hz ~ 1000 Hz Log Frequency ~ 10,000 Hz Slide 49 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 50. Mid-Frequency Analysis Character Control Measures for Mid Frequency Concerns Effective Isolation Attenuation along Key Noise Paths Slide 50 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 51. Mid-Frequency Analysis Character Control Measures for Mid Frequency Concerns Effective Isolation Attenuation along Key Noise Paths Slide 51 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 52. Isolation Effectiveness Classical SDOF: Rigid Source and Receiver “Real Structure” 1.0 Flexible (Mobile) Source and Transmissibility Ratio Receiver Isolation Region Isolation Region f/fn 1.0 1.414 10.0 Effectiveness deviates from the classical development as resonances occur in the receiver structure and in the foundation of the source. Slide 52 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 53. Mobility • Mobility is the ratio of velocity response at the excitation point on structure to the force applied in the direction of the velocity Velocity Mobility = Force • Mobility, also called Admittance, characterizes Dynamic Stiffness of the structure at load application point Frequency * Displacement Mobility = Force Frequency = Dynamic Stiffness Slide 53 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 54. Isolation • The isolation effectiveness can be quantified by a theoretical model based on analysis of the SOURCE - PATH - RECEIVER transfer across an isolator • Transmissibility Ratio (TR) is used to objectively define measure of isolation Force from source with isolator TR = Force from source without isolator V Receiver Vr V Receiver Vr V Fr Fr Fs = Yi + Y r + Y s F ir V ir Fs Vs Isolator V is Source F is V F s= Fs Yr +Ys Vs Source Slide 54 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 55. Isolation Force from source with an isolator Receiver Vm TR = Force from source without an isolator Fm TR = ( Y r + Y s ) / ( Y i + Y r + Y s ) F im V im Isolator V if Y r : Receiver mobility F if Y i : Isolator mobility Y s : Source mobility Ff Vf Source • For Effective Isolation (Low TR) the Isolator Mobility must exceed the sum of the Source and Receiver Mobilities. Recall that Y ∝1 K Slide 55 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 56. Designing Noise Paths 1 1 1 1 1 TR = ( + ) / ( + + ) K body K source K body K iso K source K source K body K iso K iso 1.0 5.0 20.0 1.0 0.67 0.55 0.51 5.0 0.55 0.29 0.20 20.0 0.51 0.20 0.09 Generic targets: body to bushing stiffness ratio of at least 5.0 source to bushing stiffness ratio of at least 20.0 Slide 56 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 57. Body-to-Bushing Stiffness Ratio Relationship to Transmissibility 0.6 For a source ratio of 20 Transmissibility Ratio TR 0.5 0.4 Target Min. = 5 0.3 gives TR = .20 0.2 0.1 0 1 2 3 4 5 6 7 8 9 10 Stiffness Ratio; K body / K iso Slide 57 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 58. Mid-Frequency Analysis Character Control Measures for Mid Frequency Concerns Effective Isolation Attenuation along Key Noise Paths Slide 58 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 59. Identifying Key NVH Paths Key NVH paths are identified by Transfer Path Analysis (TPA) Acoustic Acoustic Transfer Transfer Fi Break the system at the points where the forces enter the body (Receiver) Operating loads Operating loads Total Acoustic Response is summation of partial responses over all noise paths Pt = Σ paths [Pi ] = Σ paths [ (P/F) i * Fi ] Slide 59 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 60. Designing Noise Paths P/V Acoustic Transfer (P/F)i Acoustic Transfer (P/F)i P/F V/F F F (Kbody) F F F F Fi F Operating loads create Forces (Fi) into body at All noise paths Pt = Σ paths [Pi ] = Σ paths [ Fi * (P/F) i ] = Σ paths [ Fi * (P/V) i * (V/F) i ] Measurement Parameters Generic Targets P/F Acoustic Sensitivity 50 - 60 dBL/N V/F Structural Point Mobility 0.2 to 0.3 (Receiver Side) mm/sec/N Slide 60 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 61. “Downstream” Effects: Body Panels Recall for Acoustic Response Pt Pt = Σ paths [Pi ] = Σ paths [ Fi * (P/V) i * (V/F) i ] (P/V)i ! “Downstream” Dynamics (Body Panel) : Three Typical Effects: 1. Panel Stiffness Increased Stiffness 3. Panel Acoustic Contribution 2. Panel Damping Increased Damping Slide 61 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 62. Generic Noise Path Targets K body K source > 5.0 > 20.0 K iso K iso Structural Mobility < 0.2 to 0.3 mm/sec/N Acoustic 50 - 60 < Sensitivity dBL/N Primary: Minimize the Source Force < 1.0 N Panel Damping Loss Factor > .10 Slide 62 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 63. Final Remarks on Mid Frequency Analysis • Effective isolation at dominant noise paths is critical • Reduced mobilities at body & source and softened bushing are key for effective isolation • Mode Separation remains a valid strategy as modes in the source structure start to participate • Other means of dealing with high levels of response (Tuned dampers, damping treatments, isolator placement at nodal locations) are also effective Slide 63 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 64. Structure Borne NVH Workshop • Introduction • Low Frequency Basics • Mid Frequency Basics • Live Noise Attenuation Demo • Case Studies Greg Goetchius • Interior Noise Diagnosis using VINS • NVH Principles: Applications • Closing Remarks Slide 64 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 65. Tool Box Demo Test Results Toolbox Demo Noise Test Results 90 85 80 70 68 SPL (dBA) 63 61 60 55 50 47 40 39 30 1) Baseline: 2) Imbalance + 3) No Imbalance, 4) No Imbalance, 5) No Imbalance + 6) #5 + Absorption 7) #6 + Insulator Imbalance, No Isolation No Isolation No Isolation + Isolation + Mat Isolation Damping Damping Slide 65 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 66. Structure Borne NVH Workshop • Introduction • Low Frequency Basics • Mid Frequency Basics • Live Noise Attenuation Demo • Case Studies Kiran Govindswamy • Interior Noise Diagnosis using VINS • NVH Principles: Applications • Closing Remarks Slide 66 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 67. “Time Domain” Transfer Path Analysis VINS (Vehicle Interior Noise Simulation) Excitation Transfer Behaviour Interior Noise Airborne Loudspeaker Noise Share Airborne Path Microphones FEV FEV Overall Power Train Noise Interior Noise Intake&Exhaust Noise ... Engine Mount Vehicle Structure-Borne Path Pi Power Train Vibration Drive Line Vibration Structureborne Overall Vehicle Transfer Function ... Noise Share Slide 67 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 68. “Time Domain” Transfer Path Analysis VINS (Vehicle Interior Noise Simulation) Overall Structure-Borne Sound Transmission Resultant Dynamic Mount Stiffness ae ab Fb Mount Apparent Mass Vehicle Body Engine Excitation Transmissibility of Body Test Bench Impact Test abody Fbody Pinterior aengine = Pinterior aengine abody Fbody Resultant Dynamic Mount Stiffness Slide 68 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 69. “Time Domain” Transfer Path Analysis VINS: Correlation (Full Load Speed Sweep) Slide 69 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 70. “Time Domain” Transfer Path Analysis VINS: Application to “Idle Modulation Noise” Slide 70 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 71. “Time Domain” Transfer Path Analysis VINS: Application to “Idle Modulation Noise” Slide 71 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 72. “Time Domain” Transfer Path Analysis VINS: Application to “Transient Diesel Clatter” Measurement VINS VINS-SBN VINS-ABN Slide 72 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 73. “Time Domain” Transfer Path Analysis VINS: Application to “Transient Diesel Clatter” Mic. left Mic. right Mic. top Mic. bottom Mic. front Mic. rear Intake orif. Exhaust tp. Left mnt. Right mnt. RR A RR B Trans. link Slide 73 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 74. HEV, PHEV, ReEV, and EV NVH Coasting G D C Constant D C D C G speeds A D Acceleration B F A D D Drive-away C B F Start & A C F A F D idle B E B G Red light E A (Stop) ICE ICE Start/Stop Regeneration Power AER stopped idling ICE Batt. Charging Assist • A: Global powertrain vibration B: Driveline vibration • C: Noise of HEV specific components D: Magnetic noise E-Motor/(Generator) • E: Noise of accessories F: Gearbox rattle noise due to • G: Noise pattern changeover ICE (non-uniformity) and E-Motor Slide 74 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 75. Structure Borne NVH Workshop • Introduction • Low Frequency Basics • Mid Frequency Basics • Live Noise Attenuation Demo • Case Studies • Interior Noise Diagnosis using VINS • NVH Principles: Applications Jianmin Guan • Closing Remarks Slide 75 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 76. NVH Principles: Application Example Introduction Slide 76 Copyright © 2009 SAE International 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 77. Quietness during Idle and Electric-Vehicle Operation Root Cause Diagnostics: 1. Water pump in the inverter cooling system 2. Electromagnetic noise of the motor, the inverter, and other units Reduce Inverter Water Pump Loads: 1. Reduce pump impeller imbalance 2. Redesign bearing structure 3. Changing motor structure Improve Isolation from Body: 1. Install rubber isolator 2. Increase mounting bracket rigidity 3. Improve Inverter case Slide 77 Copyright © 2009 SAE International 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 78. Quietness during Idle and Electric-Vehicle Operation Root Cause Diagnostics: 1. Water pump in the inverter cooling system 2. Electromagnetic noise of the motor, the inverter, and other units Reduce Inverter Water Pump Loads: 1. Reduce pump impeller imbalance 2. Redesign bearing structure Reduce 3. Changing motor structure Source Effective Isolation Improve Isolation from Body: 1. Install rubber isolator Attach. Stiffness 2. Increase mounting bracket rigidity 3. Improve Inverter case Downstream Slide 78 Copyright © 2009 SAE International 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 79. Engine Start Vibration Root Cause Diagnostics: 1. Engine torque fluctuations 2. Engine torque reaction forces Reduce Torque Fluctuation: 1. Change intake valve closing timing 2. Control piston stop position 3. Adjust injected fuel volume and ignition timing Reduce Effect of Engine Loads: 1. Operating MG1 at high torque during engine start 2. Implement vibration-reducing motor control 3. Use two stage hysteretic torsional damper 4. Shorten distance between principal elastic axis and center of gravity of power plant Slide 79 Copyright © 2009 SAE International 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 80. Engine Start Vibration Root Cause Diagnostics: 1. Engine torque fluctuations 2. Engine torque reaction forces Reduce Torque Fluctuation: 1. Change intake valve closing timing 2. Control piston stop position 3. Adjust injected fuel volume and ignition timing Reduce Source Mode Manage. Reduce Effect of Engine Loads: 1. Operating MG1 at high torque during engine start Damper 2. Implement vibration-reducing motor control 3. Use two stage hysteretic torsional damper 4. Shorten distance between principal elastic axis and center of gravity of power plant Effective Isolation Slide 80 Copyright © 2009 SAE International 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 81. 2nd Order Engine Induced Boom Root Cause Diagnostics: 1. 2nd order couple of the reciprocating inertia of piston 2. THS II Trans 50 mm longer and 35 kg heavier 3. Lower power plant bending mode 4. Requires 1.5X higher mount rates Reduce Effect of 2nd order Couple: 1. Increase power plant bending mode 2. Move mount to a nodal point 3. Embed mounts inside cross member 4. Reduces distance from principle elastic axis to CG 5. Optimized vertical to lateral rate ratio Slide 81 Copyright © 2009 SAE International 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 82. 2nd Order Engine Induced Boom Root Cause Diagnostics: 1. 2nd order couple of the reciprocating inertia of piston 2. THS II Trans 50 mm longer and 35 kg heavier 3. Lower power plant bending mode 4. Requires 1.5X higher mount rates Mode Manage. Reduce Effect of 2nd order Couple: 1. Increase power plant bending mode Nodal 2. Move mount to a nodal point Mounting 3. Embed mounts inside cross member Effective 4. Reduces distance from principle Isolation elastic axis to CG 5. Optimized vertical to lateral rate ratio Slide 82 Copyright © 2009 SAE International 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 83. Engine Radiated Noise Root Cause Diagnostics: 1. 24th MG2 order excitation 2. Lower MG2 reduction gear ratio 3. Lower transmission bending mode - two key modes identified Reduce 24th order Loads: Arranged permanent magnets in V shape with optimized angle Reduce Effect of 24th order Loads: 1. Modified Trans case to improve modes 2. Added dynamic damper at a high amp. point on Trans case 3. Added ribs in high radiating area of Trans case Slide 83 Copyright © 2009 SAE International 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 84. Engine Radiated Noise Root Cause Diagnostics: 1. 24th MG2 order excitation 2. Lower MG2 reduction gear ratio 3. Lower transmission bending mode - two key modes identified Reduce Reduce 24th order Loads: Source Arranged permanent magnets in V shape with optimized angle Mode Reduce Effect of 24th order Loads: Manage. 1. Modified Trans case to improve modes Damper 2. Added dynamic damper at a high amp. point on Trans case 3. Added ribs in high radiating area of Trans case Downstream Slide 84 Copyright © 2009 SAE International 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 85. Structure Borne NVH Workshop • Introduction • Low Frequency Basics • Mid Frequency Basics • Live Noise Attenuation Demo • Case Studies • Interior Noise Diagnosis using VINS • NVH Principles: Applications • Closing Remarks Jianmin Guan Slide 85 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 86. Structure Borne NVH: Concepts Summary • Source-Path-Receiver as a system 1. 1. Reduce Source Reduce Source 2. 2. Rank and Manage Paths Rank and Manage Paths 3. 3. Consider Subjective Response Consider Subjective Response • Effective Isolation • Mode Management • Nodal Point Placement • Attachment Stiffness • “Downstream” (Body Panel) Considerations Slide 86 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 87. SAE 2011 NVH Conference Structure Borne NVH Workshop Thank You for Your Time! Q&A Slide 87 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 88. Structure Borne NVH References Primary References (Workshop Basis: 4 Papers) 1. A. E. Duncan, et. al., “Understanding NVH Basics”, IBEC, 1996 2. A. E. Duncan, et. al., “MSC/NVH_Manager Helps Chrysler Make Quieter Vibration-free Vehicles”, Chrysler PR Article, March 1998. 3. B. Dong, et. al., “Process to Achieve NVH Goals: Subsystem Targets via ‘Digital Prototype’ Simulations”, SAE 1999-01-1692, NVH Conference Proceedings, May 1999. 4. S. D. Gogate, et. al., “’Digital Prototype’ Simulations to Achieve Vehicle Level NVH Targets in the Presence of Uncertainties’”, SAE 2001-01-1529, NVH Conference Proceedings, May 2001 Structure Borne NVH Workshop - on Internet At SAE www.sae.org/events/nvc/specialevents.htm Slide 88 WS + Refs. at www.AutoAnalytics.com/papers.html 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com

- 89. Structure Borne NVH References Supplemental Reference Recommendations 5. T.D. Gillespie, Fundamentals of Vehicle Dynamics, SAE 1992 (Also see SAE Video Lectures Series, same topic and author) 6. D. E. Cole, Elementary Vehicle Dynamics, Dept. of Mechanical Engineering, University of Michigan, Ann Arbor, Michigan, Sept. 1972 7. J. Y. Wong, Theory of Ground Vehicles, John Wiley & Sons, New York, 1978 8. N. Takata, et.al. (1986), “An Analysis of Ride Harshness” Int. Journal of Vehicle Design, Special Issue on Vehicle Safety, pp. 291-303. 9. T. Ushijima, et.al. “Objective Harshness Evaluation” SAE Paper No. 951374, (1995). Slide 89 2011 SAE Structure Borne NVH Workshop www.autoanalytics.com