131445983 jembatan-balok-t

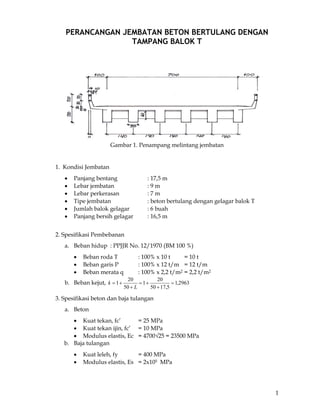

- 1. 1 PERANCANGAN JEMBATAN BETON BERTULANG DENGAN TAMPANG BALOK T Gambar 1. Penampang melintang jembatan 1. Kondisi Jembatan • Panjang bentang : 17,5 m • Lebar jembatan : 9 m • Lebar perkerasan : 7 m • Tipe jembatan : beton bertulang dengan gelagar balok T • Jumlah balok gelagar : 6 buah • Panjang bersih gelagar : 16,5 m 2. Spesifikasi Pembebanan a. Beban hidup : PPJJR No. 12/1970 (BM 100 %) • Beban roda T : 100% x 10 t = 10 t • Beban garis P : 100% x 12 t/m = 12 t/m • Beban merata q : 100% x 2,2 t/m2 = 2,2 t/m2 b. Beban kejut, 2963,1 5,1750 20 1 50 20 1 = + += + += L k 3. Spesifikasi beton dan baja tulangan a. Beton • Kuat tekan, fc’ = 25 MPa • Kuat tekan ijin, fc’ = 10 MPa • Modulus elastis, Ec = 4700√25 = 23500 MPa b. Baja tulangan • Kuat leleh, fy = 400 MPa • Modulus elastis, Es = 2x105 MPa

- 2. 2 PERANCANGAN 1. Tiang sandaran momen lentur, Mu = 1,2×2×100×1,0 = 240 kg-m = 2400 N-m gaya geser, V = 1,2 × 2 × 100 = 240 kg = 2400 N Mn = φ bd2k Mu = Mn 1095,1 1301608,0 102400 2 3 2 = ×× × = ×× = db M k u φ Mpa 3 ' ' 108502,2 2585,0 1095,12 11 400 25 85,0 85,0 2 1185,0 − ×=⎟ ⎟ ⎠ ⎞ ⎜ ⎜ ⎝ ⎛ × × −−= ⎟ ⎟ ⎠ ⎞ ⎜ ⎜ ⎝ ⎛ −−= cy c perlu f k f f ρ 3 min 105,3 400 4,14,1 − ×=== yf ρ As = ρ x b x d = 3,5×10-3 ×160×130 = 72,8 mm2 Dipakai tulangan 2∅10 (As = 157,0796 mm2) Kontrol kapasitas momen balok Dianggap baja tulangan telah luluh pada saat beton mulai retak (εc = 0,003) 5,18 1602585,0 4000796,157 85,0 ' = ×× × = ×× × = bf fA a c ys mm 7647,21 85,0 5,18 1 === β a c mm 7847,2983 7647,21 7647,21130 600600 =⎟ ⎠ ⎞ ⎜ ⎝ ⎛ − =⎟ ⎠ ⎞ ⎜ ⎝ ⎛ − = c cd fs MPa > fy O K 68,7586944 2 5,18 1304000796,157 2 =⎟ ⎠ ⎞ ⎜ ⎝ ⎛ −×=⎟ ⎠ ⎞ ⎜ ⎝ ⎛ −×= a dfAM ysn N-mm =7586,9447 N-m > Mu (2400 N-m) O K Perencanaan tulangan geser Vu = 2400 N 3333,1733313016020 6 1 6 1 ' =××=××= dbfV cc N 9999,51993333,173336,0 2 1 2 1 =××=cVφ N > Vu (secara teoritis tidak perlu sengkang) b=160 mm h=160 mm d=130 mm

- 3. 3 walaupun secara teoritis tidak perlu sengkang, tetapi untuk kestabilan struktur dan peraturan mensyaratkan dipasang tulangan minimum smaksimum = ½ d = ½ x 130 = 65 mm luas tulangan geser minimum 3333,43 400 6516025 3 1 3 1 ' min = ×× = ×× = y c v f sbf A mm2 dipakai tulangan ∅8 (As = 100,5310 mm2), maka jarak sengkang 7965,150 16025 3 1 4005310,100 3 1 ' = × × = × × = bf fA s c yv mm untuk penulangan geser dipakai sengkang ∅8-100 2. Perhitungan plat kantilever Gambar 2. Pembebanan pada plat kantilever a. momen lentur (bending moment) Perhitungan momen lentur No. Volume (m3) γ (kg/m3) W (kg) Lengan (m) Momen (kg-m) 1 0,10 × 0,16 × 0,50 = 0,008 2400 19,2 1,8 34,5600 2 0,10×(0,70×0,110)/2 = 0,00385 2400 9,24 1,04 9,6096 3 0,10×0,05×0,50 = 0,0025 2400 6 1,025 6,1500 4 0,10 × (0,15 × 0,50)/2 = 0,00375 2400 9 0,95 8,5500 5 1,00 × 1,00 × 0,20 = 0,2 2400 480 0,5 240,0000 6 1,00 × (1,00 × 0,10)/2 = 0,05 2400 120 0,33 39,6000 7 1,00 × 0,90 × 0,07 = 0,063 2200 138,6 0,375 51,9750 P 2,0 × 100 kg/m 200 1,2 240,0000

- 4. 4 T 1,2963 × 10000 12963 0,5 6481,5000 Air hujan = 2 × 0,90 × 0,05 = 0,0625 1000 62,5 0,375 23,4375 Railing = 2 × 2m× 6 kg/m = 24 24 1,08 25,9200 Total momen, M 7161,3021 Total momen, M (N-m) 71613,0210 b. Gaya geser (shear force) Berat tiang sandaran = 1 + 2 + 3 +4 + railing = 67,4400 Kg Slab kantilever dan perkerasan = 5 + 6 +7 = 738,6000 Kg Beban roda = 12963,0000 Kg Beban genangan air hujan = 62,5000 Kg Toal gaya lintang = 13831,5400 Kg = 138315,4000 N c. perhitungan baja tulangan Mu = 1,2×71613,021 =85935,6252 N-m Vu = 1,2×138315,400 = 165978,48 N h = 300 mm d = 300-40 = 260 mm 5890,1 26010008,0 1085935,6252 2 3 2 = ×× × = ×× = db M k u φ MPa 027094,0 200000 400 003,0 003,0 400 85,025 85,0 003,0 003,0 85,0 1 ' = + × × = + × × = s yy c b E ff f β ρ ρmaks = 0,75 ρb = 0,75 x 0,027094 = 0,0203205 3 ' ' 101333,4 2585,0 5890,12 11 400 25 85,0 85,0 2 1185,0 − ×=⎟ ⎟ ⎠ ⎞ ⎜ ⎜ ⎝ ⎛ × × −−= ⎟ ⎟ ⎠ ⎞ ⎜ ⎜ ⎝ ⎛ −−= cy c perlu f k f f ρ 3 min 105,3 400 4,14,1 − ×=== yf ρ As = ρ x b x d = 4,1333x10-3 x 1000 x 260 = 1074,658 mm2 Dipakai tulangan ∅16 (As = 210,0619 mm2), dengan jarak antar tulangan 4686,195 658,1074 10000619,210 = × =perlus mm dipakai tulangan ∅16-125 mm kontrol terhadap geser beton 7296,0 2601000 165978,48 8 7 8 7 = ×× = ×× = hb V cτ MPa < 0,45 fc = 11,25 MPa O K

- 5. 5 3. Perhitungan plat bagian dalam (inner slab) a. Momen lentur akibat beban hidup Gambar 3. posisi roda Penyebaran beban hidup (roda) pada slab P 20cm21 21 6cm 15cm 15cm 50cm21 21 P Gambar 4. Penyebaran beban hidup pada slab lx = 1,4 m ly = ∞ tx = 0,92 m ty =0,62 m

- 6. 6 Beban roda, T = 10000 kg Bidang kontak = 0,92 m × 0,62 m Penyebaran beban roda, 1571,22726 62,092,0 2963,110000 = × × =T kg/m2 Dipakai tabel-Bittner (dari Dr. Ing Ernst Bittner) Dengan lx = 1,4 , ly = ∞ (lantai tidak menumpu pada diafragma) 657,0 4,1 92,0 == x x l t fxm = 0,1233 443,0 4,1 62,0 == x y l t fym = 0,0661 Mxm = 0,1233 × 22726,1571 × 0,92 × 0,62 = 1598,3379 kgm = 15983,379 Nm Mym = 0,0661 × 22726,1571 × 0,92 × 0,62 = 856,8543 kgm = 8568,543 Nm b. momen lentur akibat beban mati Berat slab = 0,30 × 2400 = 720 kg/m2 Berat perkerasan = 0,06 × 2200 = 132 kg/m2 Berat air hujan = 0,05 × 1000 = 50 kg/m2 Total qDL = 902 kg/m2 7920,1764,1902 10 1 10 1 22 =××=××= xDLxm lqM kgm = 1767,920 Nm 9307,587920,176 3 1 3 1 =×=×= xmym MM kgm = 589,307 Nm c. momen total Mx = 15983,379 + 1767,920 = 17661,299 Nm My =8568,543 + 589,307 = 9157,85 Nm d. perhitungan baja tulangan arah melintang lx M = 17661,299 Nm h = 300 mm d = 300-40 = 260 mm 3267,0 26010008,0 1017661,299 2 3 2 = ×× × = ×× = db M k φ MPa 027094,0 200000 400 003,0 003,0 400 85,025 85,0 003,0 003,0 85,0 1 ' = + × × = + × × = s yy c b E ff f β ρ ρmaks = 0,75 ρb = 0,75 x 0,027094 = 0,0203205

- 7. 7 4 ' ' 102313,8 2585,0 3267,02 11 400 25 85,0 85,0 2 1185,0 − ×=⎟ ⎟ ⎠ ⎞ ⎜ ⎜ ⎝ ⎛ × × −−= ⎟ ⎟ ⎠ ⎞ ⎜ ⎜ ⎝ ⎛ −−= cy c perlu f k f f ρ 3 min 105,3 400 4,14,1 − ×=== yf ρ As = ρ x b x d = 3,5 x10-3 x 1000 x 260 = 910 mm2 Dipakai tulangan ∅16 (As = 210,0619 mm2), dengan jarak antar tulangan 8373,230 910 10000619,210 = × =perlus mm dipakai tulangan ∅16-125 mm arah memanjang ly M = 9157,85 Nm h = 300 mm d = 300-40 = 260 mm 1693,0 26010008,0 109157,85 2 3 2 = ×× × = ×× = db M k φ MPa 027094,0 200000 400 003,0 003,0 400 85,025 85,0 003,0 003,0 85,0 1 ' = + × × = + × × = s yy c b E ff f β ρ ρmaks = 0,75 ρb = 0,75 x 0,027094 = 0,0203205 4 ' ' 102495,4 2585,0 1693,02 11 400 25 85,0 85,0 2 1185,0 − ×=⎟ ⎟ ⎠ ⎞ ⎜ ⎜ ⎝ ⎛ × × −−= ⎟ ⎟ ⎠ ⎞ ⎜ ⎜ ⎝ ⎛ −−= cy c perlu f k f f ρ 3 min 105,3 400 4,14,1 − ×=== yf ρ As = ρ x b x d = 3,5 x10-3 x 1000 x 260 = 910 mm2 Dipakai tulangan ∅16 (As = 210,0619 mm2), dengan jarak antar tulangan 8373,230 910 10000619,210 = × =perlus mm dipakai tulangan ∅16-125 mm 4. Perhitungan Gelagar a. beban mati (dead load) Hand rail = {(0,10 × 0,16 × 1,00 × 2400)/2} × 1,1871 = 22,7923 kg/m Railing = 2 × 1,00 × 6 × 1,1871 = 14,2452 kg/m Perkerasan = 0,06 × 2200 × 4,5716 = 603,4512 kg/m Air hujan = 0,05 × 1000 × 4,5716 = 228,5800 kg/m Pelat lantai = 0,30 × 2400 × 4,5716 = 3291,5520 kg/m

- 8. 8 Gelagar = 1,00 × 0,50 × 2400 × 1,00 = 1200,0000 kg/m Total = 5360,6207 kg/m Balok melintang (diafragma), Tb = 0,30 × 0,60 × 2400 × 0,9 = 388,8 kg Gambar 5. Garis pengaruh momen Gambar 6. Potongan memanjang balok pada perhitungan momen lentur b. momen lentur akibat beban mati ⎭ ⎬ ⎫ ⎩ ⎨ ⎧ ⎟ ⎠ ⎞ ⎜ ⎝ ⎛ −×=→ L x L x LqMM DLxqDL 1 2 1 2 Momen pada potongan 1, x = 2,0 m (M1 DL) ⎭ ⎬ ⎫ ⎩ ⎨ ⎧ ⎟ ⎠ ⎞ ⎜ ⎝ ⎛ −××= 5,16 2 1 5,16 2 5,166207,5360 2 1 2 qDLM = 77729,0002 kgm MTb= ½ × 388,8 × 2 = 388,8000 kgm M1 DL = 78117,8002 kgm 781178,0020 Nm

- 9. 9 Momen pada potongan 2, x = 4,0 m (M2 DL) ⎭ ⎬ ⎫ ⎩ ⎨ ⎧ ⎟ ⎠ ⎞ ⎜ ⎝ ⎛ −××= 5,16 4 1 5,16 4 5,166207,5360 2 1 2 qDLM = 134015,5175 kgm MTb= ½ × 388,8 × 4 = 777,6000 kgm M2 DL = 134793,1175 kgm 1347931,1750 Nm Momen pada potongan 3, x = 6,0 m (M3 DL) ⎭ ⎬ ⎫ ⎩ ⎨ ⎧ ⎟ ⎠ ⎞ ⎜ ⎝ ⎛ −××= 5,16 6 1 5,16 6 5,166207,5360 2 1 2 qDLM = 168859,5521 kgm MTb= ½ × 388,8 × 6 = 1166,4000 kgm M3 DL 170025,9521 kgm 1700259,5210 Nm Momen pada potongan 4, x = 8,25 m (M4 DL) ⎭ ⎬ ⎫ ⎩ ⎨ ⎧ ⎟ ⎠ ⎞ ⎜ ⎝ ⎛ −××= 5,16 25,8 1 5,16 25,8 5,166207,5360 2 1 2 qDLM = 182428,6232 kgm MTb= ½ × 388,8 × 8,25 = 1603,8000 kgm M4 DL 184032,4232 kgm 1840324,2320 Nm c. Beban hidup (live load) koefisien kejut = 1,2963 beban garis, 6294,258595716,4 75,2 12000 2963,1 =××=P kg beban terbagi merata, 28,36575716,4 75,2 2200 =×=q kg/m d. Momen lentur akibat beban hidup ( ) ⎭ ⎬ ⎫ ⎩ ⎨ ⎧ ⎟ ⎠ ⎞ ⎜ ⎝ ⎛ −×= L x L x LPPM x 1 ( ) ⎭ ⎬ ⎫ ⎩ ⎨ ⎧ ⎟ ⎠ ⎞ ⎜ ⎝ ⎛ −×= L x L x LqqM x 1 2 1 2 Momen pada potongan 1, x = 2,0 m (M1 LL) ( ) ⎭ ⎬ ⎫ ⎩ ⎨ ⎧ ⎟ ⎠ ⎞ ⎜ ⎝ ⎛ −×= 5,16 2 1 5,16 2 5,166294,25859PM x = 45450,2577 kgm ( ) ⎭ ⎬ ⎫ ⎩ ⎨ ⎧ ⎟ ⎠ ⎞ ⎜ ⎝ ⎛ −××= 5,16 2 1 5,16 2 5,1628,3657 2 1 2 qM x = 53030,5600 kgm M1 LL = 98480,8177 kgm 984808,1770 Nm

- 10. 10 Momen pada potongan 2, x = 4,0 m (M2 LL) ( ) ⎭ ⎬ ⎫ ⎩ ⎨ ⎧ ⎟ ⎠ ⎞ ⎜ ⎝ ⎛ −×= 5,16 4 1 5,16 4 5,166294,25859PM x = 78362,5133 kgm ( ) ⎭ ⎬ ⎫ ⎩ ⎨ ⎧ ⎟ ⎠ ⎞ ⎜ ⎝ ⎛ −××= 5,16 4 1 5,16 4 5,1628,3657 2 1 2 qM x = 91432,0000 kgm M2 LL = 169794,5133 kgm 1697945,1330 Nm Momen pada potongan 3, x = 6,0 m (M3 LL) ( ) ⎭ ⎬ ⎫ ⎩ ⎨ ⎧ ⎟ ⎠ ⎞ ⎜ ⎝ ⎛ −×= 5,16 6 1 5,16 6 5,166294,25859PM x = 98736,7668 kgm ( ) ⎭ ⎬ ⎫ ⎩ ⎨ ⎧ ⎟ ⎠ ⎞ ⎜ ⎝ ⎛ −××= 5,16 6 1 5,16 6 5,1628,3657 2 1 2 qM x = 115204,3200 kgm M3 LL 213941,0868 kgm 2139410,8680 Nm Momen pada potongan 4, x = 8,25 m (M4 LL) ( ) ⎭ ⎬ ⎫ ⎩ ⎨ ⎧ ⎟ ⎠ ⎞ ⎜ ⎝ ⎛ −×= 5,16 25,8 1 5,16 25,8 5,166294,25859PM x = 106670,9713 kgm ( ) ⎭ ⎬ ⎫ ⎩ ⎨ ⎧ ⎟ ⎠ ⎞ ⎜ ⎝ ⎛ −××= 5,16 25,8 1 5,16 25,8 5,1628,3657 2 1 2 qM x = 124461,8100 kgm M4 LL 231132,7813 kgm 2311327,8130 Nm Tabel. Momen lentur total Pembebanan M.1 M.2 M.3 M.4 Beban mati, DL Beban hidup, LL 781178,0020 984808,1770 1347931,1750 1697945,1330 1700259,5210 2139410,8680 1840324,2320 2311327,8130 Total, Mu (1,2MD+1,6ML) 2513106,6856 4334229,6228 5463368,8140 5906513,5792 e. Gaya geser (shearing force) Beban mati terbagi merata = 0,5 × 5360,6207 × 16,5 44225,1208 kg Balok melintang = 1,4 × 388,8 544,3200 kg Beban hidup garis P = 0,5 × 6294,25859 12928,8147 kg Beban hidup terbagi merata q = 0,5 × 28,3657 × 16,5 30172,5600 kg Total V 87870,8155 kg 878708,1550 N

- 11. 11 f. Perhitungan baja tulangan Pada tumpuan V = 878708,1550 N h = 1300 mm b = 500 mm d = 1300 - 60 = 1240 mm Perencanaan tulangan geser Vu = 878708,1550 N 6667,5072911217,550025 6 1 6 1 ' =××=××= dbfV cc N 5,1521876667,5072916,0 2 1 2 1 =××=cVφ N < Vu (perlu sengkang) Gambar 7. Diagram gaya geser (SFD) Hasil perhitungan dapat dilihat pada tabel berikut No. Penampang titik 1 titik 2 titik 3 titik 4 kritis 0 - 2 m 2 - 4 m 4 - 6 m 6 - 8,25 m 1 Vu (N) 878708.1550 698350.141 517992.127 337089.793 2 Vc (N) 507291.6667 507291.6667 507291.6667 507291.6667 3 ½ φ Vc (N) 152187.5 152187.5 152187.5 152187.5 Perlu sengkang Perlu sengkang Perlu sengkang Perlu sengkang 4 Vs (N) 957221.925 656625.235 356028.545 54524.655 5 s (mm) 79.91645314 116.5014334 214.8641793 1402.994317 6 s mak (mm) 608.75 608.75 608.75 608.75 7 Dipakai D10 - 75 D10 - 110 D10 - 200 D10 - 500 Potongan I-I (8,25 m dari tumpuan) lebar efektif, diambil nilai terkecil dari : 375,45,174 1 4 1 =×== LbE m ( ) 53003001650016 =×+=+= fwE hbb mm 1400== gelagarjarakbE mm CL 878708,1550 698350.141 517992.127 517447.807 337089.793 111642.2755 bw = 500 mm bE = 1400 mm hf = 300 mm h = 1300 mm

- 12. 12 Mu = 5906513,5792 N-m s yb b E fd c + = 003,0 003,0 b s y b d E f a + = 003,0 003,0 85,0 ab = 0,6 db = 0,6 (1300-40) = 756 mm > 300 mm dalam keadaan setimbang (ΣH = 0) ( ){ }tbbbaffA wfwbcyb ×−+×××=× ' 85,0 ( ){ } ( ){ } 34425 400 30050014005007562585,085,0 ' = ×−+××× = ×−+××× = y wfwbc b f tbbbaf A mm2 kemampuan sayap mendukung momen 9906750000 2 300 12602585,03001400 2 85,0 ' = ⎭ ⎬ ⎫ ⎩ ⎨ ⎧ −××××= ⎭ ⎬ ⎫ ⎩ ⎨ ⎧ −××××= t dftbM cf Nmm M = 9906750 Nm > 5906513,5792 Nm → blok beton a ada di dalam sayap Letak garis netral, c ⎭ ⎬ ⎫ ⎩ ⎨ ⎧ −××××= 2 85,0 ' a dfabM cf ⎭ ⎬ ⎫ ⎩ ⎨ ⎧ −××××= 2 12602585,01400,25906513579 a a a2 – 2520a + 397076,5431 = 0 a = 168,8889 mm, c = 168,8889/0,85 = 198,6928 mm luas tulangan yang diperlukan 1114,4486 400 8889,1685002585,085,0 ' = ××× = ××× = y wc f abf A mm2 < 0,75×Ab = 0,75×34425 Dipakai tulangan ∅30 (As = 706,8583 mm2), jumlah tulangan yang dibutuhkan 3,6 8583,706 1114,4486 ==n dipakai 8∅30 (As = 5654,8664 mm2) Potongan II-II (6 m dari tumpuan) Mu = 5463368,8140 N-m s yb b E fd c + = 003,0 003,0 b s y b d E f a + = 003,0 003,0 85,0 ab = 0,6 db = 0,6 (1300-40) = 756 mm > 300 mm

- 13. 13 dalam keadaan setimbang (ΣH = 0) ( ){ }tbbbaffA wfwbcyb ×−+×××=× ' 85,0 ( ){ } ( ){ } 34425 400 30050014005007562585,085,0 ' = ×−+××× = ×−+××× = y wfwbc b f tbbbaf A mm2 kemampuan sayap mendukung momen 9906750000 2 300 12602585,03001400 2 85,0 ' = ⎭ ⎬ ⎫ ⎩ ⎨ ⎧ −××××= ⎭ ⎬ ⎫ ⎩ ⎨ ⎧ −××××= t dftbM cf Nmm M = 9906750 Nm > 5463368,8140 Nm → blok beton a ada di dalam sayap Letak garis netral, c ⎭ ⎬ ⎫ ⎩ ⎨ ⎧ −××××= 2 85,0 ' a dfabM cf ⎭ ⎬ ⎫ ⎩ ⎨ ⎧ −××××= 2 12602585,01400,05463368814 a a a2 – 2520a + 367285,2984 = 0 a = 155,3214 mm, c = 155,3214/0,85 = 182,7311 mm luas tulangan yang diperlukan 7247,4125 400 155,32145002585,085,0 ' = ××× = ××× = y wc f abf A mm2 < 0,75×Ab = 0,75×34425 Dipakai tulangan ∅30 (As = 706,8583 mm2), jumlah tulangan yang dibutuhkan 8,5 8583,706 7247,4125 ==n dipakai 6∅30 (As = 4241,1501 mm2) Potongan III-III (4 m dari tumpuan) Mu = 4334229,6228 N-m s yb b E fd c + = 003,0 003,0 b s y b d E f a + = 003,0 003,0 85,0 ab = 0,6 db = 0,6 (1300-40) = 756 mm > 300 mm dalam keadaan setimbang (ΣH = 0) ( ){ }tbbbaffA wfwbcyb ×−+×××=× ' 85,0 ( ){ } ( ){ } 34425 400 30050014005007562585,085,0 ' = ×−+××× = ×−+××× = y wfwbc b f tbbbaf A mm2

- 14. 14 kemampuan sayap mendukung momen 9906750000 2 300 12602585,03001400 2 85,0 ' = ⎭ ⎬ ⎫ ⎩ ⎨ ⎧ −××××= ⎭ ⎬ ⎫ ⎩ ⎨ ⎧ −××××= t dftbM cf Nmm M = 9906750 Nm > 4334229,6228 Nm → blok beton a ada di dalam sayap Letak garis netral, c ⎭ ⎬ ⎫ ⎩ ⎨ ⎧ −××××= 2 85,0 ' a dfabM cf ⎭ ⎬ ⎫ ⎩ ⎨ ⎧ −××××= 2 12602585,01400,84334229622 a a a2 – 2520a + 291376,7813 = 0 a = 121,4820 mm, c = 121,4820/0,85 = 142,92 mm luas tulangan yang diperlukan 8656,3226 400 121,48205002585,085,0 ' = ××× = ××× = y wc f abf A mm2 < 0,75×Ab = 0,75×34425 Dipakai tulangan ∅30 (As = 706,8583 mm2), jumlah tulangan yang dibutuhkan 6,4 8583,706 8656,3226 ==n dipakai 6∅30 (As = 4241,1501 mm2) Potongan IV- IV (2 m dari tumpuan) Mu = 2513106,6856 N-m s yb b E fd c + = 003,0 003,0 b s y b d E f a + = 003,0 003,0 85,0 ab = 0,6 db = 0,6 (1300-40) = 756 mm > 300 mm dalam keadaan setimbang (ΣH = 0) ( ){ }tbbbaffA wfwbcyb ×−+×××=× ' 85,0 ( ){ } ( ){ } 34425 400 30050014005007562585,085,0 ' = ×−+××× = ×−+××× = y wfwbc b f tbbbaf A mm2 kemampuan sayap mendukung momen 9906750000 2 300 12602585,03001400 2 85,0 ' = ⎭ ⎬ ⎫ ⎩ ⎨ ⎧ −××××= ⎭ ⎬ ⎫ ⎩ ⎨ ⎧ −××××= t dftbM cf Nmm M = 9906750 Nm > 2513106,6856 Nm → blok beton a ada di dalam sayap

- 15. 15 Letak garis netral, c ⎭ ⎬ ⎫ ⎩ ⎨ ⎧ −××××= 2 85,0 ' a dfabM cf ⎭ ⎬ ⎫ ⎩ ⎨ ⎧ −××××= 2 12602585,01400,62513106685 a a a2 – 2520a + 168948,3486 = 0 a = 68,9284 mm, c = 68,9284/0,85 = 81,0922 mm luas tulangan yang diperlukan 9106,1830 400 68,92845002585,085,0 ' = ××× = ××× = y wc f abf A mm2 < 0,75×Ab = 0,75×34425 Dipakai tulangan ∅30 (As = 706,8583 mm2), jumlah tulangan yang dibutuhkan 6,2 8583,706 9106,1830 ==n dipakai 3∅30 (As = 2120,5750 mm2) Tabel Penulangan balok Pembebanan M.1 M.2 M.3 M.4 Beban mati, DL Beban hidup, LL 781178,0020 984808,1770 1347931,1750 1697945,1330 1700259,5210 2139410,8680 1840324,2320 2311327,8130 Total, Mu (1,2MD+1,6ML) 2513106,6856 4334229,6228 5463368,8140 5906513,5792 tulangan 3∅30 6∅30 6∅30 8∅30

- 16. 16 DAFTAR PUSTAKA Agus Iqbal Manu, Ir.,Dipl. Heng., 1995, Dasar-Dasar Perencanaan Jembatan Beton Bertulang, Cetakan I,P.T. Mediatana Saptakarya, Jakarta Bambang Supriyadi, DR.,Ir., CES.,DEA., 2000, Jembatan, Edisi pertama, Beta Offset, Jogjakarta Departemen Pekerjaan Umum, Standar Bangunan Atas Jembatan Gelagar Beton Bertulang Tipe T, 1993, Departemen Pekerjaan Umum Ditjen Bina Marga Dit. Bina Program Jalan Subdit. Perencanaan Teknik Jembatan