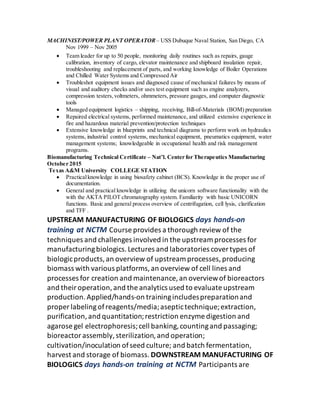

This document provides a summary of a candidate's qualifications for a career in biotech or pharmaceutical manufacturing. The candidate has over 10 years of experience in the security industry, including managing military installations and training personnel. They also have a technical certificate in biomanufacturing from the National Center for Therapeutics Manufacturing, where they received hands-on training in topics like upstream and downstream biologics manufacturing processes. The candidate is seeking to apply their experience in areas like strategic planning, process improvement, and cGMP technical abilities to support company goals in their new career.