Tito Camps Resume

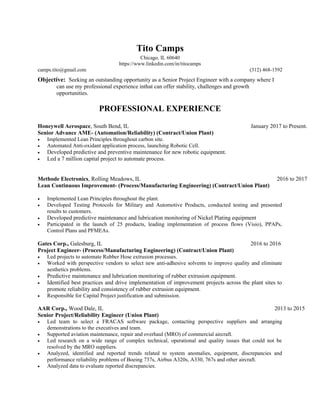

- 1. Tito Camps Chicago, IL 60640 https://www.linkedin.com/in/titocamps camps.tito@gmail.com (312) 468-1592 Objective: Seeking an outstanding opportunity as a Senior Project Engineer with a company where I can use my professional experience inthat can offer stability, challenges and growth opportunities. PROFESSIONAL EXPERIENCE Honeywell Aerospace, South Bend, IL January 2017 to Present. Senior Advance AME- (Automation/Reliability) (Contract/Union Plant) ( • Implemented Lean Principles throughout carbon site. • Automated Anti-oxidant application process, launching Robotic Cell. • Developed predictive and preventive maintenance for new robotic equipment. • Led a 7 million capital project to automate process. Methode Electronics, Rolling Meadows, IL 2016 to 2017 Lean Continuous Improvement- (Process/Manufacturing Engineering) (Contract/Union Plant) ( • Implemented Lean Principles throughout the plant. • Developed Testing Protocols for Military and Automotive Products, conducted testing and presented results to customers. • Developed predictive maintenance and lubrication monitoring of Nickel Plating equipment • Participated in the launch of 25 products, leading implementation of process flows (Visio), PPAPs, Control Plans and PFMEAs. Gates Corp., Galesburg, IL (( 2016 to 2016 Project Engineer- (Process/Manufacturing Engineering) (Contract/Union Plant) • Led projects to automate Rubber Hose extrusion processes. • Worked with perspective vendors to select new anti-adhesive solvents to improve quality and eliminate aesthetics problems. • Predictive maintenance and lubrication monitoring of rubber extrusion equipment. • Identified best practices and drive implementation of improvement projects across the plant sites to promote reliability and consistency of rubber extrusion equipment. • Responsible for Capital Project justification and submission. AAR Corp., Wood Dale, IL ddd kkkk 2013 to 2015 Senior Project/Reliability Engineer (Union Plant) • Led team to select a FRACAS software package, contacting perspective suppliers and arranging demonstrations to the executives and team. • Supported aviation maintenance, repair and overhaul (MRO) of commercial aircraft. • Led research on a wide range of complex technical, operational and quality issues that could not be resolved by the MRO suppliers. • Analyzed, identified and reported trends related to system anomalies, equipment, discrepancies and performance reliability problems of Boeing 737s, Airbus A320s, A330, 767s and other aircraft. • Analyzed data to evaluate reported discrepancies.

- 2. • Researched events to determine root cause. Developed solutions, prepared analysis, developed recommendations and presented conclusions to leadership, suppliers and customers. • Performed comprehensive FRACAS analysis on failed components with the assistance of mechanical, hydraulic, electrical and systems engineers. • Analyzed and interpreted functional problems with aircraft systems, subsystems and components. Stryker Instruments, Kalamazoo, MI 2012 to 2013 Principal Mechanical Engineer- (Contract) • Worked in multiple projects to ensure qualification of CE Mark of new products. • Developed strategies to verify compliance with IEC 60601 3rd Edition regulations. • Worked on projects to launch Stryker Instruments products in emerging markets (Middle East, Russia). Ecolab, Elk Grove Village, IL 2010 to 2011 Manufacturing Engineer/Reliability Engineer/Reliability Manager-(Contract/Union Plant) • Managed 7 Capital projects including equipment upgrades, infrastructure upgrades, and HVAC installation. • Represented the facility in negotiating purchasing contracts with two major suppliers (BDI & MSC). • Implemented CMM for the Elk Grove Village facility. • Managed an engineering technologist to develop work instructions for refurbishing of 5 dish lines. • Served as the facility point of contact with major vendors after the procurement office merged with the Beloit plant. • Predictive maintenance technologies such as vibration analysis, thermographics and lubrication monitoring. • Identified best practices and drive implementation of improvement projects across the plant sites to promote reliability and consistency of equipment refurbishing operations (re-manufacturing) • Developed CMMS usage for preventive maintenance, failure reporting and equipment history management of pet bed filling equipment • Responsible of the building maintenance of heat transfer systems, boiler systems, hydraulic, pneumatic, power transmission and fire protection systems, • Developed and supported reliability tracking methods such as asset utilization, mean time between failures and mean time between repairs of production equipment. • Developed “deep dive” preventive maintenance plans for every major work center in the refurbishing side of the plant. Weber-Stephen Products, Palatine, IL 2007 to 2010 Manufacturing Engineer-Product Documentation Manager (Union Plant) • Developed Process and Product Documentation Procedures in conjunction with the Quality Assurance Manager. • Promoted safety primarily by acting as the leading advocate for compliance to mechanic integrity and equipment management programs in stamping, enameling and assembly lines. • Moved 2 production lines from the Huntley to the Palatine facilities. • Managed 3 engineers, 1 technical writer and 3 data entry clerks. • Improved the accuracy of the routings and bills of materials by 80% for the Replacement part department. • Managed a new warehouse layout project that included negotiating quotes with vendors and installation. • Managed the nomenclature core team consisting of 10 interdepartmental individuals. Project resulted in a 90% accuracy improvement across Bill of Materials, drawings and product descriptions. • Conducted training regarding the Engineering change request process during the MAPICs to SAP migration.

- 3. • Predictive maintenance technologies such as vibration analysis, thermographics and lubrication monitoring. • Responsible of the building maintenance of heat transfer systems, boiler systems, hydraulic, pneumatic, power transmission and fire protection systems • Single point of contact with all Chinese subsidiaries. Streamlined the engineering change process and drawing revision processes. Fleximat, Plainfield, IL 2006 to 2006 Quality Assurance & Plant Safety Manager (Union Plant) • Developed New Product Developed Protocols and Incoming & Shipping Inspection Procedures. • Established Engineering Changes procedure to assure bill of materials accuracy. • Promoted safety, led initiatives to advocate for compliance to mechanic integrity and equipment management programs of filling equipment • Developed Safety Guidelines for 23 different job categories to eliminate the company’s liabilities regarding OSHA. Negotiated with Union leaders and ranking file members to implement. • Tested applicants on Fork lift operation and safety guidelines to reduce the risk of industrial accidents. • Managed biweekly inventory audits in both internal and external warehouses to ensure on time product delivery to our customers. • Develop specifications and procedures for equipment design, installation and maintenance of a new facility in Plainfield, Ilinois. • Predictive maintenance technologies such as vibration analysis, thermographics and lubrication monitoring. • Developed CMMS usage for preventive maintenance, failure reporting and equipment history management of pet bed filling equipment. • Responsible of the building maintenance of heat transfer systems, boiler systems, hydraulic, pneumatic, power transmission and fire protection systems • Managed WIP and Finished Goods inventories and personnel assigned to those areas (up to 50 hourly workers and 10 crew leaders). • Implemented Lean Manufacturing Principles working alongside JCIT Consultants. Amerock, Rockford, IL 2004 to 2005 Manufacturing Engineer/Procurement Engineer • Spearheaded strategic projects for a division of Newell Rubbermaid in support of a manufacturing facility relocation to Monterrey, Mexico. Successfully transferred three assembly lines from Illinois to Mexico. • Documented manufacturing processes in order to streamline transition of facilities. • Trained Monterrey employees on assembly processes, tool design/repair, product specifications, machinery operation, production efficiency, supplier quality control and lean manufacturing principles. • Sourced and conducted quality audits on companies engaged in supplying stamping, die casting, injection molding and other components. Successfully relocated four stamping presses and two die casting lines. • Screened 400+ suppliers and subsequently negotiated favorable terms/contracts with 50 die casting, stamping house, plastic injection molding, plating and other vendors in Monterrey and the Texas valley. • Developed new and optimized existing predictive and preventive maintenance programs focused on • Develop specifications and procedures for equipment design, installation and maintenance of a new facility in Monterrey, Mexico. • Developed specifications and procedures for equipment design, installation and maintenance for new facility in Monterrey Mexico. City Colleges of Chicago & Various Consulting Jobs 2001 to 2004 Chicago, IL Bilingual Instructor/Manufacturing Engineer Consultant • Taught various courses outside of my career profession, while looking for the right fit in my field of study (engineering).

- 4. • Worked multiple short term contract jobs Dunlee Corporation, Aurora, IL 1997 to 2001 Project Engineer • Developed bills of materials for 21 products spanning five product lines for a manufacturer of medical x- ray tubes. Created product assembly and testing procedures in compliance with ISO standards. • Managed multiple engineering projects using Six sigma principles resulting in acquiring ISO certification, as well as FDA approval and CE rating as a result of documentation efforts, that included development of PPAP, DFMEA, PFMEA, and APQP efforts. • Served as essential interface between manufacturing and engineering to ensure reliability in the manufacture and assembly of X-ray inserts. • Audited and selected vendors to ensure adequate supplies of quality materials according to ISO9000 specifications. • Collaborated with quality control, design, manufacturing engineering and compliance engineering staff to ensure CE certification and submit certifying reports to the FDA. • Created destructive testing procedures for aluminum castings to maintain product safety standards. Instituted FMEA programs to monitor product performance and troubleshoot related failures. • Tracked assembly processes and manufacturing throughput to ensure availability of required components • Instituted preventive maintenance procedures for all relocated tool and stamping presses. Additionally, implemented Lean Manufacturing principles in all production lines transferred to Monterrey EDUCATION AND PROFESSIONAL DEVELOPMENT Illinois Institute of Technology – Chicago, IL M.S. in Manufacturing Engineering Illinois Institute of Technology – Chicago, IL Graduate Certificate Purchasing & Selling Roosevelt University – Chicago, IL B.S. in Industrial Engineering College of DuPage – Glenn Ellyn, IL Lean Manufacturing & Green Belt Certification University of Cincinnati – Cincinnati, OH A.S. in Mechanical Engineering, Certification in Robotics The Management Training Institute Failure Mode and Effect Analysis MRA Institute of Management – Palatine, IL Professional Supervisor, Principal of Management Series SKILLS • Award Winning Project Engineer, Dr. Homer Stryker Medal of Honor Award 2012 • Proficient in Microsoft Office, Microsoft Project, Primavera, Visio, Access, Windchill and SAP. • Demonstrated ability to effectively lead teams including RCFA facilitation • CAD applications: AutoCAD, ProE, Solid Works and TOPS • Multilingual Skills in Spanish, French, Portuguese, Italian; and German • Aerospace experience FAA Regulations, MRO Development, Component Reliability • Experience with fixed equipment codes (API-510, 570, 653) and welding technologies. • Experience with heat transfer systems, boiler systems, hydraulic, pneumatic, power transmission and fire protection systems • Medical device experience: QSR 820, CGMP parts 210&211 • Quality: Green Belt Training, HAACP, 8D, GMP, PPAP, DMAIC Principles, FMEA, ISO 9001, ISO/TS 16949, ISO 13485, Six Sigma and APQP • Welding technology (3 graduate level courses, 5 years of relevant experience).