SUNIL KUMAR ,MECHANICAL ENGINEER

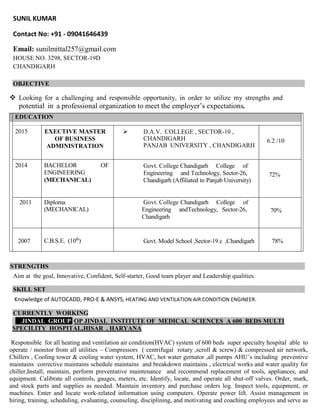

- 1. SUNIL KUMAR Contact No: +91 - 09041646439 Email: sunilmittal257@gmail.com HOUSE NO. 3298, SECTOR-19D CHANDIGARH OBJECTIVE Looking for a challenging and responsible opportunity, in order to utilize my strengths and potential in a professional organization to meet the employer’s expectations. STRENGTHS Aim at the goal, Innovative, Confident, Self-starter, Good team player and Leadership qualities. SKILL SET Knowledge of AUTOCADD, PRO-E & ANSYS, HEATING AND VENTILATION AIR CONDITION ENGINEER. CURRENTLY WORKING JINDAL GROUP OP JINDAL INSTITUTE OF MEDICAL SCIENCES A 600 BEDS MULTI SPECILITY HOSPITAL,HISAR , HARYANA Responsible for all heating and ventilation air condition(HVAC) system of 600 beds super specialty hospital able to operate / monitor from all utilities – Compressors ( centrifugal rotary ,scroll & screw) & compressed air network, Chillers , Cooling tower & cooling water system, HVAC, hot water gernator ,all pumps AHU’s including preventive maintains corrective maintains schedule maintains and breakdown maintains , electrical works and water quality for chiller,Install, maintain, perform preventative maintenance and recommend replacement of tools, appliances, and equipment. Calibrate all controls, gauges, meters, etc. Identify, locate, and operate all shut-off valves. Order, mark, and stock parts and supplies as needed. Maintain inventory and purchase orders log. Inspect tools, equipment, or machines. Enter and locate work-related information using computers. Operate power lift. Assist management in hiring, training, scheduling, evaluating, counseling, disciplining, and motivating and coaching employees and serve as EDUCATION 2015 EXECTIVE MASTER OF BUSINESS ADMINISTRATION D.A.V. COLLEGE , SECTOR-10 , CHANDIGARH PANJAB UNIVERSITY , CHANDIGARH 6.2 /10 2014 BACHELOR OF ENGINEERING (MECHANICAL) Govt. College Chandigarh College of Engineering and Technology, Sector-26, Chandigarh (Affiliated to Panjab University) 72% 2011 Diploma (MECHANICAL) Govt. College Chandigarh College of Engineering andTechnology, Sector-26, Chandigarh 70% 2007 C.B.S.E. (10th ) Govt. Model School ,Sector-19 c ,Chandigarh 78%

- 2. a role model. Repairing and maintains all types of machines like centrifugal water cooled chiller 540 tons, scroll air colled chiller 130 tons, scroll water cooled 80 tons, package units 10 tons, window split aircondition of 400 tons. 1. Using building management system to improve efficiency of HVAC system. 2. Design , modify ,implemention to increasing the effectiveness of HVAC and electric system. 3. Reduce maintains of machines and increasing efficiency of machines by inspection sheet 4. Reduce the energy consumption and overall cost of operation. 5. Zero compressor failure in HVAC maintains department since joining. 6. Reduce the breakdown of 24*7*365 days working machine by using scientific methods like total quality management, preventive maintains , 5 S,KAIZEN, QUALITY CONTROL & ASSURACE. 7. Preparing documents and validations of air handling units , relative humidity, comfort level as required. 8. Increasing productivity of team by giving regular training to team members . CHILL POINT ENGINEERS PVT. LTD ( from 23 June 2014 to 15 July 2015) I was engaged with Chill Point Engineers Pvt. Ltd in Chandigarh. My job was to installs and commissioning the 300 tons water cooled chiller Machine, duct-able package units, variable refrigerants flow , split and window air conditioned ,electric connection for different machines, electric load ,cooling and heating load . Design of piping for chilled water pipes and condenser pipes, water pumps design etc. I am also responsible for new project enquiry generation and annual maintains contracts. I am also in-charge for building management system for cost cutting of running of plant from 20 to 30 % by using different kind of sensors PROJECTS MINOR PROJECT PROJECT WORK AT COLLEGE: Made a project on first law of thermodynamic which state that energy neither be created nor be destroyed. By using this principle our team modified a cooling machine to produce unused condenser heat to make a heating box which is used for heating the food items, worm up water up to 45 degree Celsius and also used a 2 way valve to use a heat blower for raising the room temperature up to 4 degree Celsius higher than the atmospheric MAJOR PROJECT STEEL STRIP WHEEL LIMITED (SSWL) DEERA BASSI, PUNJAB, (6 JANUARY TO 6 JUNE 2014) 6 MONTH INDUSTERIAL TRAINING at manufacturing plant for wheels of different cars, trucks, buses, heavy vehicles wheels of different diameters, applying total quality management for better efficiency of manufacturing processes, inventories control, implementation of the given processes, cutting the cost of energy for given quality product to increasing bottom line of company cost. Creating a healthy atmosphere in departments. Implementation of 5S, KIAZENS, QUALITY CONTROL & ASSURENCE etc. My project at steel strip wheel to improve productivity, reduce manufacturing cost by improving the condition of different types of machines by checking machines working condition every alternative days and planning the preventive maintains for better use of machine. Coordination with different departments of company for proper working conditions. SAMMER TRAININGS SAWARJ TRACTORS DIVISION, MAHINDRA AND MAHINDRA (5th JUNE- 16th JULY, 2012) I worked on the project ‘Observation of various Manufacturing Techniques’ of a tractor which included the start from the manufacturing of gears, crank shaft, connecting rod etc. machining of differentials and gear box housing, heat treatment

- 3. processes and also about the assembly of engine, rear axle and chassis with the final roller testing. It enhanced my practical skills and knowledge. BHARAT ELECTRONICS (BEL) PANCHKULA,(1st June to 2nd July 2013) : I worked on different type of manufacturing component like powder coating, costly metal displacement on simple metal parts, working of CNC machine ,paint shop etc. Material selection for different components and there working condition where they used. HINDUSTAN MACHINE TOOLS LIMITED (1ST JUNE TO 16TH JULY ,2012): I worked on various process of manufacturing of computer numerical control (CNC) machine . I got first hand on experience of manufacturing process likes pattern making, moulding, casting, turning ,milling ,drilling ,boring ,grinding, surface finishing, case hardening, tempering, assembaly etc. Different material used in CNC MANUFUCTURING MACHINE like cast iron, mild steel, high speed steel, carbide steel etc. ESCORTS TRACTORS LTD.,FARIDABAD,(29TH July to 1ST September 2011): I worked on product testing & evaluation of different type of tractor models of company in RESEARCH AND DEVELOPMENT(R & D ) CENTER. Checking of torque of engine at different speeds, testing of tractors at different load application. EXTRA CURRICULAR ACTIVITIES PROFESIONAL CLUBS MEMBER SAE ( SOCIETY OF AUTOMOBILE ENGINEERS) ISHARE ( INDIAN SOCIETY FOR HEATING AND REFRIGERATION ENGINEER) 0 00 0 CULTURAL ACTIVITIES ORGANISING MEMBER IN COLLEGE FEST, FRESHER PARTY etc. THE INDUS ENTREPRENURS MEMBER PROMOTING AND GUIDING FOR SELF BUSINESS. HOBBIES AND OTHER INTERESTS Listening old songs Helping poor children in maths & science when they approach me. Playing cricket PERSONAL DETAILS Fathers Name : LT. SHRI SATBIR Date of Birth : 12 FABURARY, 1990 Communication Address : HOUSE NO. 3298, SECTOR-19 D, CHANDIGARH Languages Known : Hindi, English and Punjabi. I hereby declare that the particulars given herein are true and complete to the best of my knowledge and belief. Place: HISAR Sunil Signature:

- 6. 3/3