Experienced Maintenance Leader Seeking New Opportunity

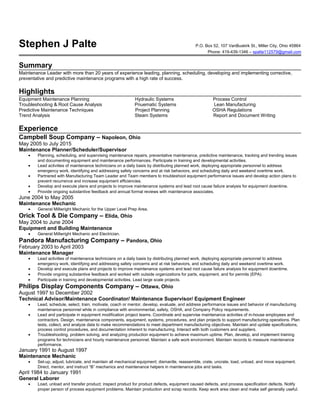

- 1. Stephen J Palte P.O. Box 52, 107 VanBuskirk St., Miller City, Ohio 45864 Phone: 419-439-1346 – spalte112579@gmail.com Summary Maintenance Leader with more than 20 years of experience leading, planning, scheduling, developing and implementing corrective, preventative and predictive maintenance programs with a high rate of success. Highlights Equipment Maintenance Planning Hydraulic Systems Process Control Troubleshooting & Root Cause Analysis Pnuematic Systems Lean Manufacturing Predictive Maintenance Techniques Project Planning OSHA Regulations Trend Analysis Steam Systems Report and Document Writing Experience Campbell Soup Company – Napoleon, Ohio May 2005 to July 2015 Maintenance Planner/Scheduler/Supervisor • Planning, scheduling, and supervising maintenance repairs, preventative maintenance, predictive maintenance, tracking and trending issues and documenting equipment and maintenance performances. Participate in training and developmental activities. • Lead activities of maintenance technicians on a daily basis by distributing planned work, deploying appropriate personnel to address emergency work, identifying and addressing safety concerns and at risk behaviors, and scheduling daily and weekend overtime work. • Partnered with Manufacturing Team Leader and Team members to troubleshoot equipment performance issues and develop action plans to prevent recurrence and increase equipment efficiencies. • Develop and execute plans and projects to improve maintenance systems and lead root cause failure analysis for equipment downtime. • Provide ongoing substantive feedback and annual formal reviews with maintenance associates. June 2004 to May 2005 Maintenance Mechanic • General Millwright Mechanic for the Upper Level Prep Area. Orick Tool & Die Company – Elida, Ohio May 2004 to June 2004 Equipment and Building Maintenance • General Millwright Mechanic and Electrician. Pandora Manufacturing Company – Pandora, Ohio February 2003 to April 2003 Maintenance Manager • Lead activities of maintenance technicians on a daily basis by distributing planned work, deploying appropriate personnel to address emergency work, identifying and addressing safety concerns and at risk behaviors, and scheduling daily and weekend overtime work. • Develop and execute plans and projects to improve maintenance systems and lead root cause failure analysis for equipment downtime. • Provide ongoing substantive feedback and worked with outside organizations for parts, equipment, and for permits (EPA). • Participate in training and developmental activities. Lead large scale projects. Philips Display Components Company – Ottawa, Ohio August 1997 to December 2002 Technical Advisor/Maintenance Coordinator/ Maintenance Supervisor/ Equipment Engineer • Lead, schedule, select, train, motivate, coach or mentor, develop, evaluate, and address performance issues and behavior of manufacturing maintenance personnel while in compliance with environmental, safety, OSHA, and Company Policy requirements. • Lead and participate in equipment modification project teams. Coordinate and supervise maintenance activities of in-house employees and contractors. Design, maintenance components, equipment, systems, procedures, and plan projects to support manufacturing operations. Plan tests, collect, and analyze data to make recommendations to meet department manufacturing objectives. Maintain and update specifications, process control procedures, and documentation inherent to manufacturing. Interact with both customers and suppliers. • Troubleshooting, problem solving, and analyzing production equipment to achieve maximum uptime. Plan, develop, and implement training programs for technicians and hourly maintenance personnel. Maintain a safe work environment. Maintain records to measure maintenance performance. January 1991 to August 1997 Maintenance Mechanic • Set-up, adjust, lubricate, and maintain all mechanical equipment; dismantle, reassemble, crate, uncrate, load, unload, and move equipment. Direct, mentor, and instruct “B” mechanics and maintenance helpers in maintenance jobs and tasks. April 1984 to January 1991 General Laborer • Load, unload and transfer product; inspect product for product defects, equipment caused defects, and process specification defects. Notify proper person of process equipment problems. Maintain production and scrap records. Keep work area clean and make self generally useful.

- 2. Village of Miller City January 1984 to July 1991 Town Marshal • Patrol the Village, enforce State, Local, and Federal Laws; report writing, court appearances, supervision of Village crime and accident scenes, and public speaking. Libby Soup Company July 1981 to February 1983 General Laborer • Lift truck operator, packing and unpack product. Machine operator and clean up. Six County Major Crime Unit June 1978 to May 1980 Detective Apprentice and Crime Analyst • Assist detectives in the investigation of drug activity, bank robbery, auto theft, burglary, safe cracking, armed robbery, murder, suicide, and other felony crimes. Education Bachelor of Arts Degree – May 2003 Bluffton College – Bluffton, Ohio Organizational Management Applied Science Associate Degrees Unfinished Owens Community College – Findlay, Ohio Mechanical Technology, Electrical Technology, Building Maintenance Hanes Industrial Training Philips In-house Courses – Ottawa, Ohio Hydraulics (80 hrs) 1993; Pneumatics (40 Hrs) 1994 Pneumatic Ladder Logic (40 hrs) 1995 Basic and Advanced Law Enforcement Training - 1979 Defiance Police Academy – Defiance, Ohio Knowledge & Skills Coaching, Mentoring, Root Cause Failure Analysis, Excel, Word, Power Point, Maximo, SAP, Leadership, Planning, Scheduling, Report Writing, Safety, OSHA, Process Control, Train Programs, Troubleshooting, Quality Control, Hydraulics, Pneumatics, Drive Systems, Lean Manufacturing, Steam Systems, Gears and Bearings, Oil Analysis, Vibration Analysis, Ultrasonic Analysis, Infrared Thermal Analysis, Problem Solving, Blue Print Reading, Electrical Schematic Reading, Continuous Improvement, Trend Analysis, Project Planning, 5S, Customer Relations, Team Building, AutoCAD, Pumping Systems, Piping Systems, TPM, Industrial Safety, High Voltage Safety, Food Safety, Heat Exchangers, Cross Functional Team Building, Conveyor Systems, Law Enforcement, Vacuum Systems, Budgeting, Project Management, Customer Relations, Vendor Relations, Maintenance Management, Personnel Supervision, Store Room Management, Asset Management, Centrifugal Pumps, Positive Displacement Pumps, Urschel Dicers, Vane Pumps, Awards Philips Quality Champions Award – 1996 North American Finalist Maintenance Quality Team presented a project to reduce scrap and increase production of department area product. Improved changeover time by implementing warm-up stands. Philips Quality Champions Award – 1997 North American Winner Maintenance Quality Team presented a project to reduce scrap and increase production of department area product. Philips Quality Champions Award – 1997 North World Finalist Maintenance Quality Team presented a project to reduce scrap and increase production of department area product. Costs were reduced greatly by reduced scrap and maintenance downtime by improving the process times. Philips Quality Champions Award – 1998 North American Finalist Maintenance Quality Team presented a project to reduce scrap and increase production of department area product. Reduced department costs by implementing an improved suction cup and also eliminated use of ear plugs.