Drug delivery nanocarriers

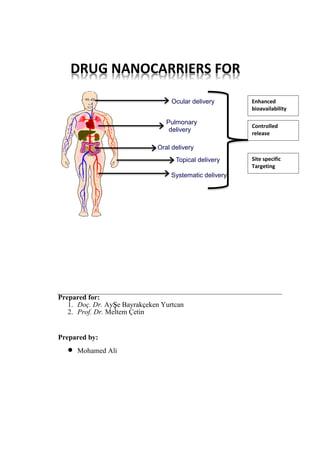

- 1. Prepared for: 1. Doç. Dr. Ayşe Bayrakçeken Yurtcan 2. Prof. Dr. Meltem Çetin Prepared by: Mohamed Ali DRUG NANOCARRIERS FOR Ocular delivery Pulmonary delivery Oral delivery Topical delivery Systematic delivery Enhanced bioavailability Controlled release Site specific Targeting

- 2. TABLE OF CON TENTS PAGE 1. INTRODUCTION 1 2. NANOCARIERS & NANO PARTICLES 2 2.1. Libid Based Drug Delivery System 2 2.1.1. Liposomes 5 2.1.2. Emulsions 6 2.2 Polymers in DDS 9 2.2.1 Polymeric Micelles 10 2.2.2 Dendrimers 12 2.3 Other nanoparticles/nanocarriers 13 3. SUPERCRITICAL BASED DDS 16 3.1. Particles formation in scCo2 16 3.1.1. Supercritical Anti Solvent (SAS) 17 3.1.2. Rapid Expansion of Supercritical Solution (RESS) 19 3.1.3. Supercritical Solvent Impregnation(SSI) 20 3.2. scCo2 preparation of Lipid nanovesicles 23 3.2.1. Supercritical Assisted liposome Formation (SuperLip) 23 3.2.2. Depressurization of an Expanded Solution into aqueous (DESAM) 24 3.3. Characterization Techniques for DDS Produced in scCO2 25 3.3.1. Particle Size & Morphology 26 3.3.2. Drug loading & Release 26 3.3.3. Drug/Excipient Structure studies 27 4. CONLUSIONS & RECOMMENDATIONS 31

- 3. 1 1 1.0 INTRODUCTION TO NANOTECHNOLOGY and NANOCARRIERS Nanotechnology involves combination of science and technology that deals with study of particles at nanoscale between 1 and 1000 nanometer in size. Nanotechnology in drug delivery system application had promising therapeutic efficiency in the medical field. Nanoparticles (Nps) are promising materials used to overcome bioavailability problems of many active biopharmaceutical principles by increasing dissolution rate of hydrophobic drugs or poorly soluble drugs (Camperdelli et al., 2015) Bioavailability is the degree and rate to which substance (such as drugs) is absorbed into living system or is made available at the site of biological activity. Biocompatible refers compatibility of drugs with living tissue or living systems by not toxic, injurious, or physiologically reactive and not causing immunological reaction. Nanocarriers are nanoparticles which can be used to deliver biological active molecules at the desired rate and for desired time the drug concentration lever in therapeutic window (Philip et al., 2017). Drug Delivery Systems (DDS) are proficient in design and bioavailability of drugs, control and sustain release of drug delivery and also capable to maintain the drug interact transport to specific site without damaging non diseased sites (Apurva et al., 2016). The main objectives of DDS are to accomplish the most therapeutic effect, in addition minimize the dose, utilize suitable dose and mode of administration, decrease side effects and improve the solubility of drug or drug molecules. Clinical trials related drug carriers have recently attracted attention due to its high effective efficiency drug delivery (Tatsuaki & Tetsuya, 2017) and it is ability to minimize drug related side effects (Zhoa et al., 2017). Developing new drug carrier systems are very crucial in the treatment for wide range of diseases includes cancer, pulmonary diseases, topical diseases, ocular diseases, systemic disease and age relates disease such as Parkinson and Alzheimer’s diseases (Mohammad & Jamal , 2016). In this report, would like to outline some Drug Delivery Carriers (DDC) recently reported include polymer based carriers, lipid based carriers, dendrimer, micelles, emulsions, nanoparticle based carriers and later would review supercritical CO2 based carrier .

- 4. 2 2 2.0 NANOPARTICLES and NANOCARRIERS According to article published by Tatsuaki & Tetsuya, 2017 most of recently clinical trials for drug delivery carriers are filled home page (HP) of ClinicalTrials.gov (https://clinicaltrials.gov/), a website owned by U.S. National Institute of Health (NIH). Figure 1 indicates some recently drug carriers extracted from this website. In this section I will be highlight these drug carriers which associated with Lipids, polymers and their derivatives such as liposomes, emulsions, micelles and dendrimers and in the end of sectionl will mention some other DDS rarely appeared in literature but useful. Source: (Tatsuaki & Tetsuya, 2017) 2.1 Lipid Based Drug Delivery Systems (LBDS) Lipids are basically fatty or waxy organic compound which are readily soluble in non-polar organic solvents, but are insoluble in polar solvent. Lipids based DDS have promising better and significant effects to deliver of drugs and provide appropriate systemic drug delivery (Tatsuaki & Tetsuya, 2017 Piya et al., 2017).The advantages and disadvantages of DDS based lipids have been summarized Table 1. I will discuss here lipid formulation, in addition liposomes and emulsions as examples of LBDDS.

- 5. 3 3 Table 1: Advantages and Disadvantages of LDDS. Advantages Disadvantages Reduce the dose of drugs Increases the entrapment efficiency through conjugation with drug to form vesicles. Marked enhancement of bioavailability of drug Improved the ability of drug to pass cell membranes and get into cells Increments the stability profile by constructing chemical bonds between drug and lipid. Decrease toxic effects Rapidly eliminated from body Lead to hemolysis Source: (Rudra et al., 2017) Lipid formulation and selection:- Drug delivery based lipids have been proved to be competitive candidates for the formulation of pharmaceuticals, diagnostics, vaccines and nutraceuticals. Thus, LBDDS have gained much attention in recent years over the other drug delivery systems. According to many published papers, specifically these systems are commercially applicable to formulate drugs for topical, oral, pulmonary, or parental delivery. Many different phospholipid formulations are available in many different papers however, Doxil® , Cleviprex® , Valium® and Silybin Phytosome™ are some phospholipids formulation, which have been used in clinic, hospital and market and achieved excellent significant effects (Rudra et al., 2017). On the other hand there is old method introduced in 2000 known as Lipid Formulation classification System (LFCS), and in 2006 new type was additionally added to this system, to be frankly, recently published papers (2016-2017) which I have read rarely mentioned LFCS. Because maybe different mechanisms modification associated when formulating as stated by Rudra and coworkers;- LBDDS formulation in drug delivery can completely change the absorption of active ingredients through following mechanisms:- Modification of drug release Increase bioavaiability Alteration of composition and thus character of intestinal location Alteration of transdermal permeation Motivation of the lymphatic transport

- 6. 4 4 Used as solubilizers, antioxidants, permeation enhancer, surfactants, release modifier, coating agent Play as carrier for various DDS. The selection or regarding points of LBDS formulation depends on functions they are desired and the structure of the drug. It involves carefully selection of formulation objectives, Figure 2 shows different lipid based carriers used different objectives, and secondly it should be consider type of drug and their morphology at room temperature (e-g their melting point), digestibility and disposability properties, fatty acid composition (drugs bearing alcohol or amino functional group couple with fatty acid, producing an ester or amide), stability (purity) and capsule compatibility , toxicity, adsorption, miscibility and cost of goods. (Rudra et al., 2017; Piya et al., 2017) Figure 1: Applications of LDDS Source: (Rudra et al., 2017)

- 7. 5 5 2.1 .1 Liposomes Liposomes are one of the most extensively studied as carrier for various drugs in number of clinical. Liposomes mainly used as LDDS are phospholipids. They are biodegradable and biocompatible nanovesicles due to their phospholipids being similar structure as cellular membrane (Ritu et al., 2016) Liposomes structure as shown in Figure 3 when hydrated form spherical bilayer which compose hydrophilic head and hydrophopic tail (fatty acid) (Rudra et al., 2017). The advantages of this method include improving drug stability, delivering both hydrophobic and hydrophilic drugs. Controlled release properties. And most of all liposomes can serve as carriers of antitumor drugs, antifungal drugs, analgestic drugs, gene therapeutics and ocular delivery as shown in Table 2. Figure 3: Liposome Structure Table 2: Examples of liposomes formulation using phospholipids Source: (Rudra et al., 2017)

- 8. 6 6 2.1.2 Emulsion Emulsion is suspension (dispersion) of two unmixable (immiscible) liquids. Nanoemulsion is nanosize emulsion (<500 nm) which is thermodynamically stable, isotopic in nature where two non-miscible liquids (oil in water o/w in drugs) are emulsified in nanosize droplets (Pranita & Amrita, 2016). Nanoemulsions is used many application include cosmetic (skincare health, sunscreen lotions), diagnostics and various different drugs delivery systems such as parenteral, ocular, transdermal or topical, intranasal, tumor targeted and oral drug delivery systems. Nanoemulsion structure is made up of phospholipid but is different from lipasome on its monolayer enclosing a lipid core Due to its unique structure, nanoemlusion helps solubilize lipophilic drugs, it also increase rate of adsorption, increase bioavaiability, and eliminate variability in adsorptions (Tatsuaki & Tetsuya, 2017). The components of nanoemulsion are aqueous, oil and surfactants/co-surfactants. One of the most factors that effects nanoemulsion formulation is surfactant. surfactants should not cause lyotropic liquid crystals. Systems containing short chain alkanes, alcohols, water, and surfactants form the phases which are generally used with the co surfactant. High pressure homogenization, microfluidization, dilution with water methods are used to prepare nanoemulsion (Rudra et al., 2017). Various techniques or methods used to prepare lipid based drug delivery systems as well as its advantages, disadvantages and limitation has been shown in Table 3. Characterization parameters of DDS based lipids have been also shown in Table 4. Table 5 indicates list of drugs and type lipids used. Table 3: Methods used to prepare LDDS Continues next page…..

- 9. 7 7 Table 3 (continues) …… Source: (Poovi & Damodharan, 2017)

- 10. 8 8 Table 4: Method of characterization of DDS based lipids Source: (Poovi & Damodharan, 2017) Table 5: Drugs used to conjugate with Lipids Source: (Piya et al., 2017)

- 11. 9 9 2.2 Polymer in DDS Recently Polymers have been extensively studied in drug delivery and tissue engineering applications. Polymers and polymer based nanocarriers have unique features such as small size, cause optimize drug loading and releasing property (Nirmal et al., 2017). Natural polymeric polysaccharide based nanocarrier include chitosan, cellulose, and pectin) have been used in DDS as nanoparticles (such as nanogels or micelles). However chitosan have widely used in many recently published papers. Chitosan is the second most abundant polysaccharides after cellulose and it is used for pharmaceutical applications due to its reactive functional groups, biocompatibility, biodegradability, gel forming capability, non- toxicity and high charge density (Tilahun et al., 2016). According to Champeau et al., (2015) natural polymeric based nanoparticles lack batch to batch consistency, making it difficult to prepare particles with reproducible characteristics and drug delivery profiles. These problems could be overcome by using synthetic polymers with high purity and batch to batch reproducibility and high drug release profile. Synthetic polymeric nanoparticles are particularly used to deliver lipophilic and small molecule drugs. Biodegradable polymers have either hydrolytically or proteolytically labile bond in their backbone to make it chemically degradable. Most widely synthetic biodegradable polymers used in drug delivery system include Polylactic acid (PLA), Polyglycolic acid (PGA), Poly (e- caprolactone), PCL, Poly (lactide-co-glycolide), PLGA, Polyhydroxybutyrate (PHB) and Polydioxanone (PDS). Factors effects degradable polymers have been summarized in Table 6. Since volatile organic solvents are often used during preparation of synthetic polymer nanocarriers . It was reported that is hard to maintain the biological activity peptides and proteins during manufacturing process. To solve this problem, another new class of polymer is being investigated for delivery of proteins. Examples are Poly (phosphoester) s (PPE), and Polyorthoesters POE, These polymers are generally referred to as Phophonates (P-O-C), polyphosphonates (P-C) orpolyphosphites depending upon the nature of the side chain attached to the phosphorus (Amit & Harshal, 2014; Apurva et al., 2016; Philip et al., 2017) Table 6: Factors effects biodegradation of synthetic polymer nanoparticles

- 12. 10 10 2.2.1 Polymeric Micelles. Micelles are self-assembled nanoparticles, formed by hydrophobic interactions, electrostatic interaction, and metal complex formation. Polymeric micelles are smaller than liposomes and emulsion particles (Tatsuaki & Tetsuya, 2017). As shown Figure 4 most of the polymeric micelles used in DDS consist of amphiphilic di-block (hydrophilic-hydrophobic) polymers, tri-block (hydrophilic-hydrophobic- hydrophilic) collectively known as copolymers. Research done by Mohammad & Jamal , (2016) included that .most commonly used hydrophilic segment of micelles for drug delivery is poly(ethylene gylycol) PEG, with a molecular weight of 2-15 KDa . The use of polymeric micelles was recently investigated for treatment of mice with melanoma and it was shown that the animals treated with drug-loaded polymeric micelles inhibited tumor growth and increased the survival rate as compared to animals treated with free drugs. Meanwhile recently there is a trend in designing and developing ant-cancer therapeutics drug carrier that has pH-sensitive (Mohammad & Jamal , 2016). Another research done by Tatsuaki & Tetsuya, (2017) stated that the environmental responsive of micelles to pH, redox potential, and enzymes has been used, resulting in efficient drug delivery and therefore comparing many other nanocarrier, polymeric micelles are good candidate in designing and developing ant-cancer therapeutics ideal drug carrier. Table 7 summarized several review papers used polymeric micelles and properties studied. Table 8 shows polymeric micelles used for ocular drug delivery.

- 13. 11 11 Table 7: summary of various polymeric micelle carrier and properties studied. Source: (Mohammad & Jamal , 2016)

- 14. 12 12 Table 8 polymeric micelles used for ocular drug delivery Source: (Abhirup et al., 2017) 2.2.2 Dendrimers Dendrimers are a class of highly branched, monodispersed, synthetic macromolecules with a well-defined composition and structure. The most commonly referenced dendrimers used in nanomedicine are polyamidoamines (PAMAM), poly(L-lysine) (PLL) scaffold dendrimers, polyesters (PGLSA-OH), polypropylimines (PPI), poly(2,2-bis (hydroxymethyl)propionic acid) scaffold dendrimers (bis-MPA), and aminobis(methylenephosphonic acid) scaffold dendrimers . Dendrimer-based NPs have been widely studied because of the scientific and technological interest relating to their possible applications in a broad range of areas, such as catalysis, optics, electronics, and biomedical applications. The uniqueness of dendrimers are hybrid formation in which other nanoparticles such as liposomes, carbon nanotube combined with dendrimer to form hybrid nanosystem, as Figure 5 depicted (Prashant et al., 2017;Tatsuaki & Tetsuya, 2017;Abhirup et al., 2017)

- 15. 13 13 Figure 5: schematic presentation hybrid formation of Dendrimers wth other nanocarrier 2.3 Other Nanoparticles/Nanocarriers The utility of nanoparticulate drug delivery systems based on various types of nanoparticle materials to treat disease has been investigated. Several interesting nanoparticles (e.g., carbon nanotubes and polymersomes) have provided promising results in both in vitro and in vivo studies but their utility has not yet been demonstrated in clinical trials. These include albumin-based nanoparticles and iron- oxide nanoparticles. Other metal nanoparticles have also been investigated in clinical trials (e.g., gold nanoparticles) (Ritu et al., 2016). Table 9 summarized various nanocarriers used to study topical drugs. Table 10 latest or currently ‘on going’ clinical trials used liposomes, emulsions, micelles, polymers based drug carier.

- 16. 14 14 Table 9: Types of nanoparticles uses as topical drug delivery carrier. Source: (Ritu et al., 2016)

- 17. 15 15 Table 10: clinical trials of currently recruiting or completed Source: (Tatsuaki & Tetsuya, 2017)

- 18. 16 16 3.0 Supercritical Based DDS Supercritical fluids (SCFs) are substances for which both pressure and temperature are above the critical values. Critical temperature is the maximum temp. were the liquid state could exist. Critical pressure is the minimum pressure needed to liquify a solvent at critical temp. Physicochemical properties SCF is intermediate between gas and liquid. SCF is dense, non- condensable but highly compressible fluid. SCF express a density value which considerable for the salvation of power. The viscosity and diffusivity properties are similar to gases, produce the mass transfer. SCF has already been used in the application of pharmaceutical, food, chemical and textile industry. SCFs are environmentally favorable, cheaper in price, and offer the capability of obtaining new products. One of their unique advantages is the capability of separating and drying products (such as Active Pharmaceutical Ingredients API and/or co-solvent) by simple expansion, at the same time without need of purification, the gas can be recovered, recycled and reused (Champeau et al., 2015). The commonly used supercritical solvents are CO2, benzene, ammonia, methane, ethane, ethanol, propane and water .The SC-CO2 critical points of temperature and pressure are Tc 31.1 0 C and Pc 73.8 bar . Comparing to other supercritical solvents like water, ammonia, or benzene, the critical points of SC-CO2 is slow and reachable. For instance, the critical point of water is Tc 374.2 0 C and Pc 220.5 bar. For this reason, SC-CO2 process and their unique properties like fast mass transfer, zero surface tension, low toxicity, inexpensive, nonflammable, non-mutagenic, and their thermodynamically stable have been extensively employed in the production nanocarriers (Onanong et al., 2017). Several researches have been performed in SC-CO2 process to produce micronic and nanoparticles using one of below processes:- 3.1 Particle formation in SC-CO2 . According to literature review available several different processes for particle formation have been reported. The process of SC-CO2 depends on the role of carbon dioxide played or acted in the process. SC-CO2 has been used as solute, solvent, anti-solvent and atomization aid in many research papers. I will divide particle formation techniques or processes based on the role of carbon dioxide as summarized in Table 11.

- 19. 17 17 Role of CO2 Techniques/Process References Solvent o Rapid expansion of supercritical solution (RESS) o Rapid Expansion of Supercritical Solution into liquid Solvent (RESOLV) o Supercritical solvent impregnation (SSI) (Camperdelli et al., 2015) (Onanong et al., 2017) Anti-solvent Supercritical Antisolvent process (SAS) Solution enhanced dispersion by supercritical (SEDS) Aerosol solvent extraction system (SES) Precipitation with compressed fluid antisolvent (PCA) Supercritical fluid extraction emulsions (SFEE) (Dalila et al., 2017) (Camperdelli et al., 2015) Solute Particles from gas saturated solutions (PGSS) (Onanong et al., 2017) Atomization Aid Supercritical assisted atomization (SAA) (Camperdelli et al., 2015) 3.1.1 Supercritical Antisolvent process (SAS) SAS technology is used in the production micronic and nanometric particles with controlled particle size and distribution. The SAS process as shown Figure 6, the SC-CO2 and the drug solution are separately and continuously fed inside the precipitation chamber through nozzles. In the normal operation of SAS technique, the SCO2 acts as non-solvent. In the SAS method, the precipitated solid accumulate inside the vessel and are collected at the end of the operation (Dalila et al., 2017). Figure 6: SAS process.

- 20. 18 18 Several important drugs in nanomdical filed have been processed using SAS as shown in Table 12, in addition with mean diameter of the particles produced and the operation conditions employed. Sometimes SAS method has been used to produce drug/polymer coprecipitates for controlled applications as shown in Table 13 , in these cases, the starting solution was prepared dissolving the selected solvent both polymer and the drug. The applicability of SAS is restricted or confined to hydrophobic drugs. However, many interested drugs in nanomedicine are water soluble, to process water soluble drugs in SAS, a modification of SAS techniques is possible in order to broaden its suitability in water soluble compounds by just adding to supercritical antisolvent, an organic solvent, might completely miscible with SC- CO2 at the process conditions (Camperdelli et al., 2015 ; Champeau et al., 2015). Table 12: Nanoparticles of various drugs and polymers produced in SAS process. Source: (Camperdelli et al., 2015) Table 13: Nanocariers produced by SAS Source: (Camperdelli et al., 2015)

- 21. 19 19 3.1.2 Rapid expansion of supercritical solution (RESS) RESS process is applicable to use drug compounds miscible with SC-CO2 . After the drug are dissolved in SC-CO2 , the mixture is expanded over a nozzle, reducing the solvation power of CO2 , leading to super saturation of the mixture and precipitation of solute as particles. As SC- CO2 is a poor solvent for many polymers and pharmaceutical drug compounds, to increase the solubility of drugs or polymers, organic co-solvent can be added as depicted in Figure 7. However, there is a risk that the solvent remain in particles, thus there is demand additional drying steps. On the other hand, the solvent may also result particle agglomeration. Many research papers noted that although the potential features of RESS are very interesting from theoretical point of view, the experimental results were not particularly good, since is problematic to control particles size of precipitates (Camperdelli et al., 2015). To minimize the problematic an to have a better control over particles size distribution, a significant changes of RESS has been proposed using liquid solvent or a solution at the receiving the end of a supercritical solution expansion. This modification method is known as Rapid Expansion of Supercritical Solution into liquid Solvent (RESOLV) or Rapid Expansion of Supercritical Solution into an Aqueous Solution (RESAS), when the receiving solution is water (Camperdelli et al., 2015). Several experiments were used RESS/RESOLV and the size of Nano carrier produced as well as the list of drugs/polymers is shown in Table 14. Figure 7: RESS process. Table 15: Nanoparticles of pharmaceutical drugs, polymers and copercipitates by RESS/RESOLV Source: (Camperdelli et al., 2015)

- 22. 20 20 3.1.3 Supercritical solvent Impregnation (SSI) Supercritical Solvent Impregnation (SSI) is a method used to form drug encapsulates by polymers. The drug is dissolved in a supercritical fluid and when this solution is brought into contact with polymer particles, they get impregnated with drug. The Sc-CO2 impregnation process takes advantage of both the density and diffusivity properties. In the meantime sc- CO2 possesses a good solvation power because of its high density, so it can solubilize several compounds. On the other hand, the high diffusivity of Sc-CO2 leads to the diffusion of CO2 into most of the conventional polymers (Champeau et al., 2015). The supercritical impregnation process involves three components; CO2 as the carrier, API and the polymer matrix. The impregnation process is mainly reported as a batch process. Fig. 8 reports a traditional configuration of the impregnation set-up. The solute and the polymer are placed in the same reactor. Generally, they are either physically separated or the drug is placed in a filter in order to avoid the deposition of the drug on the polymer. The temperature is controlled and CO2 is introduced into the reactor until the desired pressure is reached, and then, the reactor is sealed. The impregnation can be carried on in static or stirring mode (Onanong et al., 2017). The impregnated polymers are mainly biodegradable polyesters (PLLA, P(D,L)LA, PLGA, PCL), hydrogels (chitosan, agarose, acrylicbased copolymers, collagen/cellulose blends), silicon-based copolymers, polyurethane, PMMA, PVP,..i.e., typical biomaterials (Camperdelli et al., 2015). Figure 8: Schematic representation of the apparatus used for supercritical CO2 impregnation with a batch process. (1) CO2 bottle; (2) high pressure pump; (3) inlet valve; (4) temperature controlled bath or oven; (5) sealed high pressure reactor; (6) outlet valve; (7) trap; (a) polymer sample physically separated from the solute; (b) solute.

- 23. 21 21 The comparison of the literature data is complex since most of the studies measured the drug loading ex-situ but the final drug loading can be impacted by the depressurization step during which the drug can be partially removed from the matrix depending on the depressurization speed. Moreover, the thermodynamic equilibrium are sometimes not reached, the properties of the matrices such as their composition in case of commercial devices, their behavior under the investigated conditions (swelling and CO2 sorption) and their crystallinity in case of semi- crystalline polymers are generally unknown or unspecified whereas all these characteristics can influence the drug loading. Last but not least, the drug can precipitate on the surface of the polymer. If this drug is not removed before the determination of the drug loading, the real amount of drug impregnated into the polymer can be overestimated which could explain the high drug loading obtained in some cases. This lack of information makes delicate the analysis of the literature data. Table 15 indicates various drug compound, polymers and drug loading obtained (Piya et al., 2017) Table 16: SSI process used to impregnate polymers and drugs Continue next page…….

- 24. 22 22 Table 16 continues….. Source: (Champeau et al., 2015)

- 25. 23 23 3.2 SC-CO2 preparation of Lipid nanovesicles Liposomes are colloidal associations of amphiphilic lipids that arrange themselves spontaneously in bilayer vesicles, as a result of unfavorable interactions between phospholipids and water. Since they have lipophilic and hydrophilic parts, liposomes can entrap substances with different lipophilicities in the phospholipid bilayer, in the aqueous compartment or at bilayer interface. This entrapment can modify physicochemical properties and enhance the biological activity of the compounds. They also have the ability to minimize side effects of drugs, protecting them from degradation, induce specific targeting and biocompatibility (Poovi & Damodharan, 2017). Limitations related to the control of liposomes dimension and distribution, especially at nanometric scale have been reported these methods; they are batch or semi-continuous layouts and show very low encapsulation efficiencies, especially for liposomes containing hydrophilic drugs (around 10–20%). According to research done by Champeau et al., (2015) only some limited processes based on supercritical fluids were demonstrated to be able to produce nanosomes (liposomes with nanometric dimensions); the results are summarized in Table 17. Three methods are used to produce supercritical carbon dioxide based LBDDS; Supercritical assisted liposome formation (SuperLip), Supercritical fluid liposome method and Depressurization of an expanded solution into an aqueous media (DESAM) below will discuss SuperLip and DESAM only. 3.2.1 Supercritical assisted liposome formation (SuperLip) The aim of this process is to make first water based nano droplets and, then, nanosomes are formed around them. To obtain this result, the first step of the process is the atomization of water based solutions directly in a supercritical solution in which phospholipids are dis- solved. Phospholipids generally show a low solubility in SC-CO2, for this reason, an organic solvent, EtOH, is added to increase their solubility in the supercritical fluid. Since micelles formation is afast spontaneous process, lipids contained in the expanded liquid can spontaneously and rapidly organize themselves in a layer around the water nanodroplets. Besides some experiments were carried out by producing Phosphatidilcholine (PC) based empty liposomes (Champeau et al., 2015). An example of produced liposomes is shown in SEM image reported in Fig. 8; these liposomes were prepared for microscopy using a critical point dryer. Encapsulation tests were performed dissolving in water BSA, used as model protein. High encapsulation efficiencies (around 80%) were reported.

- 26. 24 24 Figure 8: Liposome vesicles produced using SuperLip, at 125 bar, 70◦C, GLR 2.42. 3.2.2 Depressurization of an expanded solution into an aqueous media (DESAM) DESAM was produced Liposomes of Phosphatidylcholine EtOH solutions of phospholipids were prepared and expanded with CO2. Then, the solution was injected in a water bath and left bubbling for one hour. During this time, also evaporation of EtOH was obtained in the vessel, heated and agitated by CO2. Isoniazid, an organic compound that is a first-line medication in prevention and treatment of tuberculosis, has been demonstrated to have promising therapeutic efficacy in the therapy of tuberculosis, when delivered using liposomes For this reason, Isoniazid was encapsulated in liposomes by DESAM. It was dissolved in water solution in which the expanded EtOH-CO2-phospholipids mixture was injected. Liposomes with mean diameters of 180 nm were formed operating in this way. Isoniazid encapsulation efficiency of 29% was reported as shown Table 17. Table 17: Nano-liposome preparation techniques based on supercritical fluids and obtained results. Source: (Camperdelli et al., 2015)

- 27. 25 25 3.3 Characterization Techniques for DDS produced in SCO-CO2 Anonong and coworkers have published a literature review about various characterization methods for analyzing DDs particles (such as particle size distribution, morphology, drug loading and release, in addition porosity, particle surface chemistry, surface charge, biocompatibility and residual solvents) obtained from different SCO-CO2 technologies processes mentioned earlier. Figure 9 summarized various methods frequently used. Figure 9: The frequency of use of particle characterization techniques used in scCO2 technology. Abbreviations; AFM (Atomic force microscopy), Cytox (Cytotoxicity by in vitro and in vivo assay), DLS and LS (dynamic light scattering and laser diffraction), DSC (Differential scanning calorimetry), EDX (Energy dispersion X-ray spectroscopy), FTIR (Fourier transform infrared spectroscopy), HPLC (high performance liquid chromatography with UV detector), IVR (In vitro release and dissolution study), Porosity (Brunauer-Emmett-Teller surface area analysis and Barrett-Joyner-Halenda determination, N2 absorption and pore size distribution), SEM (Scanning electron microscopy), Solvent analysis (Gas chromatography), TGA (Thermogravimetric analysis), TEM (Transmission electron microscopy), UV/Vis (UV/Vis spectroscopy), XPS (X-ray photoelectron spectroscopy), XRD (X-ray diffraction), and ZP (Zeta potential measurement). Source: (Onanong et al., 2017)

- 28. 26 26 3.3.1 Particle size distribution and morphology Various different techniques were used to characterize particle size distribution include; Dynamic light scattering (DLS) or photon correlation spectroscopy (PCS), laser diffraction (LD), scanning electron microscopy (SEM), Transmission electron microscopy (TEM). The PCS or DLS method can measure particles in the size range of 5 nm to 1000 nm. LD method has a measuring range of millimeter, simple to operate and is available most of laboratory, however, the size resolution is low and small traces of large particles and agglomerates can skew the results, because they scatter light much more efficiently than smaller particles do (Poovi & Damodharan, 2017). SEM is used to visualize the size and morphology or shape of particles in a dry state. SEM uses a focused beam of electrons to scan the sample. Various types of signals (secondary or back-scattered electrons and X-rays) coming from the sample can be detected to create an image, or gain information about the elemental composition of the surface. TEM is suitable for the particle s with size range of 1 nm– 5 μm can be imaged. Although better resolutions can be achieved with TEM (0.1 nm) than with SEM, the sample preparation tends to be more complex. TEM is also used to visualize the distribution of the constituents in particles and distribution of particles after uptake. Other methods like optical microscopy (OM), nanoparticle tracking analysis (NTA), light obscuration (LO), and disc centrifugal sedimentation have also been employed (Onanong et al., 2017). 3.3.2 Drug loading and release Drug loading involves drug integrates into carriers, the process subjected on the physicochemical of drugs and excipients. The integration process of drug and excipient depends on several mechanisms of interaction includes hydrogen bonding, ionic interaction, physical entrapment, precipitation, covalent bonding r surface absorption (Bouledjouidja et al., 2016). To estimate the total amount of drug in the particles, drug/excipient particles are often dissolved in an aqueous medium by using variety of methods such as UV/Vis and many others as shown in Table 18 . Drug release is a reverse process of detachment of the drug from carriers, to be ready for pharmacological action. A study of drug release can provide information on drug-excipient interactions and a prediction of in vivo behavior (Poovi & Damodharan, 2017). By using in vitro drug release tests, the particle production process can be optimized to achieve the

- 29. 27 27 desired release characteristics before in vivo pharmacokinetic tests are performed. In addition, in vitro results can guide certain aspects of the design of in vivo studies, such as sampling times. In a typical in vitro release study, a separation of the drug from a particle matrix is needed (Bouledjouidja et al., 2016). Often this separation is achieved by means of dialysis. A dialysis membrane will separate particles from released drug that can diffuse through the membrane into a release medium (Onanong et al., 2017). The release medium is collected at time intervals and analyzed by a selection of techniques that allow precise determination of the drug concentration. Use of centrifugation and filtering is also common for separation of the released drug from the particles. In vitro drug release is usually measured in physiological buffers at the physiological temperature (37 °C). Phosphate-buffered saline (PBS), with a pH of 6.8 or 7.2, is the most commonly used dissolution buffer for SC-CO2 particles (Poovi & Damodharan, 2017 ; Onanong et al., 2017) For preparation of controlled release particles by SC-CO2 processes, various polymeric carriers have been used such as 1-vinyl-2-pyrolidone, dextran, PLA, PLGA and PEG. Often the drug release mechanisms are complicated, for instance, for PLGA particles drug release involves drug diffusion through water-filled pores and a polymer, osmotic pumping, and polymer erosion (Champeau et al., 2015) . 3.3.3 Drug/excipient structure studies The drug and excipient components made during SC-CO2 process may have experienced chemical and/or physical changes in the native structure of the original components during and after manufacture. Several methods is used to measure the structure of drug/excipient components after particle processes by SC-CO2 include Differential scanning calorimetry (DSC), Spectroscopic methods such Fourier-transform infrared spectroscopy (FTIR), other methods such as X-ray diffraction (XRD) also employed as indicates Table 18.

- 30. 28 28 Table 18: Particle characterization techniques used and potentially useful in scCO2 technologies Continue next page….

- 32. 30 30 Table 18 (Continued). Source: (Onanong et al., 2017)

- 33. 31 31 4.0 Conclusions and Recommendations 4.1 Conclusion Literature review about nanocariers is complex since most of studies have been performed in vitro, with difference results obtained very few have been optimized in vivo animals, however extensive researches have been focused on developing nanocariers with low toxicity, excellent biocompatibility, and biodegradation. Liposomes, micelles, emulsions and polymers have been widely reported in most of literature due to their suitability in DDS. Metal nanocarriers have also been reported, Encapsulation drug process using SAS method of SC- CO2 was also mentioned its efficiency in the production of DDS over other Scf methods. 4.2 Recommendation Since most of 2017 published articles composed 95% of previous researches, it is very hard to track currently ‘’on going’’ researches about DDS. To solve this problem, and to track down latest DDS researches, Tatsuaki et al. 2017 reported that most of recently clinical trials used drug delivery carriers are filled home page (HP) of ClinicalTrials.gov (https://clinicaltrials.gov/), a website owned by U.S. National Institute of Health (NIH). Therefore I recommend to search latest studies related DDS. However to search a study in the website is not easy task, it gives you general not specific information. For example if you type ‘’ doxorubicin’’ and ‘’drug delivery system’’ you will get random topics which barely related for what you’re looking for, as you might see image 1. To solve this problem I found NIH matchmaker site known as https://projectreporter.nih.gov/ which will give very accurate search results. There is also another NIH database which could be search latest research information called Instramural Research Program https://irp.nih.gov/ . it has research mentors. Instruction for the 2 sites, available in YouTube. Image 2: https://projectreporter.nih.gov/ site Image 1: https://clinicaltrials.gov/), website. Image 3: https://irp.nih.gov/ website Image 2: https://projectreporter.nih.gov/ site

- 34. 32 32 1. Abhirup, M., Rohit, B., Ilva, D. & Ashim, k.M., 2017. Polymeric Micelles for Ocular Drug Delivery: From Structure frameworkds to Recent preclinical Studies. Journal Controlled Release, 248(2017), pp.96-116. 2. Apurva, S. et al., 2016. Polymers in Drug Delivery. Journal of Sciences and Medicines, 4(2016), pp.69-84. 3. Bouledjouidja, A. et al., 2016. Drug Loading of Foldable Comercial Intraocular Lenses Using Supercritical Impregnation. International Journal of Pharmaceutics, 500(2016), pp.85-99. 4. Camperdelli, R., Baldino, L. & Reverchon, E., 2015. Supercritical Fluids Application in Nanomedicine. Journal of Supercritical Fluids, 101(2015), pp.193-214. 5. Champeau, M., Thomassin, J.-M., Tassaing, T. & Jerome, C., 2015. Drug Loading of Polymer Implants by Supercritical CO2 Assisted Impregnation: A Review. Journal of Controlled Release, 209(2015), pp.248-59. 6. Dalila, A., Robiah, Y., Gun Haen, C. & Che Azurahanim, A., 2017. Single Step Encapsulation Process of Tamoxifen in Biodegradable Polymer Using Supercritical Anti-Solvent (SAS) Process. Powder Technology, 309(2017), pp.89-94. 7. Mohammad, R. & Jamal , S., 2016. Application of DPD in the Design of Polymeric Nano-micelles as Drug Carriers. Journal of Molecular Graphics & Modelling, 66(2016), pp.1-8. 8. Nirmal, M., Shadabul, H. & Lisa, M., 2017. Polymer-drug Conjugates as Inhalable Drug Delivery Systems: A Review. Current Opinion in Colloid & Interface Science, 31(2017), pp.18-29. 9. Onanong, N. et al., 2017. Journal of Supercritical Fluids. Characterization of Drug Particles Produced by Supercritcal Carbon Dioxide technolojies, 128(2017), pp.244-62. 10. Philip, G., Dominik, W., Sandro, S. & Jorg, H., 2017. PEG-GL-Based nanomedicines: A biodegradable Drug Delivery System and its Application. Journal of Controlled Release, 260(2017), pp.46-60. 11. Piya, A. et al., 2017. Nano Lipid-drug Conjugate: An Integrated Review. International Journal of Pharmaceutics, 529(2017), pp.629-41. 12. Poovi, G. & Damodharan, N., 2017. Lipid Nanoparticles: Different Preparation Techniques, Characterization, Hurdles, and Strategies for the production of Solid Lipid Nanoparticles and nanostructured Lipid Carriers for Oral Drug Delivery. Sustainable Chemistry and pharmacy, 6(2017), pp.37-56. References

- 35. 33 33 13. Pranita, S. & Amrita, B., 2016. Nano-Emulsions: A Review. International journal of Research in Pharmacy and Chemistry, 6(2016), pp.312-22. 14. Prashant, K. et al., 2017. Dendrimer Nanohybrid Carrier Systems: an Expanding Horizon for targeted Drug and Gene Delivery. Drug Discovery Today, 00(2017), pp.0-15. 15. Ritu, G., Lauren, K., Hilton, M. & Joachim, K., 2016. Nanoparticles and nanofibers for topical Drug Delivery. Journal of Controlled Release, 240(2017), pp.77-92. 16. Rudra, P.S., Gangadhrapa, H.V. & Mruthunjaya, K., 2017. Phospholipids: Unique carriers for Drug Delivery Systems. Journal of Drug Delivery Science and Technology, 39(2017), pp.166-79. 17. Tatsuak, T. & Tetsuya, O., 2017. Recent Trends in Clinical Trials Related to Carrier-Based Drugs. Journal of Pharmaceutical Sciences, 106(2017), pp.2219-26. 18. Tilahun, A.D., Shewaye, L.M. & Hsieh-CHih, T., 2016. Polysachride Based nNnogels in the Drug Deliver System: Application as the Carrier of Pharmaceutical Agents. Material Science and Engineering C, 68(2016), pp.964-81. 19. Zhoa, Y. et al., 2017. Application Progress of DNA Nanostructures in Drug Delivery and Smart Drug Carriers. Chinese Journal of Analytical Chemistry, 45(2017), pp.1078-87. .