- Worldwide wheat production reached 776.5 million tons in 2021, with India contributing 107.9 million tons and seeing a 1.8% increase from 2020.

- There are two main wheat milling methods - traditional stone grinding and modern roller milling. Roller milling uses corrugated rollers to separate the endosperm from the bran.

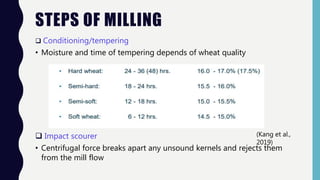

- The modern milling process involves several steps - receiving and storage, cleaning, conditioning, grinding, sifting, and packaging. The grinding process is repeated until the desired flour is obtained.

- Wheat milling produces 73-77% endosperm flour and 23-27% bran. India's milling industry is fragmented with two