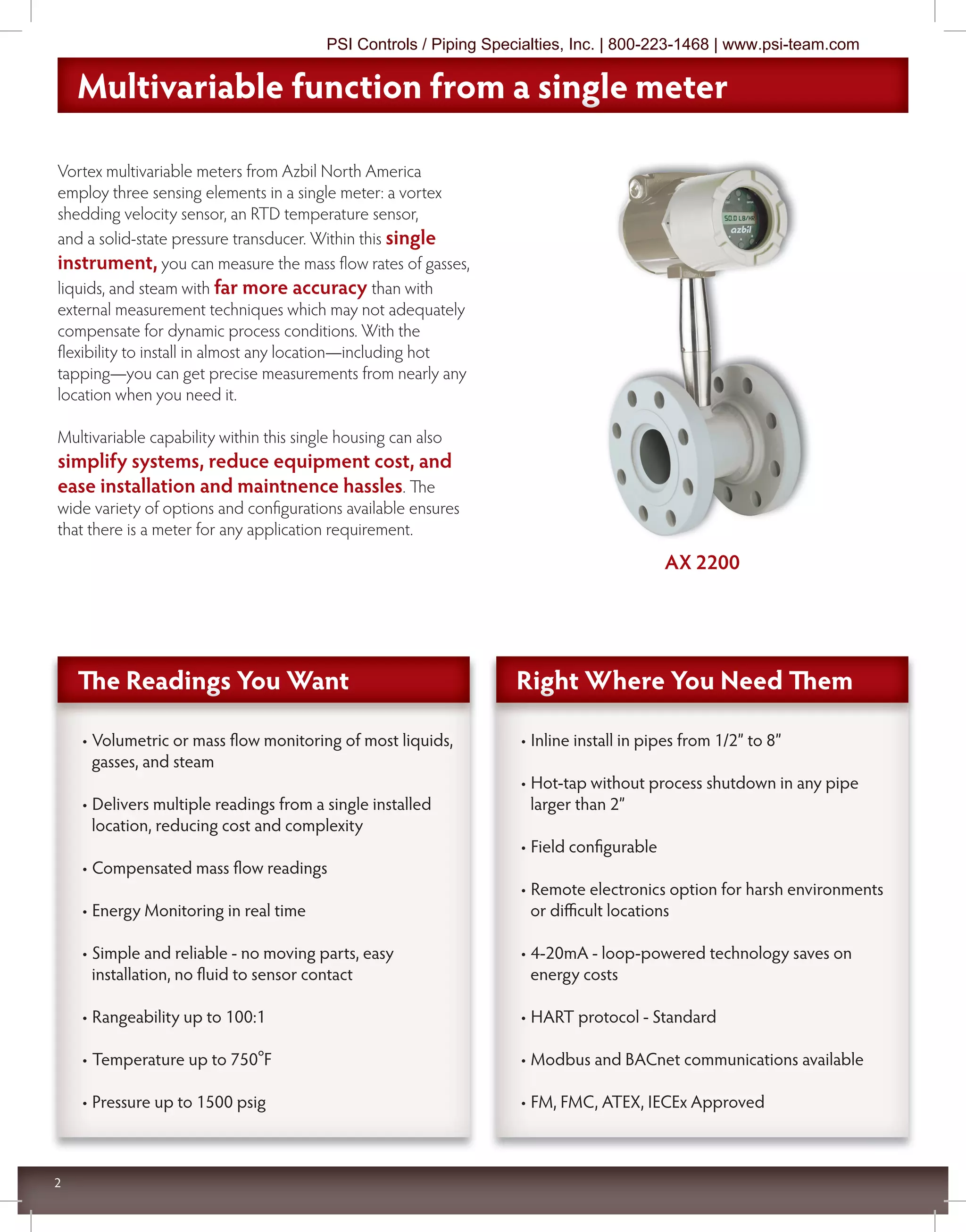

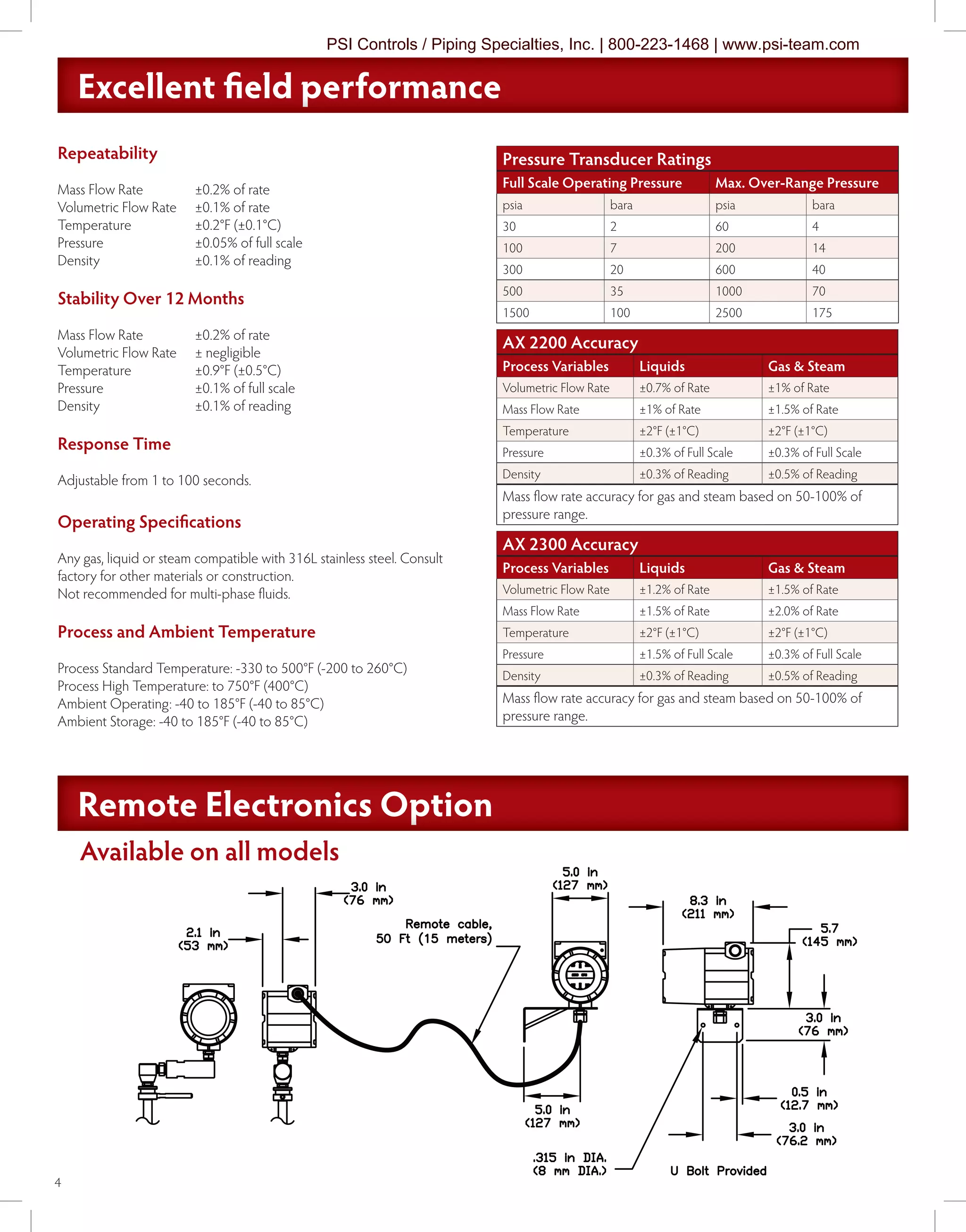

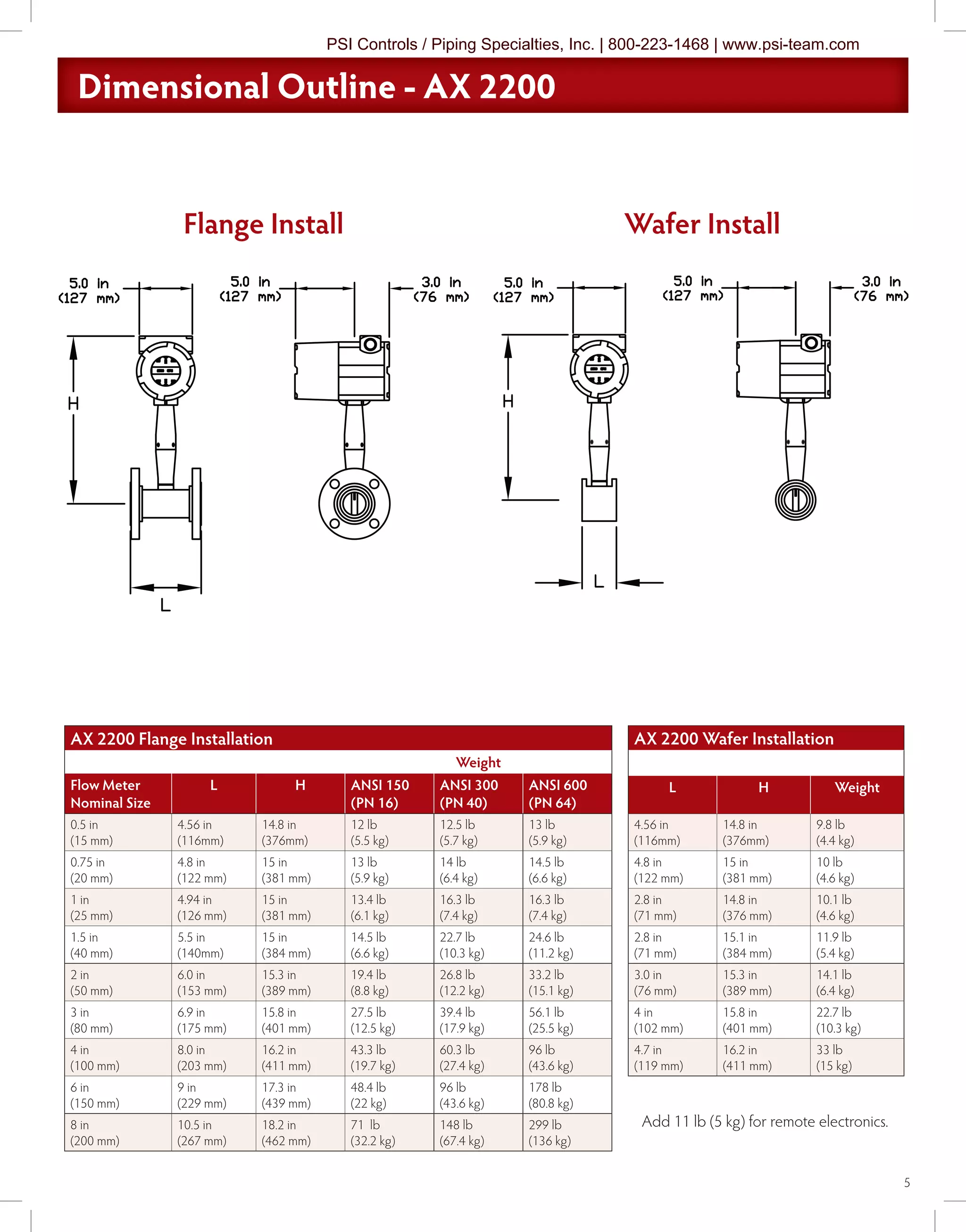

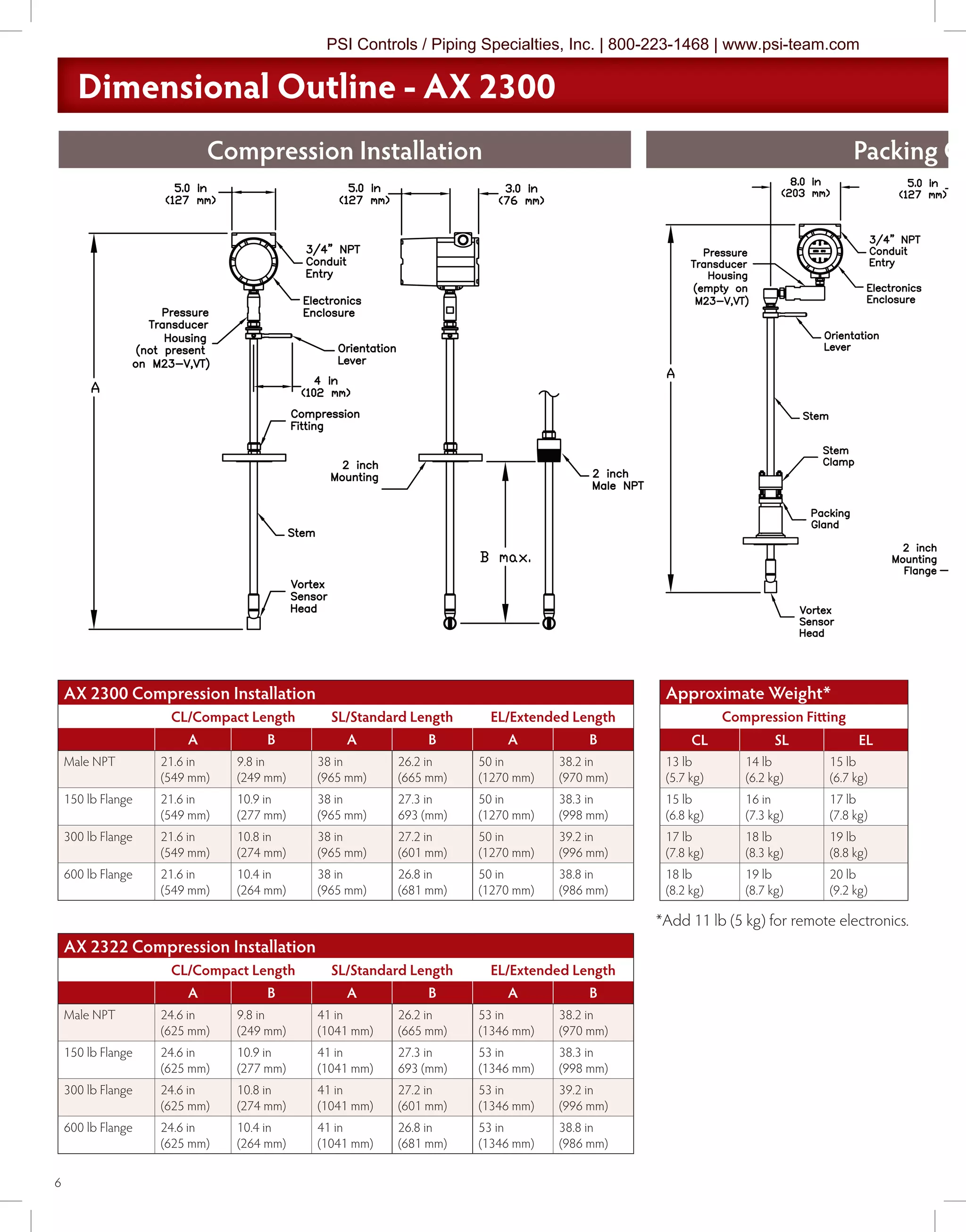

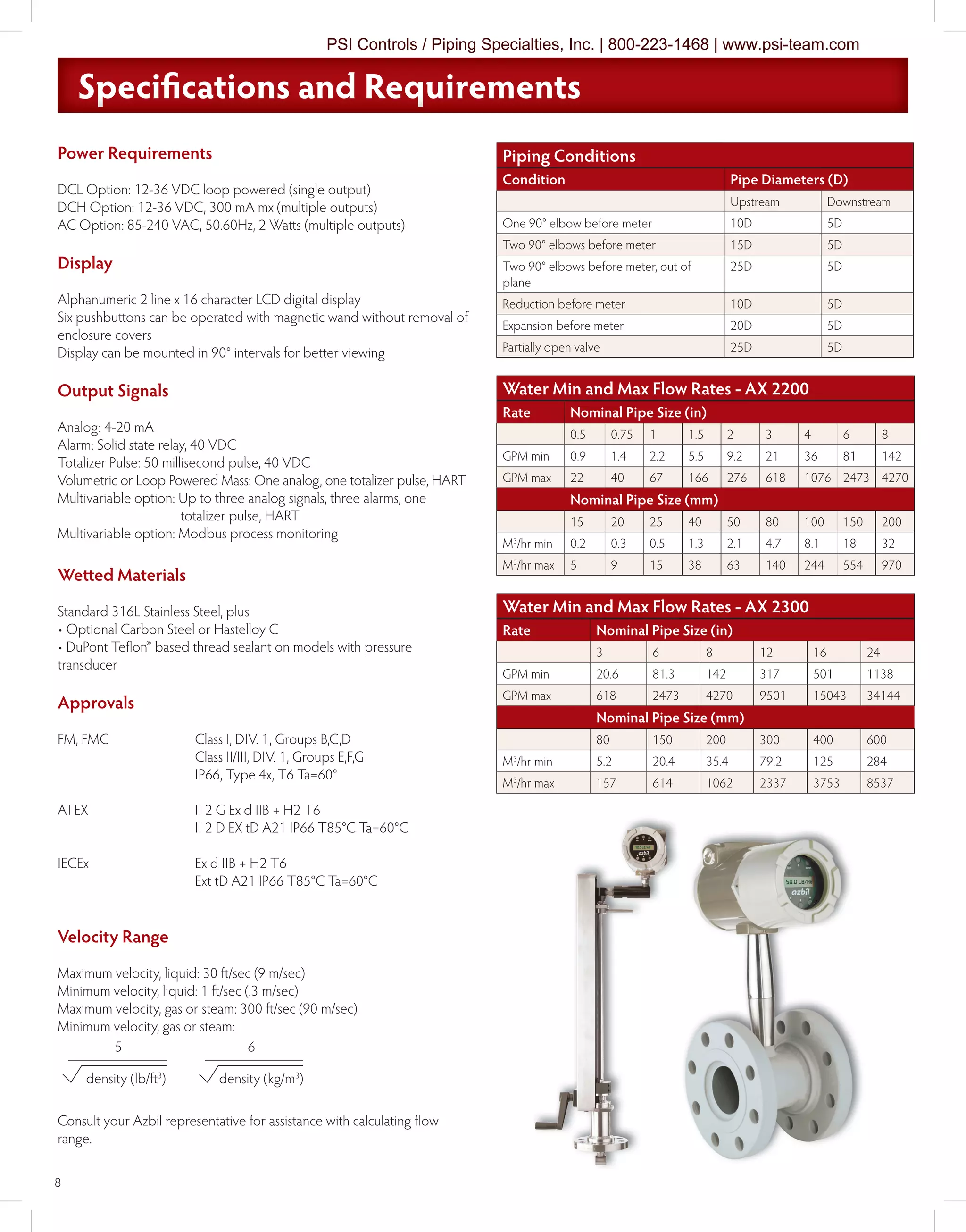

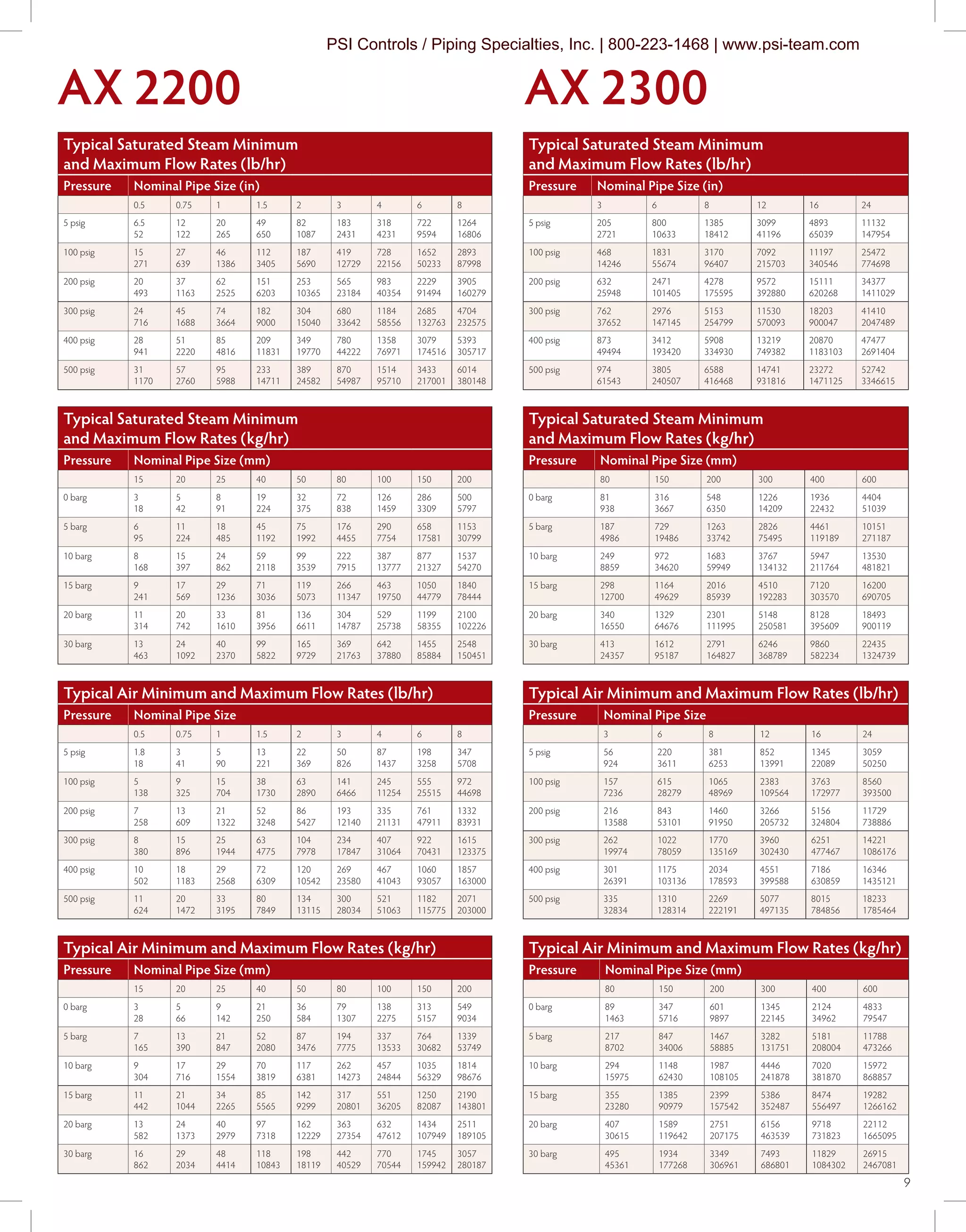

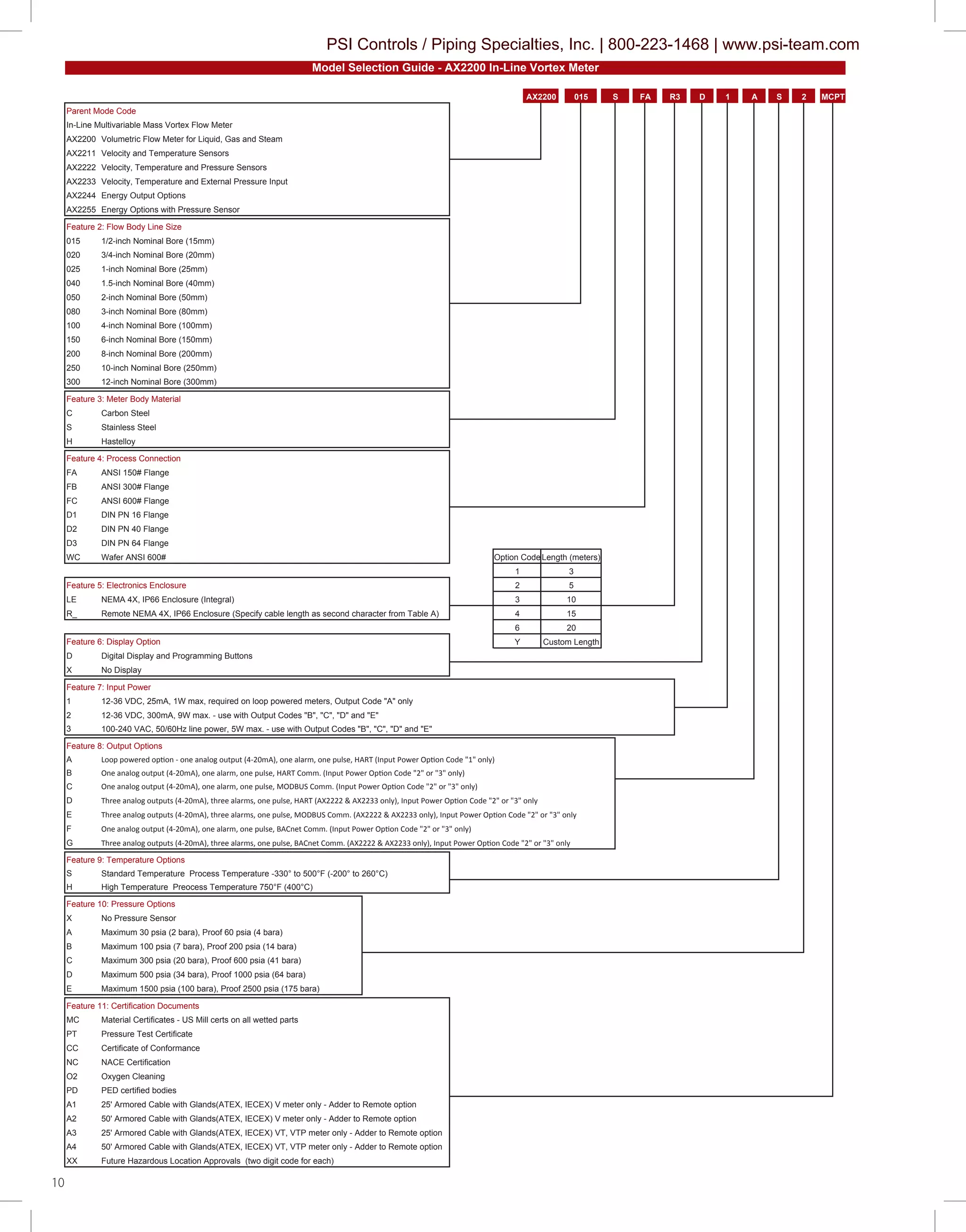

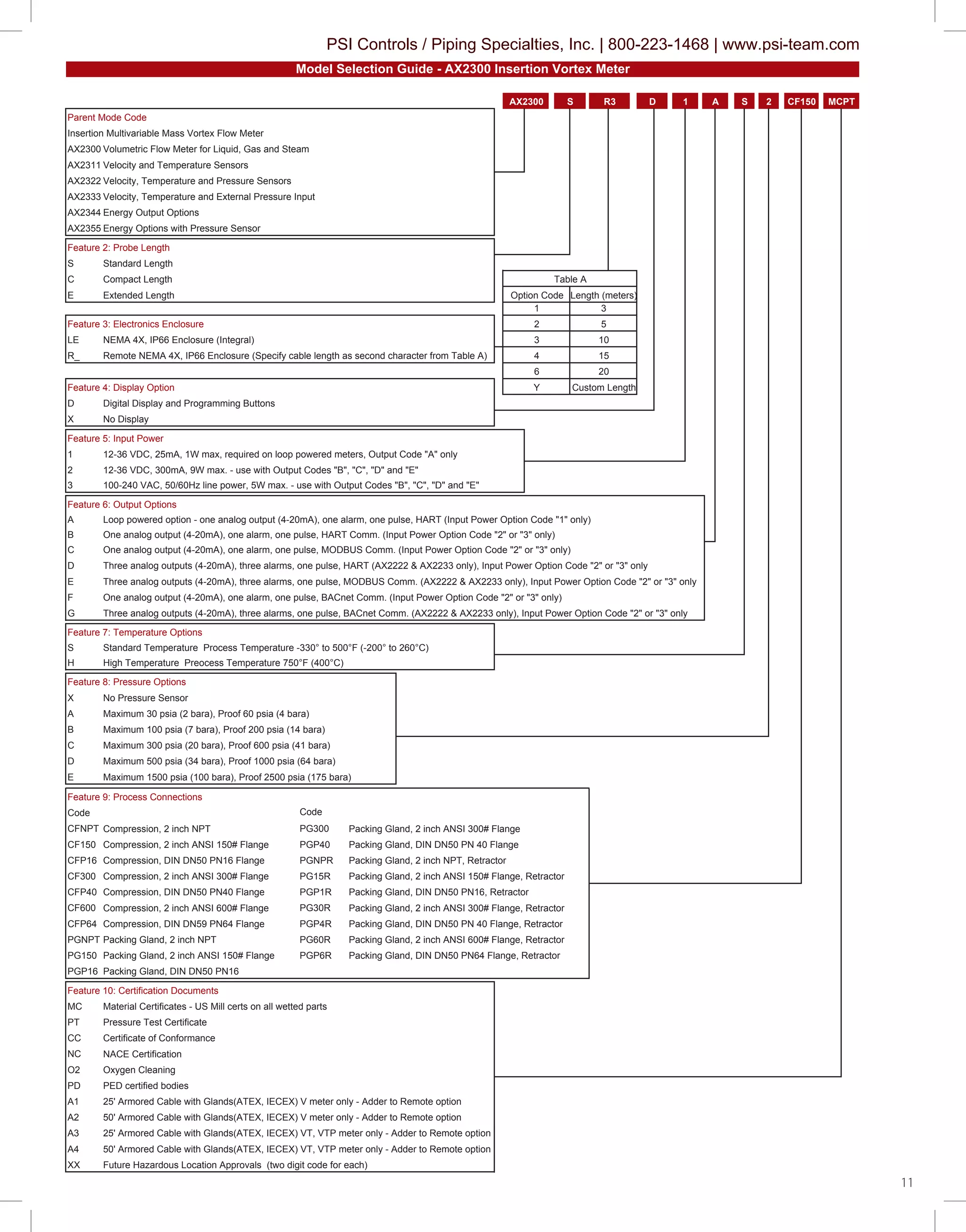

The document describes the AX series vortex meters from Azbil North America, designed to measure mass flow rates of gases, liquids, and steam with high accuracy using multiple sensors within a single housing. It outlines features such as multivariable capabilities, easy installation flexibility, remote electronics options, and energy monitoring functionalities. Various configurations and specifications are provided for different applications, emphasizing reliability and compensated mass flow readings.