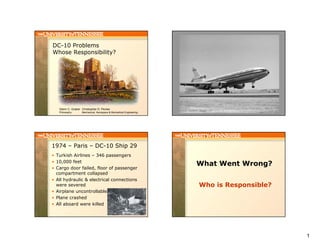

1. In 1974, Turkish Airlines Flight 981 crashed near Paris, killing all 346 passengers aboard. The crash was caused by the cargo door failing and detaching from the plane, severing hydraulic and electrical connections which made the plane uncontrollable.

2. McDonnell Douglas chose to design the DC-10 similarly to older and smaller aircraft like the DC-8 and DC-9 in the interest of speed and following a cautious approach, but this design may not have been appropriate for a wide-body aircraft. The DC-10 design incorporated fewer floor supports and other compromises compared to its competitors.

3. After another cargo door failure incident in 1972, McDonnell Douglas agreed to modify the doors but inspect