More Related Content Similar to IRC_Poster_WFTPElectrical_Final (20) 1. Wood Framing Table Project – Automation System

Edgar Tamayo, PhD Candidate in Electrical Engineering

Michael Bardwell, Engineering Physics Graduate

Supervisors: Dr. Mohamed Al-Hussein,

Dr. Jacek Olearczyk, Xiaoxi Li

Objectives

Our primary goal is to create a semi-autonomous wood framing system that is safe,

durable, and precise. To achieve this goal, our team is focusing on:

• Following CSA electrical engineering guidelines

• Purchasing top-end industrial devices from well-established companies

• Coding the workflow algorithm from scratch

Documentation

• Sensor (input) and relay/pneumatic (output) connection charts

as seen in Fig 3

• Logic flow charts as seen in Fig 4

• System power/circuit breaker calculations

• 3rd party bill of material’s

Figure 4: Cutting station

logic flow chart

Summary

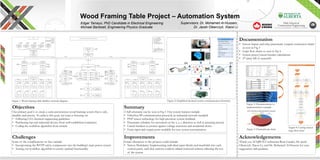

A full schematic can be seen in Fig 1. Our system features include:

• EtherNet/IP communication protocol; an industrial network standard

• PNP sensor technology for high-precision system feedback

• Pneumatic cylinders for movement in the x, y, z direction as well as actuating pistons

• Circuit breakers to protect against voltage transients and accidental shorts

• Extra input and output ports available for easy system customization

Challenges

Some of the complications we face include:

• Incorporating the WFTP safety components into the building’s main power system

• Testing our workflow algorithm to ensure optimal functionality

Figure 2: Simplified electrical system communication flowchart

Item #

Human Machine Interface 1

Programmable Logic Controller 2

Gateway 3

Input Block 4

Solenoid Valve Manifold 5

Sensor 6

Pneumatic Cylinder 7

Motor Controller 8

Motor 9

A B

1

2

6/4 3 5/7

8

9

Improvements

Future alterations to the projects could include:

• Station Modularity: Implementing individual input blocks and manifolds into each

control panel, such that stations could be added/removed without affecting the rest

of the system

Acknowledgements

Thank you ACQBUILT technician Ryan Gaudet, Dr. Jacek

Olearczyk, Xiaoxi Li, and Dr. Mohamed Al-Hussein for your

suggestions and guidance

Figure 1: Wood framing table fieldbus network diagram

WOOD FRAMING TABLE FIELDBUS NETWORK DIAGRAM

Programmable Logic Controller

TM251MESE

Human Machine Interface

HMISTU855

ENET

Left Side

ENET 490NTW00002U

Right Side

Legend

· 1ST: 1 Pin Screw Terminal

· 3ST: 3 Pin Screw Terminal

· 5ST: 5 Pin Screw Terminal

· 3WP: 3 Pin Wall Plug

· ENET: Ethernet

· CP: Cable Provided With Unit

· CB1*/CB2*/CB3*/CB4*: 14 AWG

Notes

· J1* tag is a PTI/PTO Daisy Chain

between Motor Drive on Left side and

Motor Drive on Right side. Cable

provided

EX9-AC020EN-PSRJ

ENET 490NTW00002U

P1*3ST

CP - PTI/PTO

Daisy Chain

Motor Drive

LXM32MD18M2

Ethernet Card

VW3A3616

ENET

CP – Power and Encoder

Motor Drive

LXM32MD18M2

Ethernet Card

VW3A3616

CP – Power and Encoder

Servo Motor

BMH0702T06A2A

Servo Motor

BMH0702T06A2A

CP – PTI/PTO

Daisy Chain

Motor Drive

LXM32MD18M2

Ethernet Card

VW3A3616

ENET

CP – Power and Encoder

Motor Drive

LXM32MD18M2

Ethernet Card

VW3A3616

CP – Power and Encoder

Fieldbus System – Gateway Decentralized Type

EX500GEN2

Nailing/Dragging

Input Unit

EX500DXPA

Valve Manifold

SS5Y5-11S0-13BS-N7

M12

Input Unit

EX500DXPA

Valve Manifold

SS5Y5-11S0-13BS-N7

M12 Nailing/Dragging

M12 M12

Motor Drive

JXC917

Motor Drive

JXC917

Linear Actuator

LEY25B150MGR1C918

Linear Actuator

LEY25B150MGR1C918

CP

CP

ENET

RI3

RI4

RO3

RO4

LI3

LI4

LO3

LO4

CP

EX9-AC020EN-PSRJ

M12 M12

Valve Manifold

SS5Y5-11S0-03BS-N7

Input Unit

EX500DXPA

M12 Cutting

Valve Manifold

SS5Y5-11S0-03BS-N7

M12

RI1

RI2

RO1

RO2

Drilling

Output Block

EX9-OET1

Valve Manifold

SS5Y5-11S0-03BS-N7

Valve Manifold

SS5Y5-11S0-03BS-N7

Input Unit

EX500DXPA

M12Cutting

Drilling M12

LI1

LI2

LO1

LO2

Output Block

EX9-OET1

RO5LO5

LEFT INPUTS/OUTPUTS

3 Inputs

LI4

M12

13 Inputs

LI3

M12

4 Inputs

LI1

M12

7 Inputs

LI2

M12

3 Outputs

LO1

M12

3 Outputs

LO2

M12

2 Outputs

LO4

M12

12 Outputs

LO3

M12

2 Outputs

LO5

M12

Drilling Cutting Nailing Dragging Relays

RIGHT INPUTS/OUTPUTS

3 Inputs

RI4

M12

13 Inputs

RI3

M12

4 Inputs

RI1

M12

7 Inputs

RI2

M12

3 Outputs

RO1

M12

3 Outputs

RO2

M12

2 Outputs

RO4

M12

12 Outputs

RO3

M12

2 Outputs

RO5

M12

DrillingCuttingNailingDraggingRelays

CB1* J1*

CB2*

80A Circuit Breaker

QO280

14 AWG

14 AWG

Power

14 AWG

PS1*

PS2*

PS3*

24V Power Supply

ABL8RPM24200

10 AWG

15A Circuit Breaker

9926252015

15A Circuit Breaker

9926252015

15A Circuit Breaker

9926252015

15A Circuit Breaker

9926252015

CB2*CB1* CB3* CB4*

25A Circuit Breaker

9926252025

14 AWG 14 AWG

120VAC Source

4 AWG

J1*

CB3*

CB4*

Servo Motor

BMH0702T06A2A

Servo Motor

BMH0702T06A2A

P2*

3STP3*

3STP3*

Figure 3: Documentation to

implementation example

ADDRESS

0 INPUT #0

INPUT #11

2 INPUT #2

DIGITAL INPUT

PLC: TM251MESE

3 INPUT #3

INPUT #44

5 INPUT #5

6 INPUT #6

INPUT #77

8 INPUT #8

1. ZS-1L

2.

3. JAW OPEN/CLOSE SWITCH

4.

5. DRAGGING

IN

-VDC

+VDC

CKZ2N80 BUILT-IN

QMIS-0P-0F

1. ZS-2L

2.

3. DETECTS WOOD BEHIND JAW

4.

5. DRAGGING

IN

-VDC

+VDC

1. ZS-3LA

2.

3. DETECT NAILER HORIZ. IN

4.

5. NAILING

IN

-VDC

+VDC

LJ12A3-4-Z/BY

9

10

11

1. ZS-3LB

2.

3. DETECT NAILER HORIZ. OUT

4.

5. NAILING

IN

-VDC

+VDC

LJ12A3-4-Z/BY

12

13

14

1. ZS-4LA

2.

3. DETECT CLAMP POS. A

4.

5. NAILING

IN

-VDC

+VDC

LJ12A3-4-Z/BY

1. ZS-4LB

2.

3. DETECT CLAMP POS. B

4.

5. NAILING

IN

-VDC

+VDC

LJ12A3-4-Z/BY

18

19

20

1. ZS-8LA

2.

3. TELESCOPIC CYL. PIN POS. A

4.

5. NAILING

IN

-VDC

+VDC

LJ12A3-4-Z/BY

21

22

23

1. ZS-8LB

2.

3. TELESCOPIC CYL. PIN POS. B

4.

5. NAILING

IN

-VDC

+VDC

LJ12A3-4-Z/BY

24

25

26

1. ZS-8LC

2.

3. TELESCOPIC CYL. PIN POS. C

4.

5. NAILING

IN

-VDC

+VDC

LJ12A3-4-Z/BY

9 INPUT #927

28

29

1. ZS-10L

2.

3. DETECT STOP. PLATE DIAG.

4.

5. NAILING

IN

-VDC

+VDC

D-M9PLAPC

INPUT #1010

11 INPUT #11

INPUT #1212

13

14

15

INPUT #13

INPUT #14

INPUT #15

16

17

18

INPUT #16

INPUT #17

INPUT #18

19

20

21

INPUT #19

INPUT #20

INPUT #21

22

23

INPUT #22

INPUT #23

24

COM

INPUT #24

COMMON

1. ZS-11/12LB

2.

3. DETECT TABLE UP FOR 2X6

4.

5. NAILING

IN

-VDC

+VDC

LJ12A3-4-Z/BY

1. ZS-13L

2.

3. DETECTS WOOD FRAME

4.

5. PRESENCE OF WOOD

IN

-VDC

+VDC

QMIS-0P-0F

1. ZS-14L

2.

3. DETECTS STUD

4.

5. PRESENCE OF WOOD

IN

-VDC

+VDC

OPT2040

1. ZS-15LA

2.

3. SAW POSITION ¾ CUT ON 2X4

4.

5. CUTTING

IN

-VDC

+VDC

D-M9PLAPC

1. ZS-15LB

2.

3. SAW POSITION FULL CUT ON 2X4

4.

5. CUTTING

IN

-VDC

+VDC

D-M9PLAPC

1. ZS-15LC

2.

3. SAW POSITION FULL CUT ON 2X6

4.

5. CUTTING

IN

-VDC

+VDC

D-M9PLAPC

1. ZS-16LA

2.

3. CLAMP POSITION – 2X6

4.

5. CUTTING

IN

-VDC

+VDC

LJ12A3-4-Z/BY

1. ZS-16LB

2.

3. CLAMP POSITION – 2X4

4.

5. CUTTING

IN

-VDC

+VDC

LJ12A3-4-Z/BY

1. ZS-16LC

2.

3. CLAMP POSITION – DISENGAGED

4.

5. CUTTING

IN

-VDC

+VDC

LJ12A3-4-Z/BY

1. ZS-17L

2.

3. DETECT GRIPPER FINAL POS.

4.

5. CUTTING

IN

-VDC

+VDC

LJ12A3-4-Z/BY

1. ZS-18L

2.

3. DETECT DRILL UP/DOWN

4.

5. DRILLING

IN

-VDC

+VDC

LJ12A3-4-Z/BY

1. ZS-19L

2.

3. DETECT DRILL HORIZ IN/OUT

4.

5. DRILLING

IN

-VDC

+VDC

LJ12A3-4-Z/BY

1. ZS-20LA

2.

3. DETECT CLAMP ENGAGED

4.

5. DRILLING

IN

-VDC

+VDC

D-M9PLAPC

1. ZS-20LB

2.

3. DETECT CLAMP DISENGAGED

4.

5. DRILLING

IN

-VDC

+VDC

D-M9PLAPC

1. ZS-11/12LA

2.

3. DETECT TABLE UP FOR 2X4

4.

5. NAILING

IN

-VDC

+VDC

LJ12A3-4-Z/BY

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

3

4

5

6

7

8

0

1

2

15

16

17

0V

NOTES

1. ALL CONNECTIONS MADE THROUGH EX500GEN2

LEGEND

FUSE PROTECTED

1. INSTRUMENT TAG

2. INSTRUMENT SIGNAL DESCRIPTION

3. INSTRUMENT SERVICE

4. CROSS REFERENCE DRAWING

5. FRAMING STATION

FIELD DEVICE

+24VDC WIRE TYPE JUMPER ROUTING

+24VDC

COM

Figure 5: Financials pie chart

Devices,

$6,262.28, 25%

Actuators,

$15,667.63, 64%

Accessories,

$2,395.51, 10%

Software,

$225.00, 1%

WFTP ELECTRICAL AND PNEUMATIC FINANCES