Report

Share

Download to read offline

Recommended

Recommended

Gtuit teams up with Berg Chilling Inc. to turn wellhead flare gas headaches into benefits. Using refrigeration technology, the two companies have managed to capture, reduce and recycle material that would have been burned off and wasted into the atmosphere.

Berg and gtuit system - Reduce Oil and Gas Flaring | berg chilling systems 2

Berg and gtuit system - Reduce Oil and Gas Flaring | berg chilling systems 2Berg Chilling Systems Inc.

More Related Content

What's hot

Gtuit teams up with Berg Chilling Inc. to turn wellhead flare gas headaches into benefits. Using refrigeration technology, the two companies have managed to capture, reduce and recycle material that would have been burned off and wasted into the atmosphere.

Berg and gtuit system - Reduce Oil and Gas Flaring | berg chilling systems 2

Berg and gtuit system - Reduce Oil and Gas Flaring | berg chilling systems 2Berg Chilling Systems Inc.

What's hot (20)

Development of a Gasoline Direct Injector, Nostrum Energy

Development of a Gasoline Direct Injector, Nostrum Energy

Berg and gtuit system - Reduce Oil and Gas Flaring | berg chilling systems 2

Berg and gtuit system - Reduce Oil and Gas Flaring | berg chilling systems 2

Flare Gas Recovery Innovations for Wellhead Gas Emissions

Flare Gas Recovery Innovations for Wellhead Gas Emissions

Similar to Product Review Fuel Saving Hydrosynthetic Hydraulic Fluid

PACT Carbon Capture Plant - talk by Kris Milkowski, PACT/University of Leeds, at the opening of the UKCCSRC PACT Beighton facilityPACT Carbon Capture Plant - talk by Kris Milkowski, PACT/University of Leeds,...

PACT Carbon Capture Plant - talk by Kris Milkowski, PACT/University of Leeds,...UK Carbon Capture and Storage Research Centre

Similar to Product Review Fuel Saving Hydrosynthetic Hydraulic Fluid (20)

Long term operation of a small biogasdiesel dual fuel engine for on farm elec...

Long term operation of a small biogasdiesel dual fuel engine for on farm elec...

Environment Agency Waste Technologies in Practice Conference

Environment Agency Waste Technologies in Practice Conference

Flex Leasing Power and Service Introduction Presentation 2016-02-15

Flex Leasing Power and Service Introduction Presentation 2016-02-15

Using hydrogen in SI engine as duel fuel method.pptx

Using hydrogen in SI engine as duel fuel method.pptx

PACT Carbon Capture Plant - talk by Kris Milkowski, PACT/University of Leeds,...

PACT Carbon Capture Plant - talk by Kris Milkowski, PACT/University of Leeds,...

Current Turbomachinery Projects for Energy and Power (2018)

Current Turbomachinery Projects for Energy and Power (2018)

EXPERIMENTAL INVESTIGATION ON PERFORMANCE AND EMISSION ANALYSIS OF SINGLE CYL...

EXPERIMENTAL INVESTIGATION ON PERFORMANCE AND EMISSION ANALYSIS OF SINGLE CYL...

Product Review Fuel Saving Hydrosynthetic Hydraulic Fluid

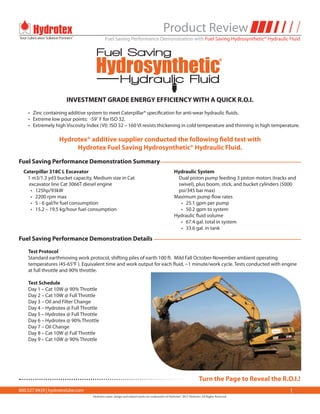

- 1. INVESTMENT GRADE ENERGY EFFICIENCY WITH A QUICK R.O.I. • Zinc containing additive system to meet Caterpillar® specification for anti-wear hydraulic fluids. • Extreme low pour points: -59˚ F for ISO 32. • Extremely high Viscosity Index (VI): ISO 32 – 160 VI resists thickening in cold temperature and thinning in high temperature. Hydrotex® additive supplier conducted the following field test with Hydrotex Fuel Saving Hydrosynthetic® Hydraulic Fluid. Fuel Saving Performance Demonstration Summary Caterpillar 318C L Excavator 1 m3/1.3 yd3 bucket capacity, Medium size in Cat excavator line Cat 3066T diesel engine • 125hp/93kW • 2200 rpm max • 5 - 6 gal/hr fuel consumption • 15.2 – 19.5 kg/hour fuel consumption Hydraulic System Dual piston pump feeding 3 piston motors (tracks and swivel), plus boom, stick, and bucket cylinders (5000 psi/345 bar max) Maximum pump flow rates • 25.1 gpm per pump • 50.2 gpm to system Hydraulic fluid volume • 67.4 gal. total in system • 33.6 gal. in tank Fuel Saving Performance Demonstration Details Test Protocol Standard earthmoving work protocol, shifting piles of earth 100 ft. Mild Fall October-November ambient operating temperatures (45-65°F ). Equivalent time and work output for each fluid, ~1 minute/work cycle. Tests conducted with engine at full throttle and 90% throttle. Test Schedule Day 1 – Cat 10W @ 90% Throttle Day 2 – Cat 10W @ Full Throttle Day 3 – Oil and Filter Change Day 4 – Hydrotex @ Full Throttle Day 5 – Hydrotex @ Full Throttle Day 6 – Hydrotex @ 90% Throttle Day 7 – Oil Change Day 8 – Cat 10W @ Full Throttle Day 9 – Cat 10W @ 90% Throttle Hydrotex name, design and related marks are trademarks of Hydrotex® 2012 Hydrotex All Rights Reserved. 1800.527.9439 | hydrotexlube.com Turn the Page to Reveal the R.O.I.! Fuel Saving Performance Demonstration with Fuel Saving Hydrosynthetic® Hydraulic Fluid Product Review

- 2. Fuel Saving Performance Demonstration Details Work Cycle Description Work Day 15 Minute Machine Warm-Up Refuel, Start Data Logger 3 Hours of Morning Work • 55 minutes continuous work, 5 minute break, Repeat 3 times 1 Hour Lunch Break • Refuel, measure fuel weight to 0.1 kg 3 Hours of Afternoon Work • 55 minutes continuous work, 5 minute break, Repeat 3 times Stop Test, Refuel, Calculate Total Fuel Consumption Take Full Scoop of Dirt Rotate 180°, Travel 100 feet Dump Load Rotate 180°, Return to Start Hydrotex name, design and related marks are trademarks of Hydrotex® 2012 Hydrotex All Rights Reserved. 2800.527.9439 | hydrotexlube.com Fuel Saving Performance Demonstration with Fuel Saving Hydrosynthetic® Hydraulic Fluid Product Review