Walter Helitronic Diamond Evolution

•

1 like•14,153 views

Walter Helitronic Diamond Evolution for Diamond and PCD Erosion. Also capable of CNC grinding of carbide and high speed steel cutting tools and body fabricating.

Report

Share

Report

Share

Download to read offline

Recommended

Technology Keeps Patient First.

Healthcare providers operate in an evolving

environment influenced by policy, regulations,

and changing technology. Yet, the number one

priority remains patient care.

In a recent survey1, nearly half (49%) of healthcare

provider executives said revamping the patient

experience is one of their organization’s top three

priorities over the next five years.

This focus is helping fuel the rise of point-ofcare

(POC) manufacturing enabled by additive

manufacturing (AM), commonly known as

3D printing.Point of Care - EOS Additive Manufacturing with Selective Laser Sintering - ...

Point of Care - EOS Additive Manufacturing with Selective Laser Sintering - ...Machine Tool Systems Inc.

Recommended

Technology Keeps Patient First.

Healthcare providers operate in an evolving

environment influenced by policy, regulations,

and changing technology. Yet, the number one

priority remains patient care.

In a recent survey1, nearly half (49%) of healthcare

provider executives said revamping the patient

experience is one of their organization’s top three

priorities over the next five years.

This focus is helping fuel the rise of point-ofcare

(POC) manufacturing enabled by additive

manufacturing (AM), commonly known as

3D printing.Point of Care - EOS Additive Manufacturing with Selective Laser Sintering - ...

Point of Care - EOS Additive Manufacturing with Selective Laser Sintering - ...Machine Tool Systems Inc.

Ariane Aerospace - Production of an injection head for rocket engines with as few components as possible and lower unit costs. EOS DMLS client. Ariane Aerospace - Production of an injection head for rocket engines using E...

Ariane Aerospace - Production of an injection head for rocket engines using E...Machine Tool Systems Inc.

Amada Machine Tools America - CNC Surface and Profile Grinder - Open House invite of Precision CNC Grinding Technology with On-Board InspectionAmada Machine Tools America - CNC Surface and Profile Grinder - Open House in...

Amada Machine Tools America - CNC Surface and Profile Grinder - Open House in...Machine Tool Systems Inc.

GF Machining Solutions - Agie Charmilles Drill 300 Series - Hole Drilling EDMGF Machining Solutions - Agie Charmilles Drill 300 Series - Hole Drilling EDM

GF Machining Solutions - Agie Charmilles Drill 300 Series - Hole Drilling EDMMachine Tool Systems Inc.

GF Machining Solutions - Agie Charmilles Drill 20 Series - Hole Drilling EDMGF Machining Solutions - Agie Charmilles Drill 20 Series - Hole Drilling EDM

GF Machining Solutions - Agie Charmilles Drill 20 Series - Hole Drilling EDMMachine Tool Systems Inc.

United Grinding - Walter Grinders - CNC Tool Grinder - Top Loader AutomationUnited Grinding - Walter Grinders - CNC Tool Grinder - Top Loader Automation

United Grinding - Walter Grinders - CNC Tool Grinder - Top Loader AutomationMachine Tool Systems Inc.

Plus Medica OT. Design, CAD engineering and production of orthoses that combine several functions, optimally tailored to the needs of the patientEOS P396 SLS user - Plus Medica OT - CAD engineering and production of orthoses

EOS P396 SLS user - Plus Medica OT - CAD engineering and production of orthosesMachine Tool Systems Inc.

Case Study: Topology Optimization & Additive Manufacturing of Actuator Support Fitting

The following is a case study of an aircraft bracket built on an EOS M280 in Aluminum AlSi10Mg optimized with Altair to improve the original design. The geometries used can only be achieved through Additive Manufacturing (AM).

EOS DMLS - Case Study: Topology Optimization & Additive Manufacturing of Actu...

EOS DMLS - Case Study: Topology Optimization & Additive Manufacturing of Actu...Machine Tool Systems Inc.

GF Machining Solutions - Microlution - Perfect Walls and Edges enable new productsGF Machining Solutions - Microlution - Perfect Walls and Edges enable new pro...

GF Machining Solutions - Microlution - Perfect Walls and Edges enable new pro...Machine Tool Systems Inc.

GF Machining Solutions - Microlution -Femtosecond laser prototyping and volume productionGF Machining Solutions - Microlution - Femtosecond laser prototyping and volu...

GF Machining Solutions - Microlution - Femtosecond laser prototyping and volu...Machine Tool Systems Inc.

GF Machining Solutions - Microlution - Catheter Ablation Tip Machining using ultra fast laserGF Machining Solutions - Microlution - Catheter Ablation Tip Machining - Ultr...

GF Machining Solutions - Microlution - Catheter Ablation Tip Machining - Ultr...Machine Tool Systems Inc.

Lofthouse Brass - far more than forgings - GF Machining Solutions - Mikron Machining CentersLofthouse Brass - far more than forgings - GF Machining Solutions - Mikron Ma...

Lofthouse Brass - far more than forgings - GF Machining Solutions - Mikron Ma...Machine Tool Systems Inc.

More Related Content

More from Machine Tool Systems Inc.

Ariane Aerospace - Production of an injection head for rocket engines with as few components as possible and lower unit costs. EOS DMLS client. Ariane Aerospace - Production of an injection head for rocket engines using E...

Ariane Aerospace - Production of an injection head for rocket engines using E...Machine Tool Systems Inc.

Amada Machine Tools America - CNC Surface and Profile Grinder - Open House invite of Precision CNC Grinding Technology with On-Board InspectionAmada Machine Tools America - CNC Surface and Profile Grinder - Open House in...

Amada Machine Tools America - CNC Surface and Profile Grinder - Open House in...Machine Tool Systems Inc.

GF Machining Solutions - Agie Charmilles Drill 300 Series - Hole Drilling EDMGF Machining Solutions - Agie Charmilles Drill 300 Series - Hole Drilling EDM

GF Machining Solutions - Agie Charmilles Drill 300 Series - Hole Drilling EDMMachine Tool Systems Inc.

GF Machining Solutions - Agie Charmilles Drill 20 Series - Hole Drilling EDMGF Machining Solutions - Agie Charmilles Drill 20 Series - Hole Drilling EDM

GF Machining Solutions - Agie Charmilles Drill 20 Series - Hole Drilling EDMMachine Tool Systems Inc.

United Grinding - Walter Grinders - CNC Tool Grinder - Top Loader AutomationUnited Grinding - Walter Grinders - CNC Tool Grinder - Top Loader Automation

United Grinding - Walter Grinders - CNC Tool Grinder - Top Loader AutomationMachine Tool Systems Inc.

Plus Medica OT. Design, CAD engineering and production of orthoses that combine several functions, optimally tailored to the needs of the patientEOS P396 SLS user - Plus Medica OT - CAD engineering and production of orthoses

EOS P396 SLS user - Plus Medica OT - CAD engineering and production of orthosesMachine Tool Systems Inc.

Case Study: Topology Optimization & Additive Manufacturing of Actuator Support Fitting

The following is a case study of an aircraft bracket built on an EOS M280 in Aluminum AlSi10Mg optimized with Altair to improve the original design. The geometries used can only be achieved through Additive Manufacturing (AM).

EOS DMLS - Case Study: Topology Optimization & Additive Manufacturing of Actu...

EOS DMLS - Case Study: Topology Optimization & Additive Manufacturing of Actu...Machine Tool Systems Inc.

GF Machining Solutions - Microlution - Perfect Walls and Edges enable new productsGF Machining Solutions - Microlution - Perfect Walls and Edges enable new pro...

GF Machining Solutions - Microlution - Perfect Walls and Edges enable new pro...Machine Tool Systems Inc.

GF Machining Solutions - Microlution -Femtosecond laser prototyping and volume productionGF Machining Solutions - Microlution - Femtosecond laser prototyping and volu...

GF Machining Solutions - Microlution - Femtosecond laser prototyping and volu...Machine Tool Systems Inc.

GF Machining Solutions - Microlution - Catheter Ablation Tip Machining using ultra fast laserGF Machining Solutions - Microlution - Catheter Ablation Tip Machining - Ultr...

GF Machining Solutions - Microlution - Catheter Ablation Tip Machining - Ultr...Machine Tool Systems Inc.

Lofthouse Brass - far more than forgings - GF Machining Solutions - Mikron Machining CentersLofthouse Brass - far more than forgings - GF Machining Solutions - Mikron Ma...

Lofthouse Brass - far more than forgings - GF Machining Solutions - Mikron Ma...Machine Tool Systems Inc.

More from Machine Tool Systems Inc. (20)

Ariane Aerospace - Production of an injection head for rocket engines using E...

Ariane Aerospace - Production of an injection head for rocket engines using E...

Amada Machine Tools America - CNC Surface and Profile Grinder - Open House in...

Amada Machine Tools America - CNC Surface and Profile Grinder - Open House in...

GF Machining Solutions - Mikron Form P Series Milling Machines

GF Machining Solutions - Mikron Form P Series Milling Machines

GF Machining Solutions - Agie Charmilles Drill 300 Series - Hole Drilling EDM

GF Machining Solutions - Agie Charmilles Drill 300 Series - Hole Drilling EDM

GF Machining Solutions - Agie Charmilles Drill 20 Series - Hole Drilling EDM

GF Machining Solutions - Agie Charmilles Drill 20 Series - Hole Drilling EDM

GF Machining Solutions - Agie Charmilles CUT P Series - Wire EDM

GF Machining Solutions - Agie Charmilles CUT P Series - Wire EDM

GF Machining Solutions - Agie Charmilles CUT E Series - Wire EDM

GF Machining Solutions - Agie Charmilles CUT E Series - Wire EDM

GF Machining Solutions - Agie Charmilles Form P Series - Die Sinking EDM

GF Machining Solutions - Agie Charmilles Form P Series - Die Sinking EDM

GF Machining Solutions - Agie Charmilles Form E Series - Die Sinking EDM

GF Machining Solutions - Agie Charmilles Form E Series - Die Sinking EDM

United Grinding - Walter Grinders - CNC Tool Grinder - Top Loader Automation

United Grinding - Walter Grinders - CNC Tool Grinder - Top Loader Automation

EOS P396 SLS user - Plus Medica OT - CAD engineering and production of orthoses

EOS P396 SLS user - Plus Medica OT - CAD engineering and production of orthoses

EOS DMLS - Case Study: Topology Optimization & Additive Manufacturing of Actu...

EOS DMLS - Case Study: Topology Optimization & Additive Manufacturing of Actu...

GF Machining Solutions - Microlution - Perfect Walls and Edges enable new pro...

GF Machining Solutions - Microlution - Perfect Walls and Edges enable new pro...

GF Machining Solutions - Microlution - Femtosecond laser prototyping and volu...

GF Machining Solutions - Microlution - Femtosecond laser prototyping and volu...

GF Machining Solutions - Microlution - Catheter Ablation Tip Machining - Ultr...

GF Machining Solutions - Microlution - Catheter Ablation Tip Machining - Ultr...

Amada America Machine Tools - CNC Grinders - June 2017 Open House

Amada America Machine Tools - CNC Grinders - June 2017 Open House

C&A Tool - implants using EOS Model M290 Additive E-manufacturing

C&A Tool - implants using EOS Model M290 Additive E-manufacturing

Lofthouse Brass - far more than forgings - GF Machining Solutions - Mikron Ma...

Lofthouse Brass - far more than forgings - GF Machining Solutions - Mikron Ma...

Recently uploaded

Differences between analog and digital communicationanalog-vs-digital-communication (concept of analog and digital).pptx

analog-vs-digital-communication (concept of analog and digital).pptxKarpagam Institute of Teechnology

Recently uploaded (20)

Complex plane, Modulus, Argument, Graphical representation of a complex numbe...

Complex plane, Modulus, Argument, Graphical representation of a complex numbe...

Research Methodolgy & Intellectual Property Rights Series 1

Research Methodolgy & Intellectual Property Rights Series 1

Involute of a circle,Square, pentagon,HexagonInvolute_Engineering Drawing.pdf

Involute of a circle,Square, pentagon,HexagonInvolute_Engineering Drawing.pdf

5G and 6G refer to generations of mobile network technology, each representin...

5G and 6G refer to generations of mobile network technology, each representin...

Introduction to Artificial Intelligence and History of AI

Introduction to Artificial Intelligence and History of AI

Introduction to Heat Exchangers: Principle, Types and Applications

Introduction to Heat Exchangers: Principle, Types and Applications

analog-vs-digital-communication (concept of analog and digital).pptx

analog-vs-digital-communication (concept of analog and digital).pptx

Fabrication Of Automatic Star Delta Starter Using Relay And GSM Module By Utk...

Fabrication Of Automatic Star Delta Starter Using Relay And GSM Module By Utk...

RM&IPR M5 notes.pdfResearch Methodolgy & Intellectual Property Rights Series 5

RM&IPR M5 notes.pdfResearch Methodolgy & Intellectual Property Rights Series 5

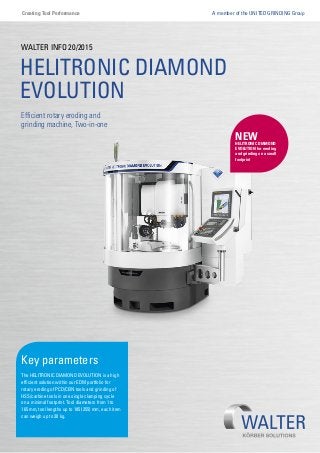

Walter Helitronic Diamond Evolution

- 1. A member of the UNITED GRINDING GroupCreating Tool Performance Key parameters The HELITRONIC DIAMOND EVOLUTION is a high efficient solution within our EDM portfolio for rotary eroding of PCD/CBN tools and grinding of HSS/carbine tools in one single clamping cycle on a minimal footprint. Tool diameters from 1 to 165 mm, tool lengths up to 185 (255) mm, each item can weigh up to 30 kg. HELITRONIC DIAMOND EVOLUTION Efficient rotary eroding and grinding machine, Two-in-one WALTER INFO 20/2015 NEWHELITRONIC DIAMOND EVOLUTION for eroding and grinding on a small footprint

- 2. 20/2015 WALTER INFO The HELITRONIC DIAMOND EVOLUTION at a glance Optimal erosion process with DIAMOND-PLUS The latest generator development “DIAMOND-PLUS” which is delivered as standard in all EDM machines, offers through the new variable accel- eration factor an optimal erosion process, independent of disturbances such as differences in material, electrode shape, stock removal, tool pro- file, etc. This means that the erosion process is continuously controlled to ensure constant quality. Such a process behavior is unique on the market. In addition, the new contour acceleration increases the eroding speed up to 40%, and with the fine finishing operation an optimal surface quality is simultaneously obtained. HELITRONIC TOOL STUDIO with integrated EDM functionality • Design, programming, simulation and production of rotationally symmetrical tools and production parts • EDM and grinding of complex tool geometries in a single clamping cycle • Built-in Wizard technology (WALTER Knowledge Base) • 3D Live simulation • Collision detection

- 3. 20/2015WALTER INFO Grinding spindle drive Max. grinding wheel diameter 150 mm Max. diameter of rotating electrode 150 mm Grinding spindle speed 0 – 10,500 rpm HELITRONIC DIAMOND EVOLUTION with belt-driven spindle Spindle ends 2 Tool holder HSK 50 Peak power 9 kW Spindle diameter 80 mm Others Paper filter Capacity approx. 350 l Tool data 1) Min. tool diameter 1 mm Max. tool diameter (vertical) 165 mm Max. tool length, complete processing 2) 185 mm Max. tool length, peripheral grinding 2) 255 mm Max. tool length, end face grinding 2) 185 mm Max. tool weight 30 kg Options Manual and automatic steady rest, manual and automatic tailstock, glass scales, extensions for robot loader, combi filter system, mist extractor, silencer, etc. Application • Rotary eroding and grinding of rotationally symmetrical tools for metalworking and woodworking industries • Cost-efficient production and / or re-sharpening • Fully automated, complete machining with only a single clamping cycle • Machinable materials include PCD, CBN, HSS, carbide, cermet, ceramic The machine • Low vibration, solid grey cast iron, gantry type construction (patented) • X, Y, Z linear axes with ball-type linear drive • A, C rotating axes with worm drives • Belt-driven spindle with two ends • Each spindle end can take up to three rotating electrodes/grinding wheels • Robot loader for HSK and cylindrical tools (option) • 3-stage rotary eroding process for highest quality finish • FANUC, the global standard for control equipment • Numerous efficiency options Software • HELITRONIC TOOL STUDIO, CAD/CAM software for design, programming, simulation and production – Now with EDM functionality • Walter Window Mode WWM • Numerous software options to extend the system’s performance and to increase its efficiency 2333 1963 1824 3101 2125 HELITRONIC DIAMOND EVOLUTION 1) The maximum tool dimensions depend on the type of tool and its geometry, as well as the type of machining. 2) From the theoretical taper diameter of the workpiece holder. Measurements in mm. Subject to modifications due to technical progress and errors. We accept no responsibility for the correctness of any information given.

- 4. HELITRONICDIAMONDEVOLUTION·Subjecttoalterations·PrintedinGermany·178·V1·06/2015·en Walter Maschinenbau GmbH Jopestr. 5 · D-72072 Tübingen Tel. +49 7071 9393-0 Fax +49 7071 9393-695 info@walter-machines.com For worldwide contact details, please visit www.walter-machines.com