Aerospace Engineer Resume Summary

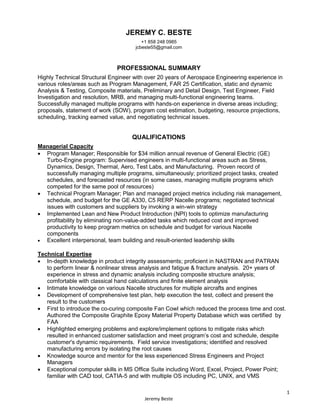

- 1. 1 Jeremy Beste JEREMY C. BESTE +1 858 248 0985 jcbeste55@gmail.com PROFESSIONAL SUMMARY Highly Technical Structural Engineer with over 20 years of Aerospace Engineering experience in various roles/areas such as Program Management, FAR 25 Certification, static and dynamic Analysis & Testing, Composite materials, Preliminary and Detail Design, Test Engineer, Field Investigation and resolution, MRB, and managing multi-functional engineering teams. Successfully managed multiple programs with hands-on experience in diverse areas including; proposals, statement of work (SOW), program cost estimation, budgeting, resource projections, scheduling, tracking earned value, and negotiating technical issues. QUALIFICATIONS Managerial Capacity Program Manager; Responsible for $34 million annual revenue of General Electric (GE) Turbo-Engine program: Supervised engineers in multi-functional areas such as Stress, Dynamics, Design, Thermal, Aero, Test Labs, and Manufacturing. Proven record of successfully managing multiple programs, simultaneously; prioritized project tasks, created schedules, and forecasted resources (in some cases, managing multiple programs which competed for the same pool of resources) Technical Program Manager; Plan and managed project metrics including risk management, schedule, and budget for the GE A330, C5 RERP Nacelle programs; negotiated technical issues with customers and suppliers by invoking a win-win strategy Implemented Lean and New Product Introduction (NPI) tools to optimize manufacturing profitability by eliminating non-value-added tasks which reduced cost and improved productivity to keep program metrics on schedule and budget for various Nacelle components Excellent interpersonal, team building and result-oriented leadership skills Technical Expertise In-depth knowledge in product integrity assessments; proficient in NASTRAN and PATRAN to perform linear & nonlinear stress analysis and fatigue & fracture analysis. 20+ years of experience in stress and dynamic analysis including composite structure analysis; comfortable with classical hand calculations and finite element analysis Intimate knowledge on various Nacelle structures for multiple aircrafts and engines Development of comprehensive test plan, help execution the test, collect and present the result to the customers First to introduce the co-curing composite Fan Cowl which reduced the process time and cost. Authored the Composite Graphite Epoxy Material Property Database which was certified by FAA Highlighted emerging problems and explore/implement options to mitigate risks which resulted in enhanced customer satisfaction and meet program’s cost and schedule, despite customer's dynamic requirements. Field service investigations; identified and resolved manufacturing errors by isolating the root causes Knowledge source and mentor for the less experienced Stress Engineers and Project Managers Exceptional computer skills in MS Office Suite including Word, Excel, Project, Power Point; familiar with CAD tool, CATIA-5 and with multiple OS including PC, UNIX, and VMS

- 2. 2 Jeremy Beste EXPERIENCE Adecco – Contract Services (2009 - Present) Stress Lead: UTAS – GTF EBU EMB 190/195 (2013 - Present) Key contributor identifying Certification and Qualification, Testing and Analysis Requirements Knowledge source for EBU design and analysis Mentored less experienced Project managers and Stress engineers Responsible for preliminary program scheduling and defining work scope Developed program qualification plan, meeting all customers’ requirements Successfully prepared and presented PDR and CDR analysis; summarized programs qualification requirements and obtained approval to release engineering Stress Lead: UTAS – GTF Engine Mount Testing (BA and MRJ) (2011-2013) Responsible for writing the Static, Fatigue, Damage Tolerance and Crack Growth Test Plans for BA and MRJ programs Authored Static Stress Report for the PW Detailed Design Phase deliverable Developed Engine Mount Tension Bolt Test Plan; wrote and presented the Test Report to customer Main contributor for the stress analysis and signoff of the Engine Mount Test Fixtures Created the FBO Engine Mount Strain Gage Calibration Test Plan, as well as the Test Report and presented to customer Recognized with the Production & Product Development Enterprise Excellent Award Stress Lead: Goodrich – GTF EBU (BA and MRJ) (2010-2011) Key contributor for the initial Layout and Preliminary Design for PW GTF EBU (BA and MRJ) systems Responsible for interfacing with ITP (Goodrich supplier) for preliminary design and stress analysis Final reviewer for ITP stress analysis for completeness Presented Stress Analysis at CDR Stress Lead: Goodrich – JSTARS EBU (2009 – 2010) Responsible for analysis and define work scope for the JSTARS re-engine program Key coordinator/negotiator with customers for technical requirements Oversaw technical content of stress team deliverables Triumph Engineering Corp. – Contract Services (2003 - 2009) Test Engineer: GE Aviation - Global Tanker Transport Aircraft (GTTA) (2009) Responsible for overseeing the schedule and integrity of the Boeing 767 GTTA Fire suppression testing Managed the Hydraulic Drum Unit (HDU) and Wing Aerial Refueling Pod (WARP) Fire test program, including procurement of parts, assembly and conformity of test units Solely authored an innovative Fire suppression system test plan for the HDU and WARP which FAA approved Main contributor of the Solid Propellant Fire Extinguisher procurement specification which resulted GE Aviation acceptance of the test units Composed the fire suppression test procedure providing a detailed checklist to sequence testing Coordinated closely with FAA Fire DERs and GE subject matter experts to establish all test parameters including pass-fail and airflow requirements

- 3. 3 Jeremy Beste Chief Engineer: Industrial Tube Corporation (ITC) on Boeing 787 (2007) Presented technical findings at GE DDR, allowing ITC to go into production Developed Certification Requirements and co-authored the Qualification Test Plan GE on-site Representative: Goodrich Aerostructures (2002 – 2009) Contracted with GE providing on-site Program Management at Goodrich Aerostructures for the EMB 190 and 195, the C5 RERP and the CX Nacelle Certification programs Intimate knowledge with Nacelle components including Inlet, Fan Cowl, Thrust Reverser, Nozzle, Exhaust and EBU Selected to supervise Engine and Nacelle hardware installation for the CX First Engine To Test in Nagoya, Japan Witnessed and approved several tests for GE, including; composite material coupon testing, sub-element testing, sub-component testing, and fire certification testing Managed multi-partner engineering teams for the development of EMB 195/195 Certification loads Envisioned an Integrated Finite Element Model (IFEM), and loads down select process that GE documented as a Black Belt project. The project’s solution enabled all partners to use NASTRAN’s IFEM super-element technology Senior Aerospace, Ketema Division (2002) Program Manager: GE Turbo-Engine Developed and managed master schedule for engineering and manufacturing requirements to meet the customer needs for $34 million annual revenue program Managed the cost vs. task progress to ensure earned value remains on track Identified and executed corrective actions to resolve essential issues which impacted the program’s cost, quality, and schedule Implemented mitigation plans to meet customer’s dynamic needs. Utilized the NPI process through various stages of development into production and to introduce new and prototype hardware into production Goodrich Aerostructures (1985 - 2002) Technical Program Manager: GE A330 Nacelle & GE C5 RERP Nacelle (1999-2002) Responsible for the technical requirements from proposal through production for GE A330 program ($100 million) and for GE C5 RERP program($250 million) Negotiated business and technical requirements with customers and vendors to obtain mutually acceptable resolutions Managed the C5 RERP SOW proposal by defining the Scope of Work for the program, generating the work break down structure, establishing Risk Assessment Matrix, projecting resource needs and estimating and tracking cost and schedule. Prioritized project tasks, established program metrics and schedules, and tracked program performance to meet the programs metrics Successfully led several Kaizen events; identified several critical items which resulted in significant cost savings with reduced takt time: eliminated a 24-hour curtain operation with a simple 10-minute procedure; replaced a non-functional composite door with the basic honeycomb bond panel During the technology transfer of the A330 Inlet to Toulouse, France, A330 cell takt time was significantly improved through time observations and standard work Main liaison/coordinator for engineering changes between Goodrich facilities in Toulouse, France and San Diego, California Resolved production integrity issues with Airbus, Boeing, GE, and with other multiple airlines

- 4. 4 Jeremy Beste Group Engineer: GE Programs (1996-1999) Managed several CF6-80 Nacelle product lines (Inlet, Fan Cowl, Core Cowl, Nozzle, Exhaust, Engine Mounts and EBU) on the following airframes: A300, A330, MD11, B747, B767, and C5 RERP Supervised multi-functional (stress, dynamics, design, thermal, aero, manufacturing) teams for the successful restart of the A330 program into production and resolved customer inquiries on field service issues identifying root cause and implementing appropriate corrective actions. Program goals were reached in reducing manufacturing costs while addressing outstanding field issues Defined scope of work: created and maintained schedule, and resource projections Developed a "Point-of-Use" tool to monitor the engineering changes and to control engineering data Integrated Product Team Lead: C2 Product Improvement Program (PIP) (1993–1996) Successfully introduced the CF6-80 C2 PIP into revenue service. The PIP incorporated several enhancements that provides a reliable, light weight, and lower cost Nacelle package for the Boeing 747, 767, and MD11 Supervised multi-functional (stress, dynamics, design, thermal, aero, composite layup, metal bond, test lab) teams to obtain FAA FAR 25 Certification Authored the Co-cured Graphite Epoxy Material Property Database, which was certified by FAA First to introduce single stage metal-bond and composite co-cured panels into revenue service These new processes reduced labor hours, autoclave cure cycles, and shop consumables while improving flow time Received Boeing’s Achievement award for successfully introducing the Boeing 464-400ER PIP Nacelle Technical Staff : GE90, A330, MD11, YF22 ATF, F14 A+ (1985-1993) Analyzed and documented the GE90 Forward Fan Case In charge of field service, dealt with issues including failure investigation, customer interface, and detailed stress analysis Key contributor for the detail static and fatigue stress analysis, and writing certification reports for MD11 and E1 Inlet, Fan Cowl, and Engine Build Up components Solely responsible for the coordination of design and analysis between Goodrich and multiple suppliers Contributed to the YF22 Advance Tactical Fighter (ATF) Bay Doors for the Nozzle “C” programs Stress Lead for the successful Recertification of the F14 A+ re-engine program General Dynamics Convair (1982-1985) Structures Engineer /Technical Staff : Atlas Centaur Program Solely responsible for the analysis to qualify the Fleet Sat Communication payload adapter Key contributor of the Material Review Board resolving manufacturing discrepancies EDUCATION B.S. Structural Engineering, University of Illinois - Chicago Circle (1982) Postgraduate Aerospace Engineering study at San Diego State University (1982-1986)