STABILISATION/SOLIDI FICATION OF SYNTHETI C NORTH SEA DRILL CUTTINGS CONTA INING OIL AND CHLORI DE

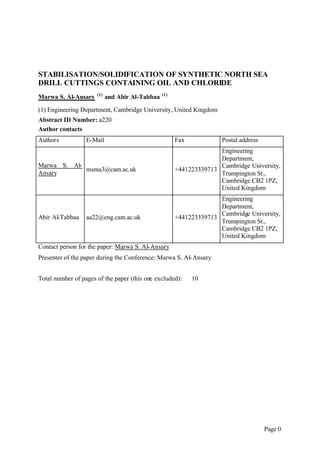

- 1. Page 0 STABILISATION/SOLIDIFICATION OF SYNTHETIC NORTH SEA DRILL CUTTINGS CONTAINING OIL AND CHLORIDE Marwa S. Al-Ansary (1) and Abir Al-Tabbaa (1) (1) Engineering Department, Cambridge University, United Kingdom Abstract ID Number: a220 Author contacts Authors E-Mail Fax Postal address Marwa S. Al- Ansary msma3@cam.ac.uk +441223339713 Engineering Department, Cambridge University, Trumpington St., Cambridge CB2 1PZ, United Kingdom Abir Al-Tabbaa aa22@eng.cam.ac.uk +441223339713 Engineering Department, Cambridge University, Trumpington St., Cambridge CB2 1PZ, United Kingdom Contact person for the paper: Marwa S. Al-Ansary Presenter of the paper during the Conference: Marwa S. Al-Ansary 11 Total number of pages of the paper (this one excluded): 10

- 2. Page 1 STABILISATION/SOLIDIFICATION OF SYNTHETIC NORTH SEA DRILL CUTTINGS CONTAINING OIL AND CHLORIDE M.S. Al-Ansary (1) and A. Al-Tabbaa (1) (1) Engineering Department, Cambridge University, United Kingdom Abstract On the UK Continental Shelf, up to 80,000 tonnes wet weight of oily drill cuttings are produced annually. These are heterogeneous wastes generated from the petroleum drilling industry, composed of significant percentages of hydrocarbons, heavy metals and chlorides. Since 1992, the discharge of drill cuttings containing more than 1% oil-on-cuttings has been prohibited. Moreover, the extensive increase in tipping fees, imposed by the Landfill Tax in October 1996, has hindered the landfilling of drill cutting as a viable option. Therefore, drill cuttings are a big problem for which the petroleum industry is keen to find solutions. This paper examines the use of stabilisation/solidification (S/S) as a technique to treat North Sea drill cuttings either as a pre-treatment prior to landfilling or for potential re-uses in construction products. Given the known difficulties with stabilising/solidifying oils and chlorides, this paper uses synthetic typical North Sea drill cutting mixes which contain typical average concentrations of hydrocarbons (4.2% w/w) and chloride (2.03% w/w) only to compare the ability of the different binder systems to treat them. A number of conventional S/S binders, namely Portland cement, hydrated lime, pulverised fuel ash and blastfurance slag, as well as novel binders, namely MgO cements, zeolites, silica fume, cement kiln dust, and compost were used. The water to dry binder ratio used was 0.4:1 and the dry binder content by weight was up to 30%. A set of physical tests (unconfined compressive strength), chemical tests (NRA leachability) and micro-structural examinations (using SEM) were conducted on the different mixes. The paper presents the behaviour of the various drill cuttings and binder mixes and compares their relative performance. Key words: stabilisation/solidification, drill cuttings, petroleum industry, North Sea, industrial by-products, wastes. 1. INTRODUCTION Drill cuttings are one of the inevitable wastes generated from the drilling process of oil exploration activities. Drill cuttings are heterogeneous wastes that are composed of significant percentages of hydrocarbons, water, heavy metals and water-soluble salts such as chlorides and sulphates. The cuttings are produced when the drilling activity commences with continuously pumping down a fluid known as ‘drilling mud’ into the drill pipe. Not only does the drilling mud provide the necessary lubrication and hydrostatic head that prevents the collapse of the pipe walls, but it also transports the rock debris (i.e. drill cuttings) to the surface, as shown in Figure 1(a). On return to the drilling facility, the mixture of cuttings and mud are processed in a circulation system in order to clean the cuttings and recover as much of the mud as possible [1]. The recycled drilling mud is reused again in the drilling, while the drill cuttings are either discharged at the seabed (before 1992) or disposed of in landfill.

- 3. Page 2 Figure 1(b) shows a sample of North Sea drill cutting that is dark in colour with a pungent odour. Figure 1: (a) Offshore Drilling Activity Generating Drill Cuttings, (b) raw drill cuttings and (c) treated drill cuttings by thermal desorption Drilling mud is a dense, sophisticated and extremely expensive material composed of many chemical compounds. Depending on the type of the base fluid, there are three kinds of drilling mud: water-based mud (WBM), oil-based mud (OBM) and synthetic-based mud (SBM) as in Table 1 which presents their relative merits. The typical composition of the drilling mud is reported in Table 2 [2]. Table 1: Comparison between the merits of drilling mud/fluid systems Criteria Water-based mud (WBM) Oil-based mud (OBM) Synthetic-based mud (SBM) Least Cost 1 2 3 Environmental Friendly 2 3 1 Technicality 2 3 1 Safety 2 3 1 Base Material Water Diesel Oleaginous (oil-like) Table 2: Typical drilling mud composition [2] Compound WBM (%w/w) OBM/SBM (%w/w) Barite 57.6 69.5 Base oil 25.8 Bentonite 4.1 0.3 Calcium chloride 2.0 Caustic soda 1.2 Emulsifiers 1.8 Oil wetting agent 0.1 Polyanionic cellulose (PAC) 1.2 Salt 33.0 Soda Ash 1.0 Starch 1.2 Xanthan 0.5 Other 0.2 0.5 Drill Mud Circulation System Recycled Mud Drill Cuttings + Mud Drill Cuttings contaminated with oil and chemicals (b)(a) (c)

- 4. Page 3 Factors affecting the choice of the correct drilling mud include: formation lithology and pressure, well design, strength and temperature, logistics and rig type, and environmental and health considerations [1]. The main drilling mud in the North Sea platforms is either water- based or synthetic-based system, while oil-based mud has been banned since 1984 because of its hazardous diesel content. The physical characteristics and the chemical composition of the drill cuttings vary significantly according to the type of drilling mud used, local geology, oil well location, oil operator and drilling techniques, recovery technique, exposure/disposal scenarios of the cuttings, weathering and bacterial conditions. 2. LEGISLATIONS AND LAWS Significant negative ecological impacts have been experienced adjacent to many oil and gas platforms in the North Sea when the cuttings are discharged to the seabed [2] and [3]. This is reflected in the recent stringent environmental regulations issued under European legislation, particularly the UK legislation controlling the discharge of the drill cuttings from the North Sea platforms. One of the main areas of legislature governing the discharge of drill cuttings in the North Sea is the Oslo and Paris Commission (OSPARCOM) Decisions 92/2 and 2000/3, which prohibits any discharge at sea for oil-based mud (OBM) cuttings containing more than 1% oil-on-cuttings by weight. In compliance with OSPARCOM, the UK has ceased any discharge of mineral oil contaminated cuttings into the sea since January 1997. It is predicted that more rigorous forthcoming legislation will be imposed on the discharge of both water-based mud (WBM) and synthetic based mud (SBM) cuttings [4]. Moreover, the UK Department of Trade and Industry (DTI) had reached an agreement with the UK operators to have Zero discharge of cuttings by the end of year 2000 [5]. From April 2004, drill cuttings will no longer be classified as ‘special waste’ in the UK, but will fall within the EU Directive’s definition of ‘hazardous waste’ [6]. Therefore, if the cuttings are to be disposed of to landfill, the cuttings will be charged at the standard rate for active wastes under the UK landfill tax (which now stands at £14/tonne). On the other hand, from July 2004 there will be no permitted hazardous waste landfills in Scotland [6]. Similarly, in England and Wales the number of hazardous landfill will be reduced. Therefore, the tipping fees will increase markedly over the next 3 years as the availability of landfills is reduced and hazardous landfills become rare in the UK. Consequently, the UK petroleum industry is currently facing a pressing need to manage the quantity and composition of drill cuttings. 3. TREATMENT METHODS AND CURRENT PRACTICE The petroleum industry’s current practice is to treat the cuttings before any re-use or disposal option in order to remove oil from the cuttings and to reduce the leachability of other contaminants. However, the presence of high percentages of contaminants is the main hindrance to the reuse option. Current treatment methods include bioremediation in-situ, bioreactors, land farming, re-injection, respreading, thermal desorption, mechanical separation, distillation, stabilisation and combustion. Figure 1(c) shows a sample of drill cuttings treated by thermal desorption. Suggested applications for the treated drill cuttings [5] include their reuse in: (a) concrete products such as concrete/cement, aggregate, blocks and bricks, (b) coastal defence, (c) land reclamation, (d) roads and cycle paths, (e) pipe beddings, (f) landfill cell construction, (g) landscaping applications such as noise abatement mounds, fill material, top soil admix and embankments in a brackish environment, and (h) as a fuel. 4. STABILISATION/SOLIDIFICATION (S/S) TREATMENT Solidification is defined as a process converting waste into a durable, dense and monolithic entity with structural integrity that is more compatible for storage, landfill, or reuse [7].

- 5. Page 4 Stabilization is a chemical process used to minimise the hazardous potential and leachability of waste by converting the contaminants into a form, which is less soluble, mobile, or toxic [7]. S/S has many advantages since it requires minimal energy input and results in minimal emissions to air [5]. However previous work has faced some limitations and disadvantages in terms of utilising this technique to treat drill cuttings [4] and [5]. The problems mainly resulted from the interference of high concentrations of organic compounds, chlorides and bentonite with the hardening and the curing processes of cement. Furthermore, the presence of high percentages of chloride prohibited the use of drill cuttings in reinforced concrete applications. Very little work has been published in the UK and elsewhere describing the use of S/S in the treatment of drill cuttings and most has been related to subsequent landfilling rather than reuse [8]. One UK source reported that S/S with cement or pulverised fuel ash (PFA) is a viable solution [4] and concluded that the disadvantage of this option is the high embodied energy from cement, transportation of the additives and increased bulk material for disposal. There are few works that have been published describing the use of S/S technique in order to treat drill cuttings for further use. A source in Turkey used kalonite, gypsum, bentonite, clinker, lime and fly ash to stabilise drill cuttings prior to landfilling and for use in road construction applications [9]. A source in Algeria recommended the stabilisation of drill cuttings with the addition of 70% of a hydraulic binder for subsequent use as a sub-base material in road construction [10]. 5. NORTH SEA CASE STUDY Between 1986 and 1995, 313 wells (on average) were drilled in the North Sea each year. It is estimated that about 1,000 tonnes of cuttings will be generated from each well if drilling continues at this rate. Therefore, over 300,000 tonnes of drill cuttings may be produced annually [5]. However, the UK Continental Shelf (UKCS) is currently estimated to produce between 50,000 to 80,000 tonnes wet weight of oily drill cuttings annually [4]. On the other hand, the old drill cuttings piles located at the North Sea bed are approximately equal to 1.3 million cubic meters, which has been built up on the North Sea bed in different locations [3]. 5.1 Physical and chemical characteristics of the drill cuttings in the North Sea Different studies have been carried out to understand the physical characteristics and chemical composition of the drill cuttings in the North Sea, which vary significantly from one oil well to another. The studies were mainly carried out by two organisations RF- Rogaland Research (Norway) and UKOOA (the United Kingdom Offshore Operators Association), in addition to other commercial and academic endeavours. The data gathered were from the following oil wells: Alwyn, Beatrice, Beryl B, Case N4, Clyde, Cod, Fulmar A, Heather A, NW Hutton, Nelson, Niniam, Oseberg B, Oseberg C and Ekofisk [1-5 and 11-13]. Due to the heterogeneous nature of the composition of drill cuttings, many contamination scenarios can be considered. However, most of the data on the drilling mud and cuttings were highly classified and confidential. In this research, the experimental methodology is based on processing the available published data from the literature and personal communications. This provided the range of values, shown in Table 3, from which the statistical average composition of the North Sea drill cuttings was calculated and used. The main contaminants were found to be hydrocarbons, chlorides, barium (from barium sulphate (barite) which is a weighing agent in the drilling mud and is the main cause of the high pH of the cuttings), zinc, chromium, lead and iron. The case considered here is of hydrocarbon and chloride contamination only.

- 6. Page 5 Figure 2: Synthetic drill cuttings Table 3: Range of properties of the North Sea drill cuttings Property Value Property Value Particle size 4 µm – 20mm Liquid Limit 33 – 70% Gravel 1 – 7% Plastic Limit 16 – 35% Sand 8 – 33% Plasticity Index 14 – 32% Silt 37 – 62% Density 1.3 – 2.7g/cm3 Clay 16 – 25% Shear Strength 1.2 – 40kN/m2 Water content 14 – 35% PH 8 – 10.1 Hydrocarbons Up to 22.4% Chloride Up to 3.5% 5.2 Experimental methodology The full experimental programme considered a number of contaminant scenarios, which include a combination of average and maximum concentration and different contaminant combinations. In this paper however the special case of contamination of hydrocarbons and sodium chloride alone is being considered. This is because conventional binders have been shown to be generally ineffective in the S/S of these two contaminants. Hence the paper discusses the results of the North Sea case study representing the averages of organic compounds (4.20% w/w) and chlorides (2.03% w/w i.e. 3.32% NaCl) only. 5.2.1 Drill cutting mixes Since the soil strata and contaminant levels vary significantly from one location to another in the North Sea, it was important to use synthetic drill cuttings. A number of trial soil mixes were produced and tested in order to ensure behaviour similar to the real drill cuttings. The hydrocarbon contaminants were modelled using paraffin oil and the chloride using sodium chloride. The properties of the selected mixed are shown in Table 4. It was noticed that the addition of paraffin oil and sodium chloride did not significantly affect the Atterberg limits. Sodium hydroxide was added to the soil mix in order to provide an alkaline medium of the cuttings. Table 4: The synthetic drill cuttings and their properties 5.2.2 Binder system Ten different binders were utilised to treat the soil mixes as summarised in Table 5 and described below. Apart from the PC only binder, all the other binders contained 50% PC except MgO-cement 1 which contained only 2% PC. The water to dry binder ratio used was 0.4:1. The two groups of binders that were used were as follows: (a) Conventional binders: - Portland Cement (PC) - Hydrated lime - Pulverised fly ash (PFA) or Fly Ash (Class F), a stable, fine powder, which is a by-product from the combustion of pulverised coal in coal-fired power stations - Blastfurnace slag (BFS), which is a by-product, produced from the iron manufacturing process by chemical reduction in a blast furnace Soil composition Value Property Value Sand content 10% Water content 27% Silt (rock flour) content 50% pH 9 Clay 1 (Polywhite kaolin E-grade) 20% Plastic Limit 24.6% Clay 2 (calcium bentonite) 20% Liquid Limit 50.6% Paraffin oil of dry soil 4.2% Sodium Chloride 3.32%

- 7. Page 6 (b) Novel binders: - MgO-cement, which is a mixture of PC, PFA and reactive magnesia and is argued to be a more sustainable type of cement than PC [14]. The magnesia in the MgO-cement hydrates to give brucite and carbonates to give magnesite and hydromagnesite - Zeolites (Clinoptilolite), which is an aluminosilicate mineral that has a rigid, 3-D crystalline structure. The zeolite framework is similar to a honeycomb consisting of interconnected tunnels and cavities allowing the free movement of water in and out of the structure while the framework remains rigid - Cement kiln dust (CKD), which is a by-product from the manufacturing of PC - Compost (Coir), which is peat free compost produced from the coir element of coconut husks - Silica fume/microsilica, which is a by-product from electric arc furnaces that are used in the manufacture of ferrosilicon or silicon metal Table 5: Summary of the binder systems used 5.2.3 Sample preparation and testing The solid constituents of the drill cuttings were first mixed together with the water, to which the sodium chloride and sodium hydroxide were added; and the paraffin oil was then added. The wet binder was then prepared and added to the drill cuttings. The dry binder content by weight was 10%, 20% and 30%. After thorough mixing, the drill cuttings and binder mixes were placed into cylindrical moulds (50mmx100mm) and left to cure for 28 days at a temperature of 21 ± 2°C and a relative humidity of 93% ± 3%. It was observed that due to the relatively high oil content, pockets of oil formed which appeared as voids within the outer surface of the samples and thus some oil leaked out of the samples on demoulding. Up to three samples from each mix were tested for their unconfined compressive strength (UCS), leachability and leachate pH and microstructure using SEM. 5.3 Experimental results and discussion A set of physical and chemical tests together with microstructural examinations was conducted on the different mixes. These are presented in separate sections below. 5.3.1 Unconfined compressive strength (UCS) A summary of the UCS at 28 days is presented in Figure 3. The different mixes were presented in the order of their relative strength at 30% dry binder content. The UCS results reveal that the PC, BFS-PC and microsilica-PC produced the highest UCS although not in the same order as the dry binder content changed. On the other hand, the compost-PC and MgO- cement 1 mixes yielded the lowest strength at all binder contents. For all the mixes the UCS Binder system Dry binder composition Ratio by weight of dry binder Water: dry binder 1 PC PC 1 0.4 : 1 2 MgO-cement 1 PFA : MgO : PC 90 : 8 : 2 0.4 : 1 3 MgO-cement 2 PFA : MgO : PC 4 : 1: 5 0.4 : 1 4 Zeolite (Clinoptilolite) Zeolite : PC 1 : 1 0.4 : 1 5 Microsilica Microsilica : PC 1 : 1 0.4 : 1 6 Compost (Coir) Compost : PC 1 : 1 0.4 : 1 7 Hydrated Lime Lime : PC 1 : 1 0.4 : 1 8 Blast Furnace slag BFS : PC 1 : 1 0.4 : 1 9 Pulverised Fly Ash PFA : PC 1 : 1 0.4 : 1 10 Cement Kiln Dust CKD : PC 1 : 1 0.4 : 1

- 8. Page 7 increased as the dry binder content increased. For the 10% dry binder addition, the UCS ranged between 92kN/m2 and 1,584kN/m2 , for the 20% between 133kN/m2 and 3,543kN/m2 and for 30% binder addition between 183kN/m2 and 4,708kN/m2 . Figure 3: UCS at 28 days of all binders Depending on the management scenario of the treated material, different minimum values of UCS apply. For burial purposes the UCS value can be as low as 140kN/m2 [15], for the production of blocks and bricks and for load bearing concrete materials the values would be much higher at 3MN/m2 and 7MN/m2 respectively [8]. Lower UCS value could find applications in areas where low-grade materials are acceptable or simply to be used as improved ground. Given the very wide range of UCS values above, all the mixes, based on their UCS values, are likely to find suitable applications. 5.3.2 Leachability The NRA leaching test [16] is the UK-approved leaching test in which 100g of the mix, after reducing it particle size to less than 5mm, are mixed with 1 litre of an extraction fluid and agitated for 24 hours. The extraction fluid used was de-ionised water, which was carbonated down to a pH of 5.6. The leachates of 28-day mix samples were analysed for chloride using ion chromatography (IC) and the results are summarised in Figure 4. The original chloride content in drill cuttings of 2.03% is equivalent to 20,300mg/kg. This means that the maximum leached chloride concentrations in the leachate test in the worst-case scenario for 10%, 20% and 30% dry binder mixes would be 17,800, 15,850 and 14,290mg/kg, respectively. The results in Figure 4 show that for the 10% dry binder mixes the chloride content in the leachates ranged between 10,670 and 16,640mg/kg, for the 20% binder mixes between 12,020 and 14,680mg/kg whilst for the 30% binder mixes between 9,970 and 13,910mg/kg. Figure 4 shows that in most cases the leached concentration decreased as the dry binder content increased with the zeolite-PC mix being the main exception to this rule. The 30% dry binder mixes generally performed the best with PC, PFA-PC, Lime-PC and MgO-cement 2 mixes giving the best results. Concentrations were typically reduced by up to 31% of the original concentrations in the drill cuttings. The UK landfill acceptance criteria limit values for chloride concentrations in compliance leaching tests are 800mg/kg, 15,000mg/kg and 25,000mg/kg for inert waste, stable non–reactive hazardous waste and hazardous waste respectively [17]. This shows that all binder mix concentrations exceeded the PC BFS-PC Microsilica-PC Zeolite-PC CKD-PC PFA-PC MgO-Cement2 Lime-PC Compost-PC MgO-Cement1 30% 20% 10% 0 500 1000 1500 2000 2500 3000 3500 4000 4500 5000 UCS(kN/m2)

- 9. Page 8 limit value for inert waste but the 20% and 30% binder mixes are all below that for the non- reactive hazardous waste. These results show that the drill cuttings have at least been reduced from a hazardous to a non-reactive hazardous waste. Figure 4: Chloride leachability from all the mixes at 28 days The oil leaching was measured by the Partition-Gravimetric method, which is a crude method, used in order to compare the relative ability of the different binder mixes to reduce the paraffin oil concentration. In this test dissolved or emulsified oil is extracted from water by intimate contact with an extracting solvent, in this case toluene. Figure 5 shows the leachate concentrations of the paraffin oil, which indicate that microsilica-PC, MgO-cement 2 and MgO-cement 1 are the best mixes for all the dry binder contents. In addition, the PC, compost-PC and BFS-PC mixes performed very well for the 20% and 30% dry binder mixes. It is worth noting that the compost-PC 30% dry binder mix absorbed most of the oil. Figure 5: Leachability of the paraffin oil from all the mixes at 28 days The original paraffin oil content in drill cuttings of 4.20% is equivalent to 40,200mg/kg. This means that the maximum leached paraffin oil concentrations in the leachate test in the worst-case scenario for 10%, 20% and 30% dry binder mixes would be 35,260, 31,400 and 28,300mg/kg respectively. The results in Figure 5 show that for the 10% dry binder mixes the oil content in the leachates ranged between 28,600 – 21,400mg/kg, for the 20% binder mixes between 2,000 – 27,800mg/kg whilst for the 30% binder mixes between 606 – 16,770mg/kg. The UK landfill acceptance criteria limit value for mineral oil (C10-C40) content in the waste is 500mg/kg for inert waste landfill [17]. In the absence of corresponding limit values for compliance leaching tests, those for total organic carbon of 500, 800 and 1000mg/kg for inert, stable non-reactive hazardous and hazardous waste are quoted here. This shows that all the 8500 9500 10500 11500 12500 13500 14500 15500 16500 17500 0 1 2 3 4 5 6 7 8 9 10 ChlorideLeachateConc.mg/kg 10% 20% 30% PC PFA-PC CKD-PC Compost-PC Lime-PC Zeolite-PC BFS-PC MgO-cement1 MgO-cement2 Microsilica-PC 100 1000 10000 100000 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5 5.5 6 6.5 7 7.5 8 8.5 9 9.5 10 10.5 ParaffinOilLeachateConc. mg/kg 10% 20% 30% PC PFA-PC CKD-PC Compost-PC Lime-PC Zeolite-PC BFS-PC MgO-cement1 Microsilica-PC MgO-cement2

- 10. Page 9 concentrations apart from one are above the leachate limit for hazardous waste. The leachate concentration for the 30% compost-PC mix of 606mg/kg, means that this mix would be classed as a stable non-reactive hazardous waste. These results indicate that a high binder content would be required to reduce the oil concentrations to acceptable levels. The NRA leachate pH is usually used as an indicator of how the heavy metals will behave. However, as there is no heavy metals included in this case study, the leachate pH was measured to provide the range of pH achieved for when heavy metals are included. The leachate pH values shown in Table 6 show a range between 10.32 and 12.67, with most over 11. For stabilised/solidified materials a pH of between 7 and 11 is usually recommended. Hence the pH values are at the upper end of this range and might require reduction by for example reducing the percentage of cement in the binder. Table 6: Average NRA leachate pH at 28 days 5.3.3 Scanning electron microscopy (SEM) Figure 6 shows typical SEM micrographs of all the mixes at 28 days. Those results have not yet been studied in detail but differences between some of the mixes are clear. What is also clear is the absence of ettringite and the abundance of gel-like hydration products typical of calcium silicate hydrate (CSH). The mixes are now being additionally tested using Energy Dispersive X-ray Analysis (EDX) to identify the various elemental compositions to help identify specific compounds present. Figure 6: SEM micrographs of all the 30% dry binder mixes at 28 days 6. CONCLUSIONS Drill cuttings are highly variable materials depending on the type of drilling mud, oil well location and soil strata, oil operator and drilling techniques, recovery technique, exposure/disposal scenarios of the cuttings and weathering and bacterial conditions leading to difficulty in testing real or typical materials. The results of this work show that the UCS of the Binder system pH for 10% pH for 20% pH for 30% Binder system pH for 10% pH for 20% pH for 30% PC 12.11 12.45 12.42 Lime-PC 12.52 12.61 12.67 BFS-PC 11.90 12.14 12.28 Compost-PC 11.93 12.19 12.39 Microsilica-PC 10.32 10.53 10.58 PFA-PC 11.82 12.15 12.25 Zeolite-PC 11.83 12.03 11.97 MgO-cement 1 10.34 10.84 10.98 CKD-PC 11.87 12.40 12.52 MgO-cement 2 11.79 12.18 12.32 PC CKD-PC BFS-PC Compost-PC Lime-PC MgO-cement 1 Microsilica-PC PFA-PC Zeolite -PC MgO-cement 2

- 11. Page 10 drill cuttings-binder mixes at 28 days ranged between 92kN/m2 and 4,708kN/m2 depending on the binder used. This is a very wide range of UCS values and covers a wide range of feasible applications. The NRA leachate concentrations of chloride ranged between 9,970mg/kg and 16,640mg/kg. This shows that some of the binders have reduced the chloride content in the drill cuttings sufficiently for them to be classified as non-reactive hazardous waste instead of hazardous waste. The oil leaching concentrations ranged between 600mg/kg and 27,800mg/kg and generally decreased as the dry binder content increased. The leachate pH values were between 10.32 and 12.67. The SEM micrographs indicated the absence of ettringite and the abundance of gel-like hydration products typical of CSH. ACKNOWLEDGEMENT The authors are grateful to Cambridge Overseas Trust, Overseas Research Student Awards Scheme and BP Egypt for their provision of financial support to the first author. REFERENCES [1] Bell, N., Cripps, S. J, Jacobsen, T., Kjeilan, G. and Picken, G. B., ‘Review of Drill Cuttings Piles in the North Sea’, (Cordah, UK, 1998). [2] Roddie, B., Skadsheim, A.; Runciman, D. and Kjeilen, G., ‘Project 1.2: Cuttings Pile Toxicity’, (UKOOA and Rogland Research, UK and Norway, 1999). [3] Wills, J., ‘A Survey of Offshore Oilfield Drilling Wastes and Disposal Techniques to Reduce the Ecological Impact of Sea Dumping: Environmental Effects of Drilling Waste Discharges, Environmental impact of offshore oil and gas exploration and production, 2000. [4] Page, P. W., Greaves, C., Lawson, R., Hayes, S. and Boyle, F., ‘SPE 80583: Options for the Recycling of Drill Cuttings’, Proceedings of the SPE/EPA/DOE Exploration and Production Environmental Conference, San Antonio, Texas, U.S.A., 2003. [5] Smith, M., Manning, A. and Lang, M., ‘The Re-use of Drill Cuttings Onshore’, (Cordah, UK, 1999). [6] Gray, C., ‘Compliant Onshore Management of Drill Cuttings (SEPA)’, Presentation on Oil and Gas IQ’s 3rd Annual Cost Effective Drill Cuttings Management 2004, Aberdeen, 2004. [7] Conner, J.R. and Hoeffner, S.L, ‘The History of Stabilization/Solidification Technology’, Environmental Science and Technology 28 (4) (1998) 325 – 396. [8] Johnson, D. Personal communication. [9] Tuncan, A., Tuncan, M. and Koyuncu, H., ‘Use of petroleum-contaminated drilling wastes as sub- base material for road construction’, Waste Management Resources 18 (2004) 89 – 505. [10] Boutemeur, R.; Haddi, A.; Bali, A. and Boutemeur, N. ‘Use of Petroleum waste as sub-base material for road construction’, Proceedings of International Symposium on Advances in waste management and recycling, Dundee, 2003. [11] ‘UKOOA Report on Task 5B: In Situ Solutions: Covering’, (UKOOA, UK, 2002). [12] Westerlund, S., Eriksen, V., Beyer, J. and Kjeilen, G., ‘Characterization of the cuttings piles at the Beryl A and Ekofisk 2/4 A platform’, (Rogaland Research, Norway, 2001). [13] ‘UKOOA Report on Drilling Cuttings initative’ Final Report (UKOOA, UK, 2001). [14] Harrison, J., ‘The Case for and Ramifications of Blending Reactive Magnesia with Portland Cement’, Paper presented on the 28th Conference on Our World in Concrete and Structures, Singapore, 2003. [15] Meegoda, J. N., Ezeldin, A. S., Fang, H-Y and Inyang, H. I., ‘Waste Immobilization Technologies’, Practice Periodical of Hazardous, Toxic and Radioactive Waste Management 7 (1) (2003) 46- 58. [16] Lewin, K., Bradshaw, K., Blakey, N.c., Turrell, J., Hennings, S.M. and Flavin, R.J. ‘Leaching Test for assessment of contaminated land’. Interim NRA Guidance (National River Authority, UK, 1994). [17] ‘Environmental Agency Guidance on sampling and testing of wastes to meet landfill waste acceptance procedures’, Version 4.3a (EA, UK, December 2003).