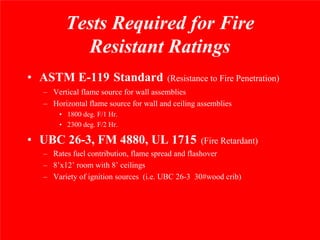

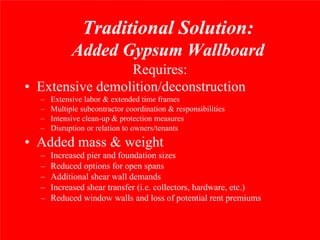

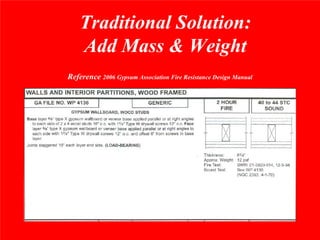

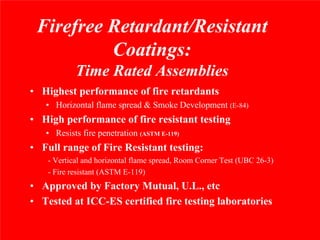

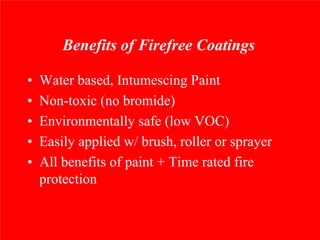

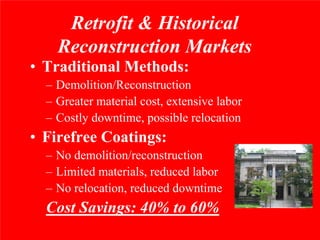

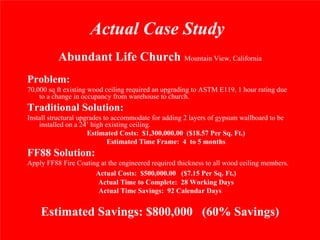

Firefree Coatings is a leading manufacturer of fire retardant and fire resistant coatings. Their coatings provide passive fire protection through compartmentalization without relying on mechanical systems or human response. Testing shows the coatings resist fire penetration and spread for extended periods, providing a cost-effective alternative to traditional fireproofing methods like adding drywall. The coatings see wide use in new construction and renovations for their installation ease and substantial cost savings over 40-60% compared to other options.