Design tab

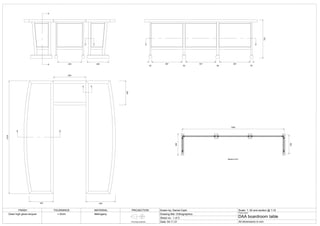

- 1. 50 567 69 557 69 567 50 2100 450 600 550 450 720 400 449 A A B B C C D D E E 1900 352 Section D-D 402 FINISH TOLERANCE MATERIAL PROJECTION Drawn by: Daniel Cash Scale: 1: 20 and section @ 1:10 Drawing title: Orthographics Sheet no.: 1 of 3 Date: 04.11.21 Project name: DAA boardroom table All dimensions in mm Clear high gloss lacquer First angle projection +-2mm Mahogany

- 2. 50 20 50 44 21 50 55 10 10 26 100 69 Section A-A 26 44 5 20 65 694 25 297 78 400 352 44 50 44 44 All joint consist of 10mm x 50mm dominos. Fielded panel consist of MDF substrate lipped with 35mm x 18mm solid mahogany lipping and veneered with mahogany . 5mm shodow gap between frame and panel. All panel grooves measure 8mm width by 10mm depth.21mm x 60mm brace at front of frame joins the two sides together with a dovetail of a 1:8 ratio. FINISH TOLERANCE MATERIAL PROJECTION Drawn by: Daniel Cash Scale: 1: 5 Drawing title: sections 1 Sheet no.: 2 of 3 Date: 04.11.21 Project name: DAA boardroom table All dimensions in mm High gloss clear lacquer +-2mm Mahogany First angle projection at A3

- 3. Section C-C 21 44 5 20 16 40 69 50 2mm mahogany edging 26 Section E-E Meeting point of small and big table. See appendix part 1 for image of clips used to join tables together. Joining clip 186 550 10 R13 Section B-B FINISH TOLERANCE MATERIAL PROJECTION Drawn by: Daniel Cash Scale: 1: 2 and 1:5 Drawing title: sections 2 Sheet no.: 3 of 3 Date: 04.11.21 Project name: DAA boardroom table All dimensions in mm High gloss clear lacquer +-2mm Mahogany First angle projection

- 4. Elevation End View Plan 800 300 800 750 900 155 130 150 819 900 Piece Length Width Thickness Quantity Material Base: Front leg 1000 40 40 2 Walnut Back leg 1000 40 40 2 Walnut Front Apron 900 70 21 2 Walnut Side Apron 300 70 21 2 Walnut Stretcher 900 30 30 1 Walnut Side stretcher 300 30 20 2 Walnut Inlay 2400 4 1 1 Ebony + maple Cab: Side 850 260 21 2 Walnut Top 800 300 21 1 Walnut Bottom 758 295 18 1 Ply Large shelf 758 245 18 1 Ply Small shelf 370 199 18 2 Ply Shelf edging 3500 5 18 1 Walnut Veneer - Shelf 1.106 m² 0.5 1 Walnut Veneer - Back panel 0.49 m² 0.5 1 Maple Veneer - Door panel 0.8 m² 0.5 1 Walnut Partition 709 250 18 1 Ply Drawer front 380 96 30 2 Walnut Drawer side 212 96 10 4 Walnut Drawer back 316 73 10 2 Walnut Drawer base 306 237 4 2 Ply Filler 100 50 21 2 Walnut Guides 194 50 18 4 Ply Back panel 694 644 4 1 Ply Back stile 800 48 15 2 Walnut Back rail 800 48 15 2 Walnut Door rail 400 66 40 4 Walnut Meeting stile left 750 46 31 1 Walnut Meeting stile right 750 40 31 1 Walnut Outside stile 750 40 40 2 walnut Door panel 643 315 4 2 Ply Hardware: Knife hinges x x x 4 Brass Door push caps x x x 2 Plastic Drawer push caps x x x 2 Plastic Binding screws x x x 4 Brass Art. no. 362.10.803 x 4 Art. no. 245.18.500 x 2 Art. no. 356.05.071 x 4 Article number N/A x 4 FINISH TOLERANCE MATERIAL PROJECTION Drawn by: DC Scale: 1: 10 Drawing title: Cover page Sheet no.: 1 of 8 Date: 09.12.21 Project name: Capstone All dimensions in mm TBD First angle projection +-2MM at A3 Walnut Maple Ebony

- 5. 30 30 900 10 50 90 50 160 20 140 40 A A B B C C Elevation End view Plan 819 210 160 50 30 210 759 FINISH TOLERANCE MATERIAL PROJECTION Drawn by: DC Scale: 1: 5 Drawing title: Base orthographics Sheet no.: 2 of 8 Date: 09.12.21 Project name: Capstone All dimensions in mm First angle projection at A3 TBD +-2MM Walnut Maple Ebony

- 6. Section C-C 10 70 40 Maple wedges 20 5 30 20 70 70 Section A-A Inlay banding Section B-B 30 30 21 15 10 30 150 FINISH TOLERANCE MATERIAL PROJECTION Drawn by: DC Scale: 1: 5 and 1: 2 Drawing title: Base sections Sheet no.: 3 of 8 Date: 09.12.21 Project name: Capstone All dimensions in mm TBD +-2mm Walnut Maple Ebony First angle projection at A3

- 7. 850 800 250 300 21 21 30 21 25 10 50 D D E E Elevation Plan End view FINISH TOLERANCE MATERIAL PROJECTION Drawn by: DC Scale: 1: 5 Drawing title: Cabinet with doors Sheet no.: 4 of 8 Date: 09.12.21 Project name: Capstone All dimensions in mm TBD First angle projection +-2mm at A3 Walnut Maple

- 8. 50 250 100 18 100 21 21 758 0 18 800 370 Elevation Plan F F 7 8mm x 30mm domino 184 184 204 250 100 4mm Walnut edging 48 631 48 Detail 3 96 4mm Walnut edging Section F-F FINISH TOLERANCE MATERIAL PROJECTION Drawn by: DC Scale: 1: 5 Drawing title: Cabinet with no doors Sheet no.: 5 of 8 Date: 09.12.21 Project name: Capstone All dimensions in mm TBD First angle projection +-2mm at A3 Walnut Maple

- 9. 50 18 Solid walnut Walnut veneered plywood 20 28 35 Back panel in 8mm x 8mm groove Section D-D Detail 1 377 250 5 Section E-E Detail 2 11 4 40 8 8mm x 4mm groove 10 21 40 8 13 11 4 8 6 FINISH TOLERANCE MATERIAL PROJECTION Drawn by: DC Scale: 1: 5 and 1:2 Drawing title: Cabinet sections Sheet no.: 6 of 8 Date: 09.12.21 Project name: Capstone All dimensions in mm TBD First angle projection +-2mm at A3 Walnut Maple Detail 1 Detail 3

- 10. G G 383 707 40 40 24 8mm x 5mm panel groove Left door elevation Plan Section G-G 8 6mm x 15mm rebate 64 354 30 12 6 12 30 30 8 24 8 8 Left top rail elevation Left top rail plan Right door meeting stile Section of stiles 46 3 3 10° 1 3 5 1 2 2 1 2 6 1 4 31 12 6 12 15 2mm V groove 43 8 36 7 FINISH TOLERANCE MATERIAL PROJECTION Drawn by: DC Scale: 1: 5 and 1:2 Drawing title: Door and door sections Sheet no.: 7 of 8 Date: 09.12.21 Project name: Capstone All dimensions in mm TBD First angle projection +-2mm and 1:1 Walnut Maple

- 11. 316 96 H H Elevation End view Plan Section H-H End view 96 10 296 4mm x 5mm panel groove 5 48 67 12 237 34 12 203 33 12 306 209 237 381 84° 9 6 ° FINISH TOLERANCE MATERIAL PROJECTION Drawn by: DC Scale: 1: 5 and 1:2 Drawing title: Drawers Sheet no.: 8 of 8 Date: 09.12.21 Project name: Capstone All dimensions in mm TBD First angle projection +-2mm at A3 Walnut Maple Drawer front in the rough

- 12. 1983 2238 664 135 FINISH TOLERANCE MATERIAL PROJECTION Drawn by: Daniel Cash Scale: 1: 20 Drawing title: Entrance door Sheet no.: 1 of 7 Date: 11.11.21 Project name: Double margin door All dimensions in mm TBD First angle projection +-2mm Iroko All work to be carried out in compliance with: TGD part M 3.1.2.1 (a) the clear opening width of at least one point of access should be a minimum of 900 mm. The access route, leading from this, should maintain a clear width of at least 900 mm and have a firm and even surface, which is suitable for people using wheelchairs or other mobility aids and reduces the risk of slipping 3.1.2.2 Level access route The dwelling should be designed, within the overall constraints of space, so that the difference in level between the entrance to the dwelling and the dwelling plots point of access is minimised. A level approach route accommodates the widest range of abilities 3.2.2 Accessible entrance (a) there should be a clear level area at least 1200 mm wide and at least 1200 mm deep in front of every accessible entrance (b) the entrance should be provided with a level entry i.e. with maximum threshold height of 15 mm with exposed edges chamfered or pencil rounded; (c) the minimum effective clear opening width of the entrance door should be 800 mm TGD part D 1.2 Resistance to moisture Where any material is likely to be adversely affected by condensation, by moisture from the ground or by airborne moisture such as rain or snow: (a) the construction should prevent the passage of moisture to the material, or (b) the material should be treated or otherwise protected from moisture 1.5 Glazing Any unguarded glazing, in critical locations in doors and door side panels, at low level in walls and partitions should be safety glazing in accordance with the recommendations of BS 6262 1.6 Letter plates Letter plates should conform to I.S. EN 13724: 2013, and should be positioned in accordance with Diagram 2 2.1 Adequacy of workmanship A proper standard of workmanship and the appropriate use of any material is essential to achieving compliance with the requirements of the Regulations Elevation Plan End view

- 13. A A 135 64 Elevation Section A-A Section B-B B B B 1983 2238 135 64 375 80 56 21 70 64 1188 200 507 215 64 End view 64 375 80 945 80 375 64 5mm drip groove FINISH TOLERANCE MATERIAL PROJECTION Drawn by: Daniel Cash Scale: 1: 10 Drawing title: Door frame Sheet no.: 2 of 7 Date: 11.11.21 Project name: Double margin door All dimensions in mm TBD First angle projection +-2mm at A3 Iroko *All rebates and grooves shown measure 12mm x 60mm. *All 45 degree chamfers measure 10mm. Glazing to consist of double glazed 5mm clear self cleaning toughened glass in accordance with the recommendations of BS626, Part 4. Any fixings and ironmongery used must consist of non corrosive materials. Ends of through tenons to be sealed with paint or suitable resin adhesive, particularly tenons in both the frame head and cill. All work to be carried out in accordance with Technical Guidance Document D Materials and Workmanship, Section 2.

- 14. 64 600 1983 135 560 Elevation Plan End view Detail 1 B B 64 135 60 Section B-B 536 45 45 45 52 64 60 Detail 1 35 25 30 25 20 FINISH TOLERANCE MATERIAL PROJECTION Drawn by: Daniel Cash Scale: 1: 10. Section @ 1:5. Detail @ 1:2. Drawing title: Elliptical frame Sheet no.: 3 of 7 Date: 11.11.21 Project name: Double margin door All dimensions in mm TBD First angle projection +-2mm Iroko

- 15. 60 963 95 100 100 95 507 754 254 2114 Folding wedge Elevation Plan End view 287 60 71 56 C C B D D 20 20 20 95 200 Section D-D Detail 2 60 20 95 200 215 20 95 Section C-C Detail 2 20 95 10 95 20 FINISH TOLERANCE MATERIAL PROJECTION Drawn by: Daniel Cash Scale: 1: 10, sections @ 1:5 Drawing title: Double margin door Sheet no.: 4 of 7 Date: 11.11.21 Project name: Double margin door All dimensions in mm TBD +-2mm Add material information First angle projection Orthographics, sections and detail of double-margin door. Meeting stiles joined with folding wedges. All grooves measure 20mmx20mm. Detail shown @ scale 1:2.

- 16. 15 12 8 15 17 5mm x 24mm weather bar Inward opening door with a rebate at the front. Rebate conceals weather bar which is housed in a groove in the cill. Drip groove in rebate prevents water traveling along the horizontal section of the rebate. Hardwood weather bar, joined to door with a tongue and groove, further prevents condensation from traveling towards the bottom of the door. Hardcore Hardcore Thermal block Infill DPC Insulation Concrete Finished floor level Concrete Gully Both threshold details are in compliance with Technical Guidance Documents: Part M section 3.2.2 Accessible entrance: (b) the entrance should be provided with a level entry i.e. with maximum threshold height of 15 mm with exposed edges chamfered or pencil rounded. Part D Section 1.2 Resistance to moisture: Where any material is likely to be adversely affected by condensation, by moisture from the ground or by airborne moisture such as rain or snow: (a) the construction should prevent the passage of moisture to the material Traditional threshold detail FINISH TOLERANCE MATERIAL PROJECTION Drawn by: Daniel Cash Scale: 1: 2 Drawing title: Traditional threshold Sheet no.: 5 of 7 Date: 11.11.21 Project name: Double margin door All dimensions in mm TBD First angle projection +-2mm Iroko

- 17. 15 20 Metal weather bar fixed to door Rubber seal stopping drafts and water Inward opening door with weather strip installed. Weather strip consisting of two independent components fixed to both the door and the cill. Door must sit 20mm above cill to accommodate weather strip. Interlocking rubber seals prevent drafts and condensation traveling past the weather strip. Hardcore Hardcore Thermal block Infill DPC Insulation Concrete Finished floor level Concrete Gully Both threshold details are in compliance with Technical Guidance Documents: Part M section 3.2.2 Accessible entrance: (b) the entrance should be provided with a level entry i.e. with maximum threshold height of 15 mm with exposed edges chamfered or pencil rounded. Part D Section 1.2 Resistance to moisture: Where any material is likely to be adversely affected by condensation, by moisture from the ground or by airborne moisture such as rain or snow: (a) the construction should prevent the passage of moisture to the material Modern threshold detail FINISH TOLERANCE MATERIAL PROJECTION Drawn by: Daniel Cash Scale: 1: 2 Drawing title: Modern threshold Sheet no.: 6 of 7 Date: 11.11.21 Project name: Double margin door All dimensions in mm TBD First angle projection +-2mm Iroko

- 18. Rise and going of stairs Face mould template Springing line Springing line Center line Center line Thickness of material needed Center line Center Twist bevel angle FINISH TOLERANCE MATERIAL PROJECTION Drawn by: Daniel Cash Scale: 1: 2 Drawing title: Wreath template Sheet no.: 7 of 7 Date: 11.11.21 Project name: Wreath template All dimensions in mm N/A +-0mm MDF First angle projection

- 19. Front Elevation Plan Side Elevation 45 45 770 101° 960 5 1 2 550 95 883 45 883 95 2000 740 A A 115 45 Front Elevation Plan Side Elevation 446 600 550 100° 15 45 1390 45 B B 71 377 1500 Section B-B 292 71 9 71 9 71 21 Section B-B shows the jointing method between the table top and frame. The table legs are joined with two stretchers with a 7mm x 5mm groove which houses the buttons and leaves room for seasonal movement. 600 Section A-A 4 5 9 1 100 230 45 Section A-A shows the meeting point of the back and seat. The rear stretcher houses the mitred tenons, while the front stretcher houses the stub tenons of the seat. FINISH TOLERANCE MATERIAL PROJECTION Drawn by: DC Scale: 1: 10 Client: Joe Soap Sheet no.: 1 of 1 Date: 13/04/21 Project name: Outdoor Furniture All dimensions in mm Teak oil First angle projection +- 2mm Details: 1:5 Iroko Table isometric Sofa isometric

- 20. 2927,5 900 100 850 50 98,5 Detail 1 shows the pitch line in dashed/dotted pink which runs between each step. The top of the handrail is positioned 900mm measured vertically from where the pitch line meets the tread, in compliance to Technical Guidance Document Part K. Detail 2 shows the where the flight meets the upper finished floor level. The final riser is housed in both the newell post and wall string. The cut string tenon is joined to the front of the newell post with a mortice and the newell post also houses the trimmer joist to the rear where a fixing is placed. A ramp easing handrail meets the newell post at the same height as the guarding balustrade handrail on the upper floor. As per Technical Guidance Document Part K, a maximum of 100mm is permitted between each spindel. Shown in the drawings are 2 spindels per tread with a distance of 100mm between them. These spindles form a set. The spacing between each set of spindles is 98.5mm Detail 1 Detail 2 Designed by Student number Assignment Module TU732 Due date Scale Detail scale Stairs Joinery 1:10 1:50 Semester 1 14-12-20 C19720711 Daniel Cash Detail 3 Detail 1 Detail 2

- 21. 900 260 260 220 220 220 21 18 A A Designed by Student number Assignment Module TU732 Due date Scale Detail scale Stairs Joinery 1:10 1:50 Semester 1 14-12-20 C19720711 Daniel Cash Section A-A shows both the riser and going measurements. Each riser and step is secured in place with slow driving wedges, shown here in the blue. Each riser has a thickness of 18mm and each tread has a thickness of 21mm. Front of the second riser is positioned on the center line of the newell post. Shown on the right is detail 3. The handrail eases and levels off in line with the handrail on the upper level. Section A-A Detail 3

- 22. 3360 2860 2 0 0 0 Designed by Student number Assignment Module TU732 Due date Scale Detail scale Stairs Joinery N/A 1:20 Semester 1 14-12-20 C19720711 Daniel Cash Site measurements of 2.86m from finished floor level to finished floor level and a max going of 3.25m. To comply with Technical Guidance Document Part K, the max permitted rise in a stairs for private use is 220mm. 2.86m ÷ 220 = 13 risers A maximum going of 260mm per tread is permitted. 12 treads @ 260mm per tread = 3.12m which falls under the max going of 3.25m. As stated in the Technical Guidance Document Part K, a stairs can have a max pitch of 42 degrees.With a rise of 220mm and a going of 260mm, trigonometry is used to determine the pitch of the stairs to be 40.2 degrees. The documents states that for a stairs to comply, the sum of: 2(rise) + going = min. 550 and max. 700. 2(220) + 260 = 700. Elevation

- 23. Kitchen Bath Bed 2 Bed 1 Lounge En-Suite Window A Window B Window C Door B Door A Window A Window A Window A

- 24. 1212 1800 549 549 1128 Window A finished cutting list Piece Length(mm) Width(mm) Thickness(mm) Quantity Top Rail 549 55 45 2 Bottom Rail 549 55 45 2 Stiles 1116 55 45 4 Mullion 1800 70 60 2 Frame head 1800 70 60 1 Frame jamb 2112 70 60 2 Frame cill 1800 70 60 1 Section G-G Section H-H Elevation G H G H Detail 4 Detail 5 Detail 6 Detail 7 Name: Student no.: Date: Module: Title: Detail scale: Scale: Assignment: Daniel Cash C19720711 26/02/21 Estimating Estimating 1:10 N/A Window A

- 25. 1212 900 550 826 Window B finished cutting list Piece Length(mm) Width(mm) Thickness(mm) Quantity Vent top Rail 826 55 45 1 Vent bottom Rail 826 55 45 1 Vent stiles 550 55 45 2 Transom 900 70 60 1 Frame head 900 70 60 1 Frame jamb 1212 70 60 2 Frame cill 900 70 60 1 Elevation Section I-I Section J-J I J I J Detail 8 Detail 9 Name: Student no.: Date: Module: Title: Detail scale: Scale: Assignment: Daniel Cash C19720711 26/02/21 Estimating Estimating 1:10 N/A Window B

- 26. 912 900 524 290 863 Window C finished cutting list Piece Length(mm) Width(mm) Thickness(mm) Quantity Vent top Rail 826 55 45 1 Vent bottom Rail 826 55 45 1 Vent stiles 290 55 45 2 Casement top rail 826 55 45 1 Casement bottom rail 826 55 45 1 Casement stile 524 55 45 2 Transom 900 70 60 1 Frame head 900 70 60 1 Frame jamb 912 70 60 2 Frame cill 900 70 60 1 Elevation Section K-K Section L-L K L Detail 10 K L Name: Student no.: Date: Module: Title: Detail scale: Scale: Assignment: Daniel Cash C19720711 26/02/21 Estimating Estimating 1:10 N/A Window C

- 27. 70 60 55 45 20 48 12 20 50 6 21 70 60 55 45 60 70 18 60 70 18 Detail 7 on the left shows where a casement stile meets a mullion. The mullion also receives a double glazed unit on the opposite side which forms a deadlight. Detail 4 on the left shows a 70mm x 60mm window jamb with a rebate at the front to receive the 55mm x 44mm top rail of the casement. Detail 5 on the left shows the window casement meeting the cill. The cill is rebated at the bottom to receive the concrete cill. Detail 6 on the left shows the vertical section of the window jamb and the stile of the window casement. Detail 8 shows the bottom rail of the vent light meeting the transom. Name: Student no.: Date: Module: Title: Detail scale: Scale: Assignment: Daniel Cash C19720711 26/02/21 Estimating Estimating N/A 1:2 Window details

- 28. 20 50 33 15 10 48 12 10 60 55 14 55 30 30 3 21 Detail 9 above shows a deadlight glazing panel meeting a cill. Detail 10 above shows the meeting point of the transom and a vent light on top and bottom. Name: Student no.: Date: Module: Title: Detail scale: Scale: Assignment: Daniel Cash C19720711 26/02/21 Estimating Estimating N/A 1:2 Window details 2

- 29. 900 2100 95 95 922 215 600 215 95 644 95 92 92 92 95 44 Door A finished cutting list Piece Length(mm) Width(mm) Thickness(mm) Quantity Top Rail 845 95 44 1 Middle rail 845 215 44 1 Bottom Rail 845 215 44 1 Stiles 2047 95 44 2 Bottom panels 632 108 44 7 Top Panels 956 108 44 7 Frame head 900 95 44 1 Frame jamb 2100 95 44 2 A B C Section A-A Section B-B Section C-C Elevation Detail 1 Detail 2 A B C Name: Student no.: Date: Module: Title: Detail scale: Scale: Assignment: Daniel Cash C19720711 26/02/21 Estimating Estimating 1:10 N/A Door A

- 30. 900 2100 922 215 600 215 95 644 95 21 92 92 92 Door B finished cutting list Piece Length(mm) Width(mm) Thickness(mm) Quantity Top Rail 845 95 44 1 Middle rail 845 215 44 1 Bottom Rail 845 215 44 1 Stiles 2047 95 44 2 Bottom panels 632 108 44 7 Glazing bead 1600 21 44 1 Frame head 900 95 44 1 Frame jamb 2100 95 44 2 Elevation Detail 3 Section F-F Section E-E Section D-D D E F D E F Name: Student no.: Date: Module: Title: Detail scale: Scale: Assignment: Daniel Cash C19720711 26/02/21 Estimating Estimating 1:10 N/A Door B

- 31. 95 44 44 29 25 20 79 47 23 Detail 1 to the left shows a 95mm x 44mm door frame with a 46mm x 15mm rebate at the front to recieve the door. The 44mm thick door is manufactured using tongue and groove boards as shown in detail 1. Shown below in detail 3 is the horizontal section of the 44mm x 23mm glazing bead between the door stiles. The glazing bead receives the double glazing panel either side and is secured with putty. Detail 2 on the left shows the door stopped 20mm before the finished floor line to allow for the stormguard to be fitted. Detail 1 Detail 2 Detail 3 Name: Student no.: Date: Module: Title: Detail scale: Scale: Assignment: Daniel Cash C19720711 26/02/21 Estimating Estimating N/A 1:2 Door details

- 33. Shown is an alternative jointing method between the curved stile and straight stile to the hammerhead tenon completed in class. The curved sections are both joined with a loose tenon while the top of the curved stile joins the straight stile also with a loose tenon. These loose tenons are sometimes called keys. The bottom of the curved stile is jointed to the straight stile with a bridle joint. Sometimes draw pins are inserted here to further secure the joint while clamping.