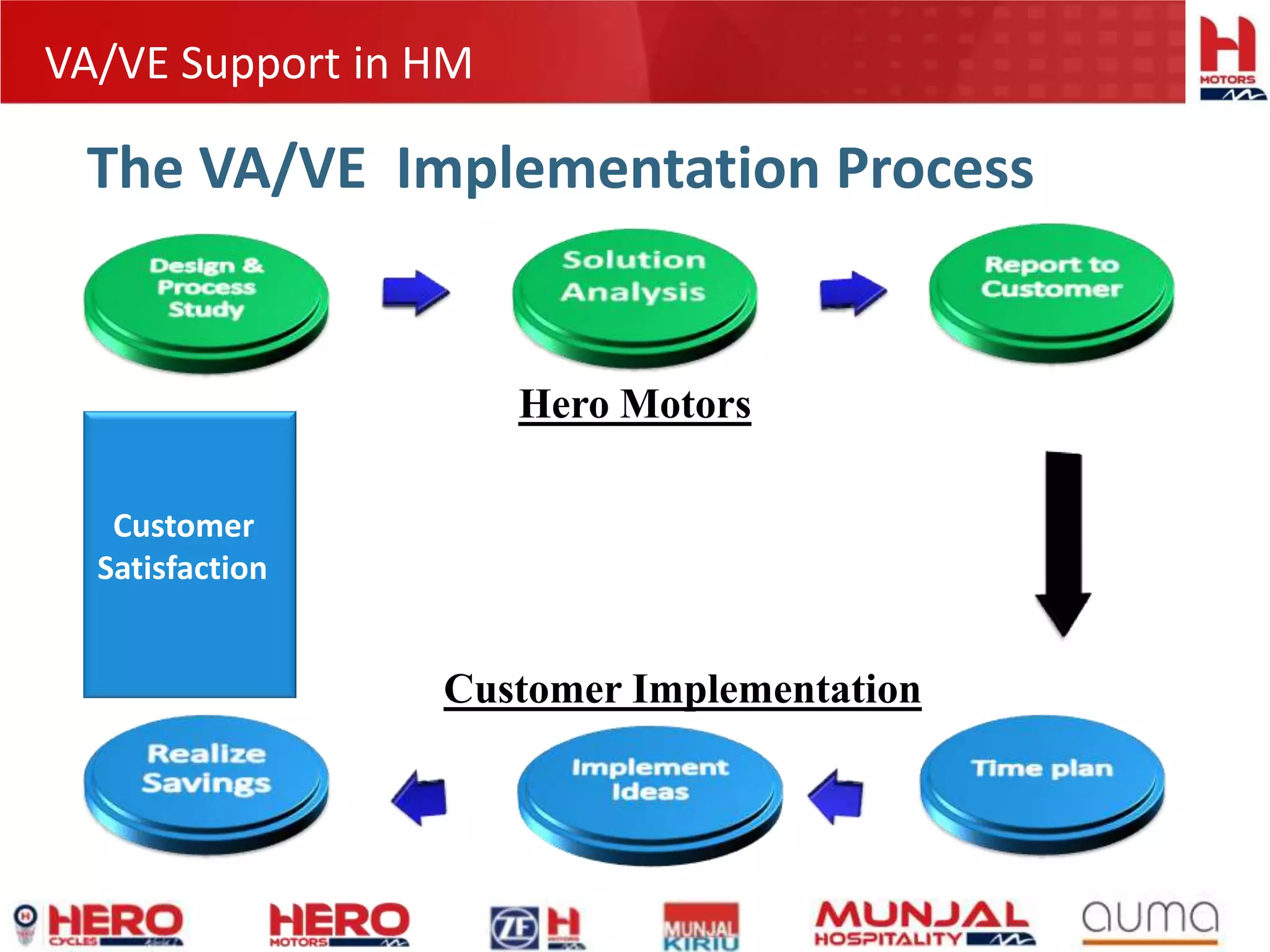

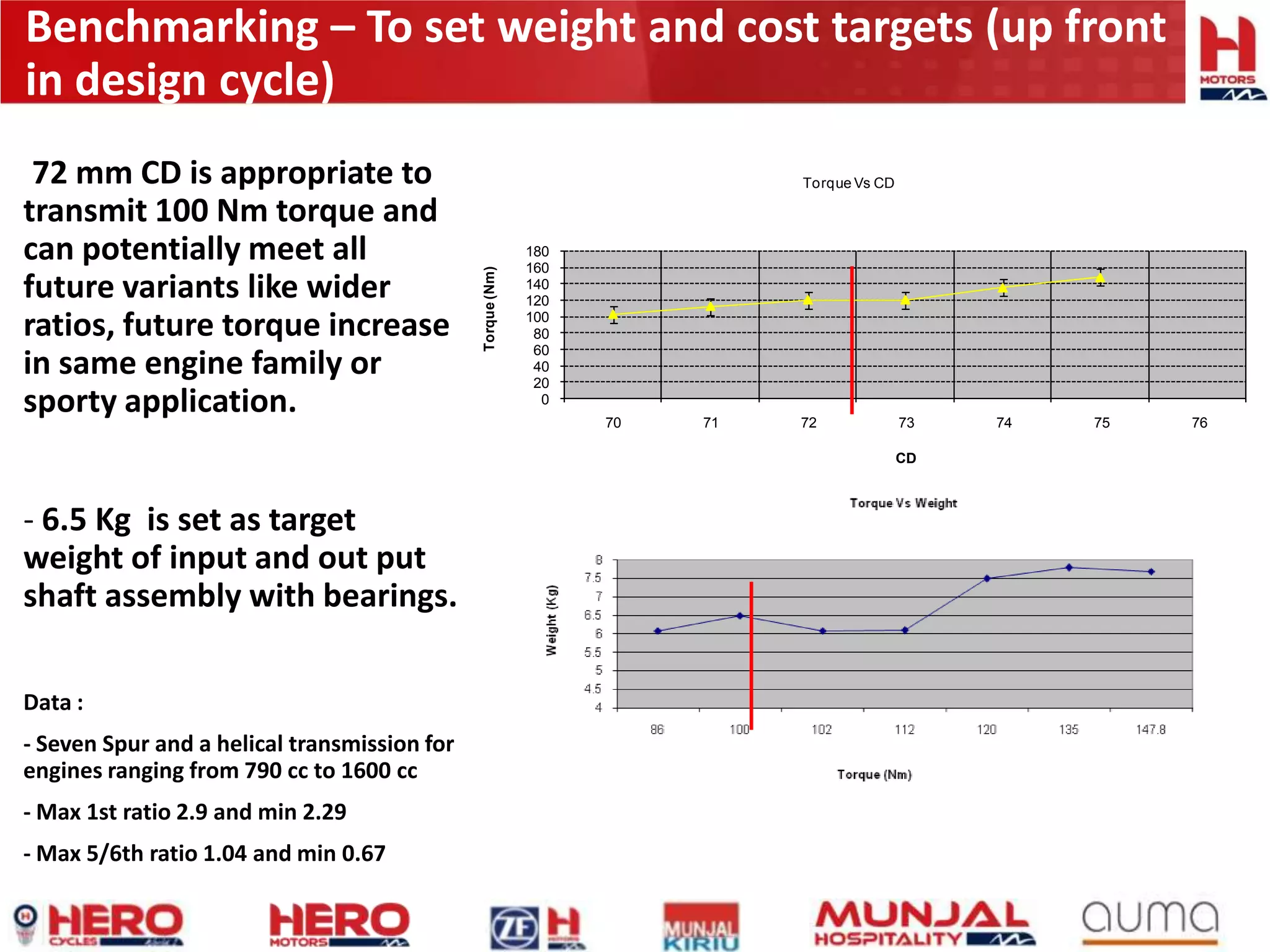

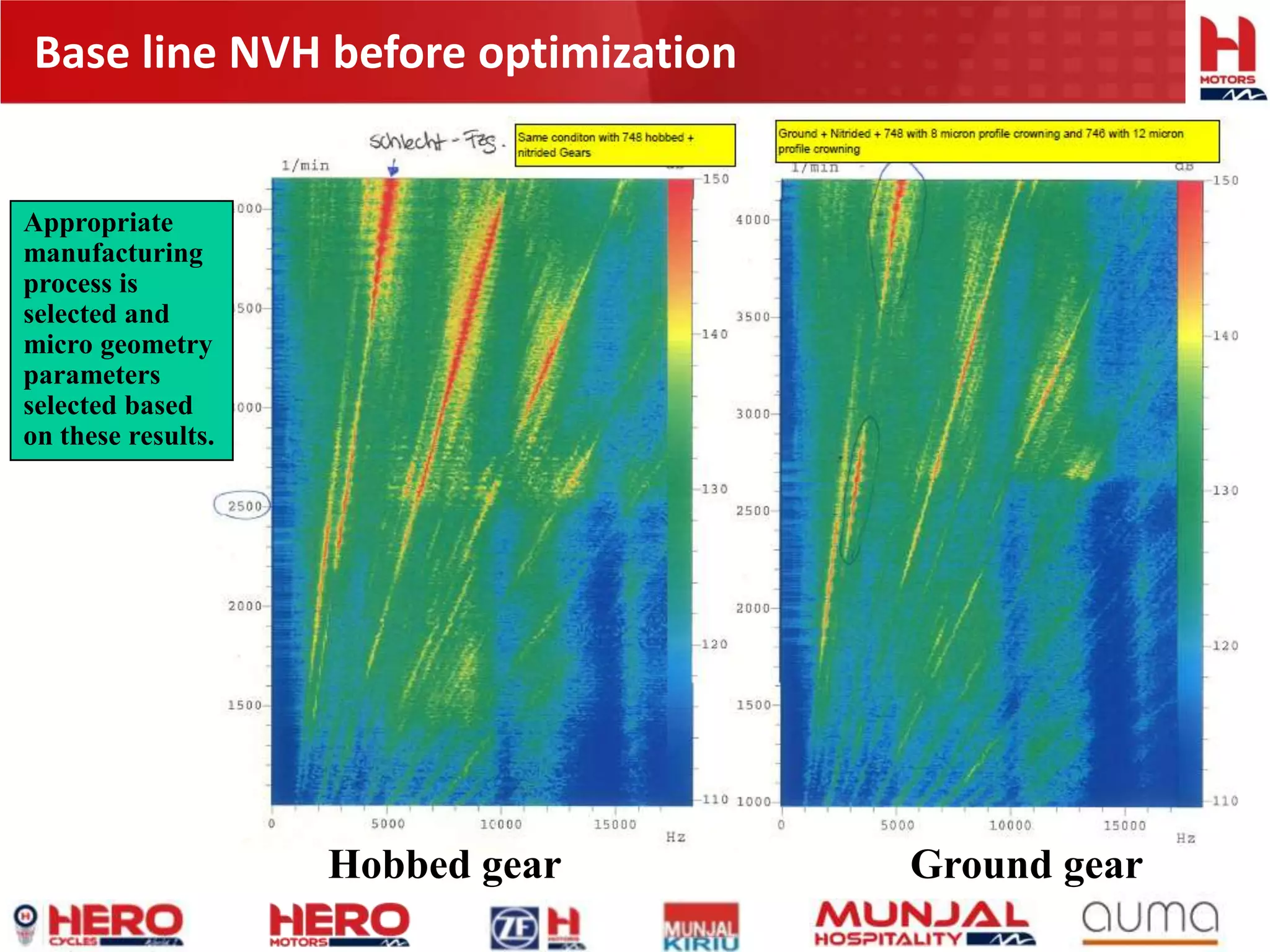

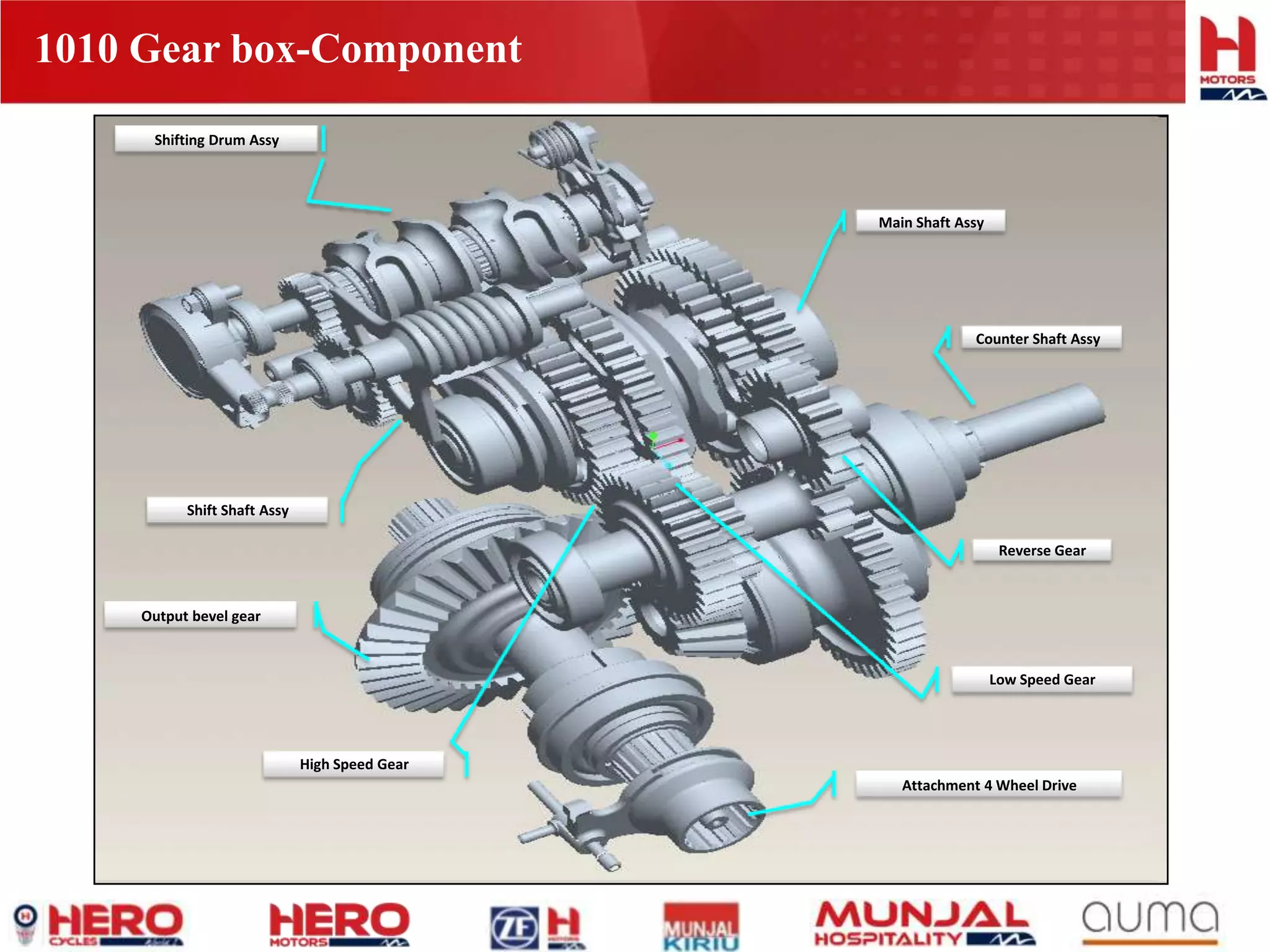

The document discusses VA/VE (value analysis/value engineering) support provided by Hero Motors (HM) to optimize design and processes, increase efficiency, improve customer satisfaction, and enhance profitability. It outlines HM's VA/VE implementation process and provides examples of design optimization, testing facilities, process optimization, and cost savings achieved through modifications to transmission and housing components.