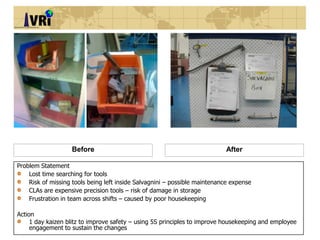

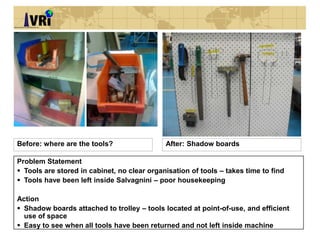

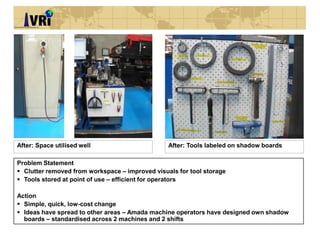

The document details a 1-day kaizen blitz event aimed at improving tool housekeeping on the Salvagnini machine in a sheet metal shop using 5S principles. Key outcomes included organized tool storage, reduced risk of damage, and enhancements in productivity and employee engagement. The initiative led to standardized storage solutions and encouraged similar improvements across other machines.