Bolt n go Chain and Flight system for Drop Forged Chains - CASE STUDY

•

1 like•390 views

Report

Share

Report

Share

Download to read offline

Recommended

Recommended

Operating Poles - PB Weir Transmission Line Earthing Operating Poles High VoltageOperating Poles - PB Weir Transmission Line Earthing Operating Poles High Vol...

Operating Poles - PB Weir Transmission Line Earthing Operating Poles High Vol...Thorne & Derrick International

More Related Content

Viewers also liked

Viewers also liked (12)

Watchdog Elite - Bucket Elevator & Conveyor Monitor

Watchdog Elite - Bucket Elevator & Conveyor Monitor

4b's material handling and hazard monitoring components

4b's material handling and hazard monitoring components

SJ elevator bucket and and steel web belt for cement elevators

SJ elevator bucket and and steel web belt for cement elevators

Similar to Bolt n go Chain and Flight system for Drop Forged Chains - CASE STUDY

Operating Poles - PB Weir Transmission Line Earthing Operating Poles High VoltageOperating Poles - PB Weir Transmission Line Earthing Operating Poles High Vol...

Operating Poles - PB Weir Transmission Line Earthing Operating Poles High Vol...Thorne & Derrick International

O’Brien Installations Limited (O’Brien) is a manufacturer of overhead cranes, jib cranes, workstation cranes, gantry cranes and a supplier of commercial doors and loading dock equipment, serving the industry for over 50 years, with sales, service and manufacturing facilities in Burlington, Ontario and Memramcook, New Brunswick and a sales and service office in Quebec, Quebec.

O‘Brien services include manufacturing, installation and service of under-running cranes, top-running cranes, gantry cranes, monorails, workstation bridge cranes, electric wire rope hoists, electric chain hoists, crane runway systems and conductor bar systems. We offer professional engineering services capable of designing material handling equipment to suit customer-specific requirements. We also offer 24-hour service and scheduled inspections to all makes and models of overhead cranes, hoists, industrial doors and dock equipment. We stock the largest inventory of spare parts in Ontario offering parts for all major brands of overhead cranes, hoists, commercial doors and dock equipment.Overhead Cranes, Jib Cranes, Commercial Doors & Loading Dock Equipment - O'Br...

Overhead Cranes, Jib Cranes, Commercial Doors & Loading Dock Equipment - O'Br...O'Brien Installations Limited

SEB Cable Laying & Cable Pulling Equipment enables the installation of LV-HV power, fibre optic, telecoms, subsea cables and umbilicals into cable duct or cable trench.

T&D service utilities, power, construction, rail, mining, street lighting, subsea, offshore, oil, gas and petrochemical industries with global market leading SEB Cable Laying & Cable Pulling Equipment.

T&D distribute the complete range of SEB Cable Pulling and Cable Laying Equipment for low and high voltage (LV-HV) power cable installations into underground trench or cable duct - this includes XLPE, PILC, EPR, waveform, service cables, triplex, 11kV, 33kV, EHV, fibre optic, telecoms and street lighting cables. We supply cable rollers, cable socks, cable jacks, drum trailers, cable pulling lubricant, underground cable protection (Stokbord & Tape Tile Cable Covers) and conduit duct rod - we service the utility cable laying contractor, electrical contractor and export markets.

SEB Cable Laying Solutions for Renewable Energy Projects

A comprehensive cable laying package includes cable rollers (straight and corner), cable drum jacks, cable winches and cable socks including stainless steel socks for pulling large diameter, high voltage subsea power cables and umbilicals up to 400kV.

SEB - Cable Pulling & Cable Laying Equipment For Low & High Voltage Cables In...

SEB - Cable Pulling & Cable Laying Equipment For Low & High Voltage Cables In...Thorne & Derrick International

Similar to Bolt n go Chain and Flight system for Drop Forged Chains - CASE STUDY (20)

Bolt ‘n’ Go Chain and Flight System - explanation and case study

Bolt ‘n’ Go Chain and Flight System - explanation and case study

Keep running costs down operating en-masse chain conveyors

Keep running costs down operating en-masse chain conveyors

Strategy of Conveyor Belt Repair - Operation and Maintenance

Strategy of Conveyor Belt Repair - Operation and Maintenance

Operating Poles - PB Weir Transmission Line Earthing Operating Poles High Vol...

Operating Poles - PB Weir Transmission Line Earthing Operating Poles High Vol...

Overhead Cranes, Jib Cranes, Commercial Doors & Loading Dock Equipment - O'Br...

Overhead Cranes, Jib Cranes, Commercial Doors & Loading Dock Equipment - O'Br...

Cable Pulling & Laying Equipment for Street Lighting

Cable Pulling & Laying Equipment for Street Lighting

SEB - Cable Pulling & Cable Laying Equipment For Low & High Voltage Cables In...

SEB - Cable Pulling & Cable Laying Equipment For Low & High Voltage Cables In...

Cable Laying Pulling Equipment Low High Voltage Cables - Catalogue

Cable Laying Pulling Equipment Low High Voltage Cables - Catalogue

dokumen.tips_cosaltbexco-offshore-mooring-systems-shell-buoy-mooring-workshop...

dokumen.tips_cosaltbexco-offshore-mooring-systems-shell-buoy-mooring-workshop...

The KAUP Carrying Ram attachment helps improve paper reel handling for contai...

The KAUP Carrying Ram attachment helps improve paper reel handling for contai...

More from 4B Braime Components

Hazardmon.com - Cloud-based hazard monitoring for conveying systems -Geaps pr...

Hazardmon.com - Cloud-based hazard monitoring for conveying systems -Geaps pr...4B Braime Components

More from 4B Braime Components (20)

4B Elektronische Schutzkomponenten für Elevatoren und Förderer

4B Elektronische Schutzkomponenten für Elevatoren und Förderer

4B Composants Electriques - Surveillance des Elevateurs et Convoyeurs

4B Composants Electriques - Surveillance des Elevateurs et Convoyeurs

Hazardmon.com – Cloud Based Hazard Monitoring System

Hazardmon.com – Cloud Based Hazard Monitoring System

Hazardmon.com - Cloud-based hazard monitoring for conveying systems -Geaps pr...

Hazardmon.com - Cloud-based hazard monitoring for conveying systems -Geaps pr...

Recently uploaded

Recently uploaded (20)

TrustArc Webinar - Unlock the Power of AI-Driven Data Discovery

TrustArc Webinar - Unlock the Power of AI-Driven Data Discovery

Connector Corner: Accelerate revenue generation using UiPath API-centric busi...

Connector Corner: Accelerate revenue generation using UiPath API-centric busi...

Spring Boot vs Quarkus the ultimate battle - DevoxxUK

Spring Boot vs Quarkus the ultimate battle - DevoxxUK

Finding Java's Hidden Performance Traps @ DevoxxUK 2024

Finding Java's Hidden Performance Traps @ DevoxxUK 2024

Axa Assurance Maroc - Insurer Innovation Award 2024

Axa Assurance Maroc - Insurer Innovation Award 2024

Apidays New York 2024 - Passkeys: Developing APIs to enable passwordless auth...

Apidays New York 2024 - Passkeys: Developing APIs to enable passwordless auth...

Biography Of Angeliki Cooney | Senior Vice President Life Sciences | Albany, ...

Biography Of Angeliki Cooney | Senior Vice President Life Sciences | Albany, ...

"I see eyes in my soup": How Delivery Hero implemented the safety system for ...

"I see eyes in my soup": How Delivery Hero implemented the safety system for ...

Cloud Frontiers: A Deep Dive into Serverless Spatial Data and FME

Cloud Frontiers: A Deep Dive into Serverless Spatial Data and FME

Boost Fertility New Invention Ups Success Rates.pdf

Boost Fertility New Invention Ups Success Rates.pdf

Strategies for Landing an Oracle DBA Job as a Fresher

Strategies for Landing an Oracle DBA Job as a Fresher

Rising Above_ Dubai Floods and the Fortitude of Dubai International Airport.pdf

Rising Above_ Dubai Floods and the Fortitude of Dubai International Airport.pdf

Bolt n go Chain and Flight system for Drop Forged Chains - CASE STUDY

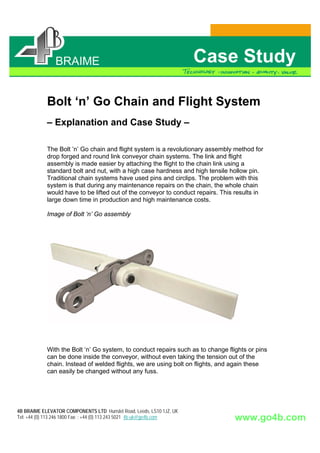

- 1. BRAIME BRAIMEBRAIMEBRAIME Case Study www.go4b.com 4B BRAIME ELEVATOR COMPONENTS LTD Hunslet Road, Leeds, LS10 1JZ, UK Tel: +44 (0) 113 246 1800 Fax: : +44 (0) 113 243 5021 4b-uk@go4b.com Bolt ‘n’ Go Chain and Flight System – Explanation and Case Study – The Bolt ’n’ Go chain and flight system is a revolutionary assembly method for drop forged and round link conveyor chain systems. The link and flight assembly is made easier by attaching the flight to the chain link using a standard bolt and nut, with a high case hardness and high tensile hollow pin. Traditional chain systems have used pins and circlips. The problem with this system is that during any maintenance repairs on the chain, the whole chain would have to be lifted out of the conveyor to conduct repairs. This results in large down time in production and high maintenance costs. Image of Bolt ‘n’ Go assembly With the Bolt ‘n’ Go system, to conduct repairs such as to change flights or pins can be done inside the conveyor, without even taking the tension out of the chain. Instead of welded flights, we are using bolt on flights, and again these can easily be changed without any fuss.

- 2. BRAIME BRAIMEBRAIMEBRAIME Case Study www.go4b.com 4B BRAIME ELEVATOR COMPONENTS LTD Hunslet Road, Leeds, LS10 1JZ, UK Tel: +44 (0) 113 246 1800 Fax: : +44 (0) 113 243 5021 4b-uk@go4b.com Image of traditional pin and circlips arrangement with welded flight Another problem with traditional systems using pins and circlips, is that circlips can come off in some circumstances, causing the chain to become disconnected, and again downtime. With the Bolt ‘n’ Go system, the pins, chain and flights are secured using a secured lock nut, which securely holds the system together in a consistent manner, but also facilitating easy and safe removal when required. One of the first installations to use this system was in November of 2006 at CHS, Superior, WI. The facility handles several commodities which include wheat and soybeans at the rate of around 1.0 million tons per annum. They have several drag conveyors which use drop forged chain, with the traditional pin and circlip assembly. While this has proved a reliable assemble method for them, it has proved time consuming when changing out bent or broken chain flights.

- 3. BRAIME BRAIMEBRAIMEBRAIME Case Study www.go4b.com 4B BRAIME ELEVATOR COMPONENTS LTD Hunslet Road, Leeds, LS10 1JZ, UK Tel: +44 (0) 113 246 1800 Fax: : +44 (0) 113 243 5021 4b-uk@go4b.com Bill Hoffer, Head of Maintenance said of the system “We installed 4B’s new Bolt ‘n’ Go chain, and I am pleased with the results. The Bolt ‘n’ Go chain is very easy and fast to install and maintain, as you eliminate the need to separate the chain each time while installing a new flight. Also there is no need to slacken of the chain or re-tension while changing flights. This alone will save untold hours on the routine maintenance of these conveyors” He goes onto to say “the Bolt ‘n’ Go system has been in service for well over 12 months, is running great and no problems”.

- 4. BRAIME BRAIMEBRAIMEBRAIME Case Study www.go4b.com 4B BRAIME ELEVATOR COMPONENTS LTD Hunslet Road, Leeds, LS10 1JZ, UK Tel: +44 (0) 113 246 1800 Fax: : +44 (0) 113 243 5021 4b-uk@go4b.com Bolt ‘n’ Go chain system running on conveyor The Bolt ‘n’ Go chain system is available for 102, 125, 142, 150, 160 and 200mm heavy metric link ranges. The system uses heavy duty Nylon flights, which bolt straight through the pins, with no need to bolt on or slide over existing steel flights. The Nylon flights also have excellent wear, strength and resistance capabilities. The Bolt ‘n’ Go pin / bolt assembly system can also be used with the traditional welded flight system, to replace the traditional pin and circlip arrangement. This like the Bolt ‘n’ Go flight system is very easy to change over to for the maintenance team on site.

- 5. BRAIME BRAIMEBRAIMEBRAIME Case Study www.go4b.com 4B BRAIME ELEVATOR COMPONENTS LTD Hunslet Road, Leeds, LS10 1JZ, UK Tel: +44 (0) 113 246 1800 Fax: : +44 (0) 113 243 5021 4b-uk@go4b.com The Bolt ‘n’ Go system is also available for round link chain, whereby the system works under a similar system of nylon flights being bolted directly to the chain, in this case without pins. The Bolt ‘n’ Go system is all about making life easier for the end user, ease of use, inexpensive and above all low maintenance and down time. Dave Wolstencroft 4B Group Product Manager – Chain For more information, please contact: 4B Braime Elevator Components 4b-uk@go4b.com www.go4b.com