This document discusses amylases, which are enzymes that degrade starch. It describes the discovery of amylases in 1833 and outlines their mechanism of breaking glycosidic bonds in starch. The document also categorizes different types of amylases based on their substrate specificity and reaction products. Finally, it reviews the industrial applications of amylases, particularly in starch processing, baking, detergents, textiles, biofuel production and paper making.

![INTRODUCTION

• Amylases are starch degrading enzymes.

• It was first isolated by French chemists Anselme and Jean François

from germinating barley and was named as "diastase" in 1833[1].

• These enzymes act by hydrolyzing glycosidic bonds-α-1,4 glycosidic

bonds and α-1,6 glycosidic bonds between adjacent glucose units,

yielding progressively smaller polymers composed of glucose units

(characteristic of the particular enzyme involved) [2] .

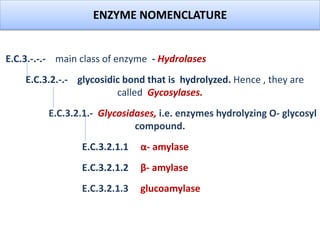

• They belong to the glycoside hydrolase group of enzymes under

which 13 enzymes are included [3] .

[1]- Sivaramakrishnan et al., 2006 [2]- Aiyer et al.,2005 [3]- ] Windish et al.,2005](https://image.slidesharecdn.com/enzymologyppt-160824085742/85/Presentation-on-Amylase-enzyme-2-320.jpg)

![MAJOR SUBSTRATE FOR AMYLASE -STARCH

Starch is a polymer of glucose

linked to another one through the

glycoside bond. Two types of

glucose polymers are present in

starch : amylose and amylopectin.

.

• Amylose is a linear polymer

consisting of up to 6000 glucose

units with α-1,4 glycosidic

bonds.

• Amylopectin consists of short α-

1,4 linked to linear chains of

10–60 glucose units and α-1,6

linked to side chains with 15–

45 glucose units.

• Amylase is able to cleave these

glycosidic bonds present in the

inner part of the amylose or

amylopectin chain[4].

[4] Muralikrishna G., Nirmala M. Cereal α-amylases—an

overview.Carbohydrate Polymers. 2005;60:163–173.](https://image.slidesharecdn.com/enzymologyppt-160824085742/85/Presentation-on-Amylase-enzyme-4-320.jpg)

![Various types of amylase associated with degradation of starch and

related polysaccharides structures have been detected and studied[5].

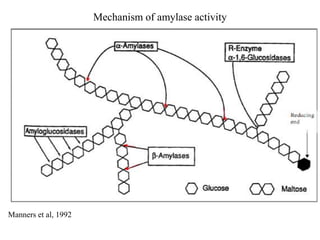

1. Enzymes that hydrolyze 𝛼-1,4 bonds e.g. 𝜶 -amylase (endoacting

amylases).

2. Enzymes that hydrolyze 𝛼 -1,4 e.g. -𝜷 amylase (exoacting amylases

producing maltose as a major end product).

3. Enzymes that hydrolyze terminal 1,4 linked 𝛼 D-glucose residues. e.g.

glucoamylase.

4. Enzymes that hydrolyze only 𝛼 -1,6 linkages e.g. pullulanase .

5. Enzymes that hydrolyze preferentially 𝛼 -1,4 linkages in short chain

oligosaccharides produced by the action of other enzymes on amylose

and amylopectin e.g. - 𝜶 glucosidases.

[5]- Van et al.,2002

TYPES OF AMYLASE](https://image.slidesharecdn.com/enzymologyppt-160824085742/85/Presentation-on-Amylase-enzyme-5-320.jpg)

![Payan 2004.

The human α-amylase is a classical calcium-containing

enzyme composed of 512 amino acids with a molecular

weight of 57.6 kDa[9]. .

The protein contains 3 domains: A, B, and C.

The A domain (residues 1-99, 169-404 )is the largest,

presenting a typical Tim barrel shaped (β/α)8 super

structure.

The B domain (residues 100-168) is the smallest

domain is attached to the A domain by disulphide

bond. The C domain (residues 405-512) is made up of

anti-parallel beta-structure and is only loosely

associated with Domains A and B.

The active site of the α-amylase is situated in a cleft

located between the carboxyl end of the A and B

domains. Asp206, Glu230 and Asp297 participate in

catalysis [10].

The calcium (Ca2+) is situated at B domain (Asn 100, Arg

158, Asp 167) against the wall of the barrel of Domain

A .

Chloride ion is present at A domain (Arg 195, Asn 298,

and Arg 337)

These ions are required for the stabilization of the

three-dimensional structure .

STRUCTURAL CHARACTERISTICS OF α-AMYLASE

Structure human α-amylase.](https://image.slidesharecdn.com/enzymologyppt-160824085742/85/Presentation-on-Amylase-enzyme-8-320.jpg)

![–

Characterization of α-amylase.

SOURCE Km

(mg

/ml)

Vmax

(μmol/m

g/min)

Kcat

(S-1)

Kcat/

Km

(ml

mg-1

S-1)

Inhibi

tors

Activat

or

Temperat

ure

pH Referen

ces

B.

Licheniformis

6.2 1.04 2000 3.22×

10-2

Hg2+

,Cd2+,

Mn2+,,

Ba2+,

Cu2+,

,EDTA

1500 Da

PEG,

increas

es the

enzyme

activity

by 24%

at

0.02%

w/v

85-90°C 6.5 [11]

Bacillus

megaterium

9.0 0.68 580 .64x

10-2

Hg2+

Ba2+,

,Zn2+,

Co2+,

Cr3+,

Fe3+

Titron X

increase

s the

enzyme

activity

by 34%

at

37-40°C 6.0 [12]](https://image.slidesharecdn.com/enzymologyppt-160824085742/85/Presentation-on-Amylase-enzyme-9-320.jpg)

![DETERMINATION OF AMYLASE ACTIVITY

• Amylase activity was estimated by measuring either the appearance of one of the

products or the disappearance of the substrate over time.

• The Enzyme – substrate reaction can be determined by measuring the increase in

reducing sugars using the 3, 5 Dinitro salicylic acid reagent[13].

• The pale yellow colored the 3, 5- dinitro salicylic acid undergo reduction in

presence of reducing sugar to yield orange colored 3- amino -5-nitrosalicylic acid.

• The absorbance of resultant solutions is read at 540nm. The intensity of color

depends on the concentration of reducing sugars produced.

Lever et al.,1972.](https://image.slidesharecdn.com/enzymologyppt-160824085742/85/Presentation-on-Amylase-enzyme-10-320.jpg)

![• One unit of amylase activity is defined as the amount of enzyme that

produces 1 μmol of reducing sugar per minute under specific conditions.

Enzyme activity =

U/ml incubation time(min) X volume of starch ( ml)X Volume of cubette

(cubic meter)

• The hydrolytic activity of Amylase can be determined based on the

principle that starch and iodine react to form a blue colored

complex[14].

• On hydrolysis of starch this complex changes. The absorbance can be

read after the enzyme substrate reaction has been terminated.

Conc. Of reducing sugar(µmol) volume content

Obtained from standard graph X in tube X dilution factor](https://image.slidesharecdn.com/enzymologyppt-160824085742/85/Presentation-on-Amylase-enzyme-11-320.jpg)

![Microorganism Fermentation pH

optimal/stability

Temperature

optimal/stability

Reference

Bacteria

Bacillus

amyloliquefaciens

SmF 7.0 33 °C [16]

Bacillus subtilis SSF 7.0 37 °C [17]

Fungi

Aspergillus niger SSF 5.5 70 °C [18]

Aspergillus

fumigatus

SmF 6.0 30°C [19]

Amylase is ubiquitous enzyme produced by plants, animals and microbes.

In the recent past, there has been extensive research on microbial production of

Amylase.

300 tonnes of α-Amylase have been accounted to be produced from B.lichinoformis

and Aspesgillus sp. per year[15].

There are two methods widely used for production of α-Amylase on a commercially -

1) Submerged fermentation

2) Solid State fermentation](https://image.slidesharecdn.com/enzymologyppt-160824085742/85/Presentation-on-Amylase-enzyme-12-320.jpg)

![APPLICATION

• Amylases constitute a major class of industrial enzymes which alone form 25% of

the enzyme market covering industrial processes.

Industrial

application

Microbial

source

Role Refere

nce

Starch

conversion

B.amyloliquefaciens,

B.licheniformis

gelatinization, liquefaction,

saccharification of starch

[20]

Bakery Bacillus

stearothermophilus

Converting starch in dough to smaller

fermentable sugars.

[21 ]

Detergent

Industry

Bacillus sp

Aspergillus sp

Degrade the residues of starchy foods

such as potatoes, gravies, custard,

chocolate, etc. to dextrins and other

smaller oligosaccharides .

[ 22]

Textile Industry Bacillus sp Used in removal of starch sizing agent

from woven fabric.

[23 ]

Fuel Production E.coli, B.subtilis Converting starch in to smaller

fermentable sugars which are acted upon

by yeast to produce ethanol.

[24 ]

Paper industry Bacillus sp Viscosity of the natural starch is too high

for paper sizing and this can be altered by

[25]](https://image.slidesharecdn.com/enzymologyppt-160824085742/85/Presentation-on-Amylase-enzyme-13-320.jpg)

![REFERENCES.

[1] Sivaramakrishnan S., Gangadharan D.,Madhavan K., Ricardo C., Pandey A. α-Amylases from

Microbial Sources. Food Technol. Biotechnol. 2006; 44 (2):173-184.

[2] Aiyer, P.V. Amylase and their applications. African Journal of Biotechnology.2005; 4(13): 1525

- 1529.

[3] Windish, W., Mhatre, N.S. Microbial amylases. Advances in applied microbiology,.2005;7:273

- 304.

[4] Van M., Leemhuis H, Dijkhuizen L.Properties and applications of starch converting enzymes

of the α-amylase family, J. Biotechnol. 2002; 94:137-155.

[5] Manners, D.J. Enzymatic synthesis and degradation of starch and glycogen. Adv. Carbohydr.

Chem. (1992);17:371–430.

[6] Gangadharan, D., Nampoothiri, K. M., Soccol, C. R., & Pandey, A. α-Amylases from Microbial

Sources. Food Technology & Biotechnology.2006.,44(2):23-27.

[7] Kaplan F., Dong S., Charles L. “Roles of β-amylase and starch breakdown” .International

Journal on Plant Physiology. 2006., 126:120–128.](https://image.slidesharecdn.com/enzymologyppt-160824085742/85/Presentation-on-Amylase-enzyme-14-320.jpg)

![[8] Reddy N.S., Nimmagadda A., Sambasiva K.R.S. An overview of the microbial

amylase family. Afr. J. Biotechnol. 2003;2:645–648.

[9] Payan F. Structural basis for the inhibition of mammalian and insect alpha-

amylases by plant protein inhibitors. Biochem Biophys Acta. 2004;1696:171–180.

[10] Muralikrishna G., Nirmala M. Cereal α-amylases—an overview. Carbohydrate

Polymers. 2005;60:163–173.

[11] Saptadip S., Das A., Kumar H., Jana A. Thermodynamic and kinetic

characteristics of an α-amylase from Bacillus licheniformis SKB4. Acta Biol

Szeged.2014; 58(2):147-156 .

[12] Tanaka, A and Hoshino, E. 2002. Calcium binding parameter of Bacillus

amyloliquefaciens amylase determined by inactivation kinetics. Biochemistry

Journal, 364: 635 – 639.

[13] Miller, G.L., Use of dinitrosalicylic acid reagent for determination of reducing

sugar, Anal. Chem.1959; 31:426-428.](https://image.slidesharecdn.com/enzymologyppt-160824085742/85/Presentation-on-Amylase-enzyme-15-320.jpg)

![[14] Hamilton, L. M., Kelly, C. T., & Fogarty, W. M. Carbohydrate Research.1998; 314, 251–257.

[15] Chi Z., Liu G., Wang F., Ju L., Zhang T. Saccharomycopsis fibuligera and its applications in

biotechnology. Biotechnol Adv. 2009;27:423–431.

[16] Gupta R., Gigras P., Mohapatra H., Goswami V.K., Chauhan B. Microbial α-amylases: a

biotechnological perspective. Process Biochem. 2003;38:1599–1616.

[17] Tanyildizi M.S., Ozer D., Elibol M. Production of bacterial α-amylase by B. amyloliquefaciens

under solid substrate fermentation. Biochem. Eng. J. 2007;37:294–297.

[18] Baysal Z., Uyar F., Aytekin C. Solid state fermentation for production of α-amylase by a

thermotolerantBacillus subtilis from hot-spring water. Process Biochemistry. 2003;38:1665–

1668.

[19] Uguru G.C., Akinyauju J.A., Sani A. The use of yam peel for growth of locally

isolated Aspergillus niger and amylase production. Enzyme Microb. Technol. 1997;21:46–51.

[20] Jin B., Leeuwen H.J., Patel B., Yu Q. Utilisation of starch processing wastewater for

production of microbial biomass protein and fungal α-amylase by Aspergillus oryzae. Bioresour.

Technol. 1998;66:201–206.](https://image.slidesharecdn.com/enzymologyppt-160824085742/85/Presentation-on-Amylase-enzyme-16-320.jpg)

![[20] Reddy N.S., Nimmagadda A., Sambasiva Rao K.R.S. An overview of the microbial α-amylase

family. Afr. J. Biotechnol.2003;2:645–648.

[21] Couto S.R., Sanromán M.A. Application of solid-state fermentation to food industry- A

review. Journal of Food Engineering. 2006;76:291–302.

[22] Hmidet N., El-Hadj Ali N., Haddar A., Kanoun S., Alya S., Nasri M. Alkaline proteases and

thermostable α-amylase co-produced by Bacillus licheniformis NH1: Characterization and

potential application as detergent additive. Biochemical Engineering Journal. 2009;47:71–79.

[23] Feitkenhauer H. Anaerobic digestion of desizing wastewater: influence of pretreatment and

anionic surfactant on degradation and intermediate accumulation. Enzyme Microb. Technol.

2003;33:250–258.

[24] Moraes L.M.P., Filho S.A., Ulhoa C.J. Purification and some properties of an α-amylase

glucoamylase fusion protein from Saccharomyces cerevisiae. World J. Microbiol. Biotechnol.

1999;15:561–564.

[25] Bruinenberg P.M., Hulst A.C., Faber A., Voogd R.H. A process for surface sizing or coating of

paper. In: European Patent Application. 1996.](https://image.slidesharecdn.com/enzymologyppt-160824085742/85/Presentation-on-Amylase-enzyme-17-320.jpg)