Mechanical Properties of Metals

•Download as PPT, PDF•

69 likes•28,339 views

Mechanical Properties of Metals

Report

Share

Report

Share

Recommended

More Related Content

What's hot

What's hot (20)

Properties of materials / Mechanical Properties of materials

Properties of materials / Mechanical Properties of materials

Stress strain curve for ductile and brittle materials

Stress strain curve for ductile and brittle materials

Mechanical properties of materials by ombaran singh

Mechanical properties of materials by ombaran singh

Similar to Mechanical Properties of Metals

Structures and Materials- Section 4 Behaviour of Materials

Structures and Materials- Section 4 Behaviour of MaterialsThe Engineering Centre for Excellence in Teaching and Learning

Demonstration of Mechanical Behaviour of Material Using a Practical Approach

Demonstration of Mechanical Behaviour of Material Using a Practical Approach Dr. Gaurav Kumar Gugliani

Demonstration of Mechanical Behaviour of Material Using a Practical Approach

Demonstration of Mechanical Behaviour of Material Using a Practical Approach Dr.Gaurav Kumar Gugliani

Demonstration of Mechanical Behaviour of Material Using a Practical Approach

Demonstration of Mechanical Behaviour of Material Using a Practical Approach Dr.Gaurav Kumar Gugliani

Similar to Mechanical Properties of Metals (20)

Mechanical properties of materials (lecture+2).pdf

Mechanical properties of materials (lecture+2).pdf

Em321 lesson 08b solutions ch6 - mechanical properties of metals

Em321 lesson 08b solutions ch6 - mechanical properties of metals

Mechanical_properties_bdcfdb47-96b7-4259-9d7a-cf39642f70d9.ppt

Mechanical_properties_bdcfdb47-96b7-4259-9d7a-cf39642f70d9.ppt

Fundamental principles and application of Universal Testing machine

Fundamental principles and application of Universal Testing machine

Structures and Materials- Section 4 Behaviour of Materials

Structures and Materials- Section 4 Behaviour of Materials

Demonstration of Mechanical Behaviour of Material Using a Practical Approach

Demonstration of Mechanical Behaviour of Material Using a Practical Approach

Demonstration of Mechanical Behaviour of Material Using a Practical Approach

Demonstration of Mechanical Behaviour of Material Using a Practical Approach

Demonstration of Mechanical Behaviour of Material Using a Practical Approach

Demonstration of Mechanical Behaviour of Material Using a Practical Approach

Terminology for Mechanical Properties The Tensile Test: Stress-Strain Diagram...

Terminology for Mechanical Properties The Tensile Test: Stress-Strain Diagram...

Recently uploaded

Book Paid Powai Call Girls Mumbai 𖠋 9930245274 𖠋Low Budget Full Independent H...

Book Paid Powai Call Girls Mumbai 𖠋 9930245274 𖠋Low Budget Full Independent H...Call Girls in Nagpur High Profile

Recently uploaded (20)

Call Girls Haridwar Just Call 8250077686 Top Class Call Girl Service Available

Call Girls Haridwar Just Call 8250077686 Top Class Call Girl Service Available

All Time Service Available Call Girls Marine Drive 📳 9820252231 For 18+ VIP C...

All Time Service Available Call Girls Marine Drive 📳 9820252231 For 18+ VIP C...

Call Girls Visakhapatnam Just Call 9907093804 Top Class Call Girl Service Ava...

Call Girls Visakhapatnam Just Call 9907093804 Top Class Call Girl Service Ava...

Call Girls Bhubaneswar Just Call 9907093804 Top Class Call Girl Service Avail...

Call Girls Bhubaneswar Just Call 9907093804 Top Class Call Girl Service Avail...

Night 7k to 12k Navi Mumbai Call Girl Photo 👉 BOOK NOW 9833363713 👈 ♀️ night ...

Night 7k to 12k Navi Mumbai Call Girl Photo 👉 BOOK NOW 9833363713 👈 ♀️ night ...

Call Girls Tirupati Just Call 8250077686 Top Class Call Girl Service Available

Call Girls Tirupati Just Call 8250077686 Top Class Call Girl Service Available

Call Girls Bangalore Just Call 8250077686 Top Class Call Girl Service Available

Call Girls Bangalore Just Call 8250077686 Top Class Call Girl Service Available

Call Girls Siliguri Just Call 8250077686 Top Class Call Girl Service Available

Call Girls Siliguri Just Call 8250077686 Top Class Call Girl Service Available

Book Paid Powai Call Girls Mumbai 𖠋 9930245274 𖠋Low Budget Full Independent H...

Book Paid Powai Call Girls Mumbai 𖠋 9930245274 𖠋Low Budget Full Independent H...

Top Rated Bangalore Call Girls Mg Road ⟟ 9332606886 ⟟ Call Me For Genuine S...

Top Rated Bangalore Call Girls Mg Road ⟟ 9332606886 ⟟ Call Me For Genuine S...

VIP Call Girls Indore Kirti 💚😋 9256729539 🚀 Indore Escorts

VIP Call Girls Indore Kirti 💚😋 9256729539 🚀 Indore Escorts

Call Girls Nagpur Just Call 9907093804 Top Class Call Girl Service Available

Call Girls Nagpur Just Call 9907093804 Top Class Call Girl Service Available

Best Rate (Guwahati ) Call Girls Guwahati ⟟ 8617370543 ⟟ High Class Call Girl...

Best Rate (Guwahati ) Call Girls Guwahati ⟟ 8617370543 ⟟ High Class Call Girl...

Premium Call Girls Cottonpet Whatsapp 7001035870 Independent Escort Service

Premium Call Girls Cottonpet Whatsapp 7001035870 Independent Escort Service

Manyata Tech Park ( Call Girls ) Bangalore ✔ 6297143586 ✔ Hot Model With Sexy...

Manyata Tech Park ( Call Girls ) Bangalore ✔ 6297143586 ✔ Hot Model With Sexy...

Call Girls Ooty Just Call 8250077686 Top Class Call Girl Service Available

Call Girls Ooty Just Call 8250077686 Top Class Call Girl Service Available

Pondicherry Call Girls Book Now 9630942363 Top Class Pondicherry Escort Servi...

Pondicherry Call Girls Book Now 9630942363 Top Class Pondicherry Escort Servi...

Call Girls Dehradun Just Call 9907093804 Top Class Call Girl Service Available

Call Girls Dehradun Just Call 9907093804 Top Class Call Girl Service Available

♛VVIP Hyderabad Call Girls Chintalkunta🖕7001035870🖕Riya Kappor Top Call Girl ...

♛VVIP Hyderabad Call Girls Chintalkunta🖕7001035870🖕Riya Kappor Top Call Girl ...

Call Girls Cuttack Just Call 9907093804 Top Class Call Girl Service Available

Call Girls Cuttack Just Call 9907093804 Top Class Call Girl Service Available

Mechanical Properties of Metals

- 1. Mechanical Properties of Metals

- 4. Direct Stress Examples Direct Stress - Tension Direct Stress - Compression Engineering Stress Engineering Strain

- 5. Tension Test Typical Universal Testing Machine Extensometer Measures L Measures P

- 6. Modern Materials Testing System Hydraulic Wedge Grips Specimen Extensometer

- 7. ASTM Tension Test Specimen 2” Gauge Length A o =0.20 in 2 L o

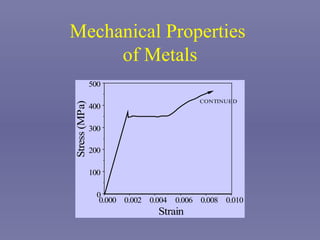

- 9. Engineering Stress-Strain Curve Elongation 0.2% offset yield stress Proportional Limit E E (Ultimate) Engineering Strain, e = L/Lo) Engineering Stress, S=P/Ao S y S u

- 12. Modulus of Elasticity - Stiffness

- 13. Atomic Origin of Stiffness

- 14. Shear Stress and Strain shear stress, = Shear Load / Area shear strain, = angle of deformation (radians) shear modulus, G = / (elastic region) Shear Stress Shear Strain

- 16. Poisson’s Ratio, For most metals, 0.25 < < 0.35 in the elastic range Furthermore :

- 17. Plastic Deformation Stress Strain 0.002 0.002 0.002 S y S y S y Most Metals - Al, Cu Clad Al-Alloys Low carbon Steel Elastic Plastic Elastic Plastic Elastic Plastic

- 19. Elastic and Plastic Strain Stress Strain Plastic Elastic e e e p P Total Strain (e,S) The 0.2% offset yield stress is the stress that gives a plastic (permanent) strain of 0.002.

- 20. Elastic Recovery Strain Stress Loading Unloading Loading Unloading Reloading elastic strain Strain

- 24. Toughness, U t Engineering Strain, e = L/Lo) Engineering Stress, S=P/Ao S u S y

- 25. Resilience, U r Engineering Strain, e = L/Lo) Engineering Stress, S=P/Ao S u S y E e y

- 26. Typical Mechanical Properties Metals in annealed (soft) condition