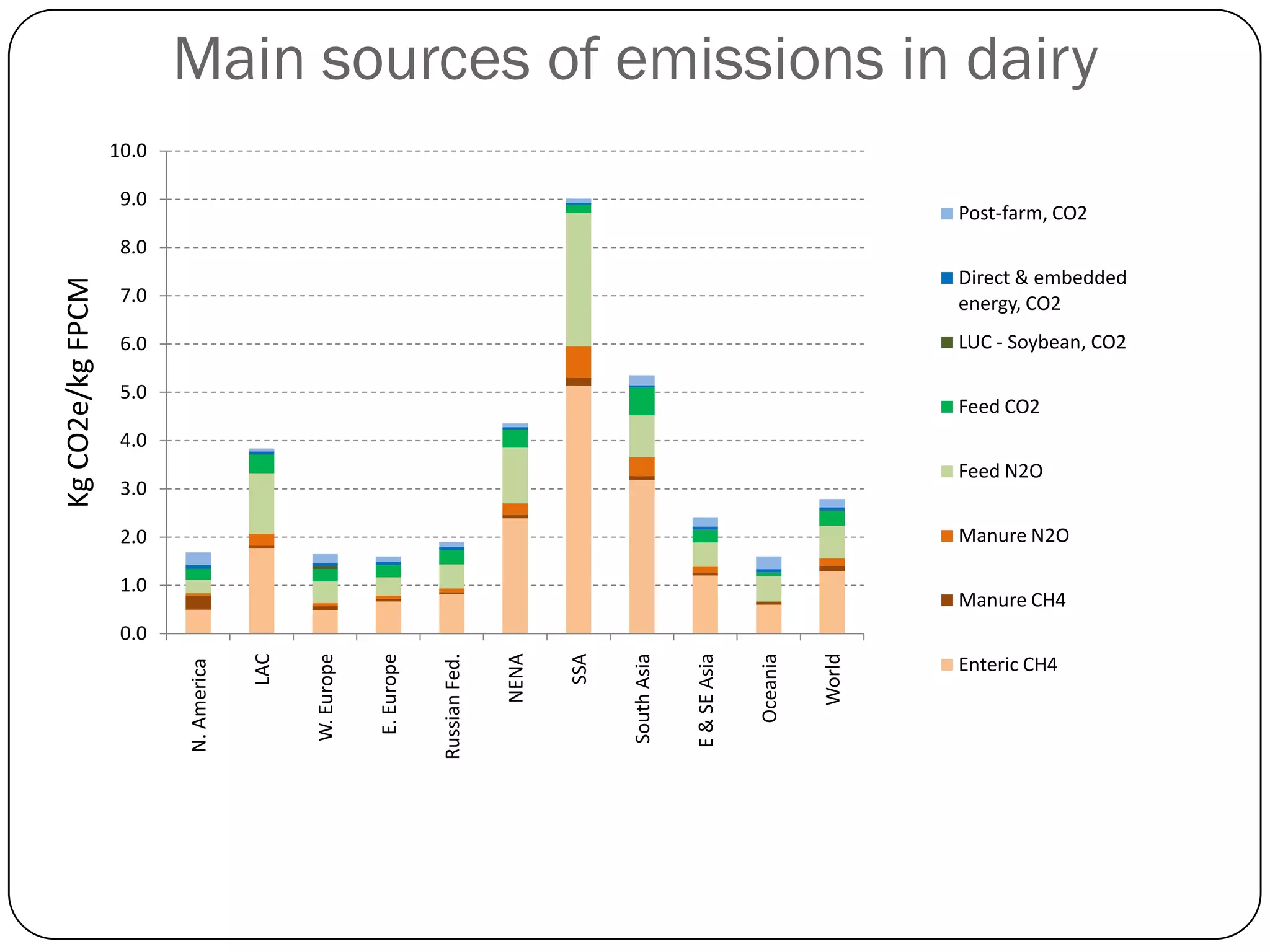

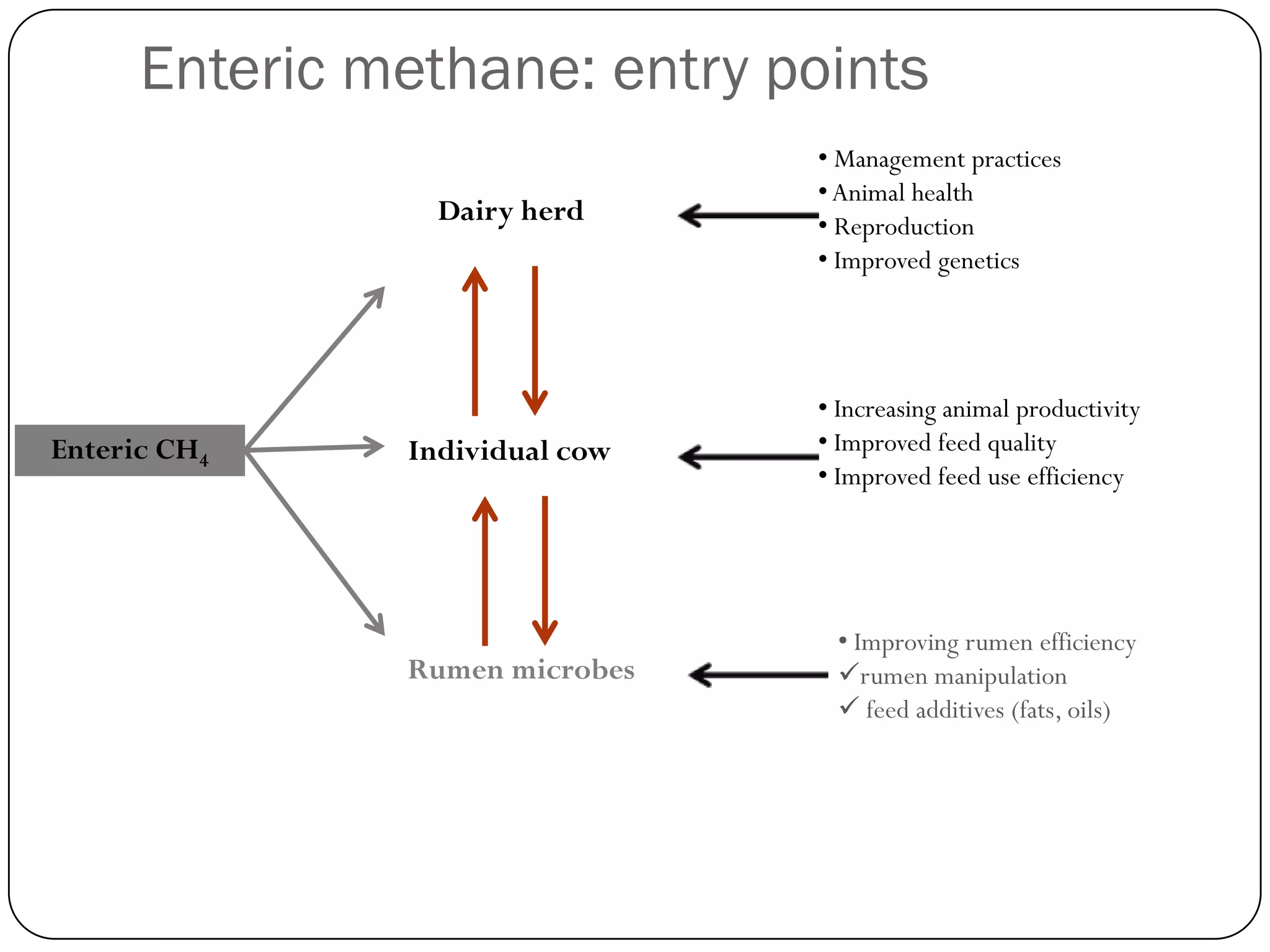

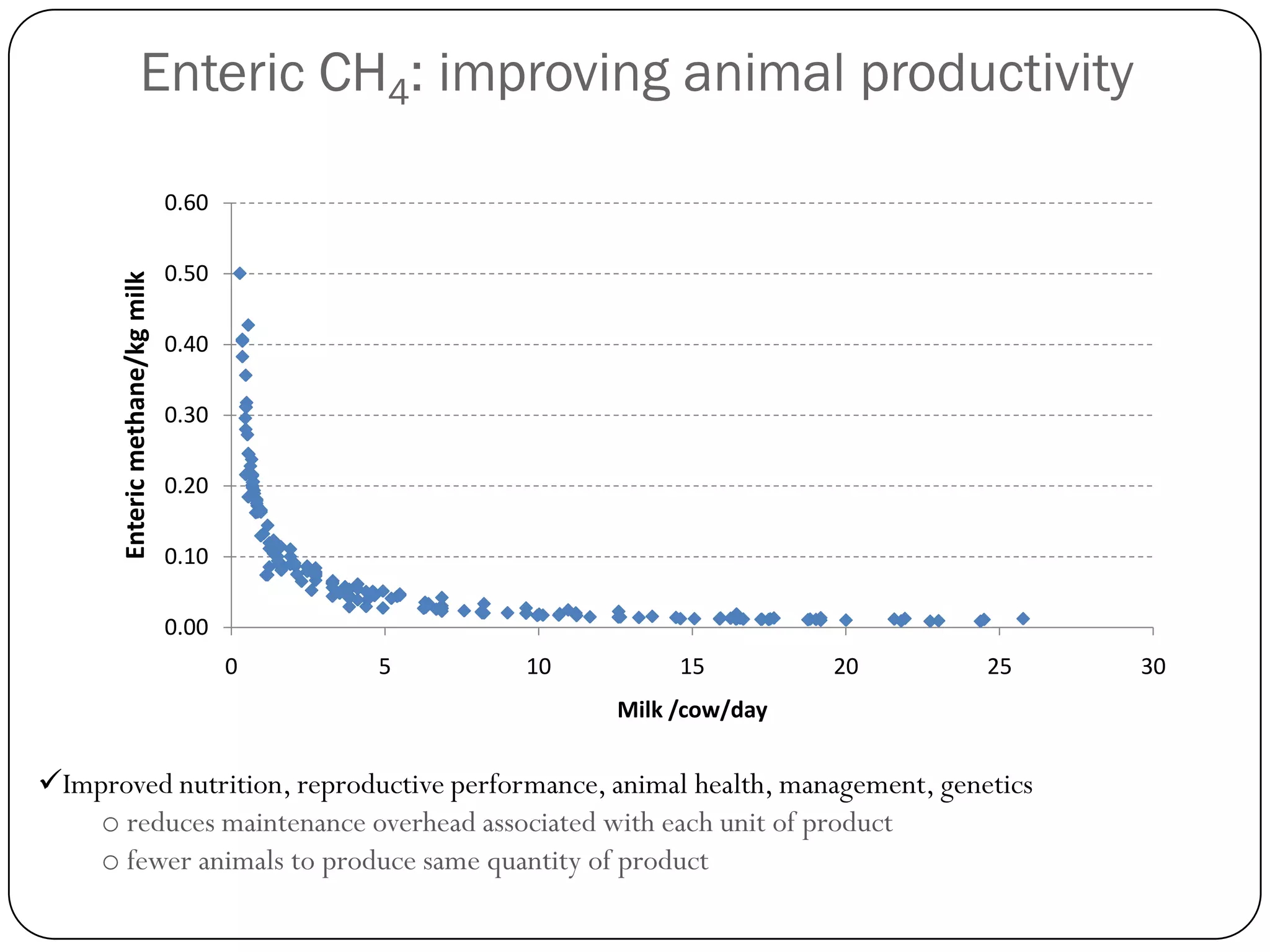

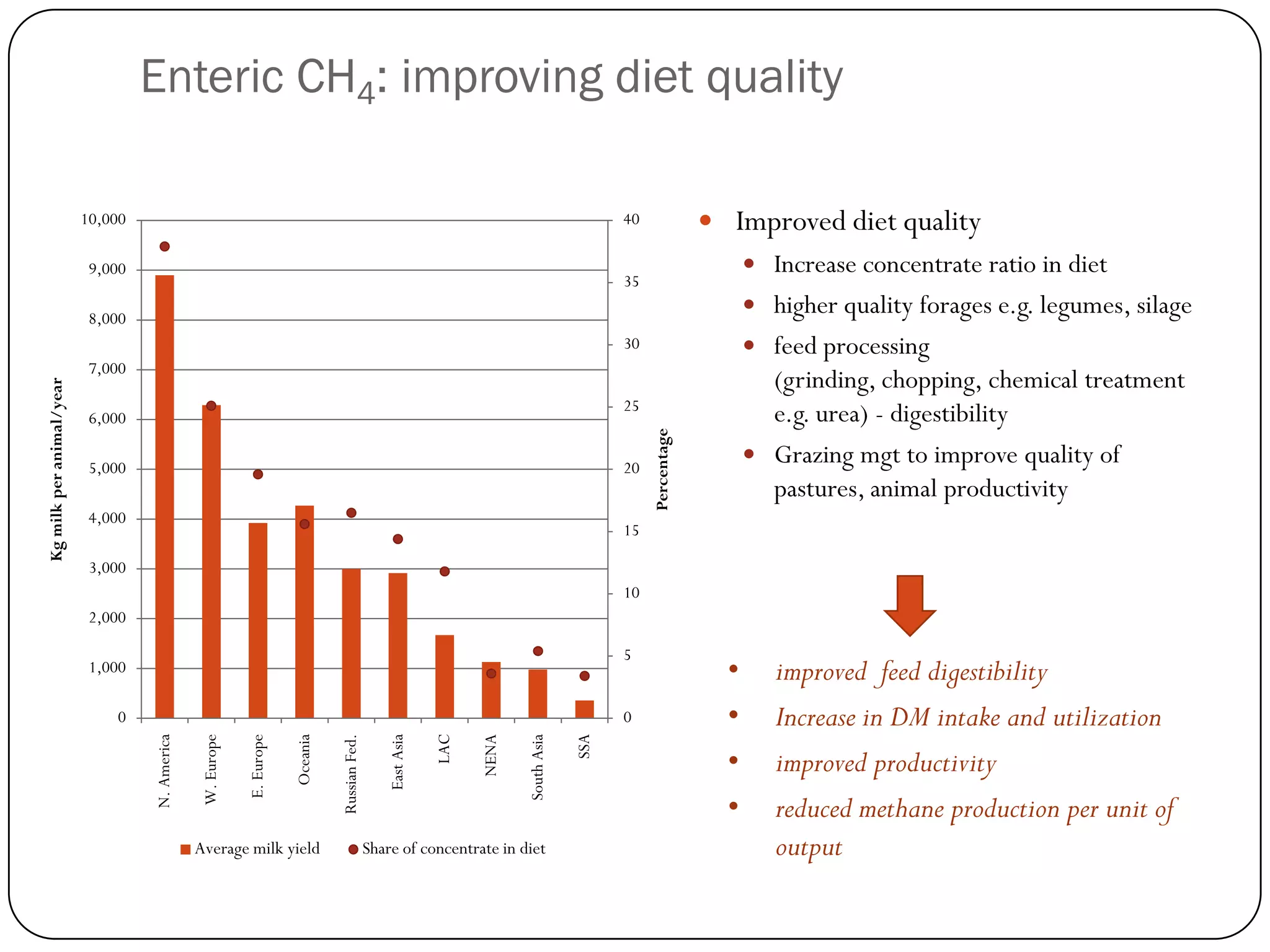

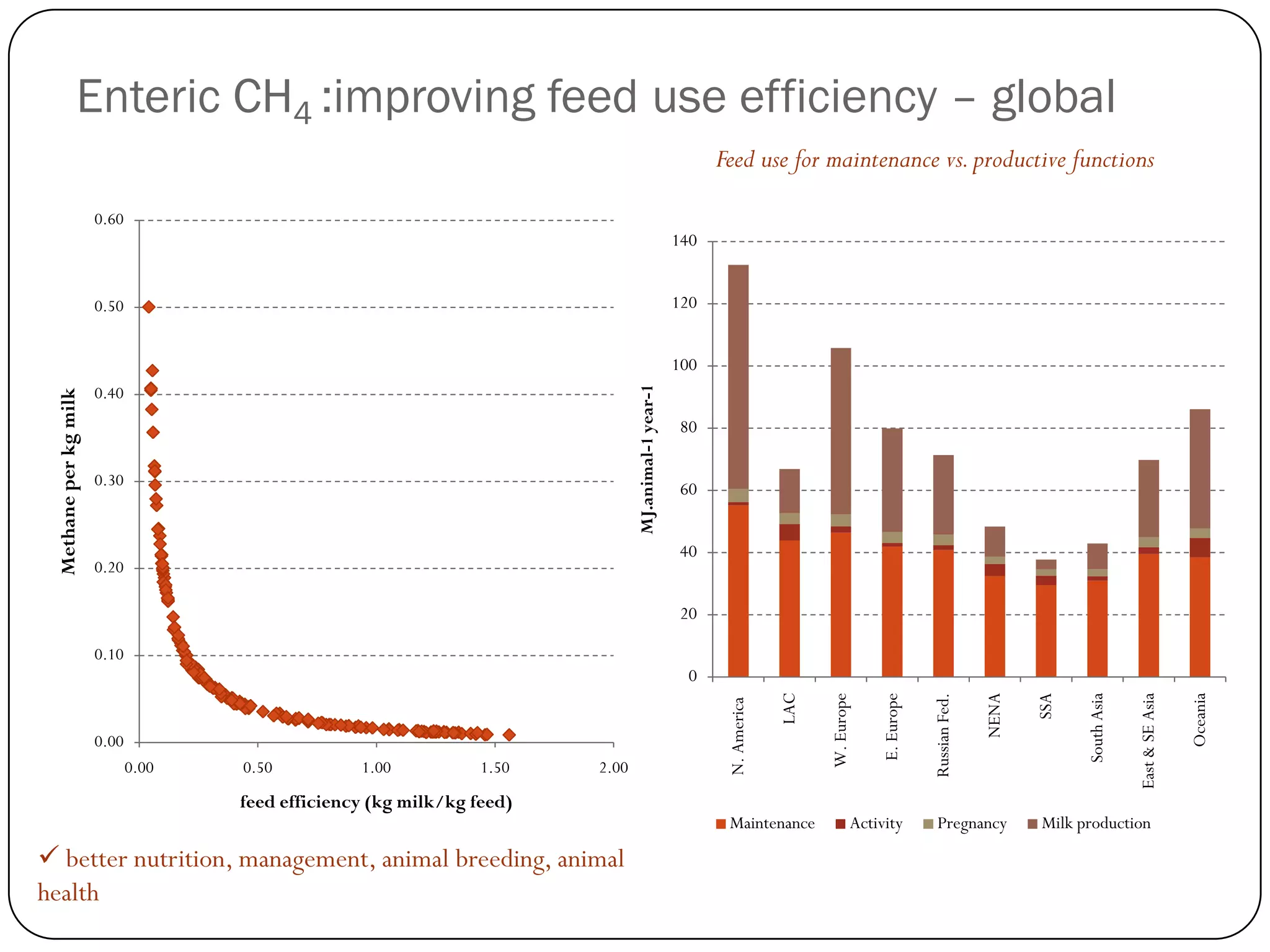

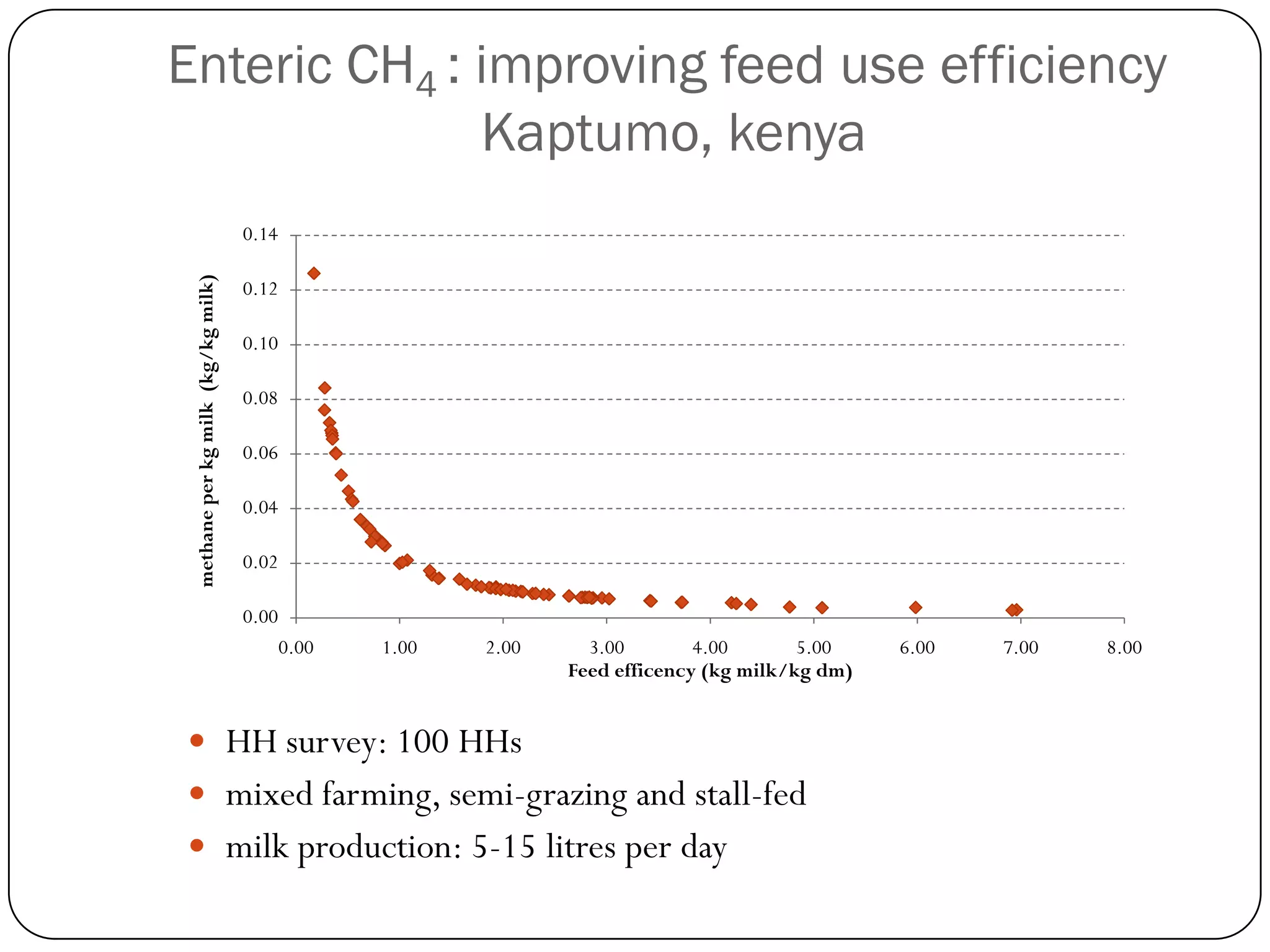

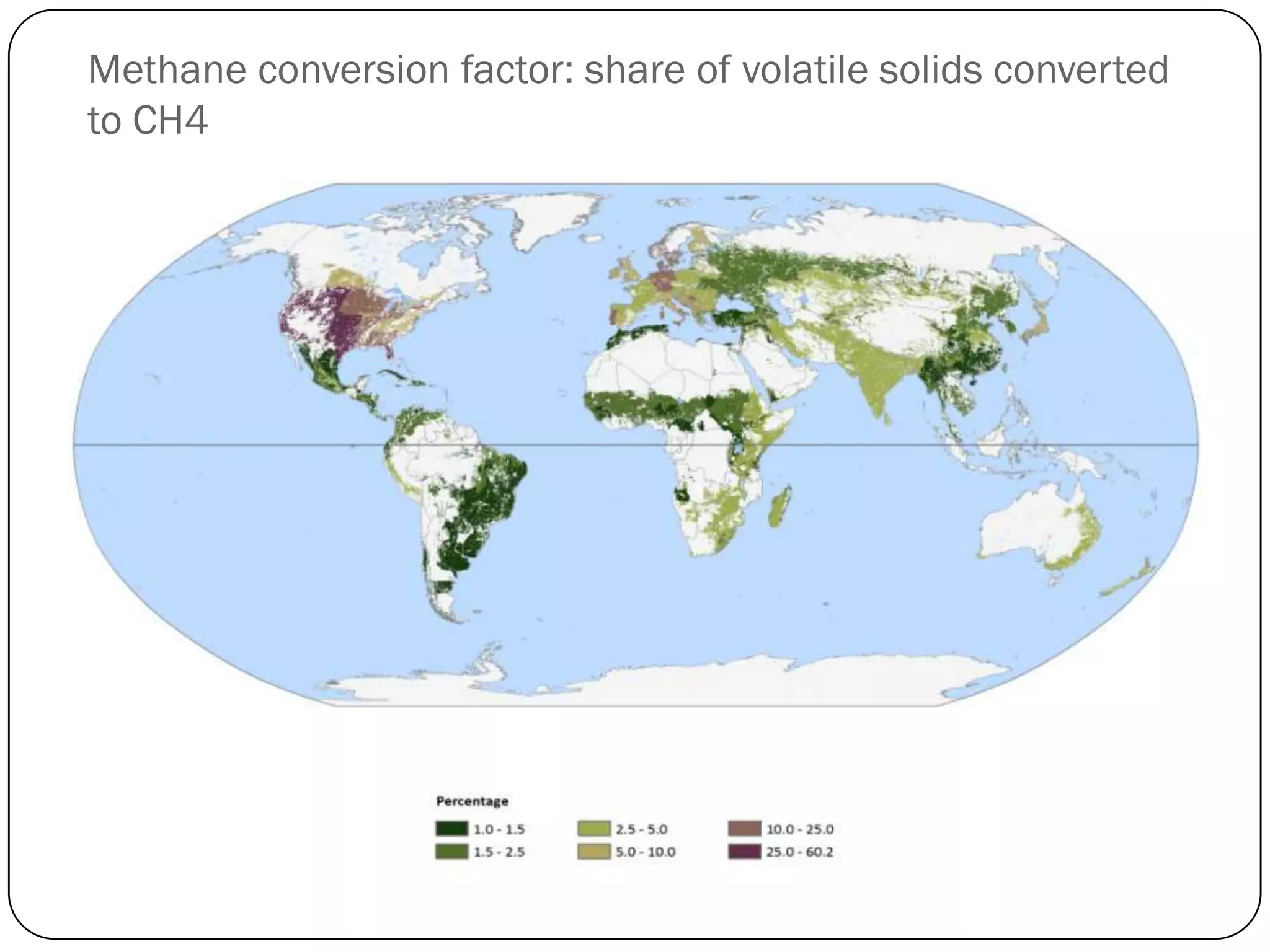

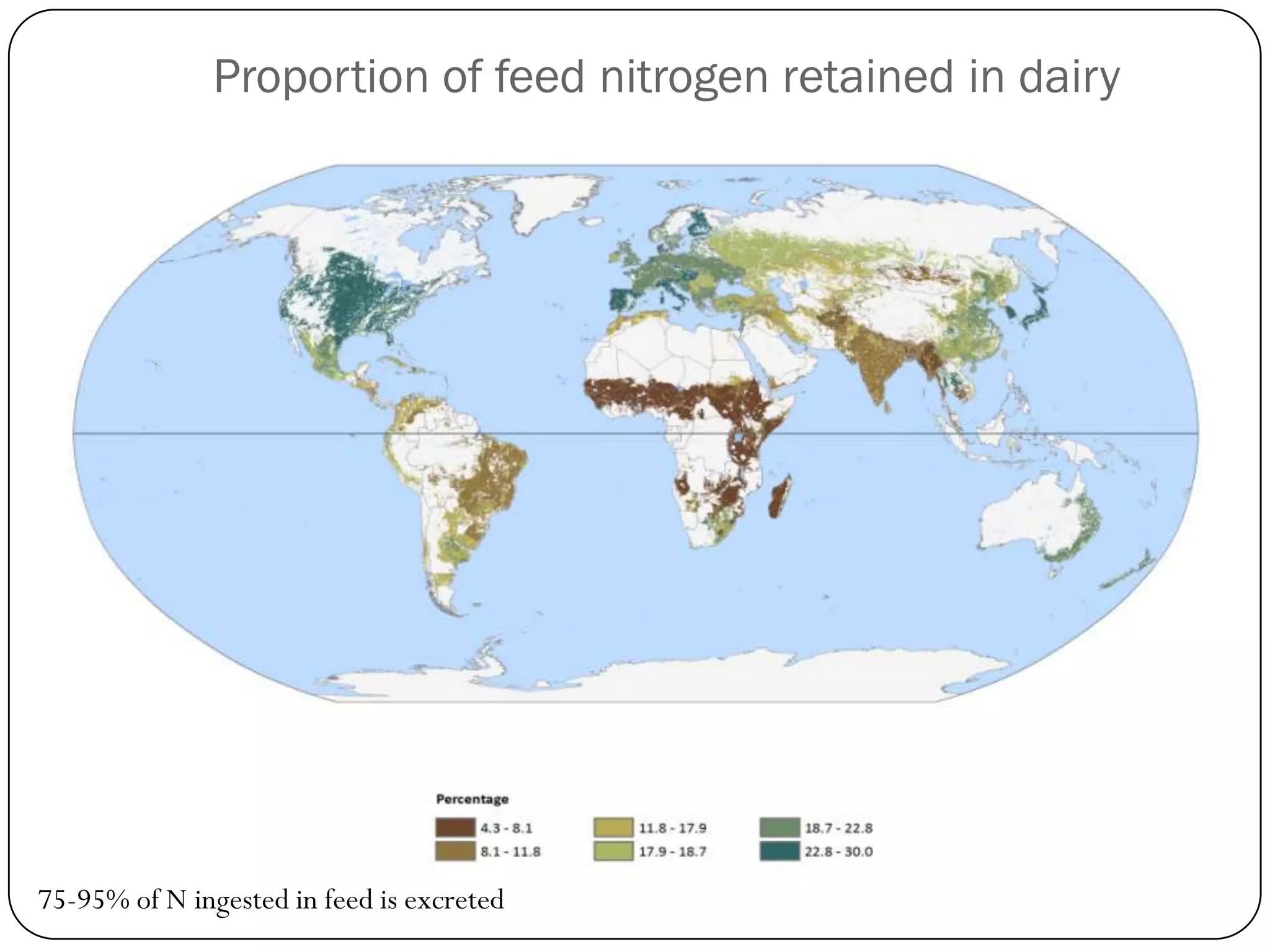

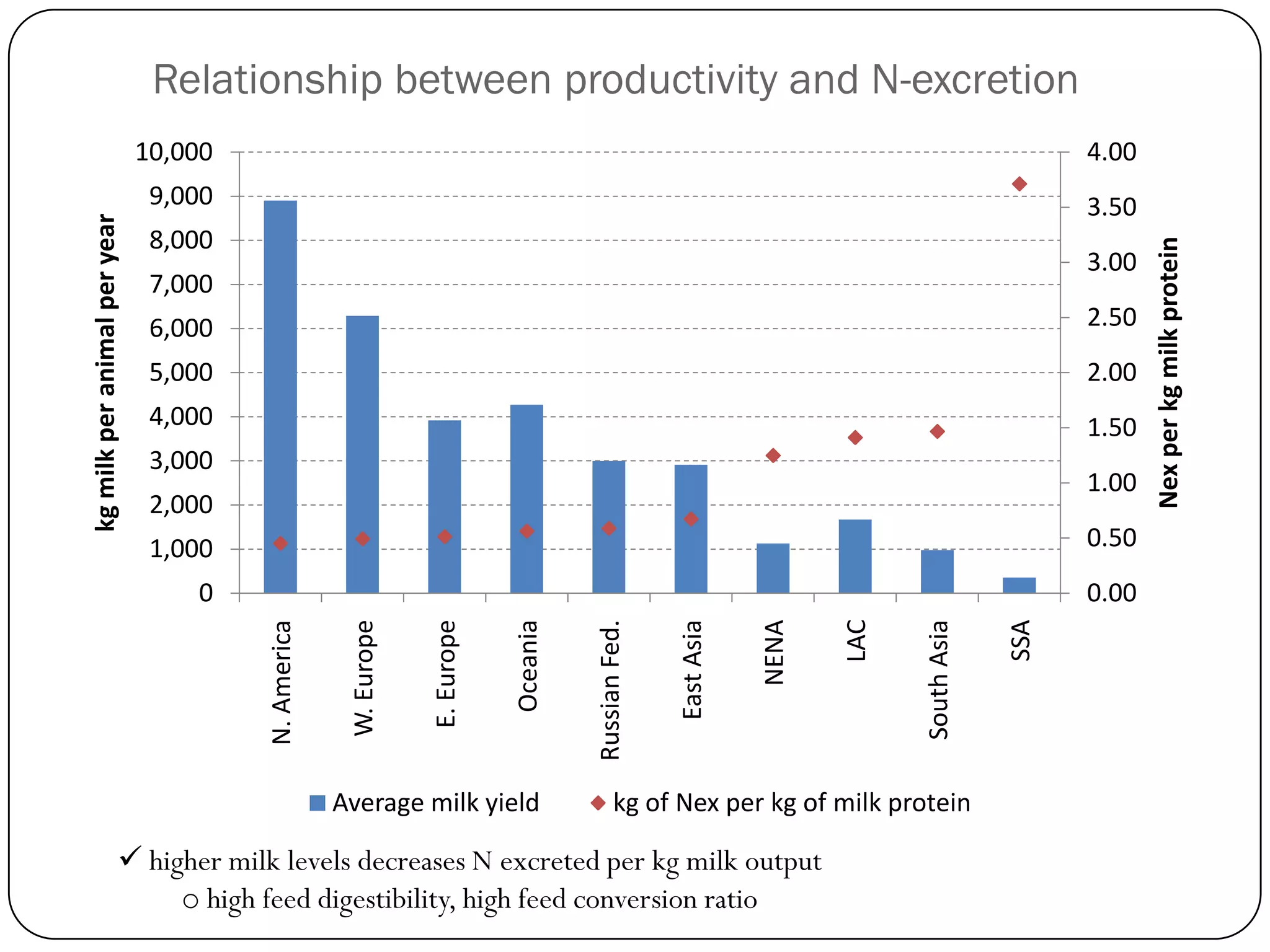

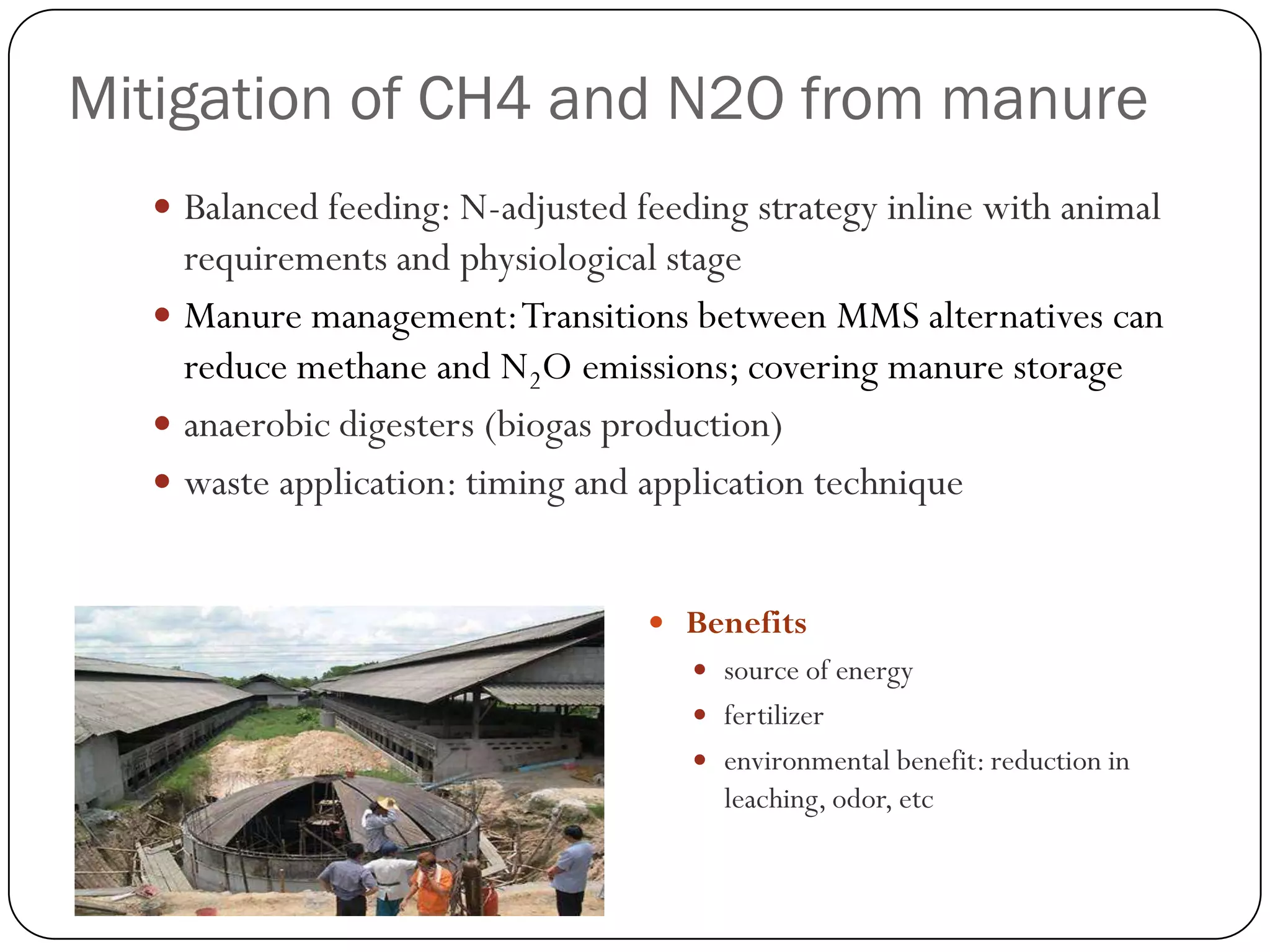

The document discusses technical mitigation options for reducing carbon emissions in dairy production, focusing on areas such as enteric methane and manure management. It presents various strategies to enhance dairy productivity while lowering emissions, including improved animal health, genetics, and feed efficiency. The need for cost-effective implementation of these options and consideration of emission trade-offs is emphasized.