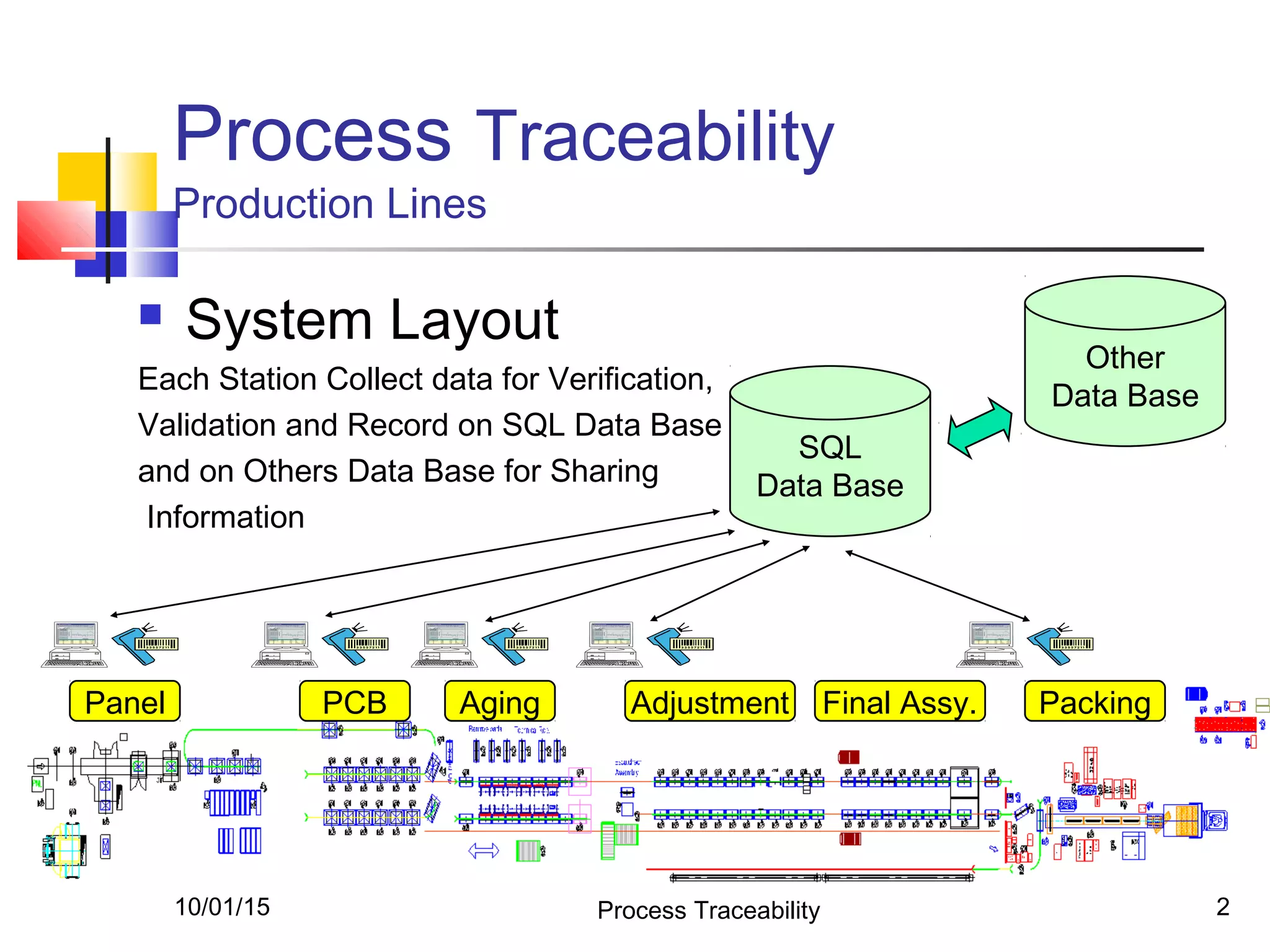

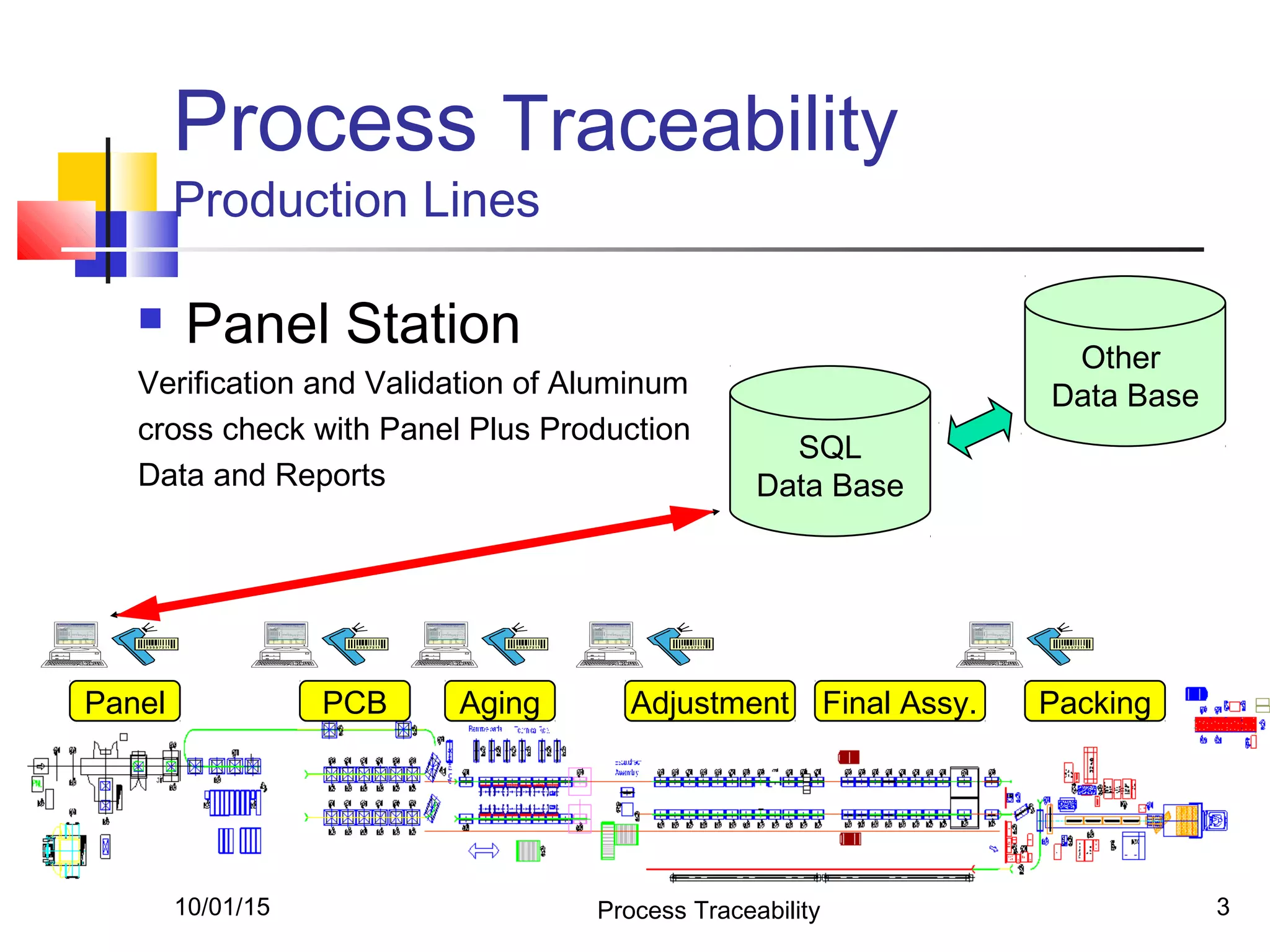

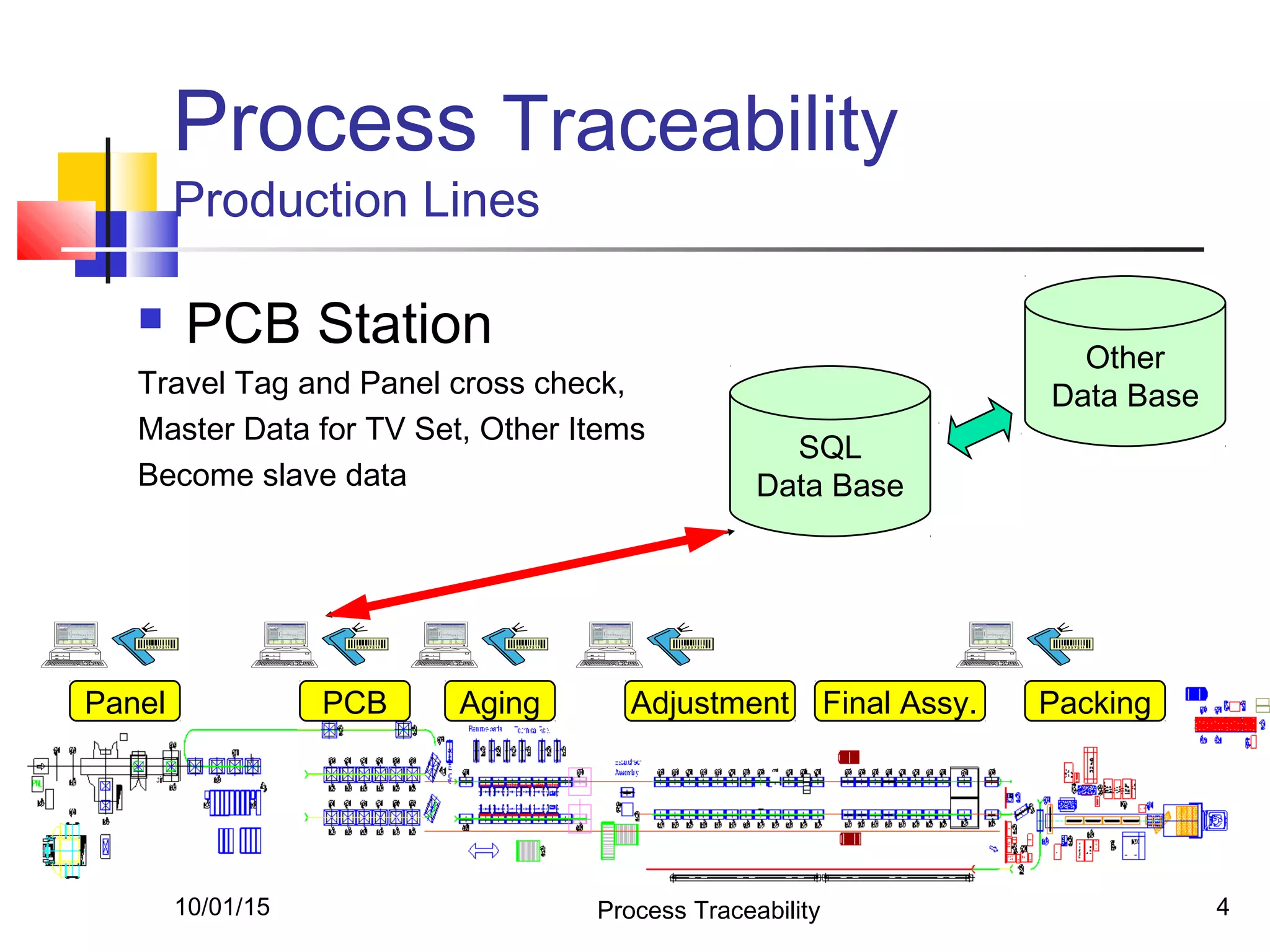

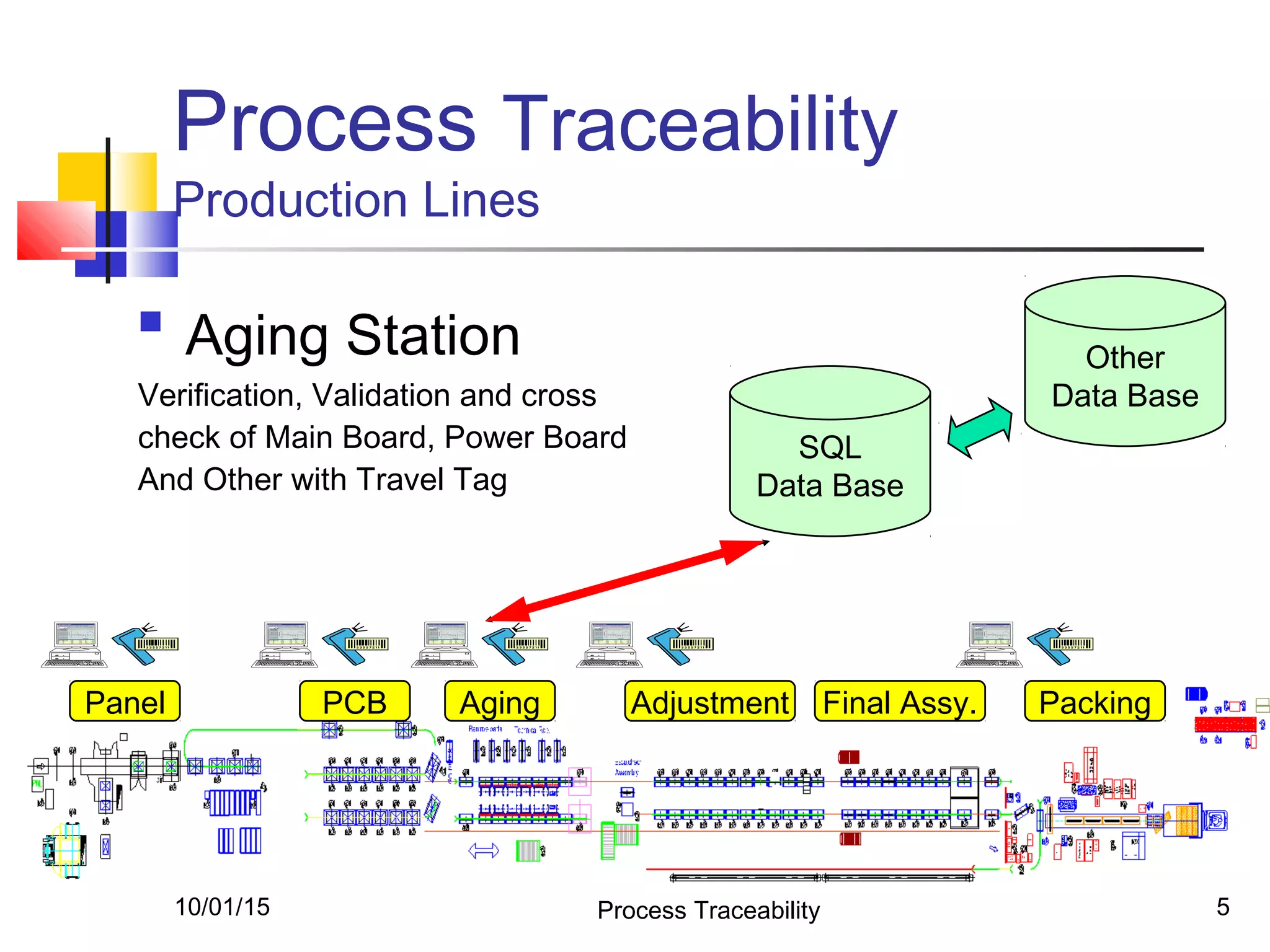

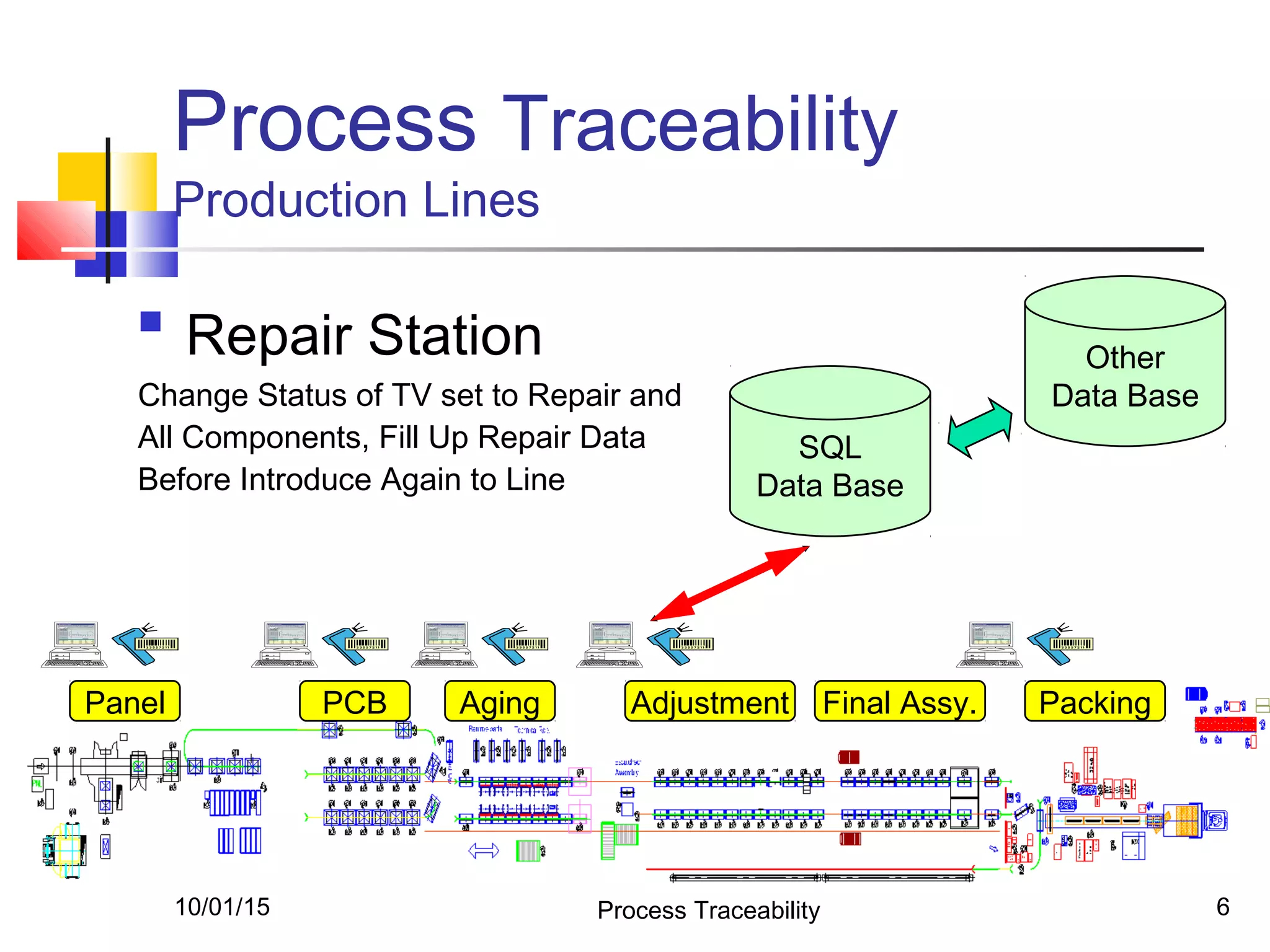

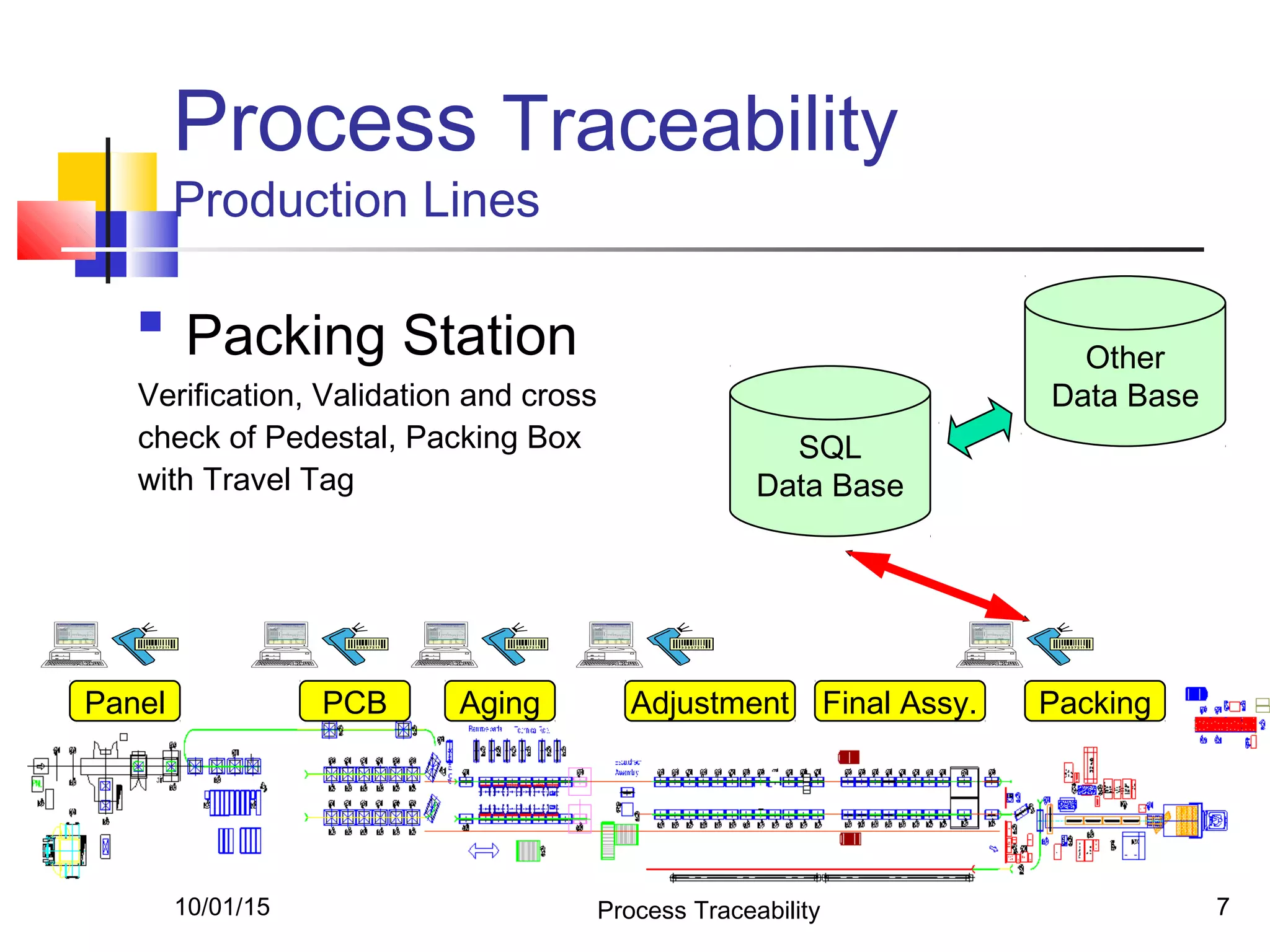

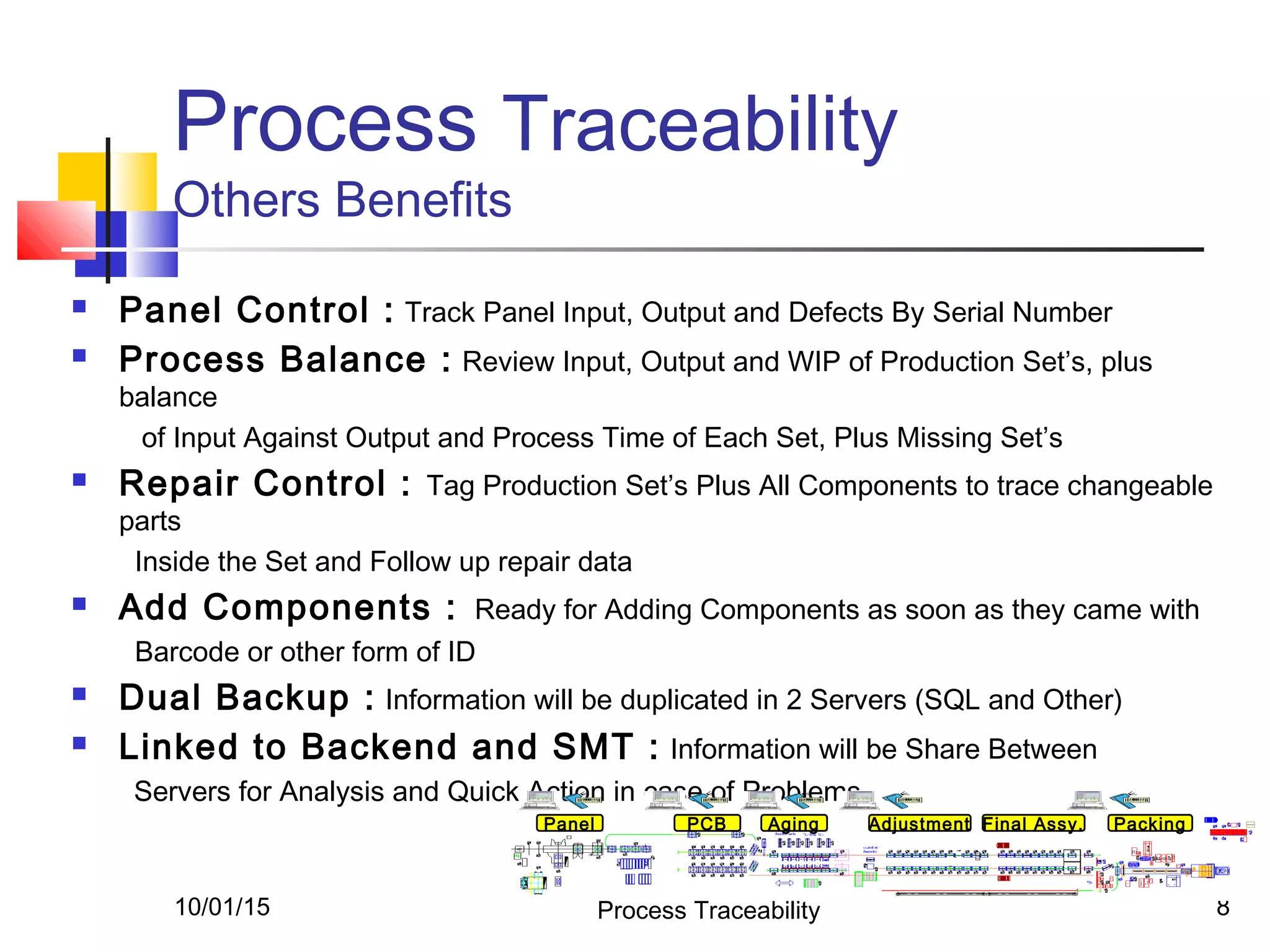

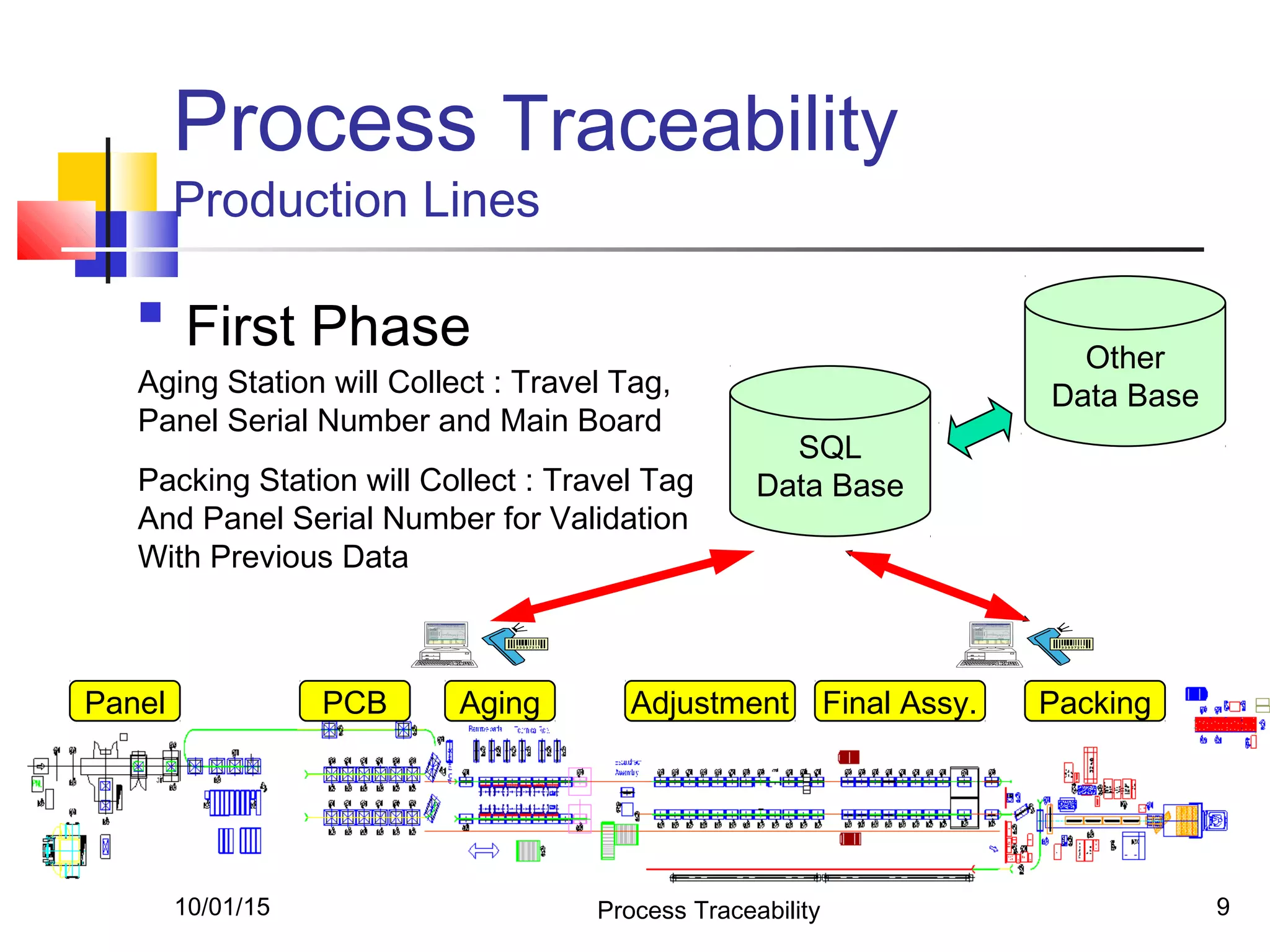

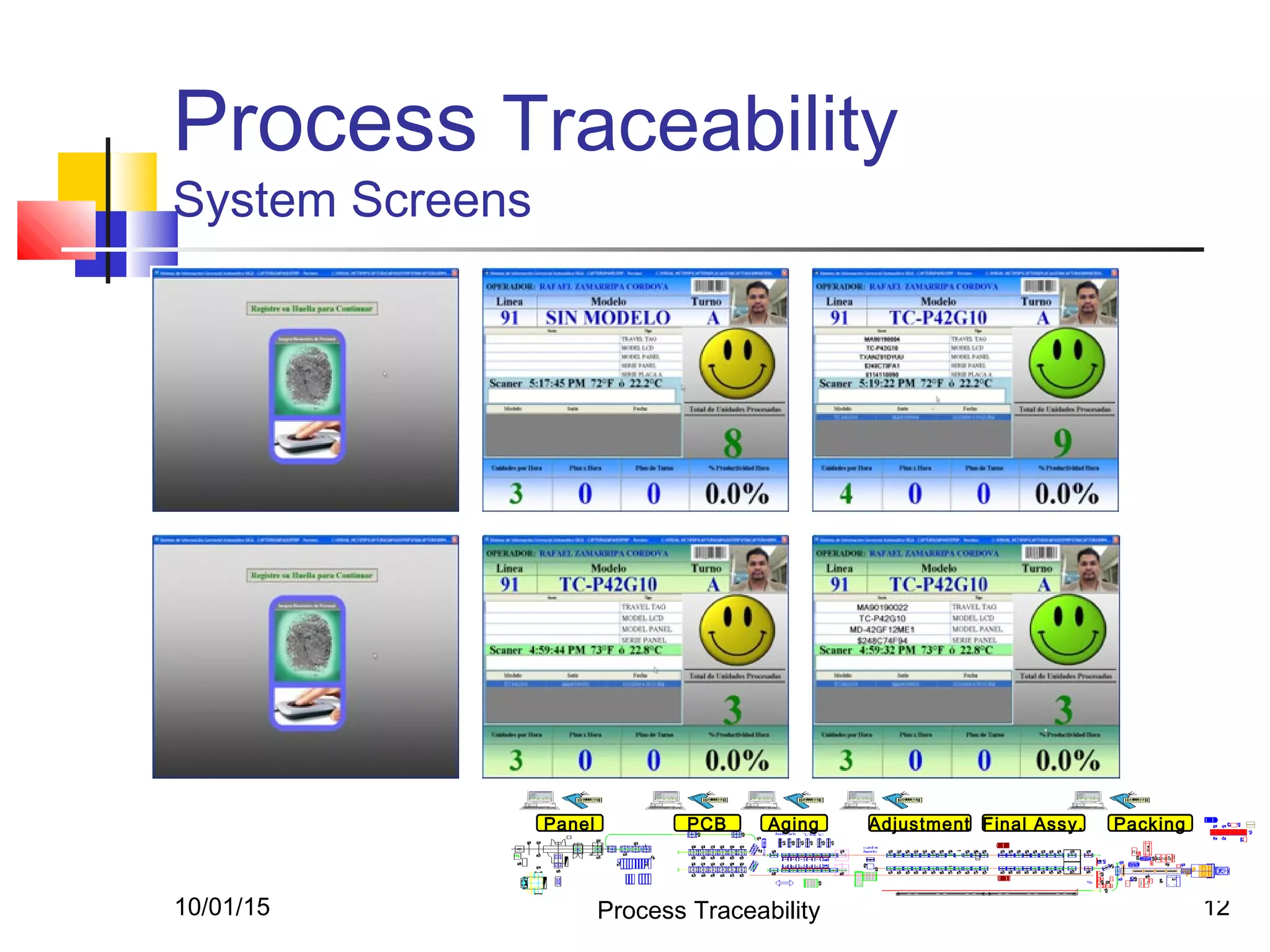

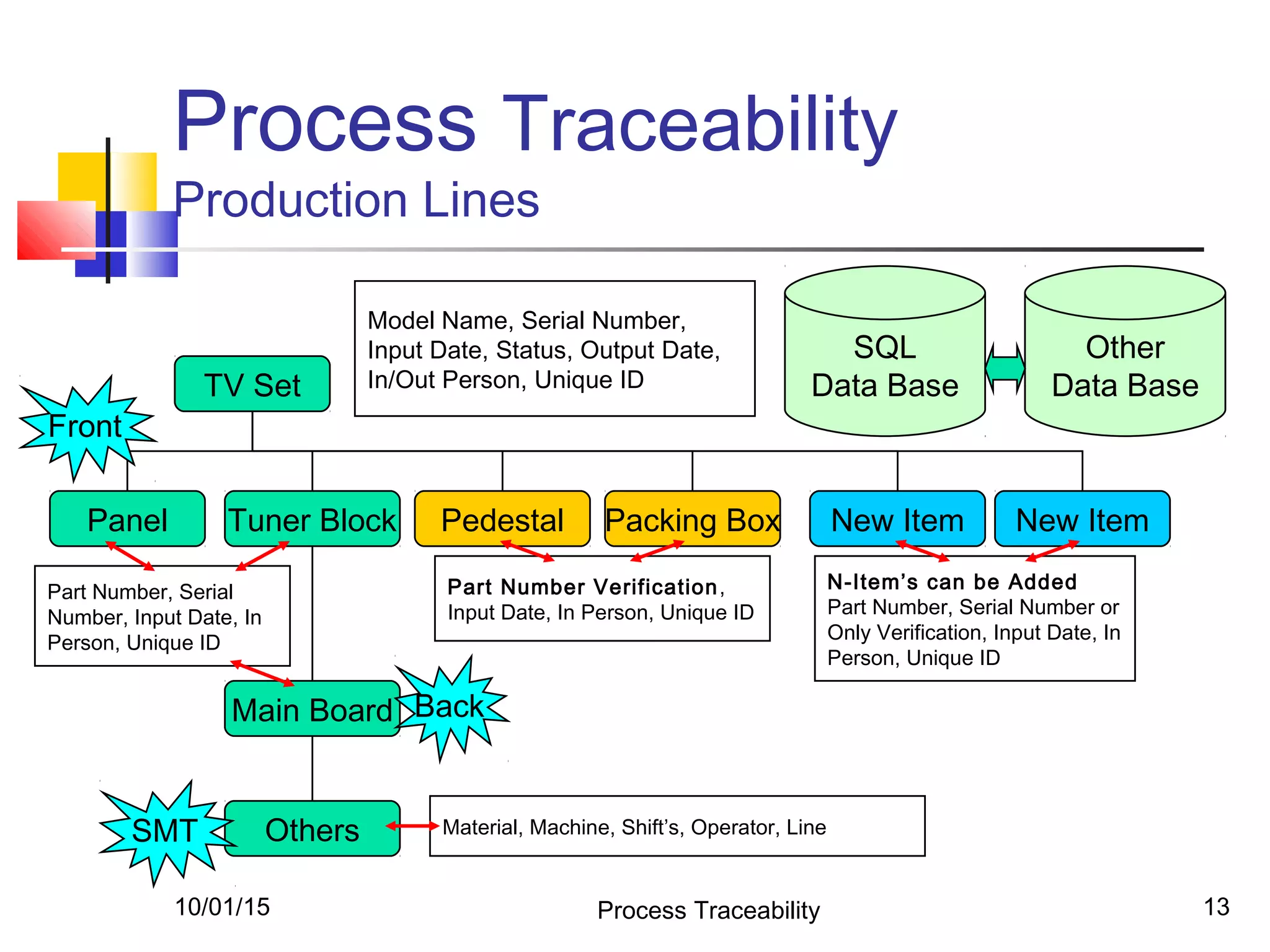

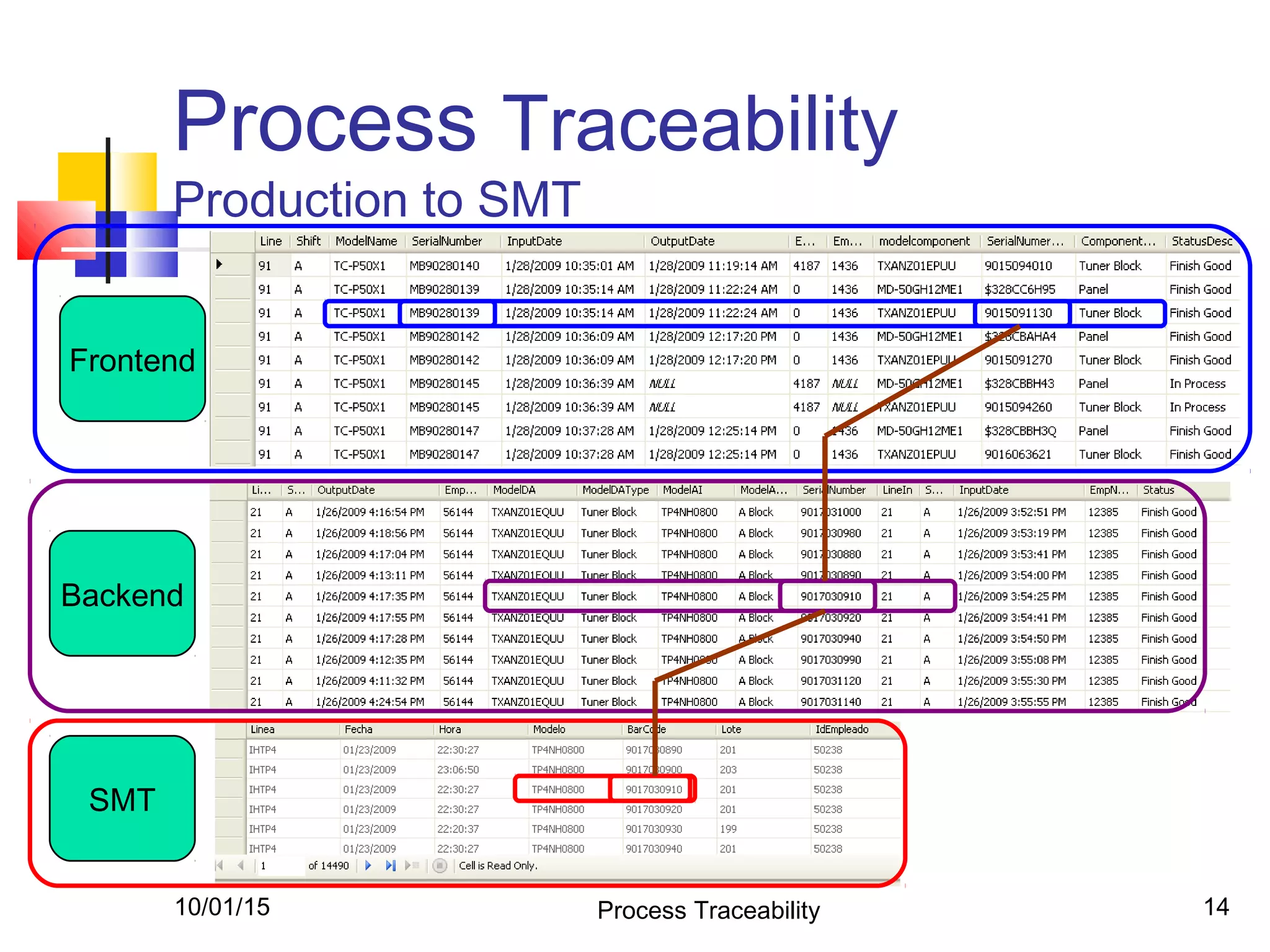

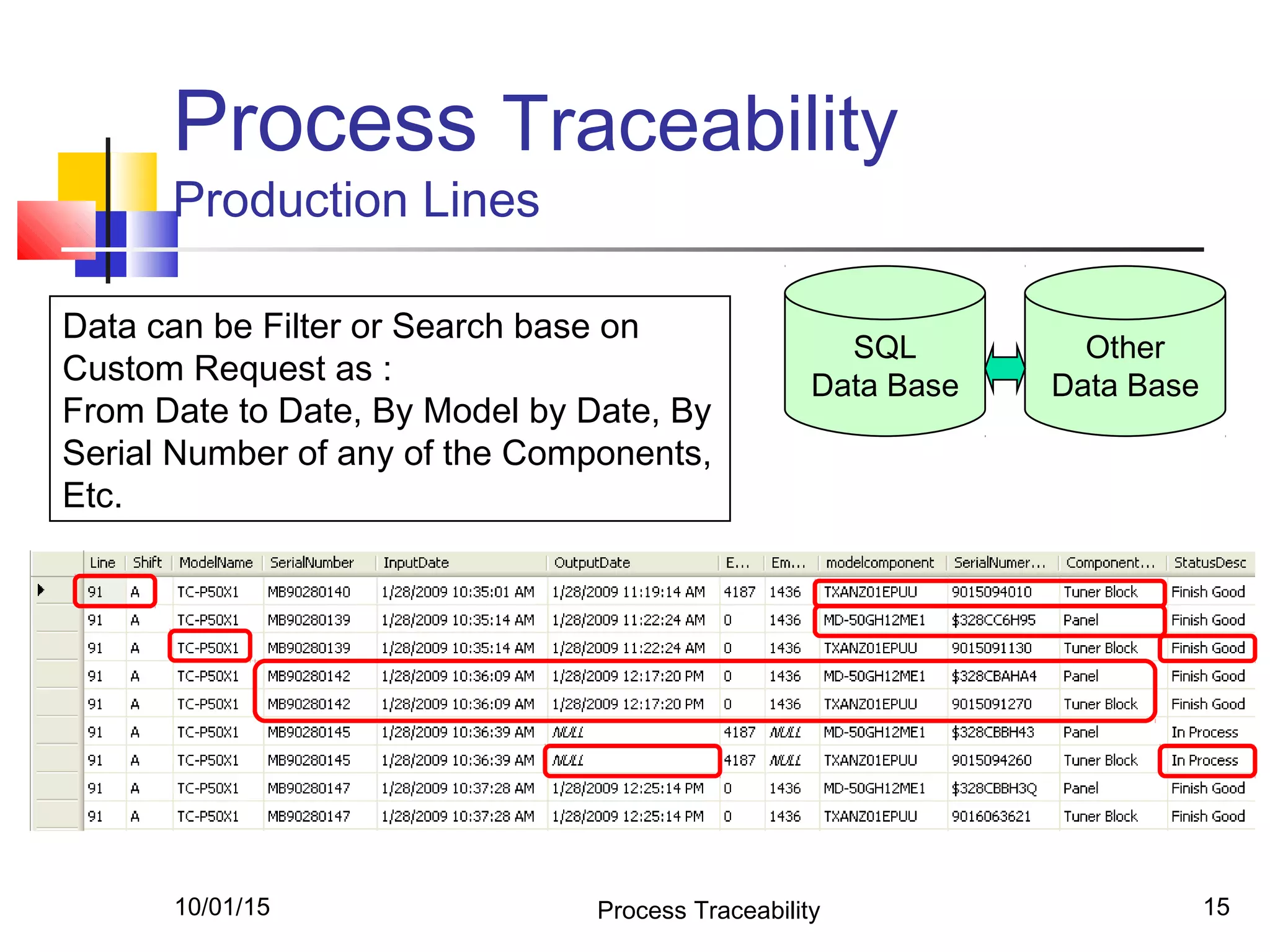

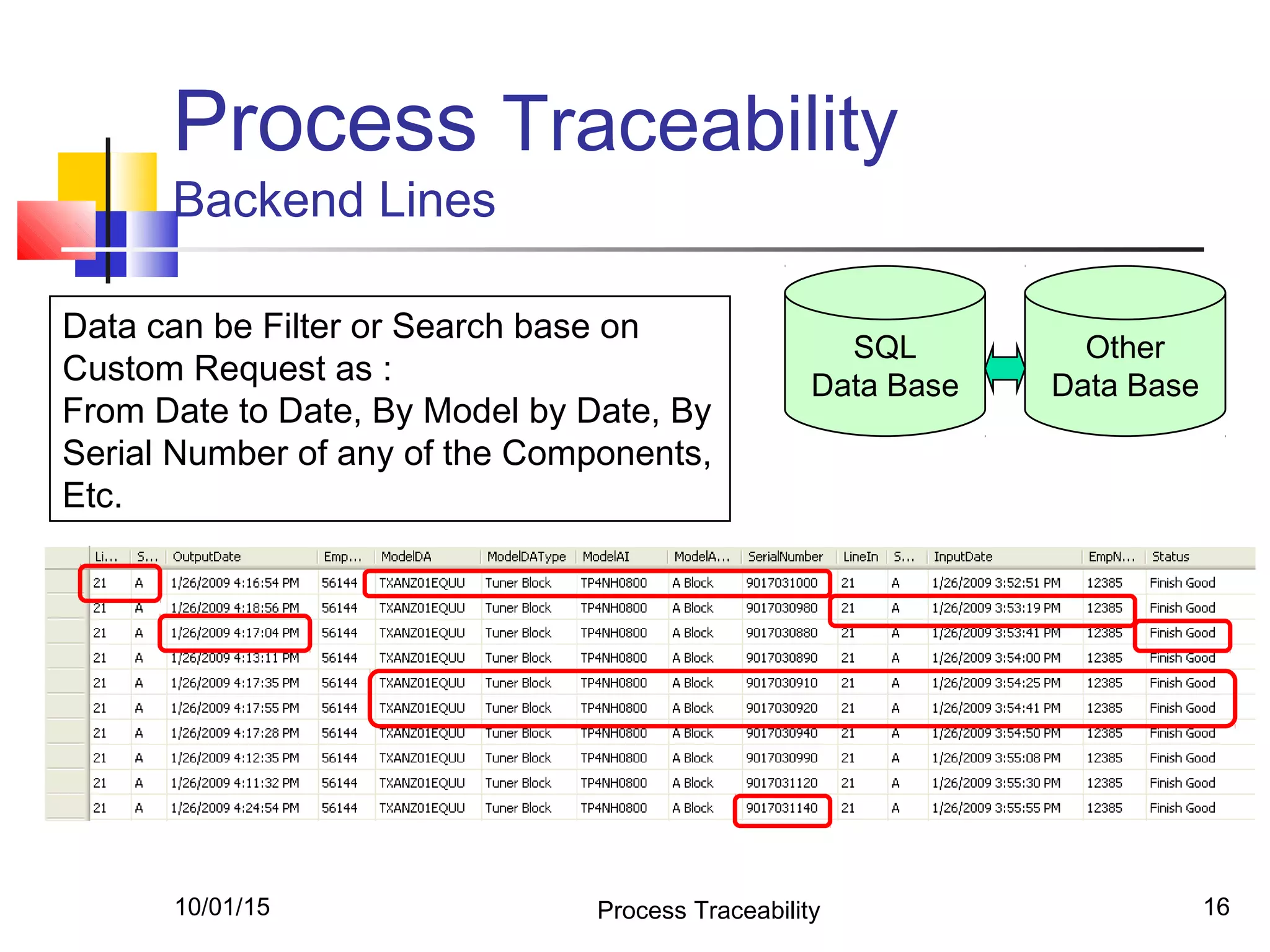

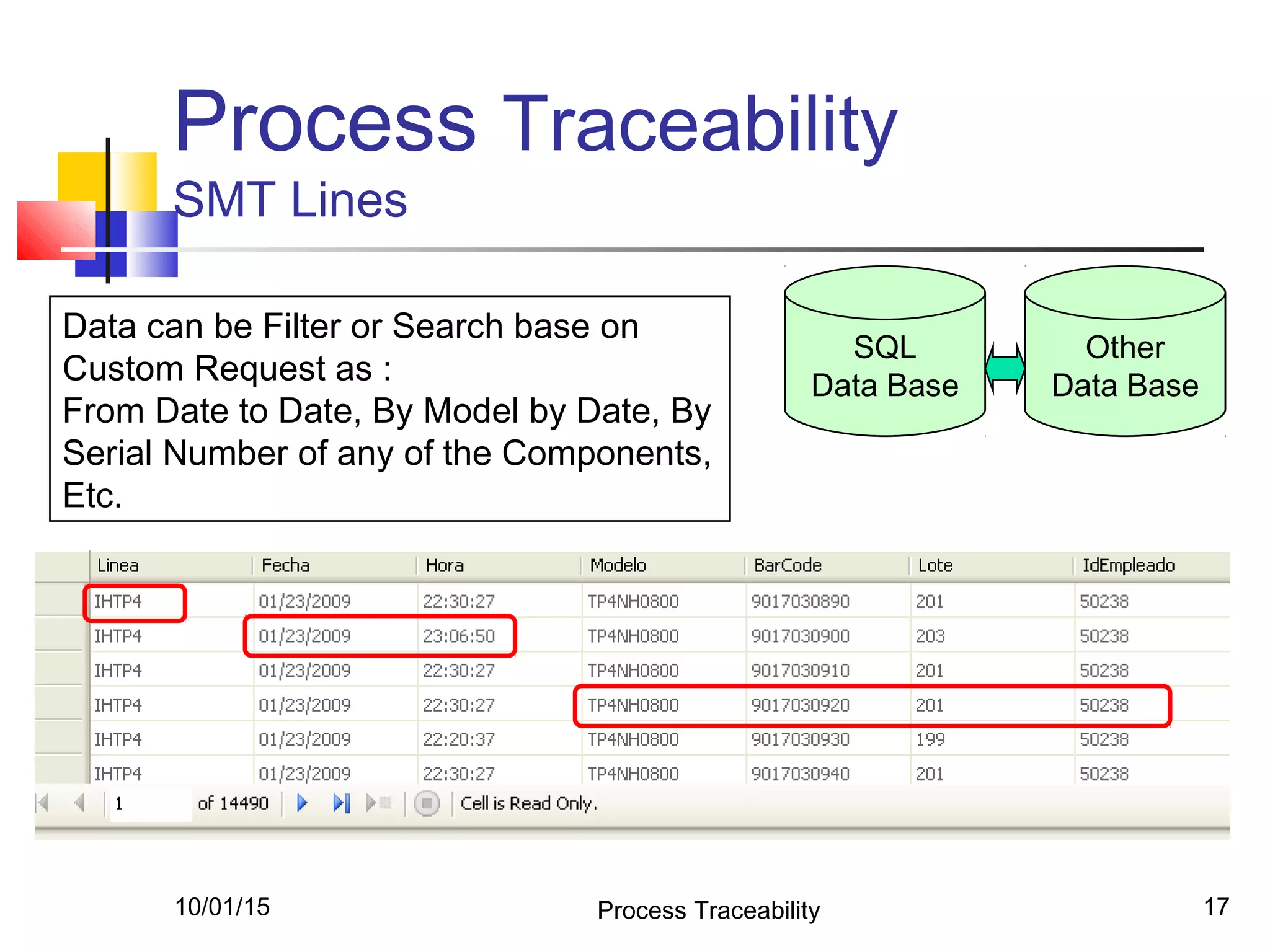

The document describes a process traceability system that collects data at each stage of production including panel, PCB, aging, repair, and packing stations. The data is stored in SQL and other databases and includes travel tags, serial numbers, statuses, and validation information to trace components through the process. Reports can be generated from the databases and the system is designed to link production, backend, and SMT lines for analysis and issue detection across the manufacturing workflow.