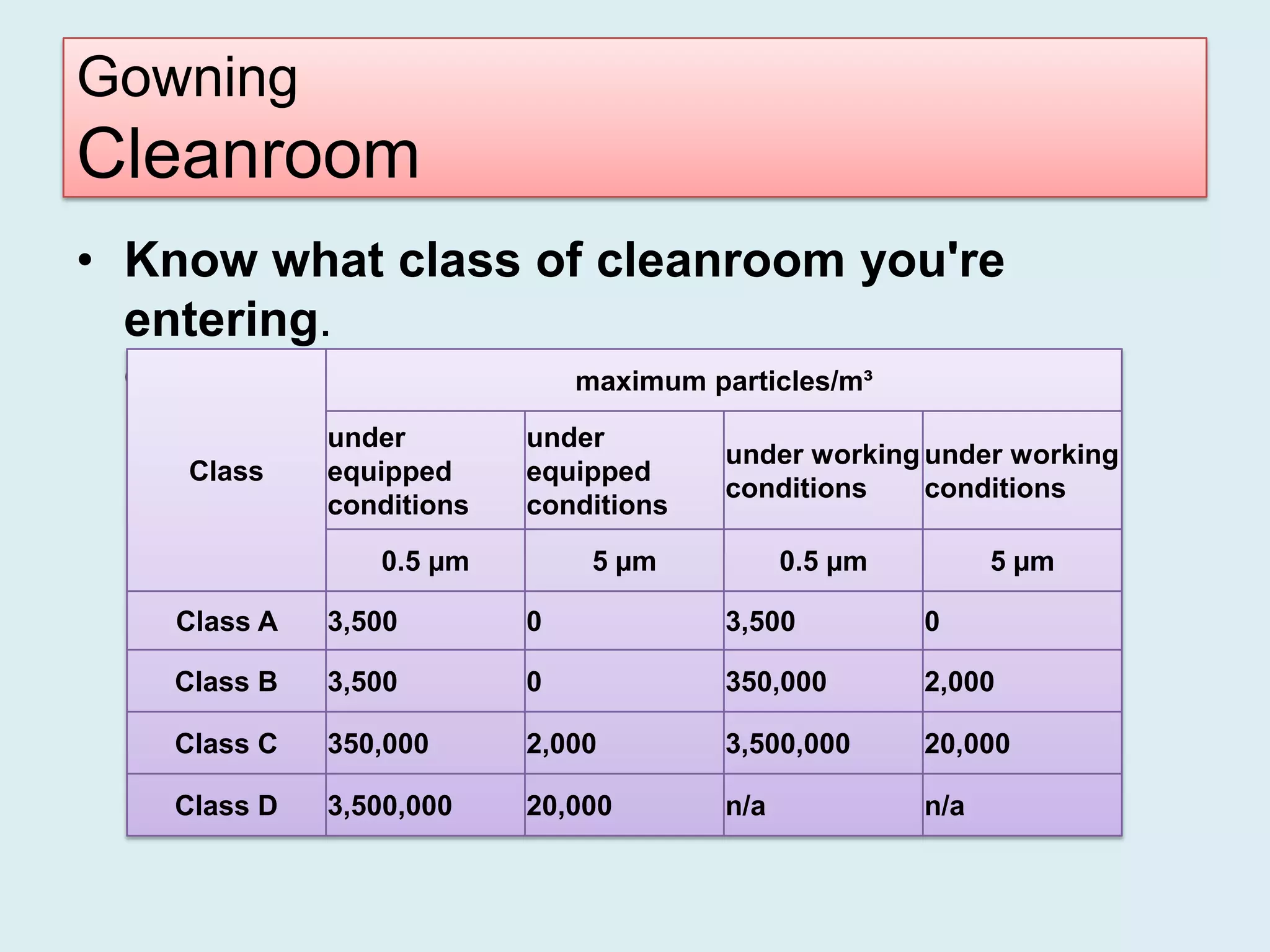

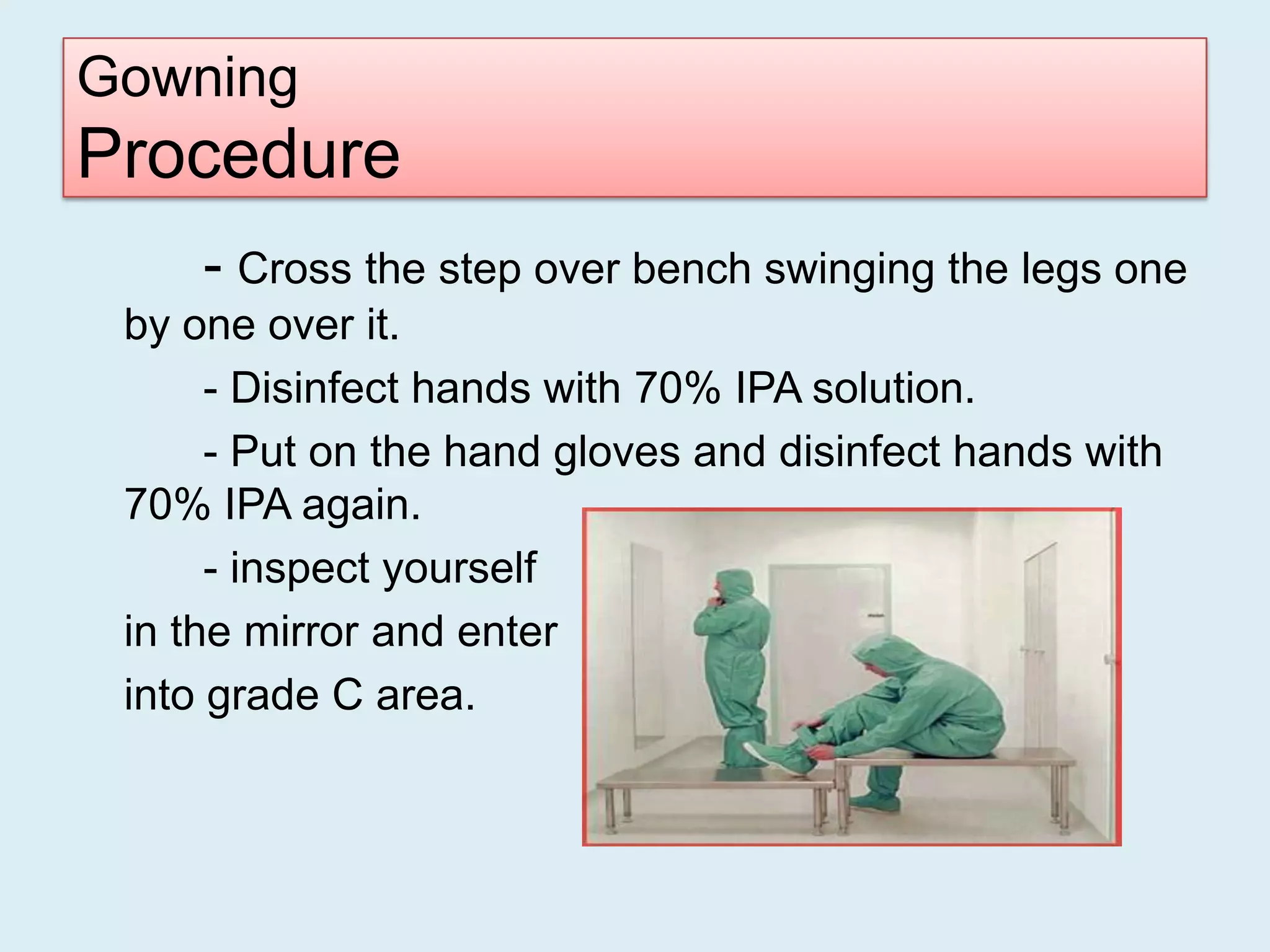

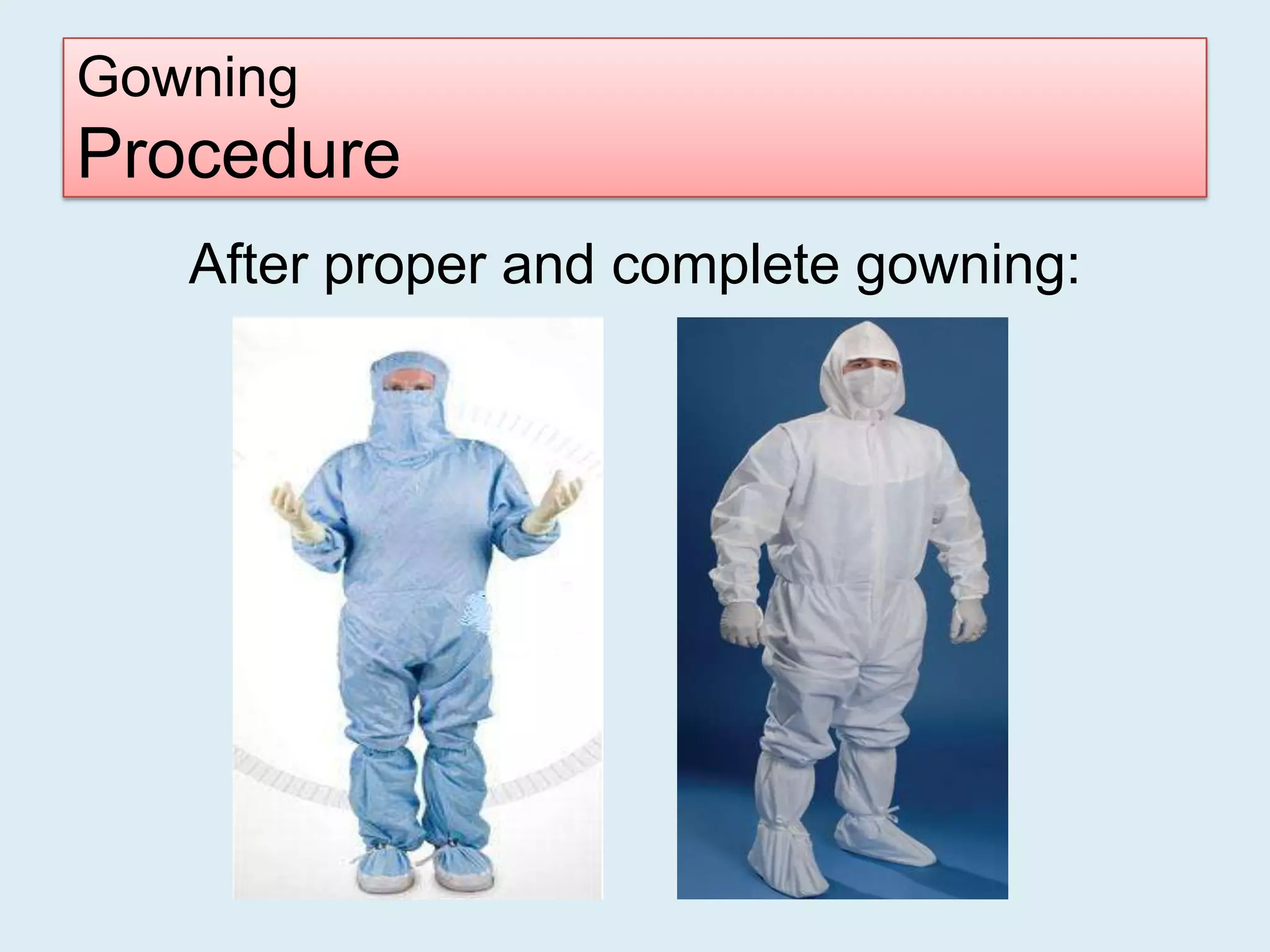

Gowning refers to wearing special garments to control particulate contamination in cleanrooms. Correct gowning procedures are important because contamination can be invisible. Operators must be well-trained in gowning to avoid introducing contamination. Gowning includes showering and hygiene at home, changing at work while avoiding contact with floors, and wearing multiple layered garments specific to each cleanroom grade that fully cover the body and shed no particles. Proper gowning allows entry to production areas while avoiding contamination.