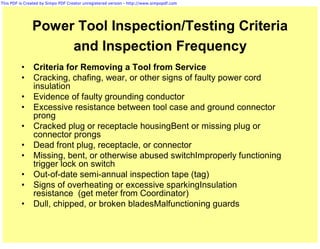

This document provides guidelines and information on industrial safety. It discusses proper use of personal protective equipment, safe tool usage, creating exclusion zones, electrical safety practices, chemical management, hazard communication, and hazardous waste handling. Specific topics covered include safety eyewear, footwear, head protection, hearing protection, portable power tool inspection criteria, establishing warning signs, lockout/tagout procedures, and chemical labeling and training requirements. The document aims to reduce accidents and adverse effects from chemicals and ensure overall workplace safety.

![This PDF is Created by Simpo PDF Creator unregistered version - http://www.simpopdf.com

• • Use proper personal protective equipment.

• • Store tools in appropriate storage facilities

when not in use.

• • Inspect all portable power tools upon

receipt, and at least semi-annually thereafter,

using the criteria given in Table 1. If a tool is

defective, remove it from service immediately

and repair or discard it. If it passes the

inspection and tests, label it with the inspection

date [as indicated in Table 2 ] on commercially

available foil labels designed for this purpose.](https://image.slidesharecdn.com/safetyfirst-110205003040-phpapp01/85/Safety-first-11-320.jpg)