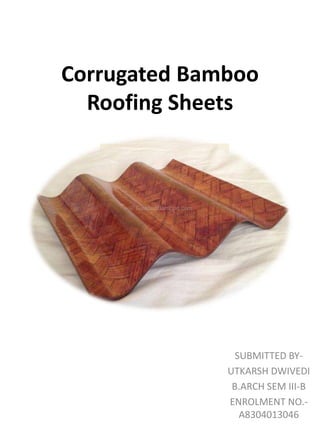

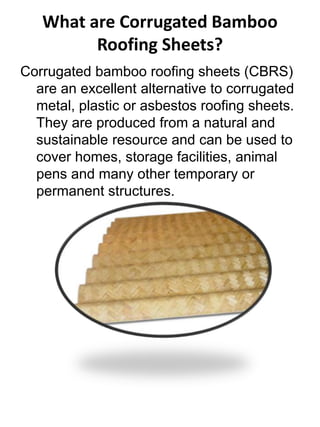

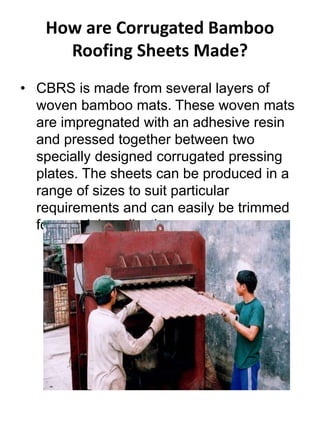

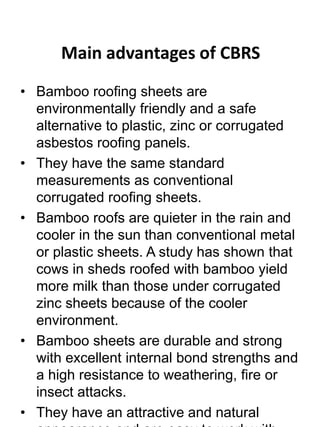

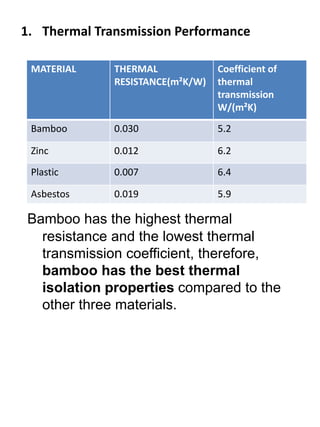

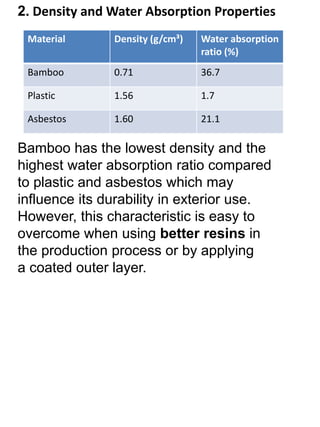

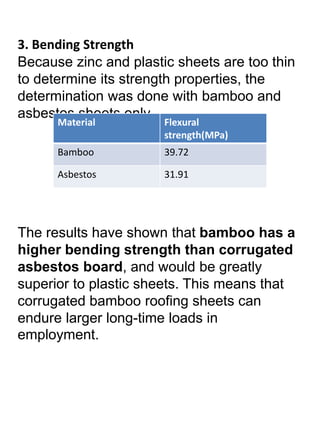

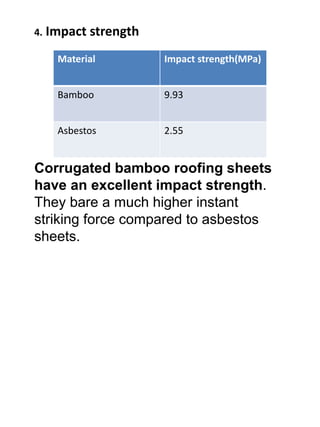

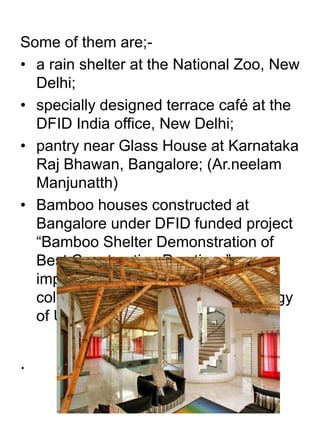

Corrugated bamboo roofing sheets are an environmentally friendly alternative to metal or plastic roofing sheets. They are made by weaving bamboo strips into mats, soaking the mats in adhesive resin, and pressing them together under heat and pressure to form sturdy, water-resistant sheets. Research showed that bamboo sheets provide better thermal insulation than zinc, plastic, or asbestos sheets. Bamboo also has higher bending and impact strength, making it a durable roofing material. Several government-funded projects in India have promoted the use of corrugated bamboo sheets for construction.