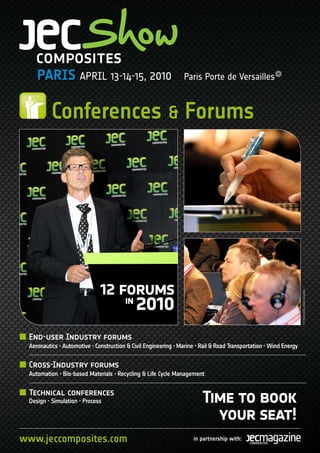

JEC Paris 2010 - Conferences and Forums program

- 1. PARIS APRIL 13-14-15, 2010 Paris Porte de Versailles Conferences & Forums 12 forums © P. Wartenweiler, Mäder Composites in 2010 End-user Industry forums Aeronautics • Automotive • Construction & Civil Engineering • Marine • Rail & Road Transportation • Wind Energy Cross-Industry forums Automation • Bio-based Materials • Recycling & Life Cycle Management Technical conferences Design • Simulation • Process Time to book your seat! www.jeccomposites.com in partnership with:

- 2. Key Topics Gain Insight into the JEC 2010 Program ...................................................... p.4 6 Industry end-user forums: • Aeronautics................................................................................................................ p.14 • Automotive ................................................................................................................ p.8 • Construction/Civil Engineering ................................................................................ p.7 • Marine ........................................................................................................................ p.15 • Rail & Road Transportation ..................................................................................... p.17 • Wind Energy.............................................................................................................. p.16 3 Cross-industry forums: • Automation................................................................................................................ p.11 • Bio-Based Materials................................................................................................. p.12 • Recycling and Life Cycle Management .................................................................. p.6 3 Technical conferences: • Composites Design in partnership with Stanford University ............................. p.10 • Composites Simulation in partnership with ESI Group ...................................... p.13 • Composites Development Process in partnership with DLR CFRP Research .. p.9 With the testimony of: 3XN architects • 5D composite A Accudyne Systems • Airbus • Airbus Deutschland GmbH • Airbus Operations Ltd • Ashland Finland Ltd • Audi Lightweight Center • Automobili Lamborghini S.p.A B BASF SE • Beijing Institute of Aeronautical Materials • Bombardier Aerospace C Carbo-Link • CFK Valley Stade Recycling • Composites Evolution Ltd • CPIL • CTC GmbH D Daher Socata • Dantec Dynamics GmbH • D’Appolonia S.p.A • Dassault Aviation • Dassault Systèmes Decathlon / Artengo (Oxylane group) • DLR - The German Aerospace Research Center Dow Deutschland GmbH & Co. OHG • DSM Composite Resins AG • DSM Composite Resins AG E EADS - Astrium Space Transportation • EADS Deutschland GmbH • Ecole Polytechnique at University of Montreal • EPL Composite Solutions Ltd. • ESI Group • Eurocopter F Fokker Aerostructures G Gamesa, Gruntech Polymer Consultants • Gurit UK • GWEC H HDS • Huntsman Advanced Materials I Icolfibra • Ifremer • Invent GmbH • ITCA S.p.A. • I-Trans L LCPC (Laboratoire Central des Ponts et Chaussées) • Lineo M MAG Europe • Mainz University of Applied Sciences • Mikkeli University of Applied Sciences N National Technical University of Athens • NCD • NpSp P Pôle Européen de la Plasturgie PPE • Premier Composite Technologies • Premium Aerotec GmbH R Ruredil S Stanford University • Swerea Sicomp AB T Technical University of Munich The Katholieke Universiteit Leuven (Belgium) • The University of Tokyo • The University of Washington • The University Tokyo • Total Petrochemicals • Toyota Motor Corporation • Trimarine SRL • TTT The Team Technology GmbH U UAM • University of Bristol • University of Nottingham V Vistagy Aerostructures. 2 www.jeccomposites.com

- 3. Edito C omposite materials have rapidly become a mainstream technology and material of choice within many industries, from aerospace to wind energy. And today, environmental regulations act as a new innovative driver for a paradigm shift in the composite market. Replacing metals by composites is fundamentally environmentally responsible. In land transportation lightweight composite structures have a big role to play in reducing both the use of petrochemicals and CO2 emissions. Demand for more composite applications keeps on increasing. Now is the time for Add to this the fact that low-weight carbon fibre structures Eco composites reach the ends of their service lives, and it then becomes obvious that Recycling and Life Cycle Management is now a key eco challenge. This is why JEC launches in 2010 its first observance forum on this subject. Bio-based fibres and resins derived from natural, renewable sources have also increasingly received significant interest in recent years due to increased environmental awareness, concern about the depletion of non-renewable resources and the insta- bility in oil prices. In the 2010 forum, you will discover more and more significant innovations in particular in transportation, architecture and sports & leisure. © P. Wartenweiler, Mäder Composites Another main topic at the 2010 JEC Conferences and Forums pro- gram, will be cost control and process automation. The tran- sition from metal parts to composite is an ongoing process but often labor intensive and therefore expensive. To exploit the full potential of composite materials for high performance lightweight structures, it is necessary to consider the entire process chain. Automation can bridge that gap for a long-term profitable serial production. Eco-design, along with cleaner and more eco-efficient processes, highly auto- mated manufacturing techniques, weight reduction, lower production costs… The JEC 2010 Conferences and Forums program will help you gain insight on major market drivers and new energy-saving strategies for composites. We look forward to meeting you at JEC Composites Show Paris. Martine Vesco JEC Forums and Conferences Manager www.jeccomposites.com 3

- 4. Gain Insight into the JEC 2010 program AERONAUTICS Aircraft structures: This Aeronautics forum will look at what has to be done to meet current and likely Cost control - the new battle future requirements for cost reductions. The recently founded UK National Composi- Next generation composite wings: tes Centre will be briefly described and its mission to tackle the issues around low Airbus, Bombardier Aerospace, cost composites will be outlined. Finally, next generation wings at Airbus, Bombar- Daher-Socata dier Aerospace and Daher-Socata, integrating as much composite in the wing as New thermoplastic and recyclable possible to make aircraft more fuel efficient, will be presented. solutions AUTOMOTIVE Energy saving strategy 2010 will be the Automotive year at JEC. Come and discover how Audi, Lamborghi- Cost-effective and lightweight ni, Nissan, Toyota Motor Corporation rely on composite to meet the most stringent materials and processes environmental regulations. Constructors experiences: Audi, Lamborghini, Nissan, Toyota Motor Corporation CONSTRUCTION AND CIVIL ENGINEERING Efficient seismic solutions Designers in Construction and Civil Engineering are getting better and better at Reinforcements for tunnels integrating all the potential of composites. Composites address very utilitarian and building needs, notably for earthquake risks. They serve just as well in new constructions, Case studies: spectacular applications in renovation and rehabilitation. In civil engineering, new modular and lightwei- ght bridges, that can be assembled and disassembled manually on site, will be presented. MARINE New solutions as part of the industry Given the opportunities for further expansion, the marine industry represents recovery a highly attractive market for OEMs, material suppliers, engine suppliers and part Comparative studies of materials suppliers. Resin and reinforcement producers constantly improve their products to Solutions for quality improvement achieve better strength, fatigue properties, surface quality, lighter products as well Thermoplastic penetration in Marine as cheaper and healthier manufacturing processes. RAIL AND ROAD TRANSPORTATION Green and thermoplastic solutions Reducing the environmental footprint of terrestrial vehicles is the roadmap of the Agro vehicles innovative cluster I-Trans. In Rail and Road Transportation, composites are in- Low CO² emissions creasingly used since they have the advantages of strength, durability and corro- sion resistance together with low weight. This increases the potential useful load and also helps to save on energy. A new urban collective vehicle, a monocoque trailer made of carbon composite, a modular bus body and composite cylinders for automobile and gas transportation, all reap the benefit of the high properties of composites. WIND ENERGY The Global World Energy Council Wind energy growth demands more and more blades being manufactured. At the market vision same time, wind turbines produce more and more power, which means that the Automation: better quality at lower blades grow larger and larger. Robustness of the design and the manufacturing costs processes is becoming more and more critical. Increasing competition forces ma- nufacturers to increase their throughput while reducing their manufacturing costs. This forum will demonstrate what wind energy companies can learn from aerospace composites best practices and how to maximize the efficiency and the robustness of the manufacturing process by introducing automation. 4 www.jeccomposites.com

- 5. RECYCLING AND LIFE CYCLE MANAGEMENT Recycling processes and applications JEC launches the first observance forum on Recycling and Life Cycle Management Life Cycle Management (LCM). Long-fibre, high-grade carbon is a valuable commodity, costing upwards Economical and Ecological benefits of £10,000 per ton when new. Add to this fact that consumption is increasing, offering competitively priced material having minimally impaired mechanical pro- perties and good surface chemistry is key. Do not miss this forum! This is a unique opportunity to compare European and Japanese LCM-strategies for carbon fibre composite aircraft and cars. You will network with all actors: universities, industry and reclaimers. BIO-BASED MATERIALS A booming market With the demand for safer and healthier products enabled by strict environmental Green materials advances regulations, there is a growing need for Bio-based materials. Different aspects give Innovative case studies: 3XN architect, the grounds for the choice of these materials: from an environmental, technical Decathon/Artengo, NPSP and economical point of view. The forum will highlight different innovations case studies and applications in construction, sports and leisure and transportation. AUTOMATION Automation through new materials, Automation is key for reducing the cost of manufacturing composites parts. Europe processes and equipments has the highest rate of automation with 83% of its processes automated. A Trends for the future market overview of the Automotive, Aerospace and Wind Energy requirements for automation will be presented. You will also learn about the most promising tech- nologies and successful examples. COMPOSITES DESIGN Opportunities for composites design Stephen W. Tsai, Professor Research Emeritus and its speakers will present the Micromechanics and design tools best available theory and also design tools that can be used to implement predic- Analysis for damage tolerance and repair tions of failure, life and damage tolerance of composites. Standard master curves for rapid life prediction Practice session COMPOSITES SIMULATION The complete simulation chain: Despite of great advances demonstrated by the academic world, the Manufactu- new effective processes ring Process Simulation (MPS) is still in its infancy in the industry. In this forum, Case study: a wing assembly a case study (composite wing assembly) will enable to introduce to the numerous challenges of MPS. Then, the presentations will demonstrate the benefits of using the numerical simulation of manufacturing. The forum will cover the underneath material modeling and how to use it in simulation like for instance fan blades RTM manufacturing for an aircraft engine. COMPOSITES DEVELOPMENT PROCESS New energy-efficient design To exploit the full potential of composite materials for high performance lightwei- and manufacturing techniques ght structures, it is necessary to consider the entire process chain. No single Research projects: key aerospace process step can be optimized without taking into account the impact to preceding players testimonials: Airbus, Eurocopter, and subsequent steps. The integration of additional functions into the load carrying Premium Aerotec structure offers further advantages of composite technology. Some examples from actual research shall illustrate the potentials and challenges in the composite development process. www.jeccomposites.com 5

- 6. RECYCLING & LIFE CYCLE MANAGEMENT FORUM Tuesday, April 13 - 10.30 am / 1.00 pm Recycling as part of an integrated life cycle management 3. Falcon JET Eco-design: The environmental Japanese new national project, and repair and MODERATOR footprint recycling of CFRTP for automotive application. The University of Nottingham Dassault Aviation Life cycle analysis of recycled CFRP. Stephen Pickering Philippe Vautey 6. Automotive recycling of production scraps Associate Professor Head of Department for New and Reader: Division Technologies, Materials and Testing WIPAG Süd GmbH & Co. KG of Materials, Mechanics Aerostructure Direction Dassault Ulrike Steigemann Aviation Airframe R&T Strategy and Structures Sales Manager Coordinator Three main drivers for the operations phase: Demands on recyclates. Biography: aerodynamism, engine and lightweight. Dr Steve Pickering has a BSc and PhD in Me- Innovative recycling technologies. chanical Engineering from the University of Major composite weight saving opportunity: wing box. Economical and ecological benefits. Nottingham, where he is currently is an As- sociate Professor and Reader in the Faculty of Materials and process issues for greener Engineering. He has broad research interests in manufacturing alternatives. the general area of thermo fluids engineering For the past 10 years, he has led research activities Life Cycle Analysis: a global approach. on the recycling of carbon fibre composites, in collaboration with the broader activities of the Preliminary comparison between composite Polymer Composites Research group at Nottin- and aluminum approaches on a wing panel. gham University. Automotive What’s new with Recycling? 4. Life Cycle Analysis of composite cars: strong, light and green! 1. Recycling processes and applications for using carbon fibre recyclate Katholieke Universiteit Leuven The University of Nottingham Ignaas Verpoest Professor Stephen Pickering Associate Professor and Reader. Division of Materials, Mechanics A brief introduction of the concept of Life and Structures Cycle Analysis (LCA), and the challenges for it’s application to products using composite Recent developments in the recycling of carbon materials. fibre reinforced polymer (CFRP) composites. A critical assessment of data used for A review of current recycling processes for CFRP. performing LCA-studies involving composite Focus upon applications for re-using the materials. carbon fibre recyclate and two multi-partner A comparison of European and Japanese LCA- industry/university projects: HIRECAR and studies for carbon fibre composite cars (and AFRECAR. car components). An outlook to the future: how can an increased use of composites further reduce the ecological Aeronautics impact of cars? © All rights reserved 2. Recycling carbon fibre as part of an integra- 5. Recycling strategy of CFRP ted waste management system The University of Tokyo CFK Valley Stade Recycling Uzawa Kiyoshi GmbH & Co. KG Professor Tim Rademacker Head of Marketing & Sales, Global prospect of CFRP recycling. Also attend Business Development Japanese national project, and the results of The AUTOMOTIVE FORUM (p.8) Cost savings by sustainable CFRP recycling the CFRP recycling for automotive application. The AERONAUTICS FORUM (p.14) solution. Recycled carbon fibre products. 6 www.jeccomposites.com

- 7. CONSTRUCTION & CIVIL ENGINEERING FORUM Tuesday, April 13 - 10.30 am / 1.00 pm In partnership with Composites becoming established MODERATOR Concrete Structures Strengthening Modular and Transportable Bridges Laboratoire Central des Ponts et Chaussées 3. Vaccum process for strengthening concrete 6. A modular CFRP bridge for military structures purposes or civil protection Monssef Drissi Habti Director of Research UAM Invent GmbH Amando Padilla Ramirez Carsten Schöppinger Professor Dipl.-Ing. Biography: Presently head of the Cable Behaviour and Effectiveness of externally bonded GFRP glass Mobile composite bridge, aero-transportable, Metal Consultancy Unit at the Division for Me- fiber fabric for increasing the flexural strength modular assembly, integral composite design, tals Reinforcements and Cables in Structures of concrete beams. high loads by low mass. at LCPC in Nantes. Senior researcher for the Japanese Ministry of International Trade and A uniform and “high pressure” vacuum process Innovative production processes, light-weight Industry (MITI, 1995-1998). Visiting professor to assure close contact between concrete surface structure, high quality standards. at the University of Tokyo (1999-2000) and at and FRP system. the Brown University of Engineering (2001- 2003). PhD in 1994 and Habilitation to Manage 4. An innovative solution for strengthening of Research in 1999. timber structures in reconstruction Mainz University of Applied Sciences Composite Seismic Solutions Kay-Uwe Schober Professor of Timber Engineering 1. Intelligent seismic composite wallpaper for and Structural Design the retrofit of masonry structures vulnerable A hybrid timber composite beam for structural to earthquake rehabilitation and upgrading. D’Appolonia S.p.A. An increase of the load-carrying capacity up to Thomas Messervey 200% for short-term loading. Project Manager A pilot project: Reconstruction of the «Blue Hall», Mansfeld Castle, Germany. 4-year investigation involving research centres, testing laboratories, industrial partners, universities, and specialised high-tech small to The Largest Use of Composite medium enterprise companies. Cladding in the World 200% increases in structural strength (max 5. The dokkaae tower, Saudi Arabia: compo- load) and over 200% increases in structural ductility (max deformation). site cladding and clock Embedded sensors to take preventive measu- Premier Composite Technologies © Mock Up of Quarter Clock for Dokkaae Tower, Mecca, KSA res during an earthquake and assess structural Sebastian Schmitz integrity post earthquake. Production Manager 2. Reinforcement systems for buildings and tunnels Gurit Mark Hobbs Ruredil Senior Engineer Giovanni Mantegazza Technical Director 35,000 sqm of composite cladding for the largest clock in the world: 23m carbon fibre Efficacy of FRCM in earthquake: proofing of pre-preg clock hands. the church of Madonna di Centurelle (L’Aquila- Italy). Presentation of the unique challenges of the project and the composite materials, testing, Strenghtening of a reinforced concrete tunnel, Omikron Consulting Motor Way (Odos-Greece). processing and fabrication technologies which Also attend were used to realize this landmark project. The BIO-BASED MATERIALS FORUM (p.12) www.jeccomposites.com 7

- 8. AUTOMOTIVE FORUM Tuesday, April 13 - 2.30 pm / 5.00 pm In partnership with Exclusive sponsor Meeting ever more stringent environmental regulations The use of state-of-the art and new techno- A project in cooperation with Deltatech S.p.A MODERATOR logies such as compression injection RTM, carbon-SMC, 3D curved braiding, 3D stitching, An integrated molding system. The University of Tokyo molded rigid PU foam cores, thermal plastic A low-cost semi-impregnated micro-sandwich Jun Takahashi CFRP, etc. system for part fabrication. Professor Department As a result, the CFRP body weighs just 131kg High-performance release agents to reduce the of Systems Innovation, including the weight of metallic inserts. number of surface treatments. School of Engineering 3. Industrializing CFRP - challenges for the automotive industry 6. RTM vs. autoclave prepreg process for Biography: monocoque in road cars: specific analysis for Jun Takahashi is specialized in mechanical en- Audi Lightweight Center a high-performance vehicle only electrically gineering and graduated from the University Günter H. Deinzer powered of Tokyo in 1987, and got a doctorate from the Head of Technology Development same University in 1992 in the field of fracture YCOM Composites mechanics. He worked for a national research Mario Saccone institute (AIST, METI, Japan) from 1992 to 2000 How the Audi experience in aluminum-lei- Composites Materials Specialist in the field of composite materials. Then, he was ghtweight-design helps to develop CFRP- promoted Responsible for national programs applications. concerning composite materials, such as stan- Roberto Catenaro Chances generated by industrialization. dardization of testing method, ultra-high tempe- Consultant at Ycom rature application, structural health monitoring, CFRP in automotive industry - designed by recycling, and LCA (life cycle assessment). Now Audi. The new vehicle for 2012: the first supercar he worked for the University of Tokyo and has with only 4 electrical engines and featuring been doing research on energy saving strategy Out-of-the-autoclave 1,000 horse powers and a joint venture among in the field of transportation and automotive several companies each one at the excellence application of CFRP and CFRTP. Molding Processes in its own industrial field. 4. RTM for primary automotive structures An extensive use of composite solutions all Global Energy-Saving Strategy around the car in particular for the structural in Transportation Automobili Lamborghini S.p.A components like the tub. Luciano De Oto A detailed analysis between RTM and standard 1. Energy-saving strategy in transportation by Head of BIW&Trim and Composite autoclave process. using CFRP Engineering and Development The University of Tokyo Huntsman Advanced Materials Non-Destructive Inspection Jun Takahashi Stephan Costantino Techniques Professor Department of Systems Process Application Specialist Innovation, School of Engineering 7. Building block approach to composite Global energy saving strategy in trans- High-performance parts for high-end crashworthiness analysis portation. automotive. University of Washington Effect of weight lightening on energy saving of RTM: a process of choice for parts Paolo Feraboli gasoline and/or electric vehicles. manufacturers. Professor and Director of the Research trend of CFRP and CFRTP for airplane Development of automotive structural parts Automobili Lamborghini, Advanced and automobile applications. and resin selection criteria. Composite Structure Laboratory Cost-effective and repeatable production of How the building block approach is being uti- structural parts with mechanical and thermal lized at Automobili Lamborghini for the design From Luxury cars to Mass Production performances comparable with autoclaved of new structural concepts that are being prepregs. evaluated as technology demonstrators. 2. The development of the new Lexus LFA’s 5. Speedy-infusion for the fabrication of a GT Also attend CFRP monocoque car composite underfloor Toyota Motor Corporation ITCA S.p.A The RECYCLING AND LIFE CYCLE Nobuya Kawamura Massimo Fazzi MANAGEMENT FORUM (p.6) Project General Manager Composites Technologies Specialist The COMPOSITES SIMULATION CONFERENCE (p.13) Is the LFA’s carbon technology conservative? Roberto Catenaro The RAIL AND ROAD TRANSPORTATION No! FORUM (p.17) Technical Director 8 www.jeccomposites.com

- 9. COMPOSITES DEVELOPMENT PROCESS CONFERENCE CE Tuesday, April 13 - 2.30 pm / 5.00 pm In partnership with Exploring challenges of process chain for CFRP structures Energy absorption concept validated by MODERATOR experiments testing triggered sandwich panels Adaptronics under mixed compression – bending loads. DLR - The German Aerospace Research Center Case study: Airbus Deutschland GmbH. 5. Droop nose morphing structure Martin Wiedemann DLR CFRP Research Head of Research Composite Design Olaf Heintze Institute Research Field Leader High Lift 3. Advanced concepts for composite airframe Biography: door and door surround structures A gapless and flexible wing leading edge Martin Wiedemann has held the different po- structure strongly supporting airframe reduc- sitions: Head of DLR Institute for Composite Eurocopter tion and allowing for a wing design with a Structures and Adaptive Systems (2007), Full Christian Seyffert fully natural laminar flow. Serious reduction of professor Adaptronics, Technical University flow resistance and, thus, emissions. Senior Manager Engineering Braunschweig (2007), Chief-Engineer, A400M Airplane Door Systems A composite design allowing for the union of Fuselage and Empennage, Airbus, Site Germany contradicting requirements such as flexibility (2005-2007), Head of Development Processes DLR CFRP Research for nose droop and stiffness along the wing and Payload Accomodation, Airbus, Site France Tobias Stroehlein span for shape conformity. (2004-2005) and Head of Specific Design Work Project Coordinator Carbon Fuselage Structure, Airbus, Site Germany (2001-2004). Full-scale testing in cooperation with Airbus Major challenges of door and door surround and EADS. A successful application of the hi- structures in CFRP fuselage, current and future ghly efficient process chain in the Institute of technical solutions to fulfill the requirements. Composite Structures and Adaptive Systems. Functional Materials Interfaces and interactions with the focus on CFRP concepts highlighted. 1. Fast processing of polymer composites for Production Technologies New design techniques with state-of-the art high volume production software to achieve maximum accuracy of flat pattern simulation and furthermore reduce 6. Advanced automated fibre placement (AFP) Dow Deutschland GmbH the weight and manufacturing costs of the & Co. OHG technology highly integral complex door and door surround Damian Feord structures. MAG Europe Epoxy R&D Leader Christian Boge Executive Vice President Industry DLR CFRP Research Composite Manufacturing Team Aerospace Peter Wierach Head of Department DLR CFRP Research 4. Sustainable production of high perfor- Methods to optimize process parameters using Dirk Röstermundt mance CFRP components already established resin systems. Research Engineer Premium AEROTEC GmbH Requirements for improved efficiency of AFP Overview about possibilities and limits to Christian Kulik up to the level for future large parts. realize fast process cycles and meet the requirements for a high volume production of A large mobile robot based-platform under pre- polymer composites. paration in cooperation with the company MAG. DLR CFRP Research 2. Crashworthiness aspects of CFRP airframe Characteristic features. Markus Kleineberg panels in fold core design Head of Department Foldcore GmbH Energy-efficient manufacturing strategies. Rainer Kehrle Adaptable mould concepts for flexible compo- CEO site component manufacturing. Online monitoring of essential production Also attend DLR CFRP Research parameters. Ralf Sturm Research Engineer Custom-tailored automation concepts for effi- The AUTOMOTIVE FORUM (p.8) cient composite component manufacturing. Development of a trigger concept for CFRP The AERONAUTICS FORUM (p.14) composite sandwich structures based on local Challenges for future composite component The COMPOSITES DESIGN modifications in the fold pattern of the core to manufacturing concepts. CONFERENCE (p.10) control the failure mode of the sandwich panel. The AUTOMATION FORUM (p.11) www.jeccomposites.com 9

- 10. COMPOSITES DESIGN CONFERENCE Wednesday, April 14 - 10.30 am / 1.00 pm In partnership with Acquiring proficiency in composites design Stephen W. Tsai Sung K. Ha Daniel Melo Department of Aeronautics Professor, Dept. of Mechanical Engineering Department of Materials Engineering, & Astronautics, Stanford University Hanyang University, Korea Federal University of Rio Grande do Norte; Visiting Professor, Department of Aeronautics Visting Professor, Department of Aeronautics & Astronautics. Stanford University & Astronautics, Stanford University Composites Design and Tools Lekhnitskii’s Exact Solutions Test Methods and Error Estimation This forum provides not only an authoritative Analytical solutions in Lekhnitskii’s Aniso- Widespread use of quasi-isotropic symmetric book: Strength & Life of Composites, but also tropic Plates cover various applications of laminates known as “black aluminum” makes a set of software tools with instructions of anisotropic beams and plates. The Stanford composite materials uncompetitive. Additio- the underlying theory and sample problems. Composite Design Team started a project to nally, many design recommendations have Materials and process engineers must reach program solutions of nearly all cases pre- been established without scientific basis, this minimum proficiency level. The tools are sented in this classic book. The first version which further penalize composites. Using devised for practical design. They can also is now released covering sections on stress uniaxial tests data to generate knock-down challenges archaic rules that often add mass distribution in a plate with elliptic or circular factors and design allowable cost millions and cost without rational bases. We believe openings. Arbitrary normal and shear in-plane of dollars and are limited to the specific in closed-formation and numerical simulation loads can be applied to the orthotropic plate loading conditions. They are often not directly tools to guide design and testing. In parti- with elastic inclusion. The inclusion in the applicable to structural design. Biaxial test cular, we recommend 3 ply angles instead of openings can be either open or filled with data using open-hole and smooth specimens 4. We also believe in homogenized laminate elastic or rigid materials. Inner pressure and will be presented. These data indicate and use ply angles as continuous variables. shear loads and rigid interferences can be that even for simple QI laminates failure These designs will increase toughness and applied to the holes. Once laminate stresses envelopes are not boxy shaped and cannot lower cost. They will reduce empiricism and are analytically obtained, each ply stress is be generated by few anchor points. The use increase confidence in design. This forum is calculated by stress transformation. Finally, of numerical simulations to produce notched an abbreviated presentation of our biannual strength ratios after failure analyses are strength data for structural design allowable Stanford-certificated online Composites Design calculated and plotted in Excel worksheets. is encouraged, in combination with biaxial Workshop that offers 44 hours of intensive These solutions are effective, preliminary test data to verify the predictions. Using few training delivered live over 11 days. design tool for many problems for bolted ply angles and as continuous variables will joints, hole repair and others. make laminates competitive. The importance of using statistical tools for error estimation 3D Beam in test data will be presented. Modeling of composite structure prior to end structural analysis first requires specification Also attTICS of geometry, laminations and loads. Such modeling process can be very tedious and NAU often requires high-end modeling and analysis The AERO .14) tools. Now a new 3D Beam, based on FEM, FORUM (p 15 2010 is developed as an easy-to-use yet power day, April Thurs / 1:00 pm tool for analysis and design of composite 10:30 am structures. Modeling time is now reduced by one or two orders of magnitude compared What you get to conventional modeling and analysis FEM during the tools. Successful applications of the 3D Beam conference? covers various types of structures ranging from very complicated wind turbine blades Each participant will receive: and airplane fuselages to simple beams such as golf shaft and box beam. Vertical 1 disk that will contain all and in-plane loads and bending and twisting viewgraphs, and design tools moments can be applied to any location of the structure. Once the global deformations of MicMac-Inplane, MicMac-Hole are calculated, ply stresses and the failure and 3D Beam. indices are calculated and plotted. The natural frequencies and vibration shapes of up to 10 modes can be additionally computed. The 3D Beam can be also effectively used for error estimation with selected design experimental parameters. 10 www.jeccomposites.com

- 11. AUTOMATION FORUM Wednesday, April 14 - 10.30 am / 1.00 pm Reducing the cost of manufacturing composite parts 6. Process monitoring and control applied in MODERATOR New Processes for Automation FRP parts production: present and future University of Stuttgart National Technical University Institute of Aircraft Design 3. Highly automated sequential processes for of Athens already qualified prepreg Klaus Drechsler Nikos Pantelelis S.A.B.C.A Research Engineer Professor Bertrand Vaneghem Project Manager R&T Process monitoring and control applied in FRP parts production. Biography: Klaus Drechsler studied Aerospace Engineering Production flow based on the use of efficient Automation of the curing process. and has a Phd at University of Stuttgart. He and highly-automated sequential processes has held different positions: Head «composite» including automatic tape laying processes, hot at DaimlerChrylser /EADS research department forming and SQRTM (adaptation of the RTM Ottobrunn, Professor at University of Stuttgart, process for prepreg technology) for the rapid Head of Institute of Aircraft Design, Professor manufacturing of integrated structures in one at University of Munich, Head of Chair for Carbon shot. Composites, Head of Fraunhofer Project Group Example of a single aisle aircraft pressure floor «Functional Lightweigth Design», Augsburg and demonstrator. SAMPE Fellow. 4. Automated preform production line for CFRP aircraft frames What’s new with Automation? EADS Deutschland GmbH Matthew Beaumont 1. Overview needs, markets and technologies Manager Structure Programme Technical University of Munich Management Klaus Drechsler Highly automated method of producing carbon Professor fiber aircraft frames. Very efficient use of materials. Market overview of the Automotive, Aerospace Enabler for high-volume production. and Wind Energy requirements for automation. Most promising technologies like advanced © EADS Innovation Works/SGL Kümpers material systems, textile preforming, tow-pla- New Equipments for Automation cement technologies and process simulation. Successful examples. 5. Applying automation to the fabrication of composite-based aerospace parts and developing a machine specification New Materials for Automation Accudyne Systems, Inc. John Melilli 2. In-line complete system to produce Vice President of Sales & Marketing thermoplastic foam core panels 5D composite Developing machine specifications based Andrew Rekret on part requirements. President Using tow path optimization software to predict material behavior. Flexibility of construction using standard basic shapes of thermoplastic foam core. In-line production with CNC fiber placement reducing cost, increasing ease and speed of Also attend production, improving quality and eliminating potential delamination. The AERONAUTICS FORUM (p.14) www.jeccomposites.com 11

- 12. BIO-BASED MATERIALS FORUM Wednesday, April 14 - 2.30pm / 5.00pm In partnership with Going green! Case studies: interior and exterior automotive MODERATOR Green Sport and Transportation parts, marine headliner panel. Applications Pôle Européen de Plasturgie 6. Composite resins’ vision on sustainability 3. Flax yarn-based prepreg for vibration Charlyse Pouteau damping in sport applications DSM Composite Resins AG Project Manager Saris Floor Lineo Key Account Manager François Vanfleteren Biography: CEO Marian Szkudlarek Charlyse Pouteau has been PhD, Project Manager R&D DSM Composite Resins at « Pôle Européen de Plasturgie » since 2003. Decathlon / Artengo (oxylane groupe) With a master in “Chemistry and physico-che- mistry of polymer“ at the University Pierre and Vincent Duminil A 55% bio-content resin for SMC and BMC Marie Curie, she worked at the Institut National Innovation Manager applications. de Recherche Agronomique in Reims. She studied there the anti-oxidant activity of lignin in polyo- The first commercial application: the cradle-to- Lineo: Advantages of flax fibres. How to inte- cradle (C2C) street bench developed by VelopA. lefin polymer matrix. She gets her PhD degree in grate flax fibres into composite parts. Past and Chemistry in 2002. Her current research interests future developments and solutions for direct are covering recycling, biodegradable polymers, processing. Round Table: Learning from Today and natural fiber-plastic composites. Decathlon: Process innovation, Flax Fiber (Why and Planning for Tomorrow and How?). Next flax developments at Artengo. What’s new with Bio-Based Katholieke Universiteit Leuven Materials? 4. Monocoque structure of electrical scooter Ignaas Verpoest out of flax fibre-reinforced composite Professor 1. Bio-based materials: new developments and recent advances NPSP Composieten BV A brief introduction on the European Flax Willem Böttger and Hemp Federation (CELC) and its Scientific Pole Européen de Plasturgie General Manager Committee. Charlyse Pouteau Project Manager The research agenda for flax- and hemp-based A structural part made of natural fibre reinfor- composites: in which R&D-programs companies ced composites. and governments should invest to increase the Overview of the different works in the domain Lighter than the glass fibre with a factor 10%, use of natural fibres in composites. of natural fiber composites. recyclable and with an environment impact A synthesis and analysis of the natural fibre Different innovations case studies and 60% lower than glass fibre reinforced hand composite applications: what do they tell us applications. laminated body parts as calculated with the for future developments? Life Cycle Assessment method. R&D projects. Natural fibres: from fillers towards a high performance material. Green Architecture for the Future Bio-composites from R&D towards commercial products. © 3XN A/S • Decathlon (Oxylane group) • Artengo 2. A sustainable pavilion in bio-composites and intelligent materials New Bio-Based Materials 3XN architects Kasper Guldager Jørgensen 5. Aligned natural fibre-reinforced bio- Architect, Head of R&D composite materials for high-performance applications Learning from nature. Composites Evolution Ltd A sustainable pavilion in bio-composites Brendon Weager Also attend and intelligent materials. Technical Manager The CONSTRUCTION & CIVIL Architectural use of bio-composites. ENGINEERING FORUM (p.7) Biotex: High-performance reinforcements based How to design our built environment on flax and hemp combined with polypropy- The RAIL AND ROAD TRANSPORTATION intelligently. lene (PP) and polylactic acid (PLA) biopolymer FORUM (p.17) using a range of novel comingling techniques. 12 www.jeccomposites.com

- 13. COMPOSITES SIMULATION CONFERENCE Wednesday, April 14 - 2.30pm / 5.00pm In partnership with Optimizing the design and manufacturing simulation processes Flow characteristics: permeability study on MODERATOR A Material Properties Provider ES-Fabrics and simulation of flow and mold filling process. ESI Group 2. Enabling use of simulation in composite Success story: path from basic research to Patrick De Luca parts development engineered materials and application of inte- Composites Solution grated structural composites. Manager ESI Group David Prono An Optimized Approach Biography: Composites Domain Expert for RTM Simulation Patrick De Luca has a PhD Applied Mathema- tics at Bordeaux University and Post-Doc at Composite materials testing through 5. A key parameter for injection simulation: Stanford University in Mechanical Engineering. simulation. permeability He has been at ESI Group since 1991 occupying several positions: Development, Project mana- Enabling use of simulation in composite parts PPE ger, Product manager of ESI Composites Suite. development. His domains of works cover composite forming Jérôme Raynal Decrease time and cost of material Project Manager, Technical simulation and the link between mechanical characterisation. Marketing performance and the manufacturing of compo- site parts. His current objective is to deliver to Investigate new material applications. RTM simulation: technical parameters to consi- industry an end-to-end simulation solution for der for an optimized approach. composite products. Controlling Process Induced Permeability. Distortion Selection of the strategy. Case Study: A Composite Wing Assembly 3. Cure induced shape distortions in a How the simulation is used to secure the composite c-spar: 2 FE-analysis methods process: «the injection road-map». 1. Managing the complexity of composite aircraft assemblies and their huge volumes of Swerea SICOMP AB 6. Advanced process simulation of RTM and highly interdependent design data Magnus Svanberg application to fan blades for an aircraft engine Senior Researcher Vistagy Aerostructures Ecole Poytechnique Steve Peck de Montréal A very fast and accurate method based on Director, Product & Market Strategy Edu Ruiz standard FE-functionality. Professor, Mechanical Engineering A state-of-the-art process-beginning with the Another method implying modeling and simula- pre-production activities involved in creating a tion of the cure processes where material proper- Fiber volume content and fiber orientations demonstrator part to full-scale production. ties and residual stresses evolve during cure. description. Specific challenges associated with designing Full thermal characterization. a resin transfer infused wing skin using NCF materials and an automated material deposi- Defining Manufacturing Processes Optimization of the fabrication process. tion process. Design of substructure components, such 4. Advancement in RTM technology as t-stringers, and managing the assembly interfaces to support an automated fastening Beijing Institute process. of Aeronautical Materials Yi Xiaosu Professor Introduction: state-of-the art of composite technology and development and the technolo- gical challenge. © Courtesy of Azimut Yachts How to toughen the structural composite ma- Also attend terials: reaction-induced phase separation me- chanism and structure-properties relationship. EX-situ technology to toughen the RTMABLE The AERONAUTICS FORUM (p.14) Composites: establishment of inter laminar tailored structure and ES-Fabrics: an innovative The AUTOMOTIVE FORUM (p.8) product. www.jeccomposites.com 13

- 14. AERONAUTICS FORUM Thursday, April 15 - 10.30 am / 1.00 pm In partnership with Controlling cost of aircraft structures Dominique Bailly MODERATOR Next Generation Composite Wings R&T Engineer University of Bristol Composites applications and advantages Kevin Potter 2. Airbus A350XWB: Composite wing spar for general aviation, regional aviation and Reader in Composites development helicopters. Manufacturing, Department of Aerospace Engineering Airbus Specific design constraints of composites Paulo Lage structures for each of these segments. Biography: Engineering Design Capability Ecowingbox: composites wing demonstrator Since graduating from Imperial College in 1974 and derivatives aerostructure applications for Kevin Potter has worked almost exclusively in the Concurrent processes and toolsets. each of these segments. field of composite materials, with an emphasis Logic behind the development of an improved on manufacturing methods and product design. composite process, the engineering tools, First Welded Thermoplastic Composite He worked for the UK MoD for almost 10 years involved logistics, and tooling complexity. Primary Structures in Series Production on materials and product development, with major interests in reinforcement deformation and Resin Transfer Moulding. The work on RTM 3. A full composite lateral and centre wing box 6. Induction welded thermoplastic control expanded on joining BP Advanced Materials surfaces to support the development and introduction Airbus Operations Ltd into series production of complex products. He Simon Topping Fokker Aerostructures joined the Aerospace Engineering Department Structures Engineer Arnt Offringa of Bristol University in 1995 and has been able Director R&D to continue and extend his research interests in collaboration with the leaders in the UK Overview of European Commission (FP6) fun- composites industry. ded project ALCAS (Advanced Low Cost Aircraft A low cost and lightweight aircraft control Structures). surface. A 20% weight reduction with no increase in The composite solution: a carbon/PPS thermo- recurring costs targeted against the state-of- Cost Control the art metallic aircraft. plastic composite multirib design. The induction welding technology and its Enabling technologies for the ALCAS airliner 1. Controlling cost in aeronautics composites advantages. wing/rear spar development. manufacturing Current first applications: rudder and elevators Structural testing scheduled for 2010 to of the new G650 business jet. University of Bristol validate the airliner wing components and all Kevin Potter tools used during the design phase. Reader in Composites Manufacturing 4. Bombardier CSeries: developing a game- changing aircraft Automating the production of the far larger number of secondary and tertiary structures Bombardier Aerospace such as sandwich panels. Gavin Campbell © Bombardier Aerospace Meeting current and likely future requirements Director, Design Engineering for cost reductions. & Technology Development, Belfast Mission of the recently founded UK National Meeting the needs of the 100- to 149-seat Composites Centre. commercial aircraft market category. Why the CSeries will be the greenest single- aisle aircraft in its class. Also attend Progress of CSeries programme. The RECYCLING AND LIFE CYCLE MANAGEMENT FORUM (p.6) Developing and manufacturing the advanced composite wings using Resin Transfer Infusion The COMPOSITES DEVELOPMENT technology developed in Belfast. PROCESS CONFERENCE (p.9) © Bombardier Aerospace / Gulfstream aircraft The COMPOSITES DESIGN 5. Composites solutions survey for small and CONFERENCE (p.10) medium-sized aircrafts The AUTOMATION FORUM (p.11) Daher-Socata The COMPOSITES SIMULATION Philippe Villard CONFERENCE (p.13) Vice President Marketing 14 www.jeccomposites.com

- 15. MARINE FORUM Thursday, April 15 - 10.30 am / 1.00 pm Improving quality and producing at low costs 3. Durable resin and reinforcement solutions 5. Strip plank foam sandwich: an effective MODERATOR for better boats solution for one-off or small custom series production Giovanni Manni Mikkeli University Marine Consulting of Applied Sciences, Research Trimarine srl and Business Services Sebastiano Rech Morassutti Martti Kemppinen CEO Biography: Research Director, From 2005 to 2009, Giovanni Manni has been Materials Technology Fernando Borges De Sena Ferretti‘s Group Quality Director and from 1997 to Founder Partner of Trimarine 2005, he was Wally Yachts Quality Manager. Ashland Finland Ltd Advanced Marine Projects, Ltd Olli Piiroinen European Industry Manager, Marine An adaptation inspired by wood strip planking and other techniques applied to the construc- tion of composite yachts. NCD Significant calendar time saved, less yard floor Yves Perrot space needed, less initial mould investment Composite Engineer and only a small work force required. Ideal for one-off projects or when testing the Damage resistance and surface quality com- market with a new design as it requires. parison of feasible resin and reinforcement Surface Quality and High Damage combinations in modern marine industry. A revisited techniques economically interesting Resistance at Reasonable Cost at a time when small yards are being pressu- 16 different injected laminates featuring tradi- red by the economic downturn. 1. The required expected quality of the market tional and novel resins and two reinforcement as compared to actual production types compared with each other and hand- laminated counterparts. Giovanni Manni High-Tech Riggings Marine Consulting Several facts measured by manufacturer-neu- tral parties. 6. High-tech composite yacht rigging Research into the maximum surface quality during principal production phases of compo- Carbo-Link site technology. New Low Cost Boat Concepts Andreas Winistörfer Degradation of surface quality during the life CEO cycle of composite boats. 4. The use of TP SEAL technology in the development of large multi-layer marine Stringent material and process requirements Optimizing research costs into composite applications surface quality. An innovative process for rigging Total Petrochemicals manufacturing. 2. Slamming impact behavior of composite Research sandwich for racing yachts Application: Alinghi. Eric Mazier Technical Service & Development IFREMER (TS&D) Rotomoulding Technical Peter Davies Manager Research Engineer, Materials Boat production by rotomoulding process. and Structures TP-SEAL®technology. © Alinghi • Dreamstime • Mikkeli University of Applied Sciences • Targa HDS Structural properties of TP-SEAL® parts com- Hervé Devaux pared to composite parts. Director Recent studies on foam and honeycomb sand- wich materials. Development of both test and numerical analy- sis to simulate a damage. Correlation between test and simulation results to validate the model. Strategies for improving impact response. www.jeccomposites.com 15