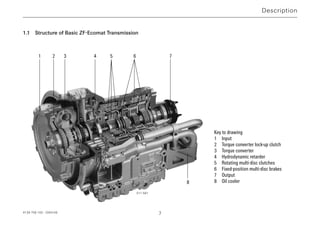

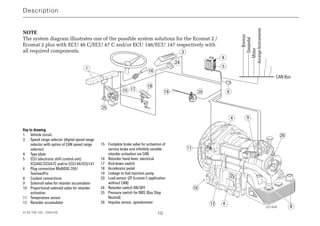

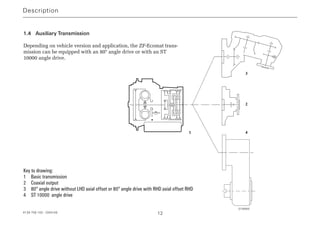

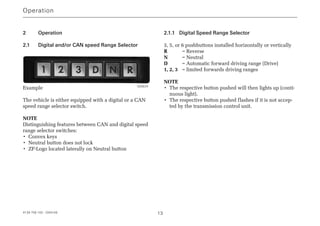

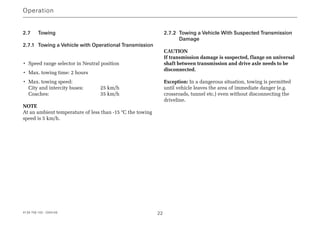

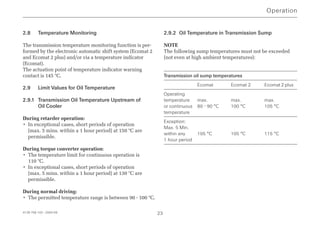

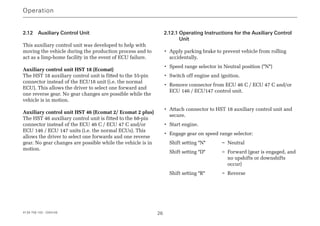

This document provides operating instructions for ZF-Ecomat transmissions. It describes the basic structure of the ZF-Ecomat transmission which includes a torque converter, lock-up clutch, hydrodynamic retarder, and planetary gear transmission. It also outlines the system solutions for different ZF-Ecomat models and details their components such as the electronic control unit, sensors, valves and switches. Maintenance procedures like checking oil levels and changing oil filters at regular intervals are also specified.