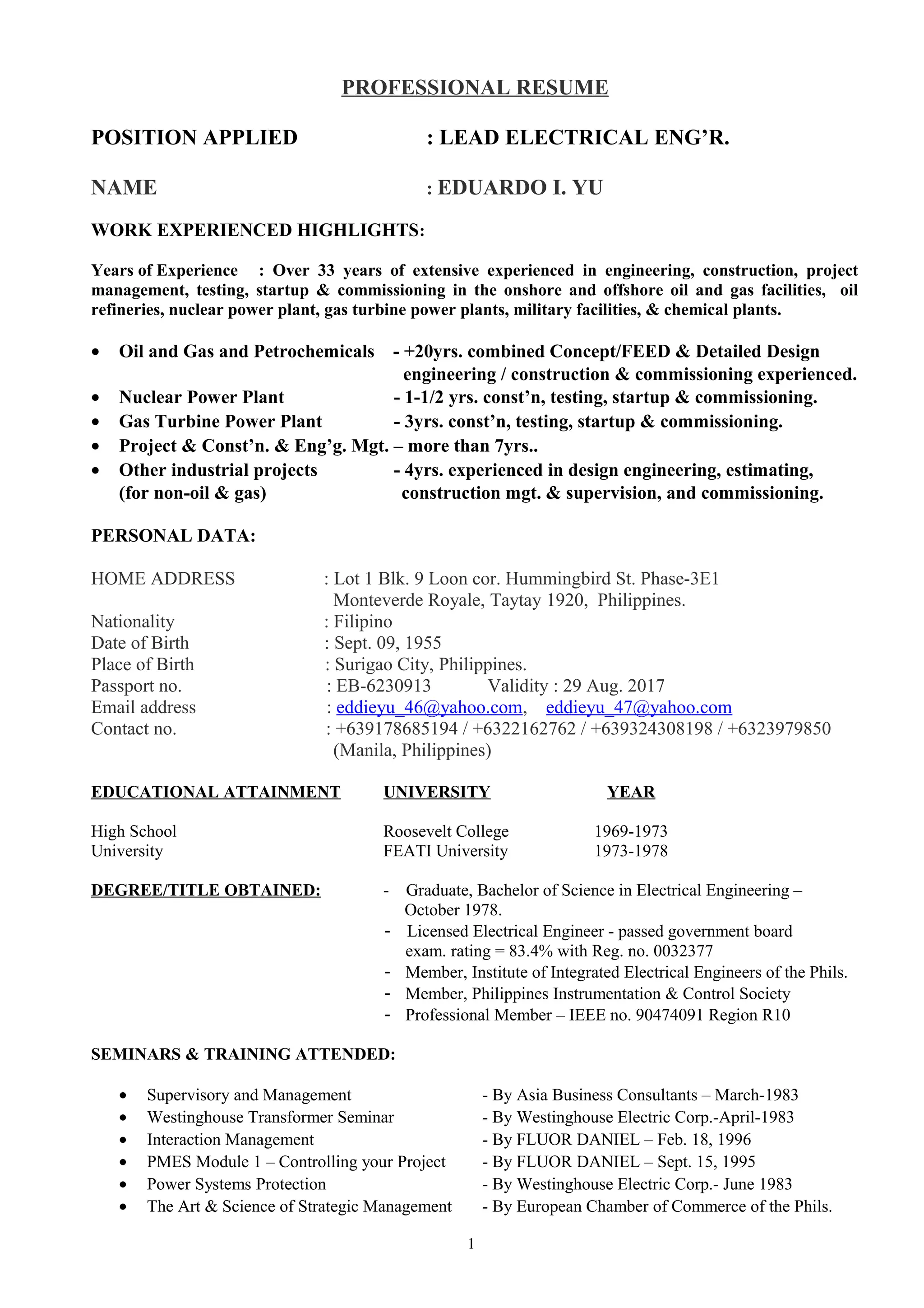

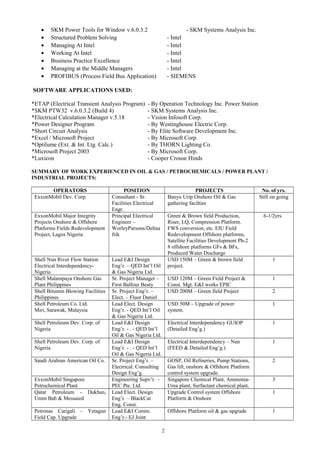

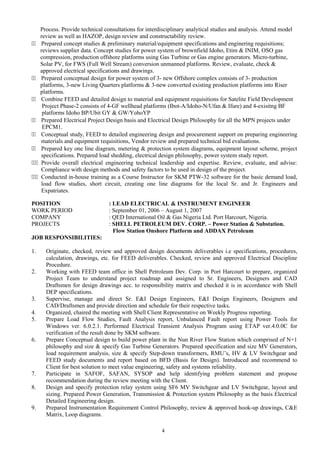

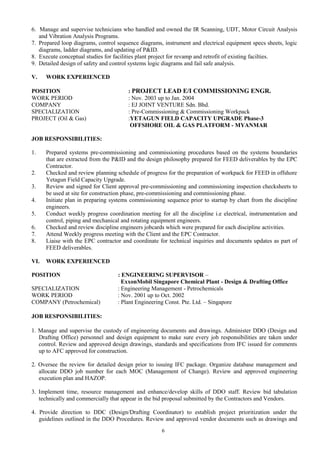

Eduardo I. Yu is applying for the position of Lead Electrical Engineer. He has over 33 years of experience in engineering, construction, project management, testing, startup and commissioning in various industries including oil and gas, petrochemicals, nuclear power, and gas turbine power plants. He has worked on numerous projects for companies such as ExxonMobil, Shell, and Saudi Aramco. Yu holds a Bachelor's degree in Electrical Engineering and is a licensed and professional engineer in the Philippines.