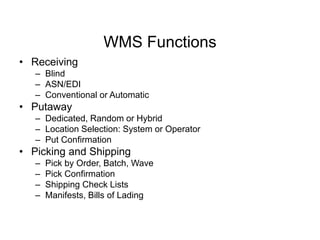

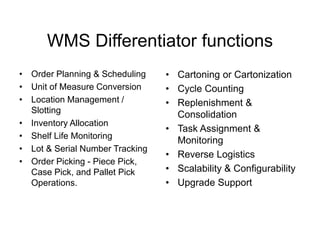

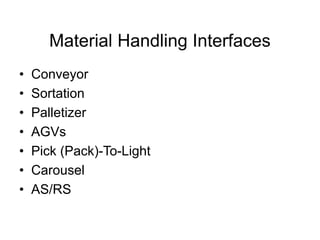

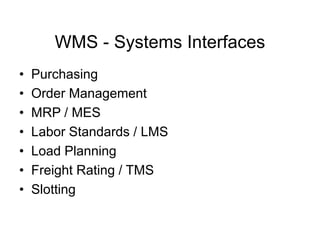

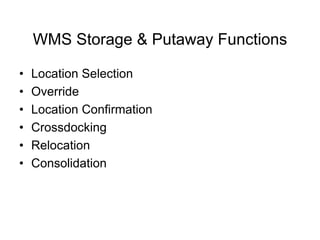

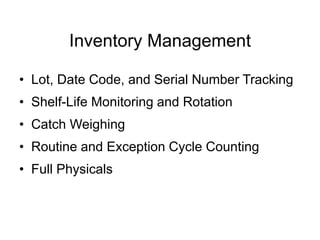

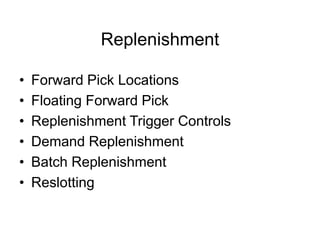

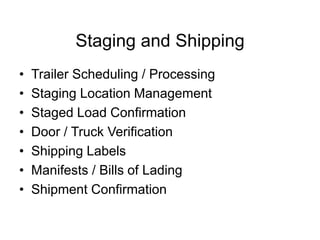

The document outlines various functions and differentiators of Warehouse Management Systems (WMS), including receiving, putaway, picking, shipping, and inventory management. It also highlights specific differentiator functions such as order planning, tracking, and reverse logistics, along with interfaces for material handling and storage operations. Additionally, it discusses storage and putaway functionalities, replenishment processes, and the importance of scalability and configurability in WMS.