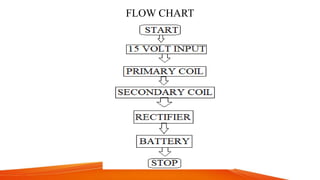

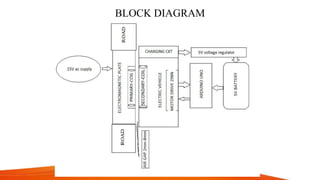

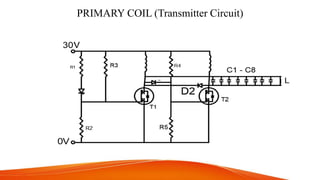

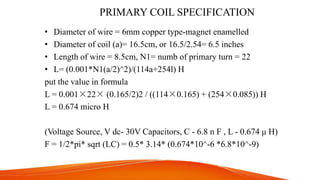

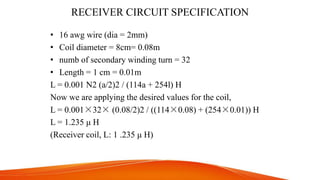

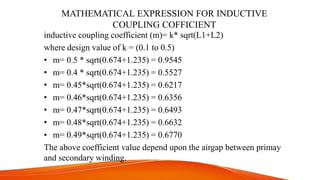

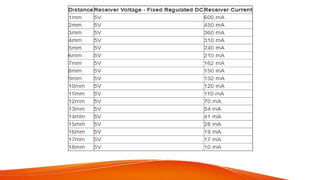

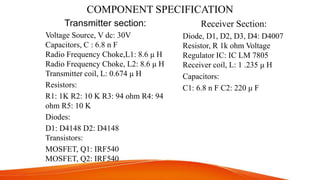

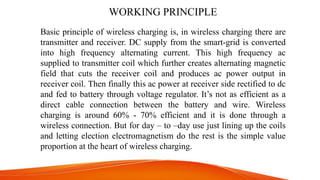

The document presents a project focused on the design and development of wireless charging for electric vehicles utilizing electromagnetic induction, aiming to improve charging efficiency and reduce costs for both providers and consumers. The project details the methodology, hardware specifications, and operational principles of the wireless charging system, which operates effectively within a specified airgap. It concludes with aspirations to establish a market presence as a charging service provider for electric vehicles.