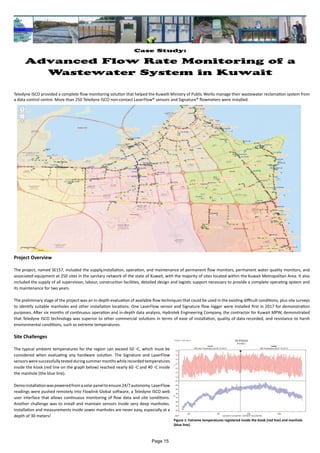

WIPAC Monthly is an update publication from the Water Industry Process Automation & Control group, providing insights into industry news and features such as river monitoring and advancements in wastewater management technologies. The October 2021 issue discusses the potential of open data in enhancing transparency and efficiency in water management, as well as innovative solutions like AI-driven leak detection. Notably, it highlights collaborations that aim to improve data management and operational performance in the water sector.