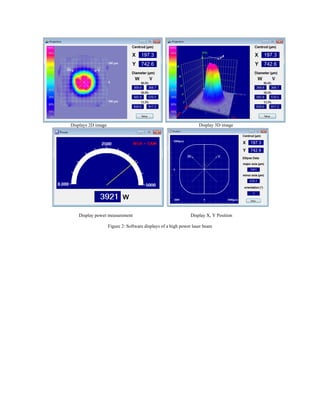

This document discusses the need for a laser beam profiler that can measure a wide range of wavelengths and power levels. It introduces the BeamOn WSR system, which uses a mosaic detector, cooled beam sampling, and advanced electronics to simultaneously measure laser beams from 190nm to 1600nm with power levels ranging from nanowatts to kilowatts. The system allows accurate profiling and alignment of dual wavelength beams, such as a high power 1550nm beam combined with a visible marking laser. Recent experiments also demonstrate initial measurement capabilities out to 3um wavelengths.