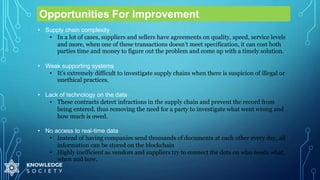

The document discusses opportunities to improve supply chain transparency and efficiency through the use of blockchain technology. It notes that current supply chains are complex with a lack of real-time data sharing and high costs. Blockchain could provide an immutable record of transactions, increased transparency across partners, and consensus without a central authority. Examples where companies like Walmart and Unilever are using blockchain to trace food sources are provided. The conclusion discusses using industry case studies to stay aware of blockchain innovations.