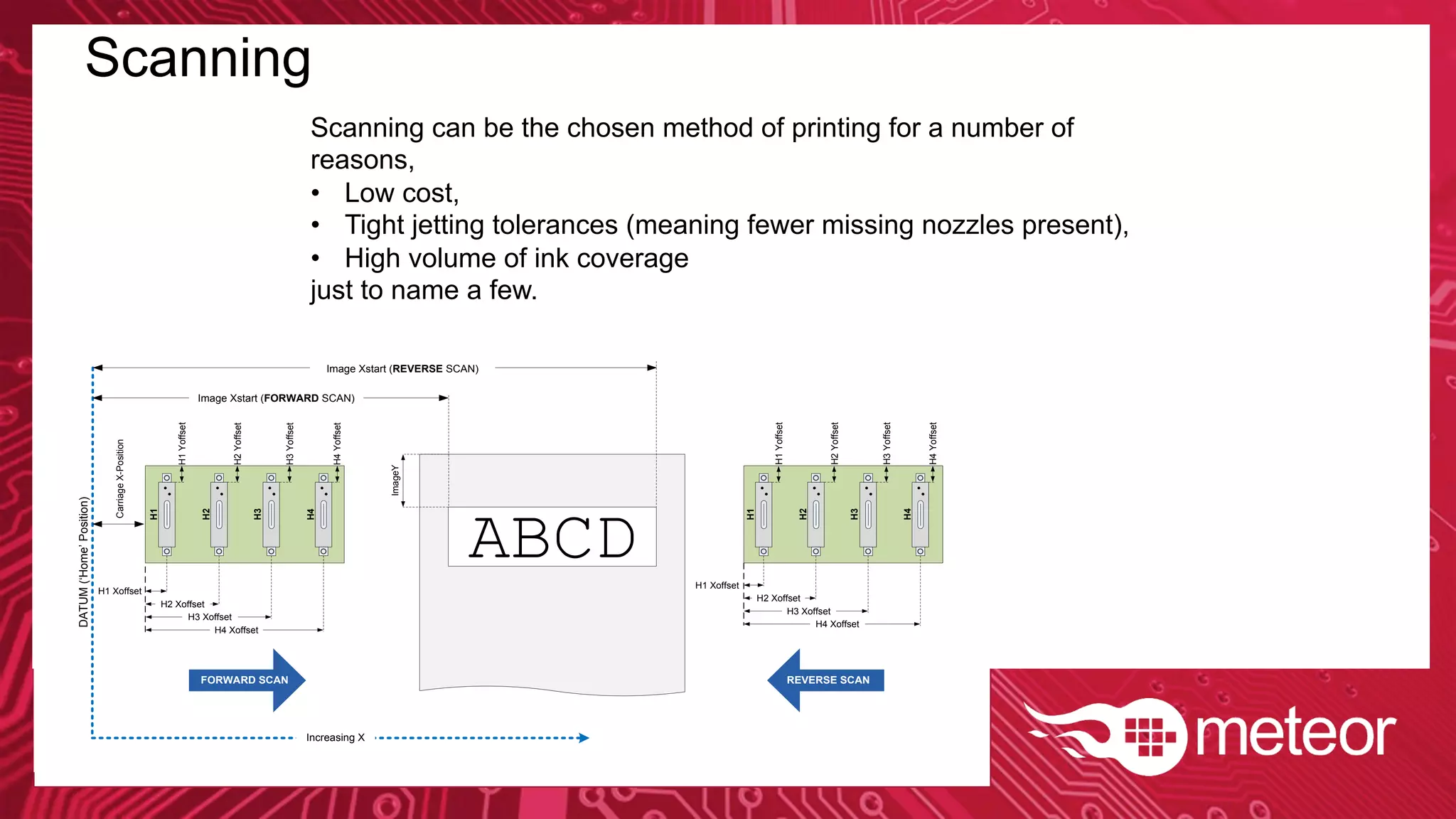

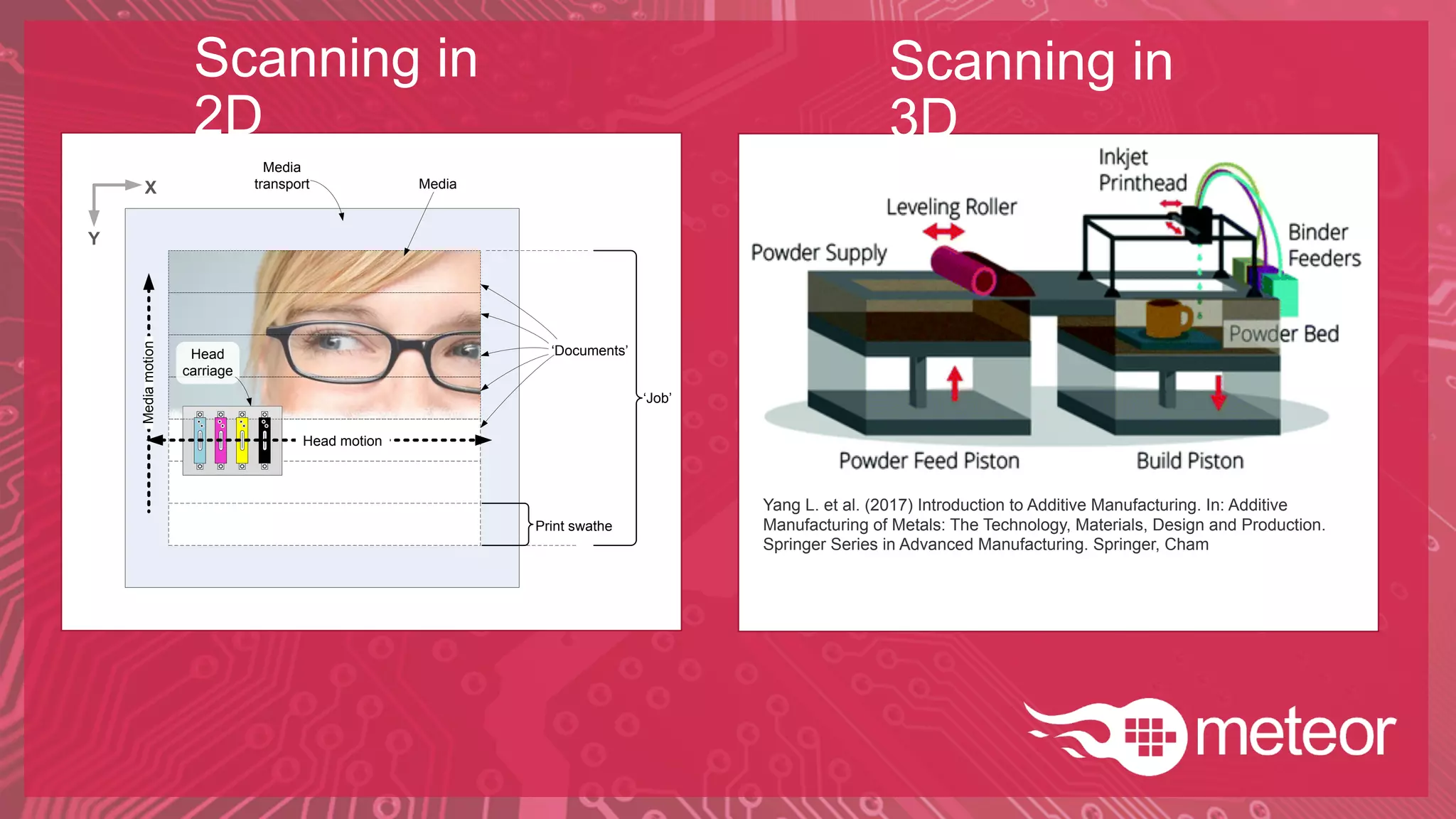

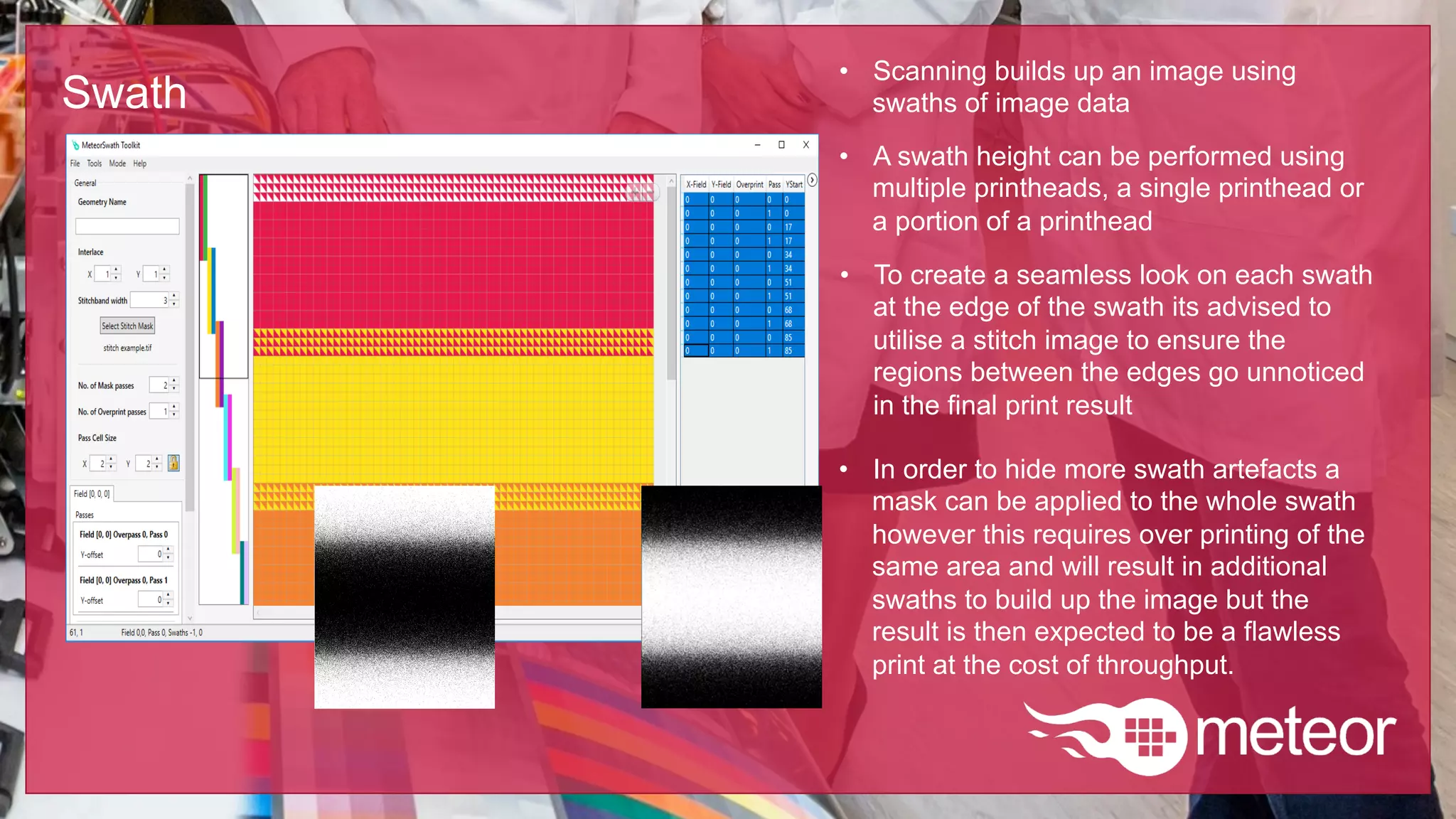

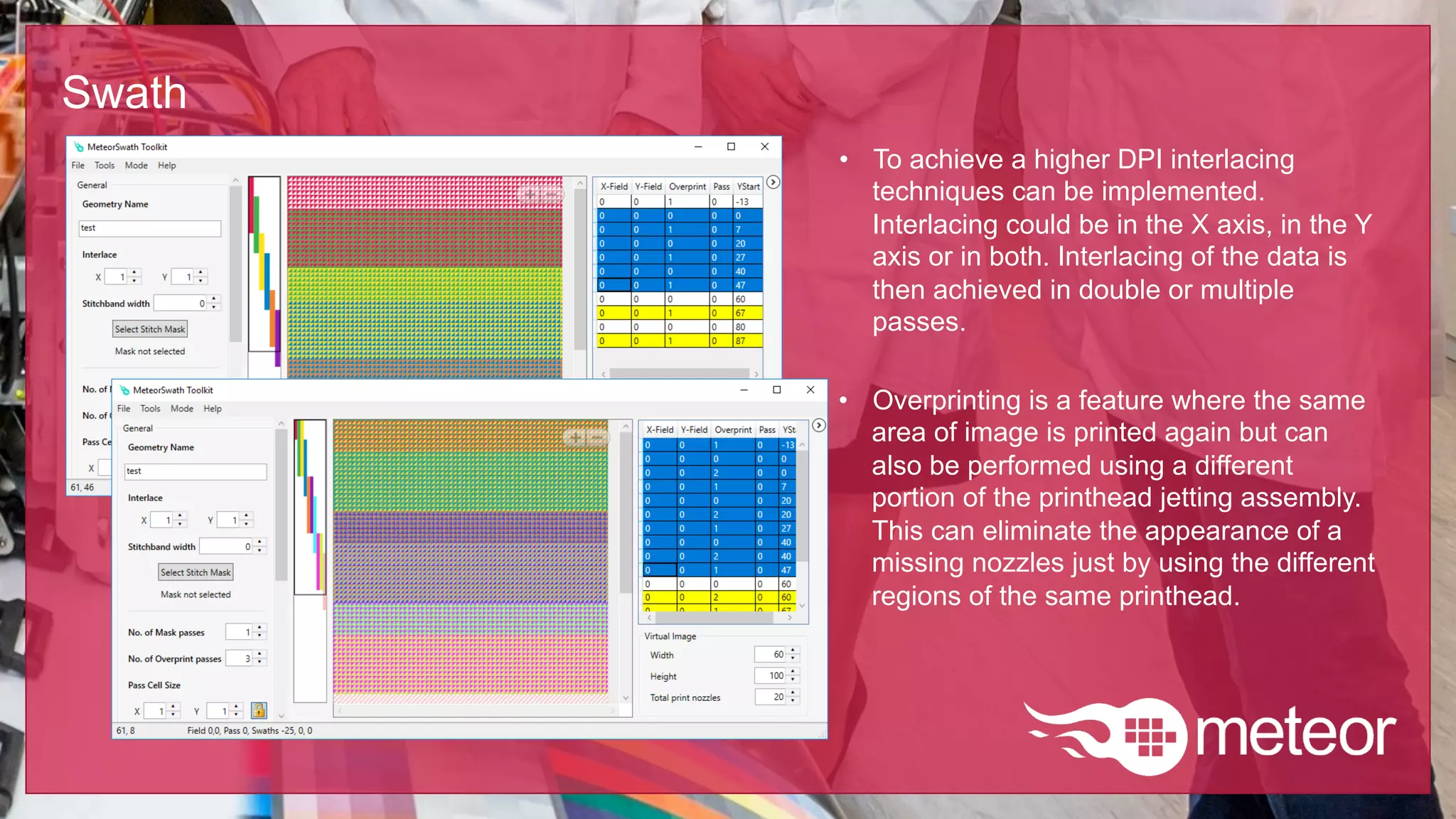

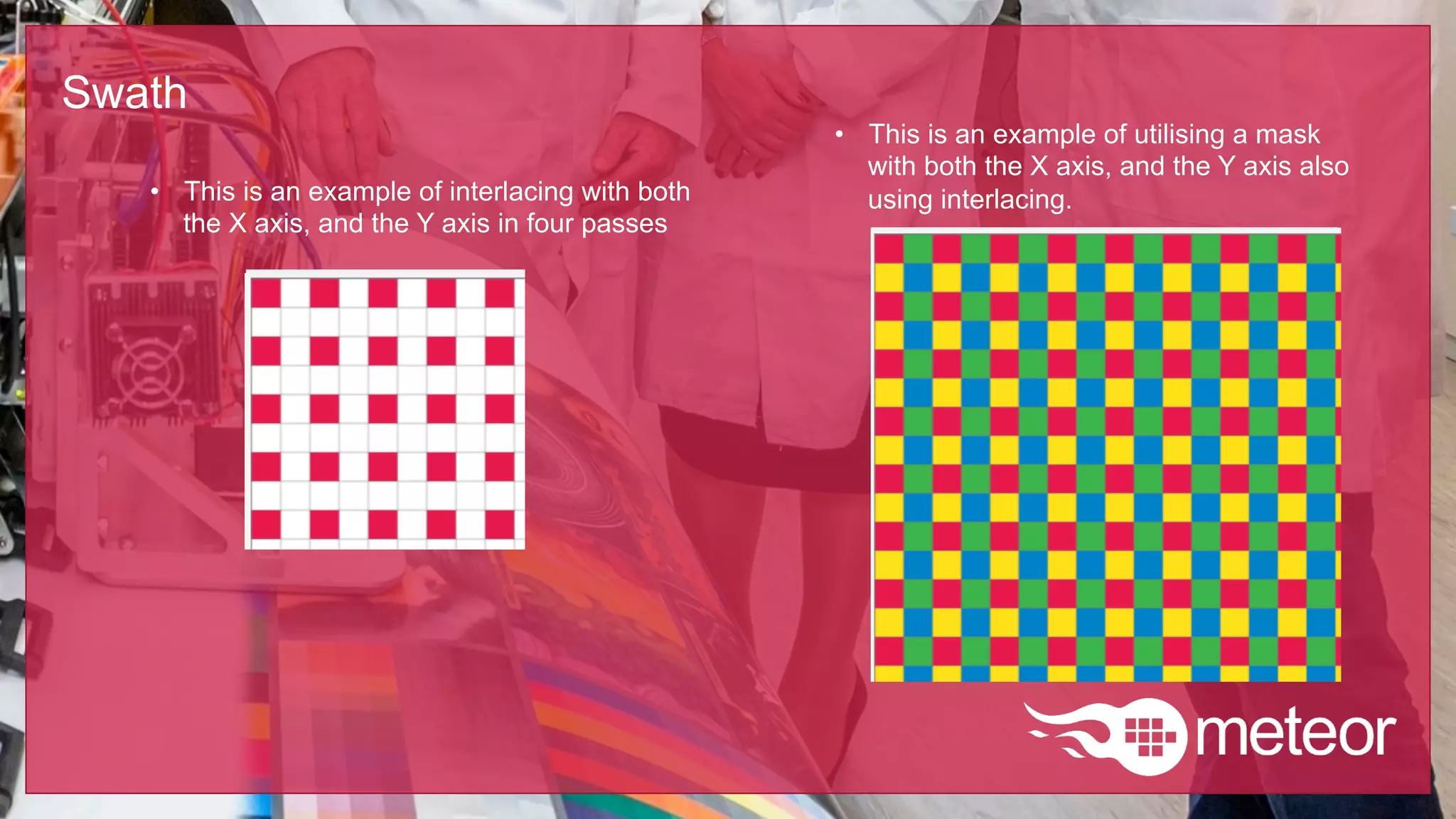

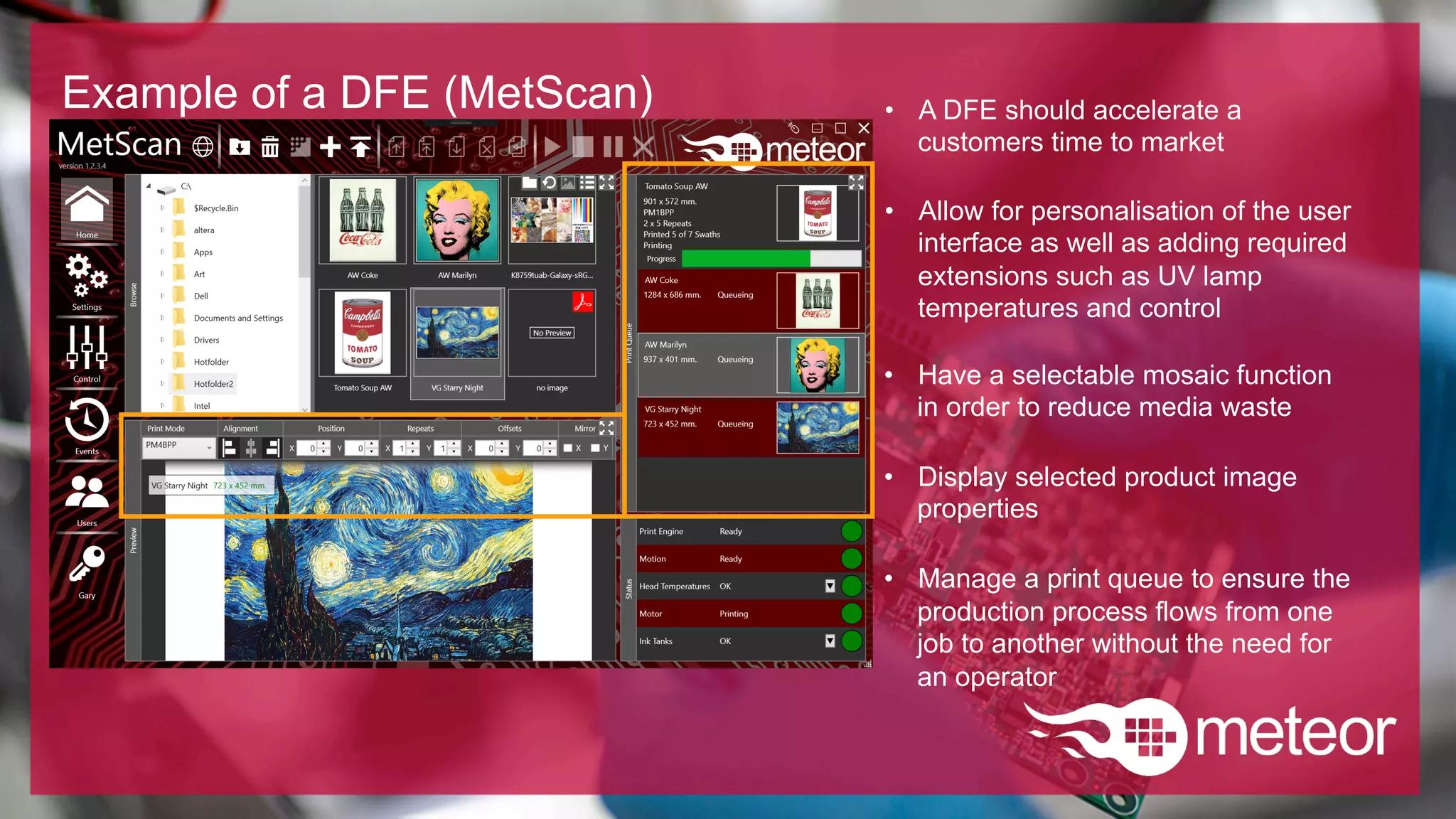

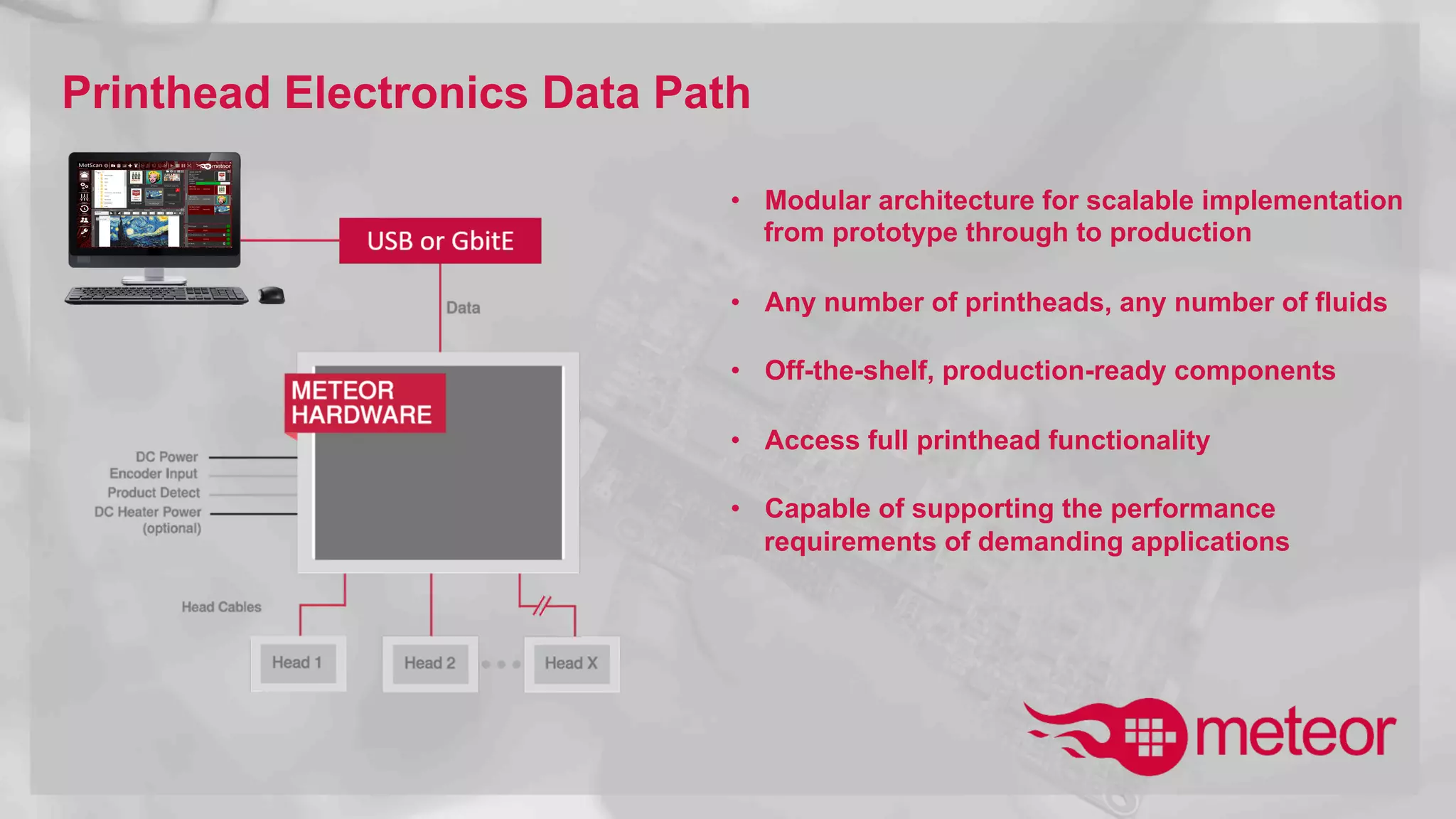

The document discusses scanning inkjet printing solutions provided by Meteor Inkjet Ltd. Scanning printing has advantages over single pass printing like lower cost, tighter jetting tolerances, and higher ink coverage. Meteor provides scanning software, digital front ends, and printhead electronics to support industrial inkjet applications across various markets like ceramics, textiles, packaging, and more. Their solutions are customizable, scalable, and help customers accelerate time to market.