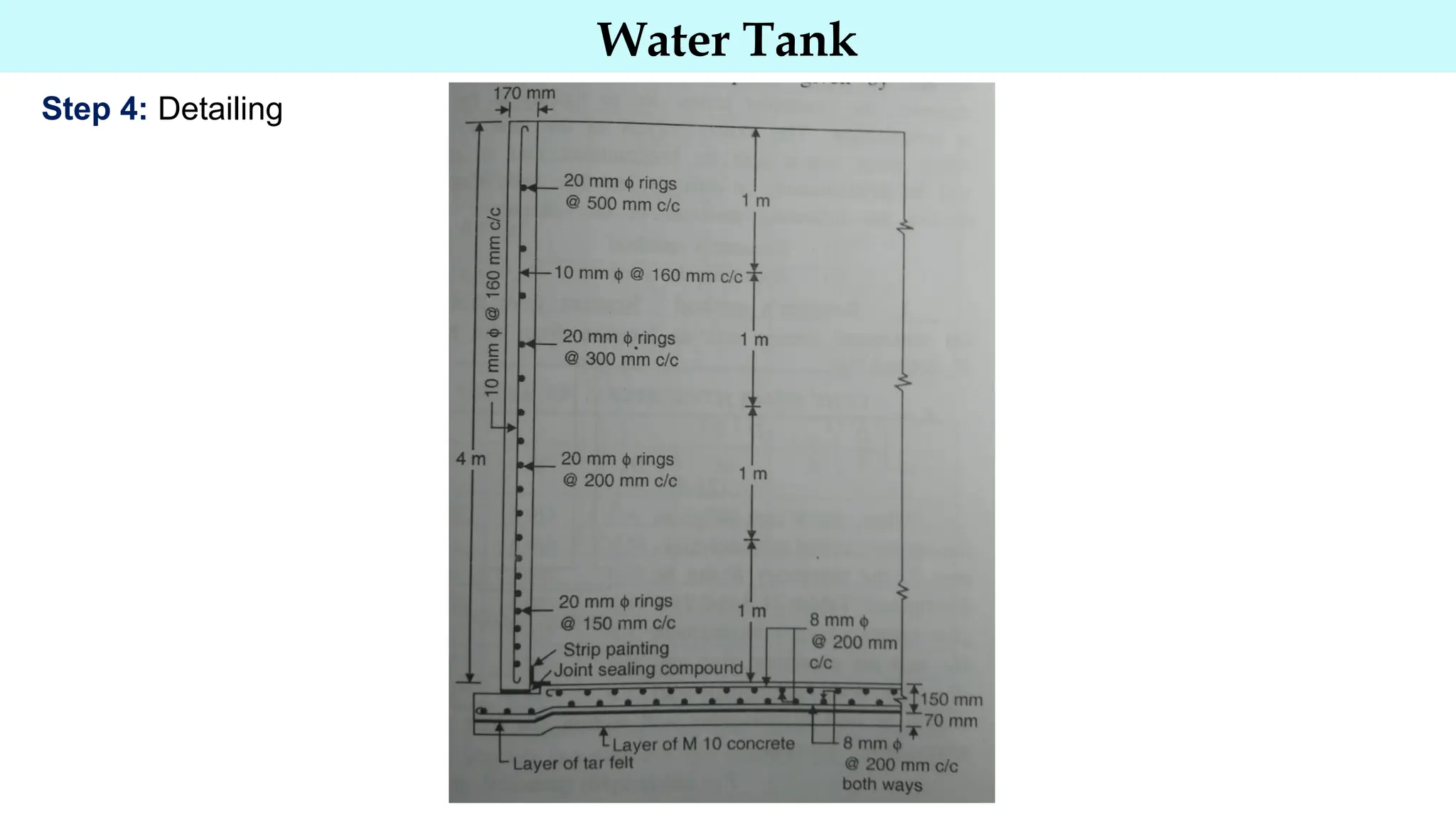

The document outlines the specifications and design requirements for water tanks, including types (ground, underground, elevated), materials, and permissible stress limits for concrete and reinforcement steel. It discusses the design criteria based on IS 3370, factors such as concrete imperviousness, tensile stress calculations, and minimum reinforcement percentages. Additionally, it illustrates a practical example of designing a circular water tank with specific capacity requirements, detailing each design step involved.