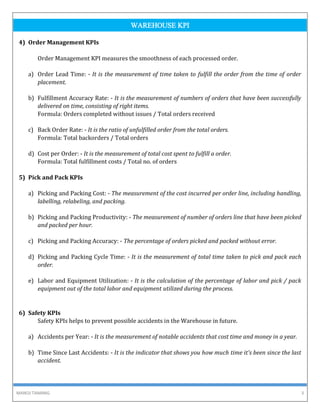

The document explains the concept and significance of Key Performance Indicators (KPIs) in warehouse operations, outlining various metrics used to measure efficiency in areas such as inventory management, receiving, order management, and safety. Key KPIs include inventory accuracy, order fulfillment rates, and employee turnover rates, which help assess operational performance and improve customer satisfaction. Ultimately, KPIs play a crucial role in optimizing warehouse management by facilitating data-driven decision making and strategic planning.