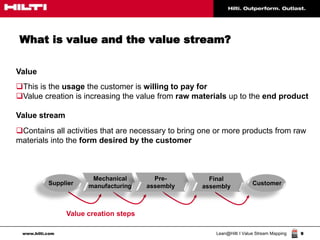

This document outlines an agenda and materials for a presentation on value stream mapping (VSM) at Hilti. The presentation introduces VSM and its uses, including creating a holistic view of processes, identifying weaknesses, and reducing throughput times. It discusses value, value streams, and the steps of VSM including creating an "as-is" map and analyzing it to highlight improvement opportunities. Examples show how VSM was used to reduce development loop times at Hilti. Attendees participate in a simulation game modeling a multi-step process to experience mapping the current state and identifying waste, before discussing how to create an improved "future state." Questions are provided to guide analyzing processes for optimization opportunities.